Abstract

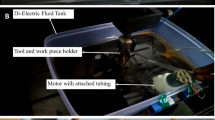

A CHANCE observation by one of us (H. G.) that if the die through which a wire was being drawn was simultaneously rotated the tension required was appreciably reduced, has led to results of considerable interest. The following series of values refer to an 80:20 cupro-nickel wire reduced from 0.073 in. to 0.0635 in. in diameter, that is, 24 per cent. A sintered tungsten carbide die of 6° taper was used, with ‘Oil-dag’, a suspension of colloidal graphite in oil, as a lubricant.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

GREENWOOD, H., THOMPSON, F. Wires drawn through Rotating Dies. Nature 128, 152 (1931). https://doi.org/10.1038/128152a0

Issue date:

DOI: https://doi.org/10.1038/128152a0

This article is cited by

-

Effect of Tube Extrusion Expander Shear on Recrystallization Behavior, Texture Evolution, and Mechanical Properties of Hot Deformed Mg-3Al-1Zn Alloy

Journal of Materials Engineering and Performance (2023)