Abstract

AN experimental investigation of the kinetic friction of non-lubricated metals has shown that, in general, friction cannot be regarded as a surface effect. Penetration and distortion occur to some depth beneath the surface, and the frictional force and the nature of sliding are both influenced by the bulk properties of the metals. The physical properties of the metals, such as their relative hardness and melting point, play an important part. In fact, it has been shown that the nature of the sliding and the value of the friction are largely determined by these factors, and it has been suggested1, 2, 3, 4 that the frictional resistance between unlubricated metals is due primarily to the shearing of the metallic junctions formed by adhesion and welding at the points of contact, and to the work of dragging or ploughing the surface irregularities of the harder metal through the softer one. Even if the metals are carefully polished and are made as flat as possible, hills and valleys which are large compared with the dimensions of a molecule will still be present on the surface, and contact will occur only locally at the summits of these surface irregularities. The formation of metallic junctions between the surfaces will, of course, take place with cold metals. It has been shown that when the speed is slow or when the surfaces are stationary, so that there is no question of temperature rise, the high pressures at the points of contact will readily cause local adhesion and welding.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Bowden and Leben, Proc. Roy. Soc., A, 169, 371 (1939).

Bowden and Tabor, Proc. Roy. Soc., A, 169, 391 (1939).

Bowden, Leben and Tabor, Engineer, London, 168, 214 (1939).

Bowden and Leben, Phil. Trans. Roy. Soc., A, 239, 1 (1940).

Bowden and Ridler, Proc. Roy. Soc., A, 154, 640 (1936).

Bowden and Hughes, Proc. Roy. Soc., A, 160, 575 (1937).

Morgan, Muskat and Reed, J. Applied Physics, 12, 743 (1941).

Bristow, NATURE, 149, 169 (1942).

Thomson and Logan, J. Roy. Tech. Coll., Glasgow, 4, 696 (1940).

Matthew, J. Roy. Tech. Coll., Glasgow, 4, 360 (1940).

Beeck, Givens and Williams, Proc. Roy. Soc., A, 177, 103 (1940).

Bowden and Tabor, Council for Scientific and Industrial Research (Aust.), Bulletin No. 145 (1942).

Ernst and Merchant, Conference on Friction and Surface Finish, Massachusetts Inst. Tech., p. 76 (1940).

Hardy, Collected Works, Camb. Univ. Press (1936).

Adam, "Physics and Chemistry of Surfaces" (Oxford Univ. Press, 1938), p. 232.

Bowden and Hughes, Proc. Roy. Soc., A, 172, 263 (1939).

Bowden and Hughes, Proc. Roy. Soc., A, 172, 280 (1939).

Atlee, Wilson and Filmer, J. Applied Physics, 11, 611 (1940).

Langmuir, J. Franklin Inst., 218, 143 (1934).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

BOWDEN, F., TABOR, D. MECHANISM OF METALLIC FRICTION. Nature 150, 197–199 (1942). https://doi.org/10.1038/150197a0

Issue date:

DOI: https://doi.org/10.1038/150197a0

This article is cited by

-

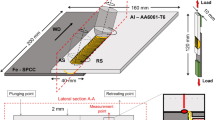

Advances in friction of aluminium alloy deep drawing

Friction (2024)

-

A discussion of model asperities as a method to study friction in metal forming

Discover Mechanical Engineering (2023)

-

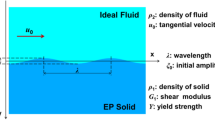

Investigation of surface textures deterioration on pavement skid-resistance using hysteresis friction models and numerical simulation method

Friction (2023)

-

Visualized atom by atom

Nature Materials (2022)

-

An Investigation of the Parameters for Characterization and Prediction of Wear of Drum Brake Friction Material

Journal of Materials Engineering and Performance (2022)