Abstract

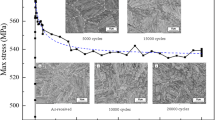

RECENT papers by Porter and Levy1 and Benham and Ford2 have suggested that the conventional S/N curve is composed of two separate curves, a discontinuity occurring at some particular stress-level. The former authors concluded from a large number of rotating bending tests on copper that the discontinuity occurred at about ± 21,500 lb./sq. in.; for lower stresses fatigue cracks originating in slip bands; for higher stresses cracks developing from L-shaped nuclei. Kemsley3 also found that with copper specimens tested at ± 15,000 lb./sq. in. (giving fracture after long endurances) cracks formed in slip bands and were transcrystalline, while at ± 25,000 lb./sq. in. (giving fracture with low endurances) slip bands were virtually absent from the specimen and cracks appeared to be inter crystalline. Benham and Ford2, who tested mild steel in direct stress, found for large stress amplitudes that the specimen gauge-length extended permanently each cycle and a ‘necked-out’ fracture resulted. They termed this phenomenon ‘cyclic creep’ and such failures occurred while the stresses corresponded to the upper portion of the composite S/N diagram. For stresses in the lower portion of the S/N diagram typical fatigue fractures occurred and they suggested that, if the fatigue mechanism could be suppressed as the cyclic stress decreased, the upper curve might flatten out to a ‘cyclic creep limit’.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Porter, J., and Levy, L. C., J. Inst. Metals, 89, 86 (1960).

Benham, P. P., and Ford, H., J. Mech. Eng. Sci., 3, 119 (1961).

Kemsley, D. S., J. Inst. Metals, 85, 417 (1957).

Coffin, L. F., Internal Stresses and Fatigue of Metals, 353 (Elsevier, 1959).

Hempel, M., Int. Conf. Fatigue, Inst. Mech. Eng., 543 (1956).

Wadsworth, N. J., Phil. Mag., 6, 397 (1961).

Wood, W. A., Phil. Mag., 3, 692 (1958).

May, A. N., Nature, 185, 303 (1960).

Holden, J., Phil. Mag., 6, 547 (1961).

Forsyth, P. J. E., Int. Conf. Fatigue, Inst. Mech. Eng., 535 (1956).

Jacquet, P. A., Int. Conf. Fatigue, Inst. Mech. Eng., 506 (1956).

Frost, N. E., J. Mech. Phys. Solids, 9, 143 (1961).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

FROST, N. Difference between High- and Low-Stress Fatigue. Nature 192, 446–447 (1961). https://doi.org/10.1038/192446b0

Issue date:

DOI: https://doi.org/10.1038/192446b0

This article is cited by

-

Factors Affecting the Fatigue Behavior of Fiber-Reinforced Polymer Matrix Composites

Journal of The Institution of Engineers (India): Series C (2023)

-

Significance of the Discontinuity in S/N Fatigue Curves

Nature (1964)