Protein-based biotherapeutics have revolutionized healthcare for more than 350 million patients worldwide, particularly for people with cancer and chronic disease. However, the mammalian-cell-based production of these biologically derived molecules is very costly. As a result, the prices of originator products and biosimilars are high—limiting patient access to these life-changing or life-saving drugs, especially in low- and middle-income countries.

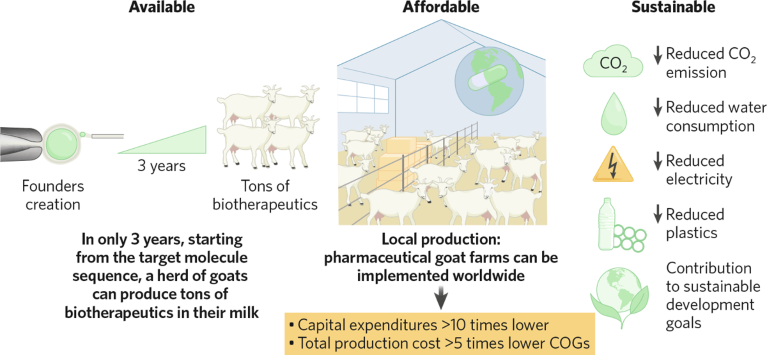

Bio-Sourcing, founded in Liège, Belgium, in 2014, is using a different approach to create an accessible, affordable and sustainable source of biotherapeutics via its BioMilk platform and herd of dairy goats (Fig. 1).

“Our mission is to use genetically edited goats to make biotherapeutics accessible through lower-cost production,” said Bertrand Mérot, founder and CEO of Bio-Sourcing.

From steel tanks to bio tanks

Most therapeutic proteins are produced in recombinant mammalian cells. While this approach has a proven track record, the yields are low, and the investments needed to set up production plants with large stainless-steel bioreactors are extremely high. Scaling-up can also be challenging, as the cells may not behave in the same way at lab and production stages. Overall, the cost per gram of protein produced using mammalian cells is around $100–150. By contrast, Bio-Sourcing’s genetically-edited goats currently produce biopharmaceuticals at only $35–40 per gram, with the potential to reduce this to $10 per gram.

“Goat mammary glands are natural bioreactors that are designed to secrete large quantities of protein into milk,” said Mérot. “The capital expenditure and production costs are much lower than for traditional mammalian-cell processes, and the process can be scaled up easily by increasing the size of the dairy goat herd.”

Bio-Sourcing’s process begins with a cell from a dairy goat selected for its good milk-production traits. The team precision-edits the DNA using clustered regularly interspaced short palindromic repeats (CRISPR)–CRISPR-associated protein 9 (Cas9) techniques to knock-out a casein gene and knock-in the gene for the protein of interest. The edited material is then introduced into an oocyte from a donor goat using nuclear-transfer technology and implanted into a surrogate female. When reaching sexual maturity, the resulting founder is mated, and the expression of the target protein is triggered in the mammary glands.

During 300 days of lactation, a single genetically edited goat can produce between 3 and 6 kilograms of a target protein, such as a fully humanized monoclonal antibody. The fat and unwanted proteins are removed from the milk, and the resulting clarified material goes through a standard purification process.

“The purification costs for proteins produced by mammalian cells or goats are currently similar, but we are working with strategic partners to reduce them,” said Mérot.

Fig. 1 | The BioMilk Platform. Enabling the ton-scale production of affordable and sustainable biotherapeutics. COGs, cost of goods.

Bio-Sourcing is working on an in-house pipeline of biosimilars to further address unmet needs in the market using the BioMilk platform.

“We are looking to work in partnership or collaboration with companies who have their own original or biosimilar target proteins, particularly in the field of infectious disease,” said Mérot. “As an example, there is a global need for around several tens of tons of monoclonal antibodies per year for the treatment of malaria, and it is hard to produce such volumes in mammalian cells. Bio-Sourcing could supply clarified milk bearing the target protein to a pharmaceutical partner that has purification capabilities to meet the need.”

Making biotherapeutics available worldwide

In contrast to the capital-intensive infrastructure required for mammalian cell culture production scaling up, which relies on building new industrial plants with additional bioreactors, Bio-Sourcing’s technology enables the creation of semen banks from the founder animals. These semen banks can be exported and used to inseminate wild-type goats around the world, rapidly establishing pharmaceutical farms of heterozygous offspring capable of local protein production. This approach offers a simple and cost-effective path to scale-up.

“The purification process is relatively straightforward. We will set up joint ventures with local companies in low- and middle-income countries to support the pharmaceutical industry in these regions,” said Mérot. “We are targeting countries that already have the technology and facilities for protein purification, and fill and finish, for example Senegal, Brazil, India and South Africa.”

Moving towards oral delivery

One of the challenges in facilitating access to biopharmaceuticals is their route of administration. Because proteins are broken down by the digestive tract, they generally need to be administered by intravenous, intramuscular or subcutaneous injection, which is only feasible where people have regular access to healthcare professionals. Goat’s milk is rich in extracellular vesicles that encapsulate milk proteins, resist degradation in the gastrointestinal tract, and could potentially deliver proteins into tissues and cells. Bio-Sourcing is investigating the potential of these naturally occurring extracellular vesicles (like exosomes) as oral delivery systems, which could be processed using existing dairy industry technologies.

“This would be a second major step-forward in terms of cost reduction and accessibility of these essential biotherapeutics,” concluded Mérot.