Abstract

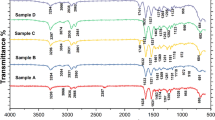

Magnetic layers were formed by use of polyrethane having SO3Na group as binder of magnetic particles. A packing degree and surface roughness of magnetic layer were investigated. When magnetic layers were soaked into silicone oil, the silicone oil could penetrate into every void perfectly. The void volume fraction could be estimated by measurement of the weight increase of magnetic layer by soak into silicone oil. Continuous void was formed along with the network structure of magnetic particles. The void in magnetic layer was still continuous after calender treatment. The void fraction of magnetic layer was affected by the intensity of interaction between binder polymer and magnetic particles, and time of formation of flocculation during dry of magnetic paint. Time of the formation of flocculation depended on the steric stabilization by adsorbed polymer, and determined surface roughness of magnetic layer. The increase of SO3Na content was effective to intensify the interaction between binder polymer and magnetic particles, but it furthered the formation of flocculation structure if solvent of magnetic paint was not suitable for binder polymer.

Similar content being viewed by others

Log in or create a free account to read this content

Gain free access to this article, as well as selected content from this journal and more on nature.com

or

References

Y. Kubota et al. “Display, Recording, Recording Technology and Material,” CMC Co., Tokyo, 1982, p. 201.

T. C. Patton, “Paint Flow and Pigment Dispersion,” translated by K. Ueki, S. Tochihara, and Y. Imaoka, Kyoritsu Publishing Co., Ltd. Tokyo, 1971, p 142.

S. Muramatsu, Shikizai, 58, 204 (1985).

T. Kawamata, H. Hagiwara, H. Komoda, N. Sugiyama, H. Ushigome, Y. Mizoh, H. Hatanaka, K. Hirai, and S. Osagawa, National Technical Report, 28, 509 (1982).

T. Takeuchi, Shikizai, 66, 495 (1993).

S. Ogasaka, H. Komoda, H. Hagiwara, and T. Kawamata, National Technical Report, 28, 517 (1982).

H. Kanai and T. Amari, Toso Kogaku, 27, 242 (1992).

K. Nakamae, Hyomen, 25, 401 (1987).

Y. Mizumura, N. Hiura, and H. Miyake, Japan Patent 58-41565 (1983).

K. Mizuhara, K. Hara, and T. Imoto, Kolloid Z.-Z. Polym., 229, 17 (1969).

K. Sumiya, N. Hirayama, T. Taii, N. Nakamae, and T. Matsumoto, Kobunshi Ronbunshu, 38, 139 (1981).

K. Sumiya, K. Nakamae, S. Watatani, F. Hayama, and T. Matsumoto, Kobunshi Ronbunshu, 37, 49 (1980).

Y. Mido, H. Suzuki, K. Sakamoto, and K. Terashita, Funtai Kogaku Kaishi, 29, 676 (1992).

H. Kondo, Nikkei New Materials, No. 90 (1992).

A. Takahashi, Shikizai, 67, 496 (1994).

K. Sumiya, N. Hirayama, T. Taii, K. Nakamae, and T. Matsumoto, Kobunshi Ronbunshu, 41, 273 (1984).

K. Nakamae, S. Tanigawa, K. Sumiya, and T. Matsumoto, Colloid Polym. Sci., 1266, 1014 (1988).

M. Imoto, “Basic Theory of Adhesion,” Kobunshi Publishing Co., Kyoto, 1993, p 102.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Yatsuka, T., Saimoto, H. & Shigemasa, Y. Evaluation of Polyurethane Having SO3Na Group as Magnetic Binder. Polym J 28, 831–838 (1996). https://doi.org/10.1295/polymj.28.831

Issue date:

DOI: https://doi.org/10.1295/polymj.28.831