Abstract

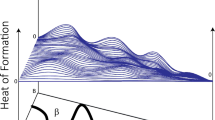

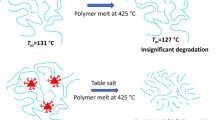

This paper examines the initiation of necking in a metallocene-catalyzed high-density polyethylene. When the specimen is uniaxially deformed, the necking is usually initiated between the first and second yield points, and the neck is stabilized at the second yield point. The initiation of necking was explained by a first-order catastrophic phase transition analogous to the model of a van der Waals gas. At the first yield point, the stacked lamellar clusters are fragmented into cubic cluster units of single chain size; the rearrangement of these units under uniaxial tension produces the texture of necking. Catastrophic arrangement of the cluster units results in a sudden emergence of a locally close-packed layer structure. This is the precursor of necking, and several layered plates are stabilized at the second yield point. The layered plate collapses via sliding of the cubic units by means of the interchain links, to form macroscopic neck; the plate thus behaves as a unit for the necking process. The continual collapse from one plate to another corresponds to the neck propagation.

Similar content being viewed by others

Log in or create a free account to read this content

Gain free access to this article, as well as selected content from this journal and more on nature.com

or

References

Brooks, N. W., Duckett, R. A. & Ward, I. M. Investigation into double yield points in polyethylene. Polymer 33, 1872–1880 (1992).

Carothers, W. H. & Hill, W. J. Studies of polymerization and ring formation. XV. Artificial fibers from synthetic linear condensation superpolymers. J. Am. Chem. Soc 54, 1579 (1932).

Séguéla, R. & Darras, O. Phenomenological aspects of the double yield of polyethylene and related copolymers under tensile loading. J. Mater. Sci. 29, 5342–5352 (1994).

Séguéla, R. On the natural draw ratio of semi-crystalline polymers: review of the mechanical, physical and molecular aspects. Macromol. Mater. Eng. 292, 235–244 (2007).

Peterlin, A. Molecular model of drawing polyethylene and polypropylene. J. Mater. Sci. 6, 490–508 (1971).

Nitta, K. & Takayanagi, M. Novel proposal of lamellar clustering process for elucidation of temsile yield behavior of linear polyethylenes. J. Macromol. Sci. Phys. B42, 107–126 (2003).

Takayanagi, M., Imada, K. & Kajiyama, T. Mechanical properties and fine structure of drawn polymers. J. Polym. Sci. C 15, 263–281 (1966).

Keith, H. D., Padden, F. J. & Vadimsky, R. G. Intercrystalline links in polyethylene crystallized from the melts. J. Polym. Sci. A-2 4, 267–281 (1966).

Takayanagi, M., Nitta, K. & Kojima, O. Application of lamellar clustering theory to isotactic polypropylene and direct observation of lamellar cluster morphology by electron microscopy. J. Macromol. Sci-Phys. B B42, 1049–1059 (2003).

Kuriyagawa, M. & Nitta, K. Structural explanation on natural draw ratio of metallocene-catalyzed high density polyethylene. Polymer 52, 3469–3477 (2011).

G'Sell, C., Aly-Helal, N. A. & Jonas, J. J. Effect of stress triaxiality on neck propagation during the tensile stretching of solid polymers. J. Mater. Sci. 18, 1731–1742 (1983).

Huchingson, J. W. & Neale, K. W. Neck propagation. J. Mech. Phys. Solid 31, 405–426 (1983).

Ericksen, J. J. Equilibrium of bars. J. Elasticity 5, 191–201 (1975).

Heise, B., Kilian, H. G. & Wulff, W. Deformation and microstructure in uniaxially stretched PE. Prog. Colloid Polym. Sci. 67, 143–147 (1980).

Killian, H.- G. Equation of state of real networks. Polymer 19, 209–217 (1981).

Kilian, H.- G. Small-strain elastic moduli of quasi-isotropic semicrystalline eutectoid copolymers and aspects of universality. Colloid Polym. Sci. 262, 374–380 (1984).

Nitta, K. & Takayanagi, M. Application of catastrophe theory to the neck-initiation of semicrystalline polymers induced by the intercluster links. Polymer J. 38, 757 (2006).

Nitta, K. & Tanaka, A. Dynamic mechanical properties of metallocene catalyzed linear polyethylenes. Polymer 42, 1219 (2001).

G'Sell, C. & Jonas, J. J. Yield and transient effects during the plastic deformation of solid polymers. J. Mater. Sci. 16, 1956–1974 (1981).

Haward, R. N. The application of a siblified model for the stress-strain curves of polymers. Polymer 28, 1485–1488 (1987).

Song, Y., Nitta, K. & Nemoto, N. Molecular orientations and true stress-strain relationship in isotactic polypropylene film. Macromolecules 36, 8066–8073 (2003).

Eyring, H. Viscosity, plasticity, and diffusion as examples of absolute reaction rates. J. Chem. Phys. 4, 283–291 (1936).

Nitta, K. & Takayanagi, M. Role of tie molecules in the yielding deformation of isotactic polypropylene. J. Polym. Sci. B Polym. Phys. 37, 357–368 (1999).

Kanig, G. Direct observation of polyethylene fine structure and its changes during drawing and annealing. J. Cryst. Growth 48, 303–320 (1980).

Strobl, G. R. The Physics of Polymers 359, (Springer-Verlag, Berlin, 1998).

Mark, J. E. in Physical Properties of Polymer 2nd edn, Ch. 1, 3–59 (ACS, Washington DC, 1993).

Poston, T. & Stewart, I. Catastrophe Theory and Its Applications. (Pitman Pub., London, UK, 1978).

Kajiyama, T., Okada, T., Sakoda, A. & Takayanagi, M. J. Macromol. Sci. Phys. B 7, 583 (1973).

Jiang, Z., Tnag, Y., Men, Y., Enderle, H- F., Lilge, D., Roth, S. V., Gehrke, R. & Rieger, J. Structural evolution of tensile-deformed high-density polytheylene during annealing: scanning synchrotron small-angle X-ray scattering study. Macromolecules 40, 7263–7269 (2007).

Ohkoshi, Y., Watanabe, J., Okumura, W., Gotoh, Y. & Nagura, M. Catastrophic neck-flow transition during laser-heated drawing of poly(ethylene terephthalate) fiber. Sen'I Gakkaishi 58, 182–184 (2002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nitta, Kh., Kuriyagawa, M. Application of catastrophe theory to neck initiation of metallocene-catalyzed high-density polyethylene. Polym J 44, 245–251 (2012). https://doi.org/10.1038/pj.2011.119

Received:

Revised:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/pj.2011.119