Abstract

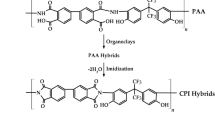

The effect of the organoclay content on the toughness of a rubbery modified amorphous polyamide (aPA)/organoclay-based nanocomposite was studied by changing the modifier (maleic anhydride) content. The dispersed rubber particle size decreased markedly with the addition of the modifier, indicating compatibilization of the nanocomposite. However, the particle size of the dispersed phase increased slightly with the organoclay content due to the interactions between the dissolved surfactant and the compatibilizer. Furthermore, we observed that the organoclay resided in the aPA matrix, and that its dispersion remained constant upon rubber addition. This resulted in materials with high stiffness and extremely large toughness values, as measured by both the standard impact strength and the essential work of the fracture method. Because the rubber content was kept constant, the inorganic part of the clay was proposed to be the main parameter that controls toughness.

Similar content being viewed by others

Log in or create a free account to read this content

Gain free access to this article, as well as selected content from this journal and more on nature.com

or

References

Lim, S. H., Dasari, A., Wang, G. T., Yu, Z. Z., Mai, Y. W., Yuan, Q., Liu, S. & Yong, M. S. Impact fracture behaviour of nylon 6-based ternary nanocomposites. Compos. Eng. 41B, 67–75 (2010).

Ali, Z., Le, H.- H., Ilisch, S., Thurn-Albrecht, T. & Radusch, H.- J. Morphologydevelopment and compatibilization effect in nanoclay filled rubber blends. Polymer 51, 4580–4588 (2010).

Mirzadeh, A., Lafleur, P. G., Kamal, M. R. & Dubois, C. The effect of compatibilizer on the co-continuity and nanoclay dispersion level of TPE nanocomposites based on PP/EPDM. Polym. Eng. Sci. 50, 2131–2142 (2010).

Borse, N. K. & Kamal, M. R. Melt processing effects on the structure and mechanical properties of PA-6/clay nanocomposites. Polym. Eng. Sci. 46, 1094–1103 (2006).

Uribe-Calderon, J. & Kamal, M. R. Evaluation of various surfactants and compatibilizers for preparation of PS/clay nanocomposites by melt compounding. J. Polym. Eng. 30, 377–411 (2010).

Motovilin, M., Denchev, Z. & Dencheva, N. On the structure-properties relationship in montmorillonite-filled polyamide 6 nanocomposites. J. Appl. Polym. Sci. 120, 3304–3315 (2011).

Mehrabzadeh, M. & Kamal, M. R. Melt processing of PA-66/clay, HDPE/clay and HDPE/PA-66/clay nanocomposites. Polym. Eng. Sci. 44, 1152–1161 (2004).

As’habim, L., Jafarim, S. H., Khonakdar, H. A. & Baghaei, B. Morphological, rheological and thermal studies in melt processed compatibilized PA6/ABS/clay nanocomposites. J. Polym. Res. 18, 197–205 (2010).

Oshinski, A. J., Keskkula, H. & Paul, D. R. Rubber toughening of polyamides with functionalized block copolymers: 2. Nylon-6,6. Polymer 33, 284–293 (1992).

Oshinski, A. J., Keskkula, H. & Paul, D. R. Rubber toughening of polyamides with functionalized block copolymers: 1. Nylon-6. Polymer 33, 268–283 (1992).

Majumdar, B., Keskkula, H. & Paul, D. R. Reactive compatibilization of Nylon-6/Abs blends with a Functionalized imidized acrylic polymer-mechanical-properties and morphology generation. Abst. Pap. Amer. Chem. Soc. 206, 9–11 (1993).

Borggreve, R. J. M., Gaymans, R. J., Schuijer, J. & Ingen Housz, J. F. Brittle-tough transition in nylon-rubber blends: effect of rubber concentration and particle size. Polymer 28, 1489–1496 (1987).

González, I., Eguiazabal, J. I. & Nazabal, J. Compatibilization level effects on the structure and mechanical properties of rubber-modified polyamide-6/clay nanocomposites. J. Polym. Sci. Polym. Phys. 43, 3611–3620 (2005).

Ahn, Y. C. & Paul, D. R. Rubber toughening of nylon 6 nanocomposites. Polymer 47, 2830–2838 (2006).

Dasari, A., Yu, Z. Z. & Mai, Y. W. Effect of blending sequence on microstructure of ternary nanocomposites. Polymer 46, 5986–5991 (2005).

Dermanaki, R. & Ramazani, A. Melt preparation and investigation of properties of toughened Polyamide 66 with SEBS-g-MA and their nanocomposites. Mat. Des. 29, 105–111 (2007).

Huang, J. J., Keskkula, H. & Paul, D. R. Rubber toughening of an amorphous polyamide by functionalized SEBS copolymers: morphology and Izod impact behavior. Polymer 45, 4203–4215 (2004).

Huang, J. J., Keskkula, H. & Paul, D. R. Elastomer particle morphology in ternary blends of maleated and non-maleated ethylene-based elastomers with polyamides: role of elastomer phase miscibility. Polymer 47, 624–638 (2006).

Huang, J. & Paul, D. R. Comparison of fracture behavior of nylon 6 versus an amorphous polyamide toughened with maleated poly(ethylene-1-octene) elastomers. Polymer 47, 3505–3519 (2006).

Huang, J. J., Keskkula, H. & Paul, D. R. Comparison of the toughening behavior of nylon 6 versus an amorphous polyamide using various maleated elastomers. Polymer 47, 639–651 (2006).

Gonzalez, I., Eguiazabal, J. I. & Nazabal, J. Toughening and brittle-tough transition in blends of an amorphous polyamide with a modified styrene/ethylene-butylene/styrene triblock copolymer. Polym. Eng. Sci. 49, 1350–1356 (2009).

Yoo, Y., Tiwari, R. R., Yoo, Y. T. & Paul, D. R. Effect of organoclay structure and mixing protocol on the toughening of amorphous polyamide/elastomer blends. Polymer 51, 4907–4915 (2010).

Yoo, Y., Cui, L., Yoon, P. J. & Paul, D. R. Morphology and mechanical properties of rubber toughened amorphous polyamide/MMT nanocomposites. Macromolecules 43, 615–624 (2010).

Dupont Selar Data Sheets. http://www2.dupont.com/Selar/en_US/assets/downloads/selar_pa_3426.pdf.

Ji, S., Hoye, T. R. & Macosko, C. W. Primary amine (−NH2) quantification in polymers: functionality by 19F NMR spectroscopy. Macromolecules 38, 4679 (2005).

Goitisolo, I., Eguiazabal, J. I. & Nazabal, J. Structure and properties of an amorphous polyamide based nanocomposite. Polym. Adv. Tech. 20, 1060–1067 (2009).

Gonzalez, I., Eguiazabal, J. I. & Nazabal, J. Rubber-toughened polyamide 6/clay nanocomposites. Compos. Sci. Tech. 66, 1833–1843 (2006).

Gonzalez, I., Eguiazabal, J. I. & Nazabal, J. Nanocomposites based on a polyamide 6/maleated styrene-butylene-co-ethylene-styrene blend: effects of clay loading on morphology and mechanical properties. Eur. Polym. J. 42, 2905–2913 (2006).

Wu, C. J., Kuo, J. F., Chen, C. Y. & Woo, E. Effects of reactive functional-groups in the compatibilizer on mechanical-properties of compatibilized blends. J. Appl. Polym. Sci. 52, 1695–1706 (1994).

Chang, J. H., Park, K. M. & Cho, D. Preparation and characterization of polyimide nanocomposites with different organo-montmorillonites. Polym. Eng. Sci. 41, 1514–1520 (2001).

Nishitani, Y., Yamada, Y., Ishii, C., Sekiguchi, I. & Kitano, T. Effects of addition of functionalized SEBS on rheological, mechanical, and tribological properties of polyamide 6 nanocomposites. Polym. Eng. Sci. 50, 100–112 (2010).

Arostegui, A. & Nazabal, J. Stiffer and super-tough poly(butylene terephthalate) based blends by modification with phenoxy and maleated poly(ethylene-octene) copolymers. Polymer 44, 239–249 (2003).

Zhang, B. Q., Ding, Y. F., Chen, P., Liu, C. Y., Zhang, J., He, J. S. & Hu, G. H. Fibrillation of thermotropic liquid crystalline polymer enhanced by nano-clay in nylon-6 matrix. Polymer 46, 5385–5395 (2005).

Shariatpanahi, H., Nazokdast, H. & Hemmati, M. Relationship between interfacial tension and dispersed-phase particle size in polymer blends. II. PP/PA6. J. Appl. Polym. Sci. 88, 54–63 (2003).

D’Orazio, L., Mancarella, C., Martuscelli, E., Sticotti, G. & Massari, B. Melt rheology, phase structure and impact properties of injection-moulded samples of isotactic polypropylene/ethylene-propylene copolymer (iPP/EPR) blends: influence of molecular structure of EPR copolymers. Polymer 34, 3671–3681 (1993).

Gonzalez, I., Eguiazabal, J. I. & Nazabal, J. Compatibilization level effects on the structure and mechanical properties of rubber-modified polyamide-6/clay nanocomposites. J. Polym. Sci. Polym. Phys. 43, 3611–3620 (2005).

Kolarik, J. & Lednicky, F. Blends of polycarbonate with poly(styrene-co-acrylonitrile): miscibility, interfacial adhesion, tensile properties, and phase structure. Polym. Net. Blend. 3, 147–154 (1993).

Cho, J. W. & Paul, D. R. Nylon 6 nanocomposites by melt compounding. Polymer 42, 1083–1094 (2001).

Fornes, T. D., Hunter, D. L. & Paul, D. R. Nylon-6 nanocomposites from alkylammonium-modified clay: the role of alkyl tails on exfoliation. Macromolecules 37, 1793–1798 (2004).

Xie, S. B., Zhang, S. M., Zhao, B., Qin, H. L., Wang, F. S. & Yang, M. S. Tensile fracture morphologies of nylon-6/montmorillonite nanocomposites. Polym. Inter. 54, 1673–1680 (2005).

Acknowledgements

The financial support of the Spanish Ministerio de Ciencia e Innovación (project MAT2010-16171) and of the Basque Government (project IT-234-07) is gratefully acknowledged. The technical support of the Polymer Characterization Service of the University of Basque Country for the TEM and XRD analyses are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

González, I., Eguiazábal, J. & Nazábal, J. Amorphous polyamide/maleated styrene–ethylene–co-butylene–styrene nanocomposites: effects of clay loading and compatibilizer content on morphology and mechanical properties. Polym J 44, 294–300 (2012). https://doi.org/10.1038/pj.2011.124

Received:

Revised:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/pj.2011.124

Keywords

This article is cited by

-

Structure-property relations of novel polyamide-6 elastomers prepared through reactive processing

Journal of Polymer Research (2017)

-

The effect of different parameters on mechanical properties of PA-6/clay nanocomposite through genetic algorithm and response surface methods

International Nano Letters (2015)