Abstract

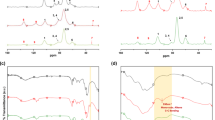

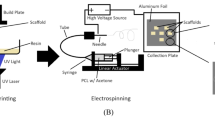

In this study, microcellular foams based on polypropylene/ethylene propylene diene monomer/organoclay (PP/EPDM/organoclay) nanocomposites were produced via a batch process using supercritical nitrogen (N2) as the physical blowing agent. The foaming temperature and morphological observation demonstrated that foaming occurred mostly in the PP phase. To evaluate the effect of organoclay distribution on the cell nucleation step and the final foam morphology, the location of the nanofillers in the nanocomposite blend was traced by means of surface energies and Young's equation. The calculated wetting coefficient predicted that the organoclays would have more affinity with PP and would primarily distribute into the PP phase. These results were confirmed by atomic force microscopy (AFM), dynamic mechanical thermal analysis (DMTA) and transmission electron microscopy (TEM). The cell density and average cell sizes are the main foam characteristics that were determined using SEM micrographs, and it was found that these parameters were influenced by the presence of nanoclays. An improved foam morphology was obtained in the nanocomposite samples.

Similar content being viewed by others

Log in or create a free account to read this content

Gain free access to this article, as well as selected content from this journal and more on nature.com

or

References

Martini-Vvedensky, J., Suh, N. & Waldman, F. Microcellular closed cell foams and their method of manufacture. US Patent 4473665 (1984).

Doroudiani, S., Park, C. B. & Kortschot, M. T. Effect of the crystallinity and morphology on the microcellular foam structure of semicrystalline polymers. Polym. Eng. Sci. 36, 2645–2662 (1996).

Kumar, V. Microcellular polymers: novel materials for the 21st century. Prog. Rubber Plast. Technol. 9, 54–70 (1993).

Reglero Ruiz, J., Viot, P. & Dumon, M. Microcellular foaming of polymethylmethacrylate in a batch supercritical CO2 process: Effect of microstructure on compression behavior. J. Appl. Polym. Sci. 118, 320–331 (2010).

Arora, K. A., Lesser, A. J. & McCarthy, T. J. Preparation and characterization of microcellular polystyrene foams processed in supercritical carbon dioxide. Macromolecules 31, 4614–4620 (1998).

Sumarno, Y., Takishima, S. & Masuoka, H. Production of polystyrene microcellular foam plastics and a comparison of late-and quick-heating. J. Appl. Polym. Sci. 77, 2383–2395 (2000).

Han, X., Koelling, K., Tomasko, D. & Lee, L. Continuous microcellular polystyrene foam extrusion with supercritical CO2. Polym. Eng. Sci. 42, 2094–2106 (2002).

Park, C. B. & Suh, N. P. Filamentary extrusion of microcellular polymers using a rapid decompressive element. Polym. Eng. Sci. 36, 34–48 (1996).

Kumar, V. & Weller, J. Polymeric Foams, ch. 7, 101–114 (American Chemical Society, 1997).

da Costa, H. M., Ramos, V. D., da Silva, W. S. & Sirqueira, A. S. Analysis and optimization of polypropylene (PP)/ethylene-propylene-diene monomer (EPDM)/scrap rubber tire (SRT) mixtures using RSM methodology. Polym. Test. 29, 572–578 (2010).

da Silva, A. L. N. & Coutinho, F. M. B. Some properties of polymer blends based on EPDM/PP. Polym. Test. 15, 45–52 (1996).

Wong, S., Naguib, H. E. & Park, C. B. Effect of processing parameters on the cellular morphology and mechanical properties of thermoplastic polyolefin (TPO) microcellular foams. Adv. Polym. Technol. 26, 232–246 (2007).

Nemoto, T., Takagi, J. & Ohshima, M. Control of bubble size and location in nano/microscale cellular poly (propylene)/rubber blend foams. Macromol. Mater. Eng. 293, 574–580 (2008).

Nemoto, T., Takagi, J. & Ohshima, M. Nanoscale cellular foams from a poly (propylene) rubber blend. Macromol. Mater. Eng. 293, 991–998 (2008).

Atsushi Tsuchiya, H. T., Kikuchi, T., Takahashi, T. & Koyama, K. Influence of filler types and contents on foaming structures in ABS microcellular foams. Polym. J. 39, 514–523 (2007).

Urbanczyk, L., Calberg, C., Detrembleur, C., Jérôme, C. & Alexandre, M. Batch foaming of SAN/clay nanocomposites with scCO2: a very tunable way of controlling the cellular morphology. Polymer 51, 3520–3531 (2010).

Lee, Y. H., Wang, K. H., Park, C. B. & Sain, M. Effects of clay dispersion on the foam morphology of LDPE/clay nanocomposites. J. Appl. Polym. Sci. 103, 2129–2134 (2007).

Shen, J., Zeng, C. & Lee, L. Synthesis of polystyrene-carbon nanofibers nanocomposite foams. Polymer 46, 5218–5224 (2005).

Zhu, B., Zha, W., Yang, J., Zhang, C. & Lee, L. J. Layered-silicate based polystyrene nanocomposite microcellular foam using supercritical carbon dioxide as blowing agent. Polymer 51, 2177–2184 (2010).

Riahinezhad, M., Ghasemi, I., Karrabi, M. & Azizi, H. Morphology and tensile properties of crosslinked nanocomposite foams of low density polyethylene and poly (ethylene co vinyl acetate) blends. J. Vinyl. Addit. Technol. 16, 229–237 (2010).

Zhai, W., Yu, J., Wu, L., Ma, W. & He, J. Heterogeneous nucleation uniformizing cell size distribution in microcellular nanocomposites foams. Polymer 47, 7580–7589 (2006).

Ema, Y., Ikeya, M. & Okamoto, M. Foam processing and cellular structure of polylactide-based nanocomposites. Polymer 47, 5350–5359 (2006).

Yokoyama, H. & Sugiyama, K. Nanocellular structures in block copolymers with CO2-philic blocks using CO2 as a blowing agent: Crossover from micro-to nanocellular structures with depressurization temperature. Macromolecules 38, 10516–10522 (2005).

Mehrabzadeh, M. & Kamal, M. R. Polymer clay nanocomposites based on blends of polyamide 6 and polyethylene. Can. J. Chem. Eng. 80, 1083–1092 (2002).

Lipatov, Y. S. Polymer blends and interpenetrating polymer networks at the interface with solids. Prog. Polym. Sci. 27, 1721–1801 (2002).

Argon, A. & Cohen, R. Toughenability of polymers. Polymer 44, 6013–6032 (2003).

Hong, J. S., Namkung, H., Ahn, K. H., Lee, S. J. & Kim, C. The role of organically modified layered silicate in the breakup and coalescence of droplets in PBT/PE blends. Polymer 47, 3967–3975 (2006).

Fenouillot, F., Cassagnau, P. & Majesté, J. C. Uneven distribution of nanoparticles in immiscible fluids: Morphology development in polymer blends. Polymer 50, 1333–1350 (2009).

As'habi, L., Jafari, S., Baghaei, B., Khonakdar, H., Pötschke, P. & Böhme, F. Structural analysis of multicomponent nanoclay-containing polymer blends through simple model systems. Polymer 49, 2119–2126 (2008).

Huitric, J., Ville, J., Médéric, P., Moan, M. & Aubry, T. Rheological, morphological and structural properties of PE/PA/nanoclay ternary blends: Effect of clay weight fraction. J. Rheol. 53, 1101 (2009).

Calcagno, C., Mariani, C., Teixeira, S. & Mauler, R. The role of the MMT on the morphology and mechanical properties of the PP/PET blends. Composites Sci. Technol. 68, 2193–2200 (2008).

Han, X., Zeng, C., Lee, L., Koelling, K. & Tomasko, D. Extrusion of polystyrene nanocomposite foams with supercritical CO2. Polym. Eng. Sci. 43, 1261–1275 (2003).

Lee, L., Koelling, K., Tomasko, D., Han, X. & Zeng, C. Polymer nanocomposite foams. US patent 6759446 (2002).

Khorasani, M. M., Ghaffarian, S. R., Babaie, A. & Mohammadi, N. Foaming BEHAVIOR and cellular structure of microcellular HDPE nanocomposites prepared by a high temperature process. J. Cell. Plast. 46, 173–190 (2010).

Riahinezhad, M., Ghasemi, I., Karrabi, M. & Azizi, H. Morphology and tensile properties of crosslinked nanocomposite foams of low density polyethylene and poly (ethylene co vinyl acetate) blends. J. Vinyl Addit. Technol. 16, 229–237 (2010).

Xu, Z., Jiang, X., Liu, T., Hu, G., Zhao, L., Zhu, Z. & Yuan, W. Foaming of polypropylene with supercritical carbon dioxide. J. Sup. Flu. 41, 299–310 (2007).

Reverchon, E. & Cardea, S. Production of controlled polymeric foams by supercritical CO2. J. Sup. Flu. 40, 144–152 (2007).

Colton, J. & Suh, N. Nucleation of microcellular foam: theory and practice. Polym. Eng. Sci. 27, 500–503 (1987).

Fletcher, N. Size effect in heterogeneous nucleation. J. Chem. Phy. 29, 572 (1958).

Sumita, M., Sakata, K., Asai, S., Miyasaka, K. & Nakagawa, H. Dispersion of fillers and the electrical conductivity of polymer blends filled with carbon black. Polym. Bull. 25, 265–271 (1991).

Lewin, M., Mey Marom, A. & Frank, R. Surface free energies of polymeric materials, additives and minerals. Polym. Adv. Technol. 16, 429–441 (2005).

Acknowledgements

We are very grateful for the financial support they received from the Iran National Science Foundation (INSF).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Keramati, M., Ghasemi, I., Karrabi, M. et al. Microcellular foaming of PP/EPDM/organoclay nanocomposites: the effect of the distribution of nanoclay on foam morphology. Polym J 44, 433–438 (2012). https://doi.org/10.1038/pj.2012.2

Received:

Revised:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/pj.2012.2

Keywords

This article is cited by

-

Preparation and characterization of carboxylated acrylonitrile butadiene rubber/carboxylated styrene butadiene rubber (XNBR/XSBR) nanocomposites in the presence of dichlorocarbene-modified SBR (DCSBR) compatibilizer and montmorillonite

Polymer Bulletin (2021)

-

Controlled elitist multi-objective genetic algorithm joined with neural network to study the effects of nano-clay percentage on cell size and polymer foams density of PVC/clay nanocomposites

Journal of Thermal Analysis and Calorimetry (2020)

-

A multi-scale three-dimensional finite element analysis of polymeric rubber foam reinforced by carbon nanotubes under tensile loads

Iranian Polymer Journal (2019)