Abstract

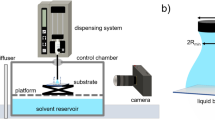

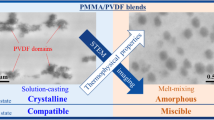

In this study, we quantified the solvent evaporation rate in the production of three poly(vinylidene fluoride) (PVDF) crystalline structures using the solvent casting method, the first known report on such quantification. The evaporation conditions of drying temperature and pressure for the solvent species during solvent casting were varied. The results indicated that the crystalline structures of forms I, II and III of PVDF were obtained when the solvent evaporation rates were <0.0001, >0.2 and between 0.03 and 0.00058 g min−1, respectively. From the above quantitative analysis, it was established that the crystalline structure of PVDF from solvent casting is predominantly determined by the solvent evaporation rate.

Similar content being viewed by others

Log in or create a free account to read this content

Gain free access to this article, as well as selected content from this journal and more on nature.com

or

References

The Society of Polymer Science, Japan (ed.), Kobunshi Bussei no Kiso 207 (Kyoritsu Shuppan, Tokyo, 1993) in Japanese.

Hasegawa, R., Kobayashi, M. & Tadokoro, H. Molecular conformation and packing of poly(vinylidene fluoride). stability of three crystalline forms and the effect of high pressure. Polym. J. 3, 591–599 (1972).

Hasegawa, R., Takahashi, Y., Chatani, Y. & Tadokoro, H. Crystal structures of three crystalline forms of poly(vinylidene fluoride). Polym. J. 3, 600–610 (1972).

Miyairi, K. Denshi Bussei no Kiso 103 (Morikita Publishing, Tokyo, 1993) in Japanese.

Nasir, M., Matsumoto, H., Minagawa, M., Tanioka, A., Danno, T. & Horibe, H. Preparation of PVDF/PMMA blend nanofibers by electrospray deposition: effects of blending ratio and humidity. Polym. J. 41, 402–406 (2009).

Danno, T., Nasir, M., Matsumoto, H., Minagawa, M., Tanioka, A. & Horibe, H. Fine structure of PVDF nanofiber fabricated by electrospray deposition. J. Polym. Sci., Part B: Polym. Phys. 46, 558–563 (2008).

Nasir, M., Matsumoto, H., Minagawa, M., Tanioka, A., Danno, T. & Horibe, H. Preparation of porous PVDF nanofiber from PVDF/PVP blend by electrospray deposition. Polym. J. 39, 1060–1064 (2007).

Nasir, M., Matsumoto, H., Minagawa, M., Tanioka, A., Danno, T. & Horibe, H. Formation of β-phase crystalline structure of PVDF nanofiber by electrospray deposition: additive effect of ionic fluorinated surfactant. Polym. J. 39, 670–674 (2007).

Horibe, H. & Baba, F. Relationship between UV transmittance and poly (vinylidene fluoride) crystal structures of poly (vinylidene fluoride)/poly (methyl methacrylate) blends after annealing. Kobunshi Ronbunsyu 57, 403–411 (2000) in Japanese.

Horibe, H. & Baba, F. Changes in crystal structures of PVDF in PVDF/PMMA blends heat-treated in several ways. Nihon Kagakukaishi 2, 121–126 (2000) in Japanese.

Horibe, H. & Baba, F. Relationship between UV transmittance and compatibility of PVDF/PMMA blends. Nihon Kagakukaishi 2, 115–120 (2000) in Japanese.

Horibe, H. & Taniyama, M. poly (vinylidene fluoride) crystal structure of poly (vinylidene fluoride) and poly (methyl methacrylate) blend after annealing. J. Electrochem. Soc. 153, G119–G124 (2006).

Danno, T., Matsumoto, H., Nasir, M., Minagawa, M., Horibe, H. & Tanioka, A. PVDF/PMMA composite nanofiber fabricated by electrospray deposition: Crystallization of PVDF induced by solvent extraction of PMMA component. J. Appl. Polym. Sci. 112, 1868–1872 (2009).

Oshiro, H., Kono, A., Danno, T. & Horibe, H. Crystal structure control of poly(vinylidene fluoride) (PVDF) in the blend films of PVDF and poly(methyl methacrylate) (PMMA) prepared by solvent casting. Kobunshi Ronbunsyu 69, 135–141 (2012) in Japanese.

Oshiro, H., Sato, T., Yamamoto, M., Kono, A., Horibe, H., Masunaga, H., Danno, T., Matsumoto, H. & Tanioka, A. Crystal structure control of poly (vinylidene fluoride) using solvent casting. Kobunshi Ronbunsyu 67, 632–639 (2010) in Japanese.

Bormashenko, Y., Pogreb, R., Stanevsky, O. & Bormashenko, E. d. Vibrational spectrum of PVDF and its interpretation. Polym. Test 23, 791–796 (2004).

Kobayashi, M., Tashiro, K. & Tadokoro, H. Molecular vibrations of three crystal forms of poly(vinylidene fluoride). Macromolecules 8, 158–171 (1975).

Matsushige, K. & Takemura, T. Melting and crystallization of poly (vinylidene fluoride) under high pressure. J. Polym. Sci. Part B: Polym. Phys. 16, 921–934 (1978).

Yu, S., Zheng, W., Yu, W., Zhang, Y., Jiang, Q. & Zhao, Z. Formation mechanism of β-phase in PVDF/CNT composite prepared by the sonication method. Macromolecules 42, 8870–8874 (2009).

Takahashi, Y. & Tadokoro, A. Kink bands in form I of poly (vinylidene fluoride). Macromolecules 13, 1318–1320 (1980).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Horibe, H., Sasaki, Y., Oshiro, H. et al. Quantification of the solvent evaporation rate during the production of three PVDF crystalline structure types by solvent casting. Polym J 46, 104–110 (2014). https://doi.org/10.1038/pj.2013.75

Received:

Revised:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/pj.2013.75

Keywords

This article is cited by

-

Interconnected porous BT-VTS/PVDF-HFP nanocomposites with enhanced electroactive β-phase and crystallinity fabricated via thermally induced phase separation

Journal of Polymer Research (2024)

-

Crystal polymorphism of poly(vinylidene fluoride) blended with alkylammonium salts exhibiting different ion-dipole interaction strengths

Polymer Journal (2023)

-

Assessment of Surface, Structural, and Viscoelastic Properties of Immiscible Polylactic Acid/Polyvinylidene Fluoride Blends

Macromolecular Research (2022)

-

Performance enhancements in poly(vinylidene fluoride)-based piezoelectric films prepared by the extrusion-casting process

Journal of Materials Science: Materials in Electronics (2021)

-

Effect of solvents on the crystal formation of poly(vinylidene fluoride) film prepared by a spin-coating process

Polymer Journal (2017)