Abstract

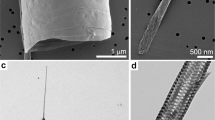

In this work, nanocellular silicone rubber foams were first prepared by supercritical carbon dioxide. The cellular morphologies and mechanical properties of the microcellular and nanocellular silicone rubber foams are presented. The cell size and cell density of the microcellular silicone rubber foams can reach 1–4 μm and 1011 cells/cm3, respectively. The nanocellular silicone rubber foams have an upper limit diameter of 59 nm, and the density of the nanocellular silicone rubber foams is on the order of 1014 cells/cm3, which is several orders of magnitude greater than that of the typical microcellular silicone rubber foams. The stretching-induced cavitation can play an important role in the formation of the nanocellular structure on cell walls. The effect of the cellular structure on the mechanical properties is investigated. As a result, the nanocellular structure causes an early breakdown, resulting in a decrease in the tensile strength. Furthermore, when the open-cell content (OCC) increases, the compressive curves change from having three regions to two regions, indicating that the compression plateau disappears when the OCC is greater than 0.45.

Similar content being viewed by others

Log in or create a free account to read this content

Gain free access to this article, as well as selected content from this journal and more on nature.com

or

References

Zhang A, Zhang Q, Bai H, Li L, Li J. Polymeric nanoporous materials fabricated with supercritical CO2 and CO2-expanded liquids. Chem Soc Rev. 2014;43:6938–53.

Costeux S. CO2‐blown nanocellular foams. J Appl Polym Sci. 2014;131:1–16.

Forest C, Chaumont P, Cassagnau P, Swoboda B, Sonntag P. Polymer nano-foams for insulating applications prepared from CO2 foaming. Prog Polym Sci. 2015;41:122–45.

Realinho V, Antunes M, Martínez AB, Velasco JI. Influence of nanoclay concentration on the CO2 diffusion and physical properties of PMMA montmorillonite microcellular foams. Ind Eng Chem Res. 2011;50:13819–24.

Zhai W, Yu J, Wu L, Ma W, He J. Heterogeneous nucleation uniformizing cell size distribution in microcellular nanocomposites foams. Polymer. 2006;47:7580–9.

Siripurapu S, De Simone JM, Khan SA, Spontak RJ. Controlled foaming of polymer films through restricted surface diffusion and the addition of nanosilica particles or CO2-philic surfactants. Macromolecules. 2005;38:2271–80.

Yokoyama H, Sugiyama K. Nanocellular structures in block copolymers with CO2-philic blocks using CO2 as a blowing agent: crossover from micro- to nanocellular structures with depressurization temperature. Macromolecules. 2005;38:10516–22.

Taki K, Waratani Y, Ohshima M. Preparation of nanowells on a PS-b-PMMA copolymer thin film by CO2 treatment. Macromol Mater Eng. 2008;293:589–97.

Ruiz JAR, Cloutet E, Dumon M. Investigation of the nanocellular foaming of polystyrene in supercritical CO2 by adding a CO2‐philic perfluorinated block copolymer. J Appl Polym Sci. 2012;126:38–45.

Liu B, Wang P-C, Ao Y-Y, Zhao Y, An Y, Chen H-B, et al. Effects of combined neutron and gamma irradiation upon silicone foam. Radiat Phys Chem. 2017;133:31–6.

Yue Y, Zhang H, Zhang Z, Chen Y. Polymer–filler interaction of fumed silica filled polydimethylsiloxane investigated by bound rubber. Compos Sci Technol. 2013;86:1–8.

Wen J, Li Y, Zuo Y, Zhou G, Li J, Jiang L, et al. Preparation and characterization of nano-hydroxyapatite/silicone rubber composite. Mater Lett. 2008;62:3307–9.

Landrock AH. Glossary - Handbook of plastic foams, Manufacture and Applications (Elsevier, Technology & Engineering, Park Ridge), 456–481 (1995).

Chen H-B, Liu B, Huang W, Wu W-H. Gamma radiation induced effects of compressed silicone foam. Polym Degrad Stab. 2015;114:89–93.

Fang H, Li J, Chen H, Liu B, Huang W, Liu Y, et al. Radiation induced degradation of silica reinforced silicone foam: experiments and modeling. Mech Mater. 2017;105:148–56.

Liu P, Liu D, Zou H, Fan P, Xu W. Structure and properties of closed-cell foam prepared from irradiation crosslinked silicone rubber. J Appl Polym Sci. 2009;113:3590–5.

Grande JB, Fawcett AS, Mclaughlin AJ, Gonzaga F, Bender TP, Brook MA. Anhydrous formation of foamed silicone elastomers using the Piers–Rubinsztajn reaction. Polymer. 2012;53:3135–42.

Hong I-K, Lee S. Microcellular foaming of silicone rubber with supercritical carbon dioxide. Korean J Chem Eng. 2013;31:166–71.

Song L, Lu A, Feng P, Lu Z. Preparation of silicone rubber foam using supercritical carbon dioxide. Mater Lett. 2014;121:126–8.

Liao X, Xu H, Li S, Zhou C, Li G, Park CB. The effects of viscoelastic properties on the cellular morphology of silicone rubber foams generated by supercritical carbon dioxide. RSC Adv. 2015;5:106981–8.

Xu H, He Y, Liao X, Luo T, Li G, Yang Q, et al. A green and structure-controlled approach to the generation of silicone rubber foams by means of carbon dioxide. Cell Polym. 2016;35:19–32.

Yan H, Wang K, Zhao Y. Fabrication of silicone rubber foam with tailored porous structures by supercritical CO2. Macromol Mater Eng. 2016;302:1600377.

Yang Q, Yu H, Song L, Lei Y, Zhang F, Lu A, et al. Solid-state microcellular high temperature vulcanized (HTV) silicone rubber foam with carbon dioxide. J Appl Polym Sci. 2017;134:44807.

Chandra A, Gong S, Yuan M, Turng LS, Gramann P, Cordes H. Microstructure and crystallography in microcellular injection‐molded polyamide‐6 nanocomposite and neat resin. Polym Eng Sci. 2005;45:52–61.

Yang J, Huang L, Zhang Y, Chen F, Fan P, Zhong M, et al. Nucleating agent for polymer foaming: applications of ordered mesoporous silica particles in polymethyl methacrylate supercritical carbon dioxide microcellular foaming. Ind Eng Chem Res. 2013;52:14169–78.

Sheng SJ, Hu X, Wang F, Ma QY, Gu MF. Mechanical and thermal property characterization of poly-l-lactide (PLLA) scaffold developed using pressure-controllable green foaming technology. Mater Sci Eng C. 2015;49:612.

Yu P, Mi HY, Huang A, Geng LH, Chen BY, Kuang TR. et al. Effect of poly(butylenes succinate) on poly(lactic acid) foaming behavior: formation of open cell structure. Ind Eng Chem Res. 2015;54:6199–6207.

Zhou C, Vaccaro N, Sundarram SS, Li W. Fabrication and characterization of polyetherimide nanofoams using supercritical CO2. J Cell Plast. 2015;48:239–55.

Guo H, Nicolae A, Kumar V. Solid-state microcellular and nanocellular polysulfone foams. J Polym Sci Part B: Polym Phys. 2015;53:975–85.

Gong P, Taniguchi T, Ohshima M. Nanoporous structure of the cell walls of polycarbonate foams. J Mater Sci. 2014;49:2605–17.

Guo H, Nicolae A, Kumar V. Solid-state microcellular and nanocellular polysulfone foams. J Polym Sci Part B: Polym Phys. 2015;53:975–85.

Gibson LJ, Ashby MF. Cellular solids: structure and properties. Cambridge, UK: Cambridge University Press; 1997.

Ma Z, Zhang G, Yang Q, Shi X, Liu Y. Mechanical and dielectric properties of microcellular polycarbonate foams with unimodal or bimodal cell-size distributions. J Cell Plast. 2014;51:307–27.

Notario B, Pinto J, Rodríguez-Pérez MA. Towards a new generation of polymeric foams: PMMA nanocellular foams with enhanced physical properties. Polymer. 2015;63:116–26.

Acknowledgements

The authors acknowledge the financial support from the National Natural Science Foundation of China (Grant numbers: 51773186 and 51503189) and the Science and Technology Foundation of Institute of Chemical Materials (Grant number: KJCX-201402).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, there is no professional or other personal interest of any nature or kind in any product, service and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled, “Mechanical properties of the microcellular and nanocellular silicone rubber foams obtained by supercritical carbon dioxide”.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xiang, B., Jia, Y., Lei, Y. et al. Mechanical properties of microcellular and nanocellular silicone rubber foams obtained by supercritical carbon dioxide. Polym J 51, 559–568 (2019). https://doi.org/10.1038/s41428-019-0175-6

Received:

Revised:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41428-019-0175-6

This article is cited by

-

A New Expanded Bead Foam Based on Bio-polypropylene (BioEPP): Fabrication and Reinforcement with Nanoparticles

Journal of Polymers and the Environment (2025)

-

Preparation and properties of silicone rubber materials with foam/solid alternating multilayered structures

Polymer Journal (2021)