Abstract

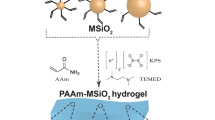

Cross-linked polymer gels are a new type of temporary plugging agent and are mainly used to control the leakage of fluid during drilling, completion, and workover operations. Improving the mechanical strength and plugging performance of these materials enables them to resist tough wellbore conditions (e.g., high pressure and high temperature). In this study, various concentrations and size of silica nanoparticles are introduced into the sulfonated polyacrylamide (SPAM)/chromium (III) acetate system to produce a nanocomposite with enhanced mechanical properties. First, the rheological behavior of gelant and viscoelastic properties of synthesized nanocomposites are investigated. Then, the surface chemistry and morphology of the synthesized gels is evaluated by Fourier transform infrared (FTIR) spectroscopy and field emission scanning electron microscopy (FESEM), respectively. Finally, the maximum sealing differential pressure for gels for temporary plugging of a wellbore is measured by applying differential pressure across the nanocomposite gel in a designed set-up. The results showed that the precrosslinking reaction and the gelant viscosity are directly related to the size and concentration of the silica nanoparticles as well as the wellbore temperature. Moreover, it is demonstrated that nanocomposites containing 20–30 nm sized particles have a higher mechanical strength and plugging capability in comparison to composites containing silica particles with sizes of 7–10 and 60–70 nm.

Similar content being viewed by others

Log in or create a free account to read this content

Gain free access to this article, as well as selected content from this journal and more on nature.com

or

References

Zhao G, Dai C, Li W, Yan Z, Zhao M. Research on a temporary plugging agent based on polymer gel for reservoir acidification. J Petrol Explor Prod Technol. 2016;6:465–72. https://doi.org/10.1007/s1320

Gano JC. Halliburton energy services inc, temporary plug system. U S Pat. 1997;5:685. 372.

Kang Y, Xu C, You L, Yu H, Zhang D. Temporary sealing technology to control formation damage induced by drill-in fluid loss in fractured tight gas reservoir. J Nat Gas Sci Eng. 2014;20:67–73. https://doi.org/10.1016/j.jngse.2014.06.016

Du G, Peng Y, Pei Y, Zhao L, Wen Z, Hu Z. Thermo-responsive temporary plugging agent based on multiple phase transition supramolecular gel. Energ Fuel. 2017;31:9283–9. https://doi.org/10.1021/acs.energyfuels.7b01691

Liu D, Kang Y, Liu Q, Lei D, Zhang B. Laboratory research on fracture-supported shielding temporary plugging drill-in fluid for fractured and fracture-pore type reservoirs. J. Chem. 2017. https://doi.org/10.1155/2017/4176593

Fan X, Zhao P, Zhang Q, Zhang T, Zhu K, Zhou C. A polymer plugging gel for the fractured strata and its application. Materials. 2018;11:856 https://doi.org/10.3390/ma11050856

Nasiri A, Ghaffarkhah A, Moraveji MK, Gharbanian A, Valizadeh M. Experimental and field test analysis of different loss control materials for combating lost circulation in bentonite mud. J Nat Gas Sci Eng. 2017;44:1–8. https://doi.org/10.1016/j.jngse.2017.04.004

Nasiri A, Ghaffarkhah A, Dijvejin ZA, Mostofi M, Moraveji MK. Bridging performance of new eco-friendly lost circulation materials. Petrol Explor Dev. 2018;45:1–12.

Feng Y, Gray KE. Review of fundamental studies on lost circulation and wellbore strengthening. J Petrol Sci Eng. 2017;152:511–22. https://doi.org/10.1016/j.petrol.2017.01.052

Ezeakacha CP, Salehi S, Kiran R. Lost circulation and filter cake evolution: Impact of dynamic wellbore conditions and wellbore strengthening implications. J Petrol Sci Eng. 2018;171:1326–37. https://doi.org/10.1016/j.petrol.2018.08.063

Kaiser MJ. Rigless well abandonment remediation in the shallow water US Gulf of Mexico. J Petrol Sci Eng. 2017;151:94–115. https://doi.org/10.1016/j.petrol.2017.01.004

Yang J, Luo J, Ran JC, Wang ZP. Probe into temporary plugging technology used in low-pressure gas well for workover. Nat Gas Ind. 2007;27:81.

Hajipour A, Baghban Salehi M, Vafaie Sefti M, Heidari A. Experimental study of polyacrylamide gel in close‐in well operation. Polym Adv Technol. 2018;29:1278–86. https://doi.org/10.1002/pat.4239

Aloise DJ, Aloise D, Rocha CT, Ribeiro CC, Ribeiro Filho JC, Moura LS. Scheduling workover rigs for onshore oil production. Discret Appl Math. 2006;154:695–702. https://doi.org/10.1016/j.dam.2004.09.021

Devold H. Oil and gas production handbook: an introduction to oil and gas production. Oslo: ABB AS; 2013.

Therond E, Bois AP, Whaley K, Murillo R. Large-scale testing and modeling for cement zonal isolation in water-injection wells. Spe Drill Complet. 2017. https://doi.org/10.2118/181428-PA

Okromelidze GV, Garshina OV, Nekrasova IL, Iljyasov SE. Method of well-killing operation by using viscoelastic gels with controllable destruction terms. In: Lie K-A, Alvarado V, Aguilera R, Fassihi R, editors. SPE Russian Oil and Gas Exploration & Production Technical Conference and Exhibition. Russia: Society of Petroleum Engineers; 2014.

KANG Yili, Chengyuan XU, TANG Long, Song LI, Daqi LI. Constructing a tough shield around the wellbore: theory and method for lost-circulation control. Petrol Explor Dev. 2014;41:520–7. https://doi.org/10.1016/S1876-3804(14)60061-6

Pei Y, Zhao L, Du G, Li N, Xu K, Yang H. Investigation of the degradation and stability of acrylamide-based polymers in acid solution: functional monomer modified polyacrylamide. Petroleum. 2016;2:399–407. https://doi.org/10.1016/j.petlm.2016.08.006

Arthur JD, Hochheiser HW. Plugging and abandonment of oil and gas wells. Working document of the NPC North American Resource Development Study. National petroleum Council; 2016. https://www.npcorg/prudent_development-topic_papers/2-25_well_plugging_and_abandonment_paper.pdf (2016)

Hossain ME, Wajheeuddin M. The use of grass as an environmentally friendly additive in water-based drilling fluids. Petrol Sci. 2016;13:292–303. https://doi.org/10.1007/s12182-016-0083-8

Majid NFF, Katende A, Ismail I, Sagala F, Sharif NM, Yunus MAC. A comprehensive investigation on the performance of durian rind as a lost circulation material in water based drilling mud. Petroleum. 2018. https://doi.org/10.1016/j.petlm.2018.10.004

Nasiri A, Shahrabi MA, Moraveji MK. Application of new eco-friendly LCMs for combating the lost circulation in heavy-weight and oil-based mud. Rsc Adv. 2018;8:9685–96. https://doi.org/10.1039/C7RA13668D

Liu G, Jiang H, Li J, Wang M, Chen F, Ding S, et al. Evaluation of the performance of polymer gels mixed with asphalt particle as a novel composite profile control system. J Ind Eng Chem. 2015;25:309–14. https://doi.org/10.1016/j.jiec.2014.11.044

Bozong H. Microscopic mechanisms and model design of close packing theory. Petrol. Drill Tech. 2007;35:5.

Cai J, Wu X, Gu S Research on environmentally safe temporarily plugging drilling fluid in water well drilling. In: Asia Pacific Health, Safety, Security and Environment Conference and Exhibition in Jakarta, Indonesia, 4–6 August 2009.

Uguna G, Rachid R, Milne A, Ali S. Controlling losses when recompleting low-pressure reservoirs. SPE European Formation Damage Conference and Exhibition, 3–5 June, Budapest, Hungary; 2015.

Wang G, Cao C, Pu X, Zhao Z. Experimental investigation on plugging behavior of granular lost circulation materials in fractured thief zone. Part Sci Technol. 2016;34:392–6. https://doi.org/10.1080/02726351.2015.1089963

Shaarpour M. Method and composition for preventing or treating lost circulation. US patent US7066285B2, Halliburton Energy Services Inc.; 2006.

Alsaba M, Al Dushaishi MF, Nygaard R, Nes OM, Saasen A. Updated criterion to select particle size distribution of lost circulation materials for an effective fracture sealing. J Petrol Sci Eng. 2017;149:641–8. https://doi.org/10.1016/j.petrol.2016.10.027.

Solomon O, Adewale D, Anyanwu C. Fracture width prediction and loss prevention material sizing in depleted formations using artificial intelligence. Nigeria Annual International Conference and Exhibition. Soc. Petrol. Eng. J. 2017. https://doi.org/10.2118/189068-MS

Razavi O, Vajargah AK, van Oort E, Aldin M, Govindarajan S. Optimum particle size distribution design for lost circulation control and wellbore strengthening. J Nat Gas Sci Eng. 2016;35:836–50. https://doi.org/10.1016/j.jngse.2016.08.038

Ravi K, Bosma M, Gastebled O. Improve the economics of oil and gas wells by reducing the risk of cement failure. IADC/SPE Drilling Conference, 26–28 February, Dallas, TX; 2002.

Mangadlao JD, Cao P, Advincula RC. Smart cements and cement additives for oil and gas operations. J Petrol Sci Eng. 2015;129:63–76. https://doi.org/10.1016/j.petrol.2015.02.009

Brufatto C, Cochran J, Conn L, Power D, SZAA El-Zeghaty, Fraboulet B, et al. From mud to cement—building gas wells. Oilfield Rev. 2003;15:62–76.

Nelson EB. Well cementing. 2nd ed. Sugar Land, TX: Schlumberger Dowell; 2006.

Liu H, Bu Y, Sanjayan J, Shen Z. Effects of chitosan treatment on strength and thickening properties of oil well cement. Constr Build Mater. 2015;75:404–14. https://doi.org/10.1016/j.conbuildmat.2014.11.047

Smith RC. Improved method of setting successful cement plugs. J Petrol Technol. 1984;36:1–897. https://doi.org/10.2118/11415-PA

Santra AK, Kulakofsky D. Carbon dioxide-resistant Portland based cement composition. US patent US20130048284A1, Halliburton Energy Services Inc.; 2017.

Abid K, Gholami R, Choate P, Nagaratnam BH. A review on cement degradation under CO2-rich environment of sequestration projects. J Nat Gas Sci Eng. 2015;27:1149–57. https://doi.org/10.1016/j.jngse.2015.09.061

Crawshaw JP, Frigaard I. Cement plugs: stability and failure by buoyancy-driven mechanism. Offshore in Europe Oil and Gas Exhibition and Conference, 7–10 September, Aberdeen, UK.

Ukaji M, Takamura M, Shirai K, Gang W, Yamauchi T, Tsubokawa N. Curing of epoxy resin by hyperbranched poly (amidoamine)-grafted silica nanoparticles and their properties. Polym J. 2008;40:607.

Bai B, Zhou J, Yin M. A comprehensive review of polyacrylamide polymer gels for conformance control. Petrol Explor Dev. 2015;42:525–32. https://doi.org/10.1016/S1876-3804(15)30045-8

Farasat A, Sefti MV, Sadeghnejad S, Saghafi HR. Mechanical entrapment analysis of enhanced preformed particle gels (PPGs) in mature reservoirs. J Petrol Sci En. 2017;157:441–50. https://doi.org/10.1016/j.petrol.2017.07.028

Onorato J, Pakhnyuk V, Luscombe CK. Structure and design of polymers for durable, stretchable organic electronics. Polym J. 2017;49:41 https://doi.org/10.1038/pj.2016.76

Farasat A, Sefti MV, Sadeghnejad S, Saghafi HR. Effects of reservoir temperature and water salinity on the swelling ratio performance of enhanced preformed particle gels. Korean J Chem Eng. 2017;34:1509–16. https://doi.org/10.1007/s11814-017-0017-1

Glushkov DO, Lyrshchikov SY, Shevyrev SA, Strizhak PA. Burning properties of slurry based on coal and oil processing waste. Energ Fuel. 2016;30:3441–50. https://doi.org/10.1021/acs.energyfuels.5b02881

Novel WilsonA. Thermally stable fluid-loss pill performs better than guar-based gels. J Petrol Technol. 2013;65:134–6.A. https://doi.org/10.2118/1113-0134-JPT

Gamage P, Deville JP, Sherman J. Solids-free fluid-loss pill for high-temperature reservoirs. Spe Drill Complet. 2014;29:125–30.P. https://doi.org/10.2118/164064-PA

Ziad AB, Gromakovskii D, Al-Sagr A, Al-Driweesh S. First successful application of temporary gel plug replacing calcium carbonate chips to isolate depleted reservoir, case study from Saudi Arabia Gas Field. SPE International Conference and Exhibition on Formation Damage Control, 24–26 February, Lafayette, LO, USA.

Ashrafizadeh M, Ahmad RS, Sadeghnejad S. Improvement of polymer flooding using in-situ releasing of smart nano-scale coated polymer particles in porous media. Energy Explor Exploit. 2012;30:915–39. https://doi.org/10.1260/0144-5987.30.6.915

Ashrafizadeh M, SA AR, Sadeghnejad S. Enhanced polymer flooding using a novel nano‐scale smart polymer: Experimental investigation. Can J Chem Eng. 2017;95:2168–75. https://doi.org/10.1002/cjce.22860

Jia H, Chen H. The potential of using Cr3 + /salt-tolerant polymer gel for well workover in low-temperature reservoir: laboratory investigation and pilot test. SPE Prod Oper. 2018. https://doi.org/10.2118/189460-PA

Imran AB, Seki T, Takeoka Y. Recent advances in hydrogels in terms of fast stimuli responsiveness and superior mechanical performance. Polym J. 2010;42:839.

Kadam Y, Pochat-Bohatier C, Sanchez J, El Ghzaoui A. Modulating viscoelastic properties of physically crosslinked self-assembled gelatin hydrogels through optimized solvent conditions. J Dispers Sci Technol. 2015;36:1349–56. https://doi.org/10.1080/01932691.2014.984721

Azimi Dijvejin Z, Ghaffarkhah A, Vafaie Sefti M, Moraveji MK. Synthesis, structure and mechanical properties of nanocomposites based on exfoliated nano magnesium silicate crystal and poly (acrylamide). J Dispers Sci Technol. 2018. https://doi.org/10.1080/01932691.2018.1467777

Liang Z, Liu C, Li L, Xu P, Luo G, Ding M, et al. Double-network hydrogel with tunable mechanical performance and biocompatibility for the fabrication of stem cells-encapsulated fibers and 3D assemble. Sci Rep-Uk. 2016;6:33462.

Koyama Y. Synthesis of topologically crosslinked polymers with rotaxane-crosslinking points. Polym J. 2014;46:315.

Haraguchi K, Takehisa T. Nanocomposite hydrogels: a unique organic–inorganic network structure with extraordinary mechanical, optical, and swelling/de‐swelling properties. Adva Mater. 2002;14:1120–4. https://doi.org/10.1002/1521-4095(20020816)14:16 < 1120::AID-ADMA1120 > 3.0.CO;2-9

Kargarzadeh H, Mariano M, Huang J, Lin N, Ahmad I, Dufresne A, et al. Recent developments on nanocellulose reinforced polymer nanocomposites: a review. Polymer. 2017. https://doi.org/10.1016/j.polymer.2017.09.043

Jain R, Mahto V, Sharma VP. Evaluation of polyacrylamide-grafted-polyethylene glycol/silica nanocomposite as potential additive in water based drilling mud for reactive shale formation. J Nat Gas Sci Eng. 2015;26:526–37. https://doi.org/10.1016/j.jngse.2015.06.051

D’Arienzo M, Redaelli M, Callone E, Conzatti L, Di Credico B, Dirè S, et al. Hybrid SiO 2@ POSS nanofiller: a promising reinforcing system for rubber nanocomposites. Mater Chem Front. 2017;1:1441–52.M. https://doi.org/10.1039/C7QM00045F

Hanifpour A, Bahri-Laleh N, Nekoomanesh-Haghighi M, Karimi M. Synthesis and characterization of poly1-hexene/silica nanocomposites. Polym Test. 2017;61:27–34. https://doi.org/10.1016/j.polymertesting.2017.05.002

Yu B, Kang W, Sarsenbekuly B, Yang R, Fan H, Yin X. Thickening behavior and synergistic mechanism of mixed system of two hydrophobically associating polymers. J Dispers Sci Technol. 2017;38:1196–203.

Gaharwar AK, Rivera C, Wu CJ, Chan BK, Schmidt G. Photocrosslinked nanocomposite hydrogels from PEG and silica nanospheres: structural, mechanical and cell adhesion characteristics. Mater Sci Eng C. 2013;33:1800–7. https://doi.org/10.1016/j.msec.2012.12.099

Wu L, Zeng L, Chen H, Zhang C. Effects of silica sol content on the properties of poly (acrylamide)/silica composite hydrogel. Polym Bull. 2012;68:309–16. https://doi.org/10.1007/s00289-011-0536-6

Zhao W, Li X, Gao S, Feng Y, Huang J. Understanding mechanical characteristics of cellulose nanocrystals reinforced PHEMA nanocomposite hydrogel: in aqueous cyclic test. Cellulose. 2017;24:2095–110. https://doi.org/10.1007/s10570-017-1244-7

Koohi AD, Moghaddam AZ, Sefti MV, Moghadam AM. Swelling and gelation time behavior of sulfonated polyacrylamide/chromium triacetate hydrogels. J Macromol Sci B. 2011;50:1905–20. https://doi.org/10.1080/00222348.2010.549419

Zhu D, Bai B, Hou J. Polymer gel systems for water management in high-temperature petroleum reservoirs: a chemical review. Energy Fuels. 2017;31:13063–87. https://doi.org/10.1021/acs.energyfuels.7b02897

Aalaie J, Vasheghani-Farahani E, Rahmatpour A, Semsarzadeh MA. Effect of montmorillonite on gelation and swelling behavior of sulfonated polyacrylamide nanocomposite hydrogels in electrolyte solutions. Eur Polym J. 2008;44:2024–31. https://doi.org/10.1016/j.eurpolymj.2008.04.031

Zhu D, Hou J, Wei Q, Chen Y. Development of a high-temperature-resistant polymer-gel system for conformance control in Jidong oil field. SPE Reserv Eval Eng. 2018. https://doi.org/10.2118/186235-PA

Nowak AP, Sato J, Breedveld V, Deming TJ. Hydrogel formation in amphiphilic triblock copolypeptides. Supramol Chem. 2006;18:423–7. https://doi.org/10.1080/10615800600659105

Czerner M, Fellay LS, Suárez MP, Frontini PM, Fasce LA. Determination of elastic modulus of gelatin gels by indentation experiments. Proc Mat Sci 2015. https://doi.org/10.1016/j.mspro.2015.04.075

Haraguchi K. Synthesis and properties of soft nanocomposite materials with novel organic/inorganic network structures. Polym J. 2011;43:223.

Mohammadi S, Vafaie Sefti M, Baghban Salehi M, Mousavi Moghadam A, Rajaee S, Naderi H. Hydrogel swelling properties: comparison between conventional and nanocomposite hydrogels for water shutoff treatment. Asia. Pac J Chem Eng. 2015;10:743–53. https://doi.org/10.1002/apj.1912

Karnib M, Kabbani A, Holail H, Olama Z. Heavy metals removal using activated carbon, silica and silica activated carbon composite. Enrgy Proced. 2014;50:113–20. https://doi.org/10.1016/j.egypro.2014.06.014

Choi J, Shin H, Yang S, Cho M. The influence of nanoparticle size on the mechanical properties of polymer nanocomposites and the associated interphase region: a multiscale approach. Compos Struct. 2015;119:365–376. https://doi.org/10.1016/j.compstruct.2014.09.014

Jang JS, Bouveret B, Suhr J, Gibson RF. Combined numerical/experimental investigation of particle diameter and interphase effects on coefficient of thermal expansion and young’s modulus of SiO2/epoxy nanocomposites. Polym Compos. 2012;33:1415–23. https://doi.org/10.1002/pc.22268

Liu H, Brinson LC. Reinforcing efficiency of nanoparticles: A simple comparison for polymer nanocomposites. Compos Sci Technol. 2008;68:1502–12.

Zare Y. Study of nanoparticles aggregation/agglomeration in polymer particulate nanocomposites by mechanical properties. Compos Part A-Appl S Manuf. 2016;84:158–64. https://doi.org/10.1016/j.compositesa.2016.01.020

Zare Y. The roles of nanoparticles accumulation and interphase properties in properties of polymer particulate nanocomposites by a multi-step methodology. Compos Part A Compos Part A-Appl S Manuf. 2016;91:127–32. https://doi.org/10.1016/j.compositesa.2016.10.003

Wang J, He YS, Yang J. Sulfur‐based composite cathode materials for high‐energy rechargeable lithium batteries. Adv Mat. 2015;27:569–75. https://doi.org/10.1002/adma.201402569

Wang C, Sun D, Zhuo K, Zhang H, Wang J. Simple and green synthesis of nitrogen, sulfur, and phosphorus-co-doped carbon dots with tunable luminescence properties and sensing application. RSC Adv. 2014;4:54060–5. https://doi.org/10.1039/C4RA10885J

Jin F, Feng M, Huang X, Long C, Jia K, Liu X. Effect of SiO2 grafted MWCNTs on the mechanical and dielectric properties of PEN composite films. Appl Surf Sci. 2015;357:704–11. https://doi.org/10.1016/j.apsusc.2015.09.086

Shokri B, Firouzjah MA, Hosseini SI. FTIR analysis of silicon dioxide thin film deposited by metal organic-based PECVD. Vol. 2631. In: von Keudell A and Winter J, editors. Proceedings of 19th International Symposium on Plasma Chemistry Society. Bochum, Germany: Center for Plasma Science and Technology (CPST), Ruhr-University Bochum; 2009.

Tian Q, Zhao X, Tang X, Zhang Y. Hydrophobicity of fluoro‐containing physical crosslinkage domains in hydrophobically modified poly (acrylic acid) gels. J Polym Sci Phys. 2002;40:1236–44. https://doi.org/10.1002/polb.10182

Kiefer J, Wagenfeld S, Kerlé D. Chain length effects on the vibrational structure and molecular interactions in the liquid normal alkyl alcohols. Spectrochim Acta A. 2018;189:57–65. https://doi.org/10.1016/j.saa.2017.07.061

Crupi V, Majolino D, Migliardo P, Venuti V, Wanderlingh U. A FT-IR absorption analysis of vibrational properties of water encaged in NaA zeolites: evidence of a “structure maker” role of zeolitic surface. Eur Phys J E. 2003;12:55–58. https://doi.org/10.1140/epjed/e2003-01-014-4

Crupi V, Majolino D, Migliardo P, Venuti V. Diffusive relaxations and vibrational properties of water and H-bonded systems in confined state by neutrons and light scattering: state of the art. J Phys Chem A. 2000;104:11000–12. https://doi.org/10.1021/jp001736l

Fahmy A, Eisa WH, Yosef M, Hassan A. Ultra-thin films of poly (acrylic acid)/silver nanocomposite coatings for antimicrobial applications. J. Spectrosc. 2016. https://doi.org/10.1155/2016/7489536

Magalhães ASG, Almeida Neto MP, Bezerra MN, Ricardo NM, Feitosa J. Application of FTIR in the determination of acrylate content in poly (sodium acrylate-co-acrylamide) superabsorbent hydrogels. Quím Nova. 2012;35:1464–7. https://doi.org/10.1590/S0100-40422012000700030

Okay O, Gürün Ç. Formation and structural characteristics of porous ethylene glycol dimethacrylate networks. J Appl Polym Sci. 1992;46:421–34. https://doi.org/10.1002/app.1992.070460307

Hu Z, Haruna M, Gao H, Nourafkan E, Wen D. Rheological properties of partially hydrolyzed polyacrylamide seeded by nanoparticles. Ind Eng Chem Res. 2017;6:3456–63.

Zhao F, Yao D, Guo R, Deng L, Dong A, Zhang J. Composites of polymer hydrogels and nanoparticulate systems for biomedical and pharmaceutical applications. Nanomaterials. 2015;5:2054–130. https://doi.org/10.3390/nano5042054

Oun AA, Rhim JW. Carrageenan-based hydrogels and films: effect of ZnO and CuO nanoparticles on the physical, mechanical, and antimicrobial properties. Food Hydrocoll. 2017;67:45–53. https://doi.org/10.1016/j.foodhyd.2016.12.040

Acknowledgements

We thank Dr. Marjan Ashrafizadeh for her great assistance with the interpretation of our results, Dr. Maral Ghahramani for comments that improved the manuscript, and the anonymous reviewers for their helpful comments and suggestions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Azimi Dijvejin, Z., Ghaffarkhah, A., Sadeghnejad, S. et al. Effect of silica nanoparticle size on the mechanical strength and wellbore plugging performance of SPAM/chromium (III) acetate nanocomposite gels. Polym J 51, 693–707 (2019). https://doi.org/10.1038/s41428-019-0178-3

Received:

Revised:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/s41428-019-0178-3

This article is cited by

-

Effect of sizes of vinyl modified narrow-dispersed silica cross-linker on the mechanical properties of acrylamide based hydrogel

Scientific Reports (2023)

-

Rheological properties and swelling behavior of nanocomposite preformed particle gels based on starch-graft-polyacrylamide loaded with nanosilica

Rheologica Acta (2021)

-

Surface modification of synthesized Fe3O4 super-paramagnetic nanoparticles and performance investigation in gelation parameters enhancement: application in enhanced oil recovery

Applied Nanoscience (2020)