Abstract

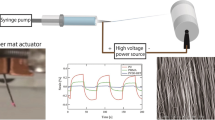

An ionic electroactive polymer actuator (IEPA) was fabricated in this study using a blend of regioregular-poly(3-hexylthiophene) (RR-P3HT) nanofibers, regiorandom-P3HT (RRa-P3HT), and polybutadiene rubber (PBR). The RR-P3HT nanofiber mat, which was reinforced with RRa-P3HT as tie chains and PBR as a flexible matrix, exhibited a large surface area where the nanofibers contacted the electrolyte. Therefore, efficient actuation is expected to synergize with the superior carrier mobility inherent in the nanofibrous architecture. The blended actuator, which preserved the RR-P3HT nanofiber structure, exhibited a substantial bending angle exceeding 80° following the redox reaction while sustaining reversible actuation for more than 30 cycles. An optimal scan rate below 100 mV s−1 was required to obtain substantial actuation. Therefore, the RR-P3HT nanofibers blended with RRa-P3HT and PBR demonstrated remarkable functionality as an IEPA, which was characterized by a significant bending angle and enduring cyclic actuation capabilities.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Hines L, Petersen K, Lum GZ, Sitti M. Soft actuators for small-scale robotics. Adv Mater. 2017;29:1603483 https://doi.org/10.1002/adma.201603483.

Mirvakili SM, Hunter IW. Artificial muscles: mechanisms, applications, and challenges. Adv Mater. 2018;30:1704407 https://doi.org/10.1002/adma.201704407.

Ahn J, Gu J, Choi J, Han C, Jeong Y, Park J, et al. A review of recent advances in electrically driven polymer-based flexible actuators: smart materials, structures, and their applications. Adv Mater. 2022;7:2200041 https://doi.org/10.1002/admt.202200041.

Smela E. Conjugated polymer actuators for biomedical applications. Adv Mater. 2003;15:481 https://doi.org/10.1002/adma.200390113.

Baughman RH. Conducting polymer artificial muscles. Synth Met. 1996;78:339 https://doi.org/10.1016/0379-6779(96)80158-5.

Otero TF, Angulo E, Rodriguez J, Santamaria C. Electrochemomechanical properties from a bilayer - polypyrrole nonconducting and flexible material artificial muscle. J Electroanal Chem. 1992;341:369 https://doi.org/10.1016/0022-0728(92)80495-P.

Madden JD, Cush RA, Kanigan TS, Hunter IW. Fast contracting polypyrrole actuators. Synth Met. 2000;113:185 https://doi.org/10.1016/S0379-6779(00)00195-8.

Hutchison AS, Lewis TW, Molton SE, Spinks GM, Wallace GG. Development of polypyrrole-based electromechanical actuators. Synth Met. 2000;113:121 https://doi.org/10.1016/S0379-6779(00)00190-9.

Hara S, Zama T, Takashima W, Kaneto K. Free-standing polypyrrole actuators with response rate of 10.8% s–1. Synth Met. 2005;149:199 https://doi.org/10.1016/j.synthmet.2005.01.003.

Roschning B, Weissmüller J. Stress-charge coupling coefficient for thin-film polypyrrole actuators - Investigation of capacitive ion exchange in the oxidized state. Electrochim Acta. 2019;318:504 https://doi.org/10.1016/j.electacta.2019.05.166.

Kaneto K, Kaneko H, Takashima W. Response of chemomechanical deformation in polyaniline film on variety of anions. Jpn J Appl Phys Part 2. 1995;34:L837 https://doi.org/10.1143/Jjap.34.L837.

Kaneto K, Kaneko M, Min Y, Macdiarmid AG. Artificial muscle - electromechanical actuators using polyaniline films. Synth Met. 1995;71:2211 https://doi.org/10.1016/0379-6779(94)03226-V.

Kaneko M, Kaneto K. Deformation of poly(-methoxyaniline) film induced by polymer conformation on electrochemical oxidation. Polym J. 2001;33:104 https://doi.org/10.1295/polymj.33.104.

Sansiñena JM, Gao JB, Wang HL. High-performance, monolithic polyaniline electrochemical actuators. Adv Funct Mater. 2003;13:703. https://doi.org/10.1002/adfm.200304347.

Beregoi M, Evanghelidis A, Matei E, Enculescu I. Polyaniline based microtubes as building-blocks for artificial muscle applications. Sens Actuat B-Chem. 2017;253:576 https://doi.org/10.1016/j.snb.2017.06.128.

Spinks GM, Mottaghitalab V, Bahrami-Saniani M, Whitten PG, Wallace GG. Carbon-nanotube-reinforced polyaniline fibers for high-strength artificial muscles. Adv Mater. 2006;18:637 https://doi.org/10.1002/adma.200502366.

Spinks GA, Shin SR, Wallace GG, Whitten PG, Kim IY, Kim SI, et al. A novel “dual mode” actuation in chitosan/polyaniline/carbon nanotube fibers. Sens Actuat B-Chem. 2007;121:616 https://doi.org/10.1016/j.snb.2006.04.103.

Kato Y, Sugino T. Effect of the polyaniline/carbon black additive on the dispersion state of carbon nanotubes and polymer actuator performance. Sens Actuat A-Phys. 2023;355:114302 https://doi.org/10.1016/j.sna.2023.114302.

Xi B, Whitten PG, Gestos A, Truong V-T, Spinks GM, Wallance GG. Electrochemical pneumatic actuators utilizing carbon nanotube electrodes. Sens Actuat B-Chem. 2009;138:48 https://doi.org/10.1016/j.snb.2008.12.067.

Kong L, Chen W. Carbon nanotube and Graphene-based bioinspired electrochemical actuators. Adv Mater. 2014;26:1025 https://doi.org/10.1002/adma.201303432.

Kim SH, Haines CS, Li N, Kim KJ, Mun TJ, Choi C, et al. Harvesting electrical energy from carbon nanotube yarn twist. Science. 2017;357:773 https://doi.org/10.1126/science.aam8771.

Yoshino K, Nakao K, Onoda M, Sugimoto R. Novel doping effect of conducting polymer gel. Jpn J Appl Phys Part 2. 1989;28:L682 https://doi.org/10.1143/Jjap.28.L682.

Yoshino K, Nakao K, Onoda M. Anisotropic characteristics of drawn poly(3-alkylthiophene) gel. Jpn J Appl Phys Part 2. 1989;28:L1032 https://doi.org/10.1143/Jjap.28.L1032.

Shakuda S, Morita S, Kawai T, Yoshino K. Dynamic characteristics of bimorph with conducting polymer gel. Jpn J Appl Phys Part 1. 1993;32:5143 https://doi.org/10.1143/Jjap.32.5143.

Chen XW, Inganas O. Doping-induced volume changes in poly(3-octylthiophene) solids and gels. Synth Met. 1995;74:159 https://doi.org/10.1016/0379-6779(95)03355-6.

McCullough, RD & Lowe, RD Enhanced electrical-conductivity in regioselectively synthesized poly(3-alkylthiophenes). J Chem Soc Chem Comm. 1992;70. https://doi.org/10.1039/c39920000070.

Chen TA, Rieke RD. The first regioregular head-to-tail poly(3-hexylthiophene-2,5-diyl) and a regiorandom isopolymer - nickel versus palladium catalysis of 2(5)-bromo-5(2)-(bromozincio)-3-hexylthiophene polymerization. J Am Chem Soc. 1992;114:10087 https://doi.org/10.1039/10.1021/ja00051a066.

Merlo JA, Frisbie CD. Field effect conductance of conducting polymer nanofibers. J Polym Sci Pol Phys 2003;41:2674 https://doi.org/10.1002/Polb.10656.

Merlo JA, Frisbie CD. Field effect transport and trapping in regioregular polythiophene nanofibers. J Phys Chem B. 2004;108:19169 https://doi.org/10.1021/Jp047023a.

Chang JF, Sun BQ, Breiby DW, Nielsen MM, Solling TI, Giles M, et al. Enhanced mobility of poly(3-hexylthiophene) transistors by spin-coating from high-boiling-point solvents. Chem Mater. 2004;16:4722 https://doi.org/10.1021/Cm049617w.

Yang H, Shin TJ, Yang L, Cho K, Ryu CY, Bao Z. Effect of mesoscale crystalline structure on the field-effect mobility of regioregular poly(3-hexyl thiophene) in thin-film transistors. Adv Func Mater. 2005;15:671. https://doi.org/10.1002/adfm.200400297.

Kim DH, Jang Y, Park YD, Cho K. Controlled one-dimensional nanostructures in poly(3-hexylthiophene) thin film for high-performance organic field-effect transistors. J Phys Chem B. 2006;110:15763 https://doi.org/10.1021/Jp062899y.

Oosterbaan WD, Bolsée J-C, Gadisa A, Vrindts V, Bertho S, D’Haen J, et al. Alkyl-chain-length-independent hole mobility via morphological control with poly(3-alkylthiophene) nanofibers. Adv Funct Mater 2010;20:792. https://doi.org/10.1002/adfm.200901471.

Samitsu S, Shimomura T, Heike S, Hashizume T, Ito K. Field-effect carrier transport in poly(3-alkylthiophene) nanofiber networks and isolated nanofibers. Macromolecules. 2010;43:7891 https://doi.org/10.1021/ma101655s.

Shimomura T, Takahashi T, Ichimura Y, Nakagawa S, Noguchi K, Heike S, et al. Relationship between structural coherence and intrinsic carrier transport in an isolated poly(3-hexylthiophene) nanofiber. Phys Rev B. 2011;83:115314 https://doi.org/10.1103/PhysRevB.83.115314.

Shan HT, He JX, Zhu BY, Zhou JJ, Huo H. The role of the commercial nucleating agent HPN-68 L in the stretchable and electrical properties of solvent vapor annealed P3HT. J Mater Chem C. 2022;10:17583 https://doi.org/10.1039/d2tc02121h.

Gu KC, Onorato JW, Luscombe CK, Loo YL. The role of tie chains on the mechano-electrical properties of semiconducting polymer films. Adv Electron Mater. 2020;6:1901070 https://doi.org/10.1002/aelm.201901070.

Na JY, Kang B, Park YD. Influence of molecular weight on the solidification of a semiconducting polymer during time-controlled spin-coating. J Phys Chem C. 2019;123:17102 https://doi.org/10.1021/acs.jpcc.9b03203.

Lim E, Glaudell AM, Miller R, Chabinyc ML. The role of ordering on the thermoelectric properties of blends of regioregular and regiorandom poly(3-hexylthiophene). Adv Electron Mater. 2019;5:1800915 https://doi.org/10.1002/aelm.201800915.

Qiu L, Lim JA, Wang X, Lee WH, Hwang M, Cho K. Versatile use of vertical-phase-separation-induced bilayer structures in organic thin-film transistors. Adv Mater. 2008;20:1141 https://doi.org/10.1002/adma.200702505.

Qiu LZ, Wang X, Lee WH, Lim JA, Kim JS, Kwak D, et al. Organic thin-film transistors based on blends of poly(3-hexylthiophene) and polystyrene with a solubility-induced low percolation threshold. Chem Mater. 2009;21:4380 https://doi.org/10.1021/cm900628j.

Morita J, Goto T, Kanehashi S, Shimomura T. Electrical double percolation of polybutadiene/polyethylene glycol blends loaded with conducting polymer nanofibers. Polymers. 2020;12:2658 https://doi.org/10.1021/10.3390/polym12112658.

Li N, Wang P, Shi HF, Chen Y, Yang L, Zhang YF, et al. An ultrahigh efficiency electrochemical actuator. Extrem Mech Lett. 2022;53:101691 https://doi.org/10.1016/j.eml.2022.101691.

Acknowledgements

This study was supported by KAKENHI (grant nos. JP21K18995 and JP22H02136) from the Japan Society for the Promotion of Science (JSPS). The authors thank Dr. Shinji Kanehashi at the TUAT for the mechanical strength measurements. The XRD measurements were performed at TUAT for the Research Center for Science and Technology, and the authors thank Dr. Keiichi Noguchi for the technical assistance.

Funding

This study was supported by KAKENHI (grant nos. JP21K18995 and JP22H02136) from the Japan Society for the Promotion of Science (JSPS).

Author information

Authors and Affiliations

Contributions

The manuscript was written with contributions from all authors. All authors approved the final version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Murasawa, Y., Yoshii, T., Suzuki, T. et al. Soft electroactive polymer actuators based on regioregular/regiorandom-poly(3-hexylthiophene) blends with a nanofiber structure. Polym J 56, 1187–1195 (2024). https://doi.org/10.1038/s41428-024-00949-y

Received:

Revised:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41428-024-00949-y