Abstract

Owing to the digital revolution and growing emphasis on sustainability, the demand for innovative electrochemical devices, such as flexible and wearable sensors, energy-harvesting devices, and high-capacity secondary batteries, has been increasing. Alongside this, various high-performance gel electrolytes with excellent mechanical and electrochemical properties have been developed. This focus review presents our recent research on enhancing the mechanical properties of gel electrolytes and their application in lithium secondary batteries. It discusses the efforts made to achieve self-healing ion gels, which utilize ionic liquids as the electrolyte solutions. Additionally, the review covers the application of functional gel electrolytes in next-generation lithium secondary batteries. It focuses particularly on improving the cycling performance of lithium metal anodes, which are considered the very promising anode material. Moreover, the future prospects of functional polymer gel electrolytes have been discussed in this review.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Zhang Y, Jeong CK, Wang J, Chen X, Choi KH, Chen LQ, et al. Hydrogel ionic diodes toward harvesting ultralow-frequency mechanical energy. Adv Mater. 2021;33:2103056.

Wang H, Wang Z, Yang J, Xu C, Zhang Q, Peng Z. Ionic gels and their applications in stretchable electronics. Macromol Rapid Commun. 2018;39:1800246.

Shi Y, Zhang J, Pan L, Shi Y, Yu G. Energy gels: A bio-inspired material platform for advanced energy applications. Nano Today. 2016;11:738–62.

Cheng X, Pan J, Zhao Y, Liao M, Peng H. Gel polymer electrolytes for electrochemical energy storage. Adv Energy Mater. 2018;8:1702184.

Wang Z, Li H, Tang Z, Liu Z, Ruan Z, Ma L, et al. Hydrogel electrolytes for flexible aqueous energy storage devices. Adv Funct Mater. 2018;28:1804560.

Chen T, Kong W, Zhang Z, Wang L, Hu Y, Zhu G, et al. Ionic liquid-immobilized polymer gel electrolyte with self-healing capability, high ionic conductivity and heat resistance for dendrite-free lithium metal batteries. Nano Energy. 2018;54:17–25.

Kamio E, Yasui T, Iida Y, Gong JP, Matsuyama H. Inorganic/organic double‐network gels containing ionic liquids. Adv Mater. 2017;29:1704118.

Wang M, Zhang P, Shamsi M, Thelen JL, Qian W, Truong VK, et al. Tough and stretchable ionogels by in situ phase separation. Nat Mater. 2022;21:359–65.

Zhao Y, Zhang Y, Sun H, Dong X, Cao J, Wang L, et al. A self-healing aqueous lithium-ion battery. Angew Chem Int Ed. 2016;55:14384–8.

Wang C, Li R, Chen P, Fu Y, Ma X, Shen T, et al. Highly stretchable, non-flammable and notch-insensitive intrinsic self-healing solid-state polymer electrolyte for stable and safe flexible lithium batteries. J Mater Chem A. 2021;9:4758–69.

Wu H, Cao Y, Su H, Wang C. Tough gel electrolyte using double polymer network design for the safe, stable cycling of lithium metal anode. Angew Chem Int Ed. 2018;57:1361–5.

Hashimoto K, Tatara R, Ueno K, Dokko K, Watanabe M. Design of polymer network and Li + solvation enables thermally and oxidatively stable, mechanically reliable, and highly conductive polymer gel electrolyte for lithium batteries. J Electrochem Soc. 2021;168:090538.

Angell CA, Ansari Y, Zhao Z. Ionic liquids: past, present and future. Faraday Discuss. 2012;154:9–27.

Ueno K, Tokuda H, Watanabe M. Ionicity in ionic liquids: correlation with ionic structure and physicochemical properties. Phys Chem Chem Phys. 2010;12:1649–58.

MacFarlane DR, Tachikawa N, Forsyth M, Pringle JM, Howlett PC, Elliott GD, et al. Energy applications of ionic liquids. Energy Environ Sci. 2014;7:232–50.

Hayes R, Warr GG, Atkin R. Structure and nanostructure in ionic liquids. Chem Rev. 2015;115:6357–426.

Ohno H, Yoshizawa-Fujita M, Kohno Y. Functional design of ionic liquids: Unprecedented liquids that contribute to energy technology, bioscience, and materials sciences. Bull Chem Soc Jpn. 2019;92:852–68.

Tamate R, Hashimoto K, Ueki T, Watanabe M. Block copolymer self-assembly in ionic liquids. Phys Chem Chem Phys. 2018;20:25123–39.

Wang M, Hu J, Dickey MD. Tough ionogels: synthesis, toughening mechanisms, and mechanical properties─a perspective. JACS Au. 2022;2:2645–57.

MacFarlane DR, Forsyth M, Howlett PC, Kar M, Passerini S, Pringle JM, et al. Ionic liquids and their solid-state analogues as materials for energy generation and storage. Nat Rev Mater. 2016;1:15005.

Yan CC, Li WZ, Liu ZY, Zheng SJ, Hu Y, Zhou YJ, et al. Ionogels: preparation, properties and applications. Adv Funct Mater. 2024;34:2314408.

Cho KG, An S, Cho DH, Kim JH, Nam J, Kim M, et al. Block copolymer‐based supramolecular ionogels for accurate on‐skin motion monitoring. Adv Funct Mater. 2021;31:2102386.

Chen N, Zhang H, Li L, Chen R, Guo S. Ionogel electrolytes for high-performance lithium batteries: a review. Adv Energy Mater. 2018;8:1702675.

Wu DY, Meure S, Solomon D. Self-healing polymeric materials: a review of recent developments. Prog Polym Sci. 2008;33:479–522.

Yang Y, Urban MW. Self-healing polymeric materials. Chem Soc Rev. 2013;42:7446–67.

Kang J, Tok JBH, Bao Z. Self-healing soft electronics. Nat Electron. 2019;2:144–50.

Maeda T, Otsuka H, Takahara A. Dynamic covalent polymers: Reorganizable polymers with dynamic covalent bonds. Prog Polym Sci. 2009;34:581–604.

Wang S, Urban MW. Self-healing polymers. Nat Rev Mater. 2020;5:562–83.

Li B, Cao P-F, Saito T, Sokolov AP. Intrinsically self-healing polymers: from mechanistic insight to current challenges. Chem Rev. 2023;123:701–35.

Tamate R, Watanabe M. Recent progress in self-healable ion gels. Sci Technol Adv Mater. 2020;21:388–401.

Tamate R. Healable soft materials based on ionic liquids and block copolymer self-assembly. Polym J. 2021;53:789–98.

Tamate R, Ueki T. Adaptive ion-gel: stimuli-responsive, and self-healing ion gels. Chem Rec. 2023;23:e202300043.

Cao Y, Morrissey TG, Acome E, Allec SI, Wong BM, Keplinger C, et al. A transparent, self‐healing, highly stretchable ionic conductor. Adv Mater. 2017;29:1605099.

Saruwatari A, Tamate R, Kokubo H, Watanabe M. Photohealable ion gels based on the reversible dimerisation of anthracene. Chem Commun. 2018;54:13371–4.

Xu L, Huang Z, Deng Z, Du Z, Sun TL, Guo ZH, et al. A transparent, highly stretchable, solvent‐resistant, recyclable multifunctional ionogel with underwater self‐healing and adhesion for reliable strain sensors. Adv Mater. 2021;33:2105306.

Yang L, Sun L, Huang H, Zhu W, Wang Y, Wu Z, et al. Mechanically robust and room temperature self-healing ionogel based on ionic liquid inhibited reversible reaction of disulfide bonds. Adv Sci. 2023;10:2207527.

Kim YM, Kwon JH, Kim S, Choi UH, Moon HC. Ion-cluster-mediated ultrafast self-healable ionoconductors for reconfigurable electronics. Nat Commun. 2022;13:3769.

Kim S, Yeo J, Kim SJ, Park S, Cho KG, Paeng K, et al. Photopatternable and self-healable ionogels for organic thin-film transistors. Org Electron. 2023;122:106895.

Yu Z, Wu P. Underwater communication and optical camouflage ionogels. Adv Mater. 2021;33:2008479.

Tamate R, Hashimoto K, Horii T, Hirasawa M, Li X, Shibayama M, et al. Self-healing micellar ion gels based on multiple hydrogen bonding. Adv Mater. 2018;30:1802792.

Tamate R, Hashimoto K, Li X, Shibayama M, Watanabe M. Effect of ionic liquid structure on viscoelastic behavior of hydrogen-bonded micellar ion gels. Polymer. 2019;178:121694.

Yamaguchi M, Ono S, Okamoto K. Interdiffusion of dangling chains in weak gel and its application to self-repairing material. Mater Sci Eng B. 2009;162:189–94.

Kamiyama Y, Tamate R, Hiroi T, Samitsu S, Fujii K, Ueki T. Highly stretchable and self-healable polymer gels from physical entanglements of ultrahigh–molecular weight polymers. Sci Adv. 2022;8:eadd0226.

Harrisson S, Mackenzie SR, Haddleton DM Unprecedented solvent-induced acceleration of free-radical propagation of methyl methacrylate in ionic liquids. Chem Commun. 2002:2850-1.

Low K, Wylie L, Scarborough DLA, Izgorodina EI. Is it possible to control kinetic rates of radical polymerisation in ionic liquids? Chem Commun. 2018;54:11226–43.

Suzuki Y, Shinagawa Y, Kato E, Mishima R, Fukao K, Matsumoto A. Polymerization-induced vitrification and kinetic heterogenization at the onset of the Trommsdorff effect. Macromolecules. 2021;54:3293–303.

Cordier P, Tournilhac F, Soulié-Ziakovic C, Leibler L. Self-healing and thermoreversible rubber from supramolecular assembly. Nature. 2008;451:977–80.

Stukalin EB, Cai LH, Kumar NA, Leibler L, Rubinstein M. Self-healing of unentangled polymer networks with reversible bonds. Macromolecules. 2013;46:7525–41.

Ge T, Grest GS, Robbins MO. Tensile fracture of welded polymer interfaces: miscibility, entanglements, and crazing. Macromolecules. 2014;47:6982–9.

Kamiyama Y, Tamate R, Fujii K, Ueki T. Controlling mechanical properties of ultrahigh molecular weight ion gels by chemical structure of ionic liquids and monomers. Soft Matter. 2022;18:8582–90.

Tikekar MD, Choudhury S, Tu Z, Archer LA. Design principles for electrolytes and interfaces for stable lithium-metal batteries. Nat Energy. 2016;1:16114.

Guo Y, Li H, Zhai T. Reviving lithium-metal anodes for next-generation high-energy batteries. Adv Mater. 2017;29:1700007.

Cheng X-B, Zhang R, Zhao CZ, Zhang Q. Toward safe lithium metal anode in rechargeable batteries: a review. Chem Rev. 2017;117:10403–73.

Watanabe M, Dokko K, Ueno K, Thomas ML. From ionic liquids to solvate ionic liquids: challenges and opportunities for next generation battery electrolytes. Bull Chem Soc Jpn. 2018;91:1660–82.

Yamada Y, Yamada A. Review—superconcentrated electrolytes for lithium batteries. J Electrochem Soc. 2015;162:A2406–A2423.

Xiao P, Yun X, Chen Y, Guo X, Gao P, Zhou G, et al. Insights into the solvation chemistry in liquid electrolytes for lithium-based rechargeable batteries. Chem Soc Rev. 2023;52:5255–316.

Yoshida K, Nakamura M, Kazue Y, Tachikawa N, Tsuzuki S, Seki S, et al. Oxidative-stability enhancement and charge transport mechanism in glyme–lithium salt equimolar complexes. J Am Chem Soc. 2011;133:13121–9.

Yamada Y, Furukawa K, Sodeyama K, Kikuchi K, Yaegashi M, Tateyama Y, et al. Unusual stability of acetonitrile-based superconcentrated electrolytes for fast-charging lithium-ion batteries. J Am Chem Soc. 2014;136:5039–46.

Ciurduc DE, Boaretto N, Fernández-Blázquez JP, Marcilla R. Development of high performing polymer electrolytes based on superconcentrated solutions. J Power Sources. 2021;506:230220.

Hao Z, Zhao Q, Tang J, Zhang Q, Liu J, Jin Y, et al. Functional separators towards the suppression of lithium dendrites for rechargeable high-energy batteries. Mater Horiz. 2021;8:12–32.

Huang B, Luo J, Xu B, Li Z, Li Y, Che Y, et al. Surface coating on a separator with a reductive solid Li-ion conductor for dendrite-free Li-metal batteries. ACS Appl Energy Mater. 2021;4:8621–8.

Poungsripong P, Tamate R, Ono M, Sakaushi K, Ue M. Fabrication of single-ion conducting polymer-coated separators and their application in nonaqueous Li-O2 batteries. Polym J. 2021;53:549–56.

Shomura R, Tamate R, Matsuda S. Lithium-ion-conducting ceramics-coated separator for stable operation of lithium metal-based rechargeable batteries. Materials. 2022;15:322.

Ryou MH, Lee DJ, Lee JN, Lee YM, Park JK, Choi JW. Excellent cycle life of lithium-metal anodes in lithium-ion batteries with mussel-inspired polydopamine-coated separators. Adv Energy Mater. 2012;2:645–50.

Zhang W, Tu Z, Qian J, Choudhury S, Archer LA, Lu Y. Design principles of functional polymer separators for high-energy, metal-based batteries. Small. 2018;14:1703001.

Yu Z, Cui Y, Bao Z. Design principles of artificial solid electrolyte interphases for lithium-metal anodes. Cell Rep. Phys Sci. 2020;1:100119.

Tu Z, Choudhury S, Zachman MJ, Wei S, Zhang K, Kourkoutis LF, et al. Designing artificial solid-electrolyte interphases for single-ion and high-efficiency transport in batteries. Joule. 2017;1:394–406.

Xu R, Zhang XQ, Cheng XB, Peng HJ, Zhao CZ, Yan C, et al. Artificial soft-rigid protective layer for dendrite-free lithium metal anode. Adv Funct Mater. 2018;28:1705838.

Yang D, Li J, Yang F, Li J, He L, Zhao H, et al. A rigid-flexible protecting film with surface pits structure for dendrite-free and high-performance lithium metal anode. Nano Lett. 2021;21:7063–9.

Gao Y, Yan Z, Gray JL, He X, Wang D, Chen T, et al. Polymer–inorganic solid–electrolyte interphase for stable lithium metal batteries under lean electrolyte conditions. Nat Mater. 2019;18:384–9.

Xu R, Cheng XB, Yan C, Zhang XQ, Xiao Y, Zhao CZ, et al. Artificial interphases for highly stable lithium metal anode. Matter. 2019;1:317–44.

Liu K, Pei A, Lee HR, Kong B, Liu N, Lin D, et al. Lithium metal anodes with an adaptive “solid-liquid” interfacial protective layer. J Am Chem Soc. 2017;139:4815–20.

Wang Y, Zanelotti CJ, Wang X, Kerr R, Jin L, Kan WH, et al. Solid-state rigid-rod polymer composite electrolytes with nanocrystalline lithium ion pathways. Nat Mater. 2021;20:1255–63.

Jaumaux P, Liu Q, Zhou D, Xu X, Wang T, Wang Y, et al. Deep-eutectic-solvent-based self-healing polymer electrolyte for safe and long-life lithium-metal batteries. Angew Chem Int Ed Engl. 2020;59:9134–42.

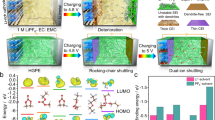

Tamate R, Peng Y, Kamiyama Y, Nishikawa K. Extremely tough, stretchable gel electrolytes with strong interpolymer hydrogen bonding prepared using concentrated electrolytes to stabilize lithium‐metal anodes. Adv Mater. 2023;35:2211679.

Ueno K, Yoshida K, Tsuchiya M, Tachikawa N, Dokko K, Watanabe M. Glyme–lithium salt equimolar molten mixtures: concentrated solutions or solvate ionic liquids? J Phys Chem B. 2012;116:11323–31.

Mandai T, Yoshida K, Ueno K, Dokko K, Watanabe M. Criteria for solvate ionic liquids. Phys Chem Chem Phys. 2014;16:8761–72.

Shkrob IA, Marin TW, Zhu Y, Abraham DP. Why bis(fluorosulfonyl)imide is a “magic anion” for electrochemistry. J Phys Chem C. 2014;118:19661–71.

Tatara R, Ikeda K, Ueno K, Watanabe M, Dokko K Solid–electrolyte interphase formation during Li metal deposition in LiN(SO2F)2-based solvate ionic liquids. J Solid State Electrochem. https://doi.org/10.1007/s10008-024-05843-4

Chang J, Huang Q, Gao Y, Zheng Z. Pathways of developing high‐energy‐density flexible lithium batteries. Adv Mater. 2021;33:2004419.

Kong L, Tang C, Peng HJ, Huang JQ, Zhang Q. Advanced energy materials for flexible batteries in energy storage: a review. SmartMat. 2020;1:e1007.

Liu J, Bao Z, Cui Y, Dufek EJ, Goodenough JB, Khalifah P, et al. Pathways for practical high-energy long-cycling lithium metal batteries. Nat Energy. 2019;4:180–6.

Tamate R, Matsuda S. Asymmetric volume expansion of the lithium metal electrode in symmetric lithium/lithium cells under lean electrolyte and high areal capacity conditions. ACS Appl Energy Mater. 2023;6:573–9.

Acknowledgements

The author is sincerely grateful to all his colleagues for their collaboration and encouragement in this work. This work was financially supported by JSPS KAKENHI (23K26409), JST PRESTO program (JPMJPR2196), COI-NEXT (JPMJPF2016), and Green Technologies of Excellence (GteX) Program (JPMJGX23S3).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tamate, R. Development of functional polymer gel electrolytes and their application in next-generation lithium secondary batteries. Polym J 57, 43–55 (2025). https://doi.org/10.1038/s41428-024-00969-8

Received:

Revised:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/s41428-024-00969-8

This article is cited by

-

An advanced PVA-based hydrogel flexible electrolyte material with high anti-dehydration and electrochemistry performance

Journal of Materials Science (2025)