Abstract

Contemporary polymer physics emphasizes polymer material design, which uses nano- and microscale structures to predict and optimize material properties. Despite their importance, predicting the mechanical behavior of polymers remains challenging because of the diverse configurations of their molecular chains. In recent years, quantitative structure‒property relationship modeling based on molecular dynamics (MD) simulations has become increasingly important. MD simulations excel at resolving sub-10-nm-scale morphological features, providing critical insights into network topology, chemical conformation, and molecular transitions. This review highlights recent MD simulation studies that have focused on subcontinuum heterogeneities in polymers from the perspective of their mechanical properties. The theoretical framework for rationally distributing the stress tensor to individual molecular components is revisited, and the key achievements made via this approach are summarized.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Le T, Epa VC, Burden FR, Winkler DA. Quantitative structure–property relationship modeling of diverse materials properties. Chem Rev. 2012;112:2889–919.

Theodorou DN. Understanding and predicting structure–property relations in polymeric materials through molecular simulations. Mol Phys. 2004;102:147–66.

Afzal MAF, Browning AR, Goldberg A, Halls MD, Gavartin JL, Morisato T, et al. High-throughput molecular dynamics simulations and validation of thermophysical properties of polymers for various applications. ACS Appl Polym Mater. 2020;3:620–30.

Nguyen D, Tao L, Li Y. Integration of machine learning and coarse-grained molecular simulations for polymer materials: physical understandings and molecular design. Front Chem. 2022;9:820417.

Okabe T, Oya Y, Tanabe K, Kikugawa G, Yoshioka K. Molecular dynamics simulation of crosslinked epoxy resins: curing and mechanical properties. Eur Polym J. 2016;80:78–88.

Bandyopadhyay A, Valavala PK, Clancy TC, Wise KE, Odegard GM. Molecular modeling of crosslinked epoxy polymers: the effect of crosslink density on thermomechanical properties. Polymer. 2011;52:2445–52.

Varshney V, Patnaik SS, Roy AK, Farmer BL. A molecular dynamics study of epoxy-based networks: cross-linking procedure and prediction of molecular and material properties. Macromolecules. 2008;41:6837–42.

Park H, Kim B, Choi J, Cho M. Influences of the molecular structures of curing agents on the inelastic-deformation mechanisms in highly-crosslinked epoxy polymers. Polymer. 2018;136:128–42.

Wick CD, Peters AJ, Li G. Quantifying the contributions of energy storage in a thermoset shape memory polymer with high stress recovery: a molecular dynamics study. Polymer. 2021;213:123319.

Li C, Strachan A. Evolution of network topology of bifunctional epoxy thermosets during cure and its relationship to thermo-mechanical properties: a molecular dynamics study. Polymer. 2015;75:151–60.

Zihan W, Peibin K, Tianyu W, Dongli C, Xiaoping Y, Gang S. Atomistic understanding of cross-linking network in different epoxy resin: effect of loop structure. Polymer. 2022;243:124629.

Radue MS, Jensen BD, Gowtham S, Klimek‐McDonald DR, King JA, Odegard GM. Comparing the mechanical response of di‐, tri‐, and tetra‐functional resin epoxies with reactive molecular dynamics. J Polym Sci Part B Polym Phys. 2018;56:255–64.

Bukowski C, Zhang T, Riggleman RA, Crosby AJ. Load-bearing entanglements in polymer glasses. Sci Adv. 2021;7:eabg9763.

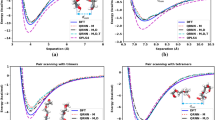

Kim H, Choi J. Subcontinuum interpretation of mechanical behavior for cross-linked epoxy networks. Macromolecules. 2022;55:5916–25.

Kim Y, Kim H, Choi J. Mechanical origin of shape memory performance for crosslinked epoxy networks. Eur Polym J. 2023;194:112162.

Kim H, Choi J. Theoretical analysis of phase transition behavior of ALCP/CNT nanocomposites interface by photo and thermal stimulation. Compos A Appl Sci Manuf. 2023;175:107824.

Heyes DM. Pressure tensor of partial-charge and point-dipole lattices with bulk and surface geometries. Phys Rev B Condens Matter. 1994;49:755.

Thompson AP, Plimpton SJ, Mattson W. General formulation of pressure and stress tensor for arbitrary many-body interaction potentials under periodic boundary conditions. J Chem Phys. 2009;131:154107.

Subramaniyan AK, Sun C. Continuum interpretation of virial stress in molecular simulations. Int J Solids Struct. 2008;45:4340–6.

Reda H, Chazirakis A, Behbahani AF, Savva N, Harmandaris V. A methodology for determining the local mechanical properties of model atomistic glassy polymeric nanostructured materials. MethodsX. 2022;9:101931.

Reda H, Chazirakis A, Behbahani AF, Savva N, Harmandaris V. Mechanical properties of glassy polymer nanocomposites via atomistic and continuum models: the role of interphases. Comput Methods Appl Mech Eng. 2022;395:114905.

Barakat M, Reda H, Katsamba P, Shraim H, Harmandaris V. Predicting mechanical heterogeneity in glassy polymer nanocomposites via an inverse computational approach based on atomistic molecular simulations and homogenization methods. Mech Mater. 2024;197:105082.

Elder RM, Mattson WD, Sirk TW. Origins of error in the localized virial stress. Chem Phys Lett. 2019;731:136580.

Lu J, Lazar EA, Rycroft CH. An extension to Voro++ for multithreaded computation of Voronoi cells. Comput Phys Commun. 2023;291:108832.

Rycroft C. VORO++: a three-dimensional Voronoi cell library in C++. 2009.

Choi J, Shin H, Yang S, Cho M. The influence of nanoparticle size on the mechanical properties of polymer nanocomposites and the associated interphase region: a multiscale approach. Compos Struct. 2015;119:365–76.

Choi J, Shin H, Cho M. A multiscale mechanical model for the effective interphase of SWNT/epoxy nanocomposite. Polymer. 2016;89:159–71.

Reda H, Chazirakis A, Behbahani AF, Savva N, Harmandaris V. Revealing the role of chain conformations on the origin of the mechanical reinforcement in glassy polymer nanocomposites. Nano Lett. 2023;24:148–55.

Reda H, Chazirakis A, Savva N, Ganghoffer J-F, Harmandaris V. Gradient of mechanical properties in polymer nanocomposites: from atomistic scale to the strain gradient effective continuum. Int J Solids Struct. 2022;256:111977.

Sahraei AA, Mokarizadeh AH, George D, Rodrigue D, Baniassadi M, Foroutan M. Insights into interphase thickness characterization for graphene/epoxy nanocomposites: a molecular dynamics simulation. Phys Chem Chem Phys. 2019;21:19890–903.

Putz KW, Palmeri MJ, Cohn RB, Andrews R, Brinson LC. Effect of cross-link density on interphase creation in polymer nanocomposites. Macromolecules. 2008;41:6752–6.

Bortz DR, Heras EG, Martin-Gullon I. Impressive fatigue life and fracture toughness improvements in graphene oxide/epoxy composites. Macromolecules. 2012;45:238–45.

Kim H, Choi J. Interfacial and mechanical properties of liquid crystalline elastomer nanocomposites with grafted Au nanoparticles: a molecular dynamics study. Polymer. 2021;218:123525.

Li C, Strachan A. Free volume evolution in the process of epoxy curing and its effect on mechanical properties. Polymer. 2016;97:456–64.

Sridhar AS. Effect of stoichiometry on crosslinked epoxy resin characteristics: structural heterogeneities, topological defects, properties, free volume and segmental mobility. Soft Matter. 2022;18:2354–72.

Shudo A, Izumi A, Hagita K, Nakao T, Shibayama M. Structure-mechanical property relationships in crosslinked phenolic resin investigated by molecular dynamics simulation. Polymer. 2017;116:506–14.

Yan C, Li G. A mechanism-based four-chain constitutive model for enthalpy-driven thermoset shape memory polymers with finite deformation. J Appl Mech. 2020;87:061007.

Fan J, Li G. High enthalpy storage thermoset network with giant stress and energy output in rubbery state. Nat Commun. 2018;9:642.

Kim H, Ahn S-K, Mackie DM, Kwon J, Kim SH, Choi C, et al. Shape morphing smart 3D actuator materials for micro soft robot. Mater Today. 2020;41:243–69.

Pang X, Lv JA, Zhu C, Qin L, Yu Y. Photodeformable azobenzene‐containing liquid crystal polymers and soft actuators. Adv Mater. 2019;31:1904224.

Kim H, Lee JA, Ambulo CP, Lee HB, Kim SH, Naik VV, et al. Intelligently actuating liquid crystal elastomer‐carbon nanotube composites. Adv Funct Mater. 2019;29:1905063.

Bi M, He Y, Wang Y, Yang W, Qin B, Xu J, et al. Photo actuation performance of nanotube sheet incorporated azobenzene crosslinked liquid crystalline polymer nanocomposite. Polymers. 2019;11:735.

Rau H. Photoisomerization of azobenzenes. Photochem. Photophys. 1990;2:119–41.

Heinz H, Vaia R, Koerner H, Farmer B. Photoisomerization of azobenzene grafted to layered silicates: simulation and experimental challenges. Chem Mater. 2008;20:6444–56.

Choi J, Chung H, Yun J-H, Cho M. Photo-isomerization effect of the azobenzene chain on the opto-mechanical behavior of nematic polymer: A molecular dynamics study. Appl Phys Lett. 2014;105:221906.

Kim H, Kim H, Choi J. Interface mechanics of liquid crystal polymer nanocomposites with high concentrations of MWCNTs. Compos Sci Technol. 2022;222:109376.

Kim H, Choi J. Mechanical assessment of interfacial stability of LCP/MWCNT nanocomposites during phase transition. Compos A Appl Sci Manuf. 2023;167:107461.

Choi J, Chung H, Yun J-H, Cho M. Molecular dynamics study on the photothermal actuation of a glassy photoresponsive polymer reinforced with gold nanoparticles with size effect. ACS Appl Mater Interfaces. 2016;8:24008–24.

Choi J, Shin H, Cho M. Multiscale multiphysical analysis of photo-mechanical properties of interphase in light-responsive polymer nanocomposites. Compos Sci Technol. 2018;160:32–41.

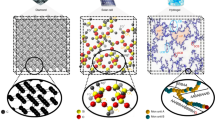

Kim H, Choi J. A lamellar-morphology-based computational modeling for predicting the thermal conductivity of semicrystalline polymers. Int J Mech Sci. 2024;282:109622.

Kim H, Choi J. Influence of crystalline structure on creep resistance capability in semi-crystalline Polymers: a coarse-grained molecular dynamics study. Int J Fatigue. 2024;188:108517.

Kim H, Won D, Ko SH, Choi J. Thermodynamic mechanism governing the coalescence of conductive particles in PEDOT: PSS under laser irradiation. Macromolecules. 2024;57:2048–56.

Ma R, Wang Y, Huang H, Zhao X, Li X, Zhang L, et al. Insight into the fracture properties and molecular mechanism of polyurethane. Macromolecules. 2024;57:4484–94.

Acknowledgements

This study was supported by a National Research Foundation of Korea (NRF) grant (RS-2023-00210865) funded by the Korean government (MSIT).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kim, H., Choi, J. A computational method for characterizing molecular-scale load transfer in polymer systems with structural heterogeneity. Polym J 57, 385–394 (2025). https://doi.org/10.1038/s41428-024-00997-4

Received:

Revised:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41428-024-00997-4