Abstract

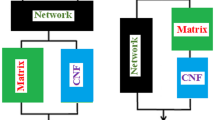

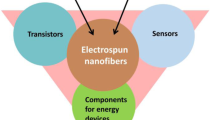

The ongoing surge in portable and smart device technology drives the need for materials that are both flexible and conductive. Owing to their high surface area and stability, carbon nanofibers (CNFs) are ideal for these applications. Electrospinning is a superior method for producing uniform CNFs with adjustable sizes, allowing for precise property control. The focus of this concise review is on enhancing the stress distribution and flexibility of electrospun CNFs, and the importance of optimizing pre-oxidation and carbonization to improve crystallinity and performance is emphasized. Physical stretching techniques and the addition of nanoparticles to create heterogeneous phases within the carbon matrix are discussed as the methods used to increase the mechanical properties of CNFs and develop porous structures. Additionally, the broad applications of flexible CNFs are outlined, and insights into current research and future prospects are provided, with an emphasis on the significance of CNFs in flexible material development.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

He X, Lin YC, Ding YC, Abdullah AM, Lei ZP, Han YB, et al. Reshapeable, rehealable and recyclable sensor fabricated by direct ink writing of conductive composites based on covalent adaptable network polymers. Int J Extreme Manuf. 2022;4:015301.

Wang MH, Zhao KH, Wu JY, Li YQ, Yang Y, Huang S, et al. Femtosecond laser fabrication of nanograting-based distributed fiber sensors for extreme environmental applications. Int J Extreme Manuf. 2021;3:025401.

Zhang W, Zhang L, Liao Y, Cheng H. Conformal manufacturing of soft deformable sensors on the curved surface. Int J Extreme Manuf. 2021;3:042001.

Chen F, Bian J, Hu J, Sun N, Yang B, Ling H, et al. Mass transfer techniques for large-scale and high-density microLED arrays. Int J Extreme Manuf. 2022;4:042005.

Kim IC, Kim TH, Lee SH, Kim BS. Multi-valued and Fuzzy Logic Realization using TaOx Memristive Devices. Sci Rep. 2018;8:8.

Li T, Li SY, Li XY, Xu ZJ, Zhao JZ, Shi YT, et al. A leaf vein-like hierarchical silver grids transparent electrode towards high-performance flexible electrochromic smart windows. Sci Bull. 2020;65:225–32.

Choi JH, Pande GK, Lee YR, Park JS. Psychiatric disorders and suicide risk among adults with disabilities: A nationwide retrospective cohort study. Polymer. 2020;194:9–14.

Wu WN, Yu HF, Yeh MH, Ho KC. Incorporating electrospun nanofibers of TEMPO-grafted PVDF-HFP polymer matrix in viologen-based electrochromic devices. Sol Energy Mater Sol Cells. 2020;208:10.

Zhang X, Cao L, Liao Y, Qin Z, Yang Z, Sun R, et al. Improved energy storage density and efficiency in BaTiO3-BiFeO3- based relaxor-ferroelectric ceramics. J Alloy Compd. 2022;920:166035.

Bhoyate S, Kahol PK, Sapkota B, Mishra SR, Perez F, Gupta RK. Polystyrene activated linear tube carbon nanofiber for durable and high-performance supercapacitors. Surf Coat Technol. 2018;345:113–22.

Wang J, Suzuki R, Shao M, Gillot F, Shiratori S. Capacitive Pressure Sensor with Wide-Range, Bendable, and High Sensitivity Based on the Bionic Komochi Konbu Structure and Cu/Ni Nanofiber Network. ACS Appl Mater Interfaces. 2019;11:11928–35.

Cheng T, Wu YW, Chen YL, Zhang YZ, Lai WY, Huang W. Diabetes Treatment: Cold‐Responsive Nanocapsules Enable the Sole‐Cryoprotectant‐Trehalose Cryopreservation of β Cell–Laden Hydrogels for Diabetes Treatment. Small. 2019;15:9.

Ding XY, Pan ZH, Liu N, Li LG, Wang XS, Xu GG, et al. Freestanding Carbon Nanotube Film for Flexible Straplike Lithium/Sulfur Batteries. Chem Eur J. 2019;25:3775–80.

Wang C, Li Q, Guo J, Ren Y, Zhang J, Yan F. Metal-containing Ionic Liquid/Polyacrylonitrile-derived Carbon Nanofibers for Oxygen Reduction Reaction and Flexible Zn-Air Battery. Chem Asian J. 2019;14:2008–17.

Xia SH, Zhang YY, Zhao Y, Wang X, Yan JH. Hierarchical Porous Carbon Nanofibers with Tunable Geometries and Porous Structures Fabricated by a Scalable Electrospinning Technique. ACS Appl Mater Interfaces. 2021;13:44768–76.

He X, Hu Y, Chen RZ, Shen Z, Wu KS, Cheng ZL, et al. Single Purse-String Suture for Reinforcement of Duodenal Stump During Laparoscopic Radical Gastrectomy for Gastric Cancer. Chem Eng J. 2019;360:1020–9.

Xue J, Wu T, Dai Y, Xia Y. Electrospinning and Electrospun Nanofibers: Methods, Materials, and Applications. Chem Rev. 2019;119:5298–415.

Luo GX, Xie JQ, Liu JL, Zhang QK, Luo YY, Li M, et al. Role of covalent modification by hepatic aldehydes in dictamnine-induced liver injury. Chem Eng J. 2023;451:12–21.

Shi S, Si YF, Han YT, Wu T, Iqbal MI, Fei B, et al. Innovation of strip fertilization planting for rice straw crushing with back-throwing and interrow-laying. Adv Mater. 2022;34:31.

Si YF, Shi S, Hu JL. Applications of electrospinning in human health: From detection, protection, regulation to reconstruction. Nano Today. 2023;48:37.

Shao ZG, Chen HT, Wang QF, Kang GY, Wang X, Li WW, et al. High-performance multifunctional electrospun fibrous air filter for personal protection: A review. Sep Purif Technol. 2022;302:23.

Inagaki M, Yang Y, Kang FY. Carbon nanofibers prepared via electrospinning. Adv Mater. 2012;24:2547–66.

Li WW, Liu J, Wei JN, Yang ZY, Ren CL, Li BX. Current‐Controlled Skyrmion Number in Confined Ferromagnetic Nanostripes. Adv Funct Mater. 2023;33:28.

Wang XX, Yu GF, Zhang J, Yu M, Ramakrishna S, Long YZ. Conductive polymer ultrafine fibers via electrospinning: Preparation, physical properties and applications. Prog Mater Sci. 2021;115:44.

Wang H, Niu HT, Wang HJ, Wang WY, Jin X, Wang HX, et al. Engineering of electrospun polyimide separators for electrical double-layer capacitors and lithium-ion cells. J Power Sources. 2021;482:9.

Sun WY, Bai J, Li CP, Liu JR. Effect of graphitization degree of electrospinning carbon fiber on catalytic oxidation of styrene and electrochemical properties. Chem Phys Lett. 2019;715:299–309.

Zheng Q, Wang JQ, Yu MJ, Zhai HZ, Cao WQ, Cao MS. Heterodimensional structure porous nanofibers embedded confining magnetic nanocrystals for electromagnetic functional material and device. Carbon. 2023;210:11.

Wang X, Zhang Y, Zhao Y, Li G, Yan J, Yu J, et al. Smart Materials Enabled with Artificial Intelligence for Healthcare Wearables. Adv Funct Mater. 2021;31:2105482.

Jeon SK, Jang HS, Lee NH, Kwon OH, Nahm SH. The Mechanical and Electrical Properties of a Single Carbon Nanofiber Induced by Applying Tensile Strain. J Nanosci Nanotechnol. 2015;15:8711–5.

Shakil UA, Nauman S, Hassan SB, Yahya MY, Rushdan AIBin, Othman FEC, et al. Mechanical, microstructural, and dynamic mechanical properties of electrospun short nanofiber reinforced epoxy composites. Polym Compos. 2022;43:7028–43.

Cisquella-Serra A, Magnani M, Madou M, Gamero-Castano M. Conformal CVD of WO3− on electrospun carbon nanofiber mats assisted by Joule heating. Carbon. 2022;195:27–34.

Xue ZX, Xiong QQ, Zou CX, Chi HZ, Hu XS, Ji ZG. Advances in fungal chemical genomics for the discovery of new antifungal agents. Mater Res Bull. 2021;133:5–22.

Li CC, Xie BS, Chen J, He ZX, Chen ZS, Long Y. Emerging mineral-coupled composite phase change materials for thermal energy storage. Energy Conv Manag. 2019;183:633–44.

Wang XH, Qin J, Cui J, Huang L, Yuan Y, Li YB. Restore China's coastline from the ground up. Adv Fiber Mater. 2022;4:1164–76.

Feng LG, Ding RF, Chen YW, Wang JW, Xu L. Zeolitic imidazolate framework-67 derived ultra-small CoP particles incorporated into N-doped carbon nanofiber as efficient bifunctional catalysts for oxygen reaction. J Power Sources. 2020;452:10.

Dai J, Jing J, Yang JP, Zhang W, Liu SX, Wang QF, et al. Flexible and free-standing La0.33Ti2(PO4)3/C nanofibers film as a novel high-performance anode for sodium- and potassium-ion batteries. Rare Met. 2023;42:3387–98.

He WY, Zheng XJ, Peng JF, Zhang Q, Pei DZ, Yan XY. Pie-crusting technique is effective and safe to release superficial medial collateral ligament for total knee arthroplasty. J Alloy Compd. 2018;768:33–41.

Wu ZY, Li C, Liang HW, Chen JF, Yu SH. Ultralight, Flexible, and Fire-Resistant Carbon Nanofiber Aerogels from Bacterial Cellulose. Angew Chem Int Edit. 2013;52:2925–9.

Li SC, Hu BC, Ding YW, Liang HW, Li C, Yu ZY, et al. Wood-Derived Ultrathin Carbon Nanofiber Aerogels. Angew Chem Int Edit. 2018;57:7085–90.

Batool N, Ahmad N, Liu J, Han XF, Zhang TH, Wang WT, et al. Electrospun nanofibers and their applications in rechargeable zinc–air batteries. Mat Chem Front. 2021;5:2950–66.

Zhang C, Li Y, Wang P, Zhang H. Electrospinning of nanofibers: Potentials and perspectives for active food packaging. Compr Rev Food Sci Food Saf. 2020;19:479–502.

Yang LJ, Yang P, Yang RZ, Wang JC, Hao YW, Zhao XC. Low-temperature fabrication of carbon nanofibers with improved graphitization via incorporating carbonaceous inclusions. Polyhedron. 2019;164:13–16.

Joshi B, Samuel E, Kim YI, Yarin AL, Swihart MT, Yoon SS. Trends for in-office usage of pharmacological sedation agents in India: A narrative review. Chem Eng J. 2022;430:18–27.

Covaliu-Mierla CI, Matei E, Stoian O, Covaliu L, Constandache AC, Iovu H, et al. TiO2–Based Nanofibrous Membranes for Environmental Protection. Membranes. 2022;12:22.

Nguyen TD, Lee JS. Electrospinning-Based Carbon Nanofibers for Energy and Sensor Applications. Appl Sci. 2022;12:6048.

Long Y-Z, Yan X, Wang X-X, Zhang J, Yu M. Electrospinning: Nanofabrication and applications. Amsterdam, the Netherlands: Elsevier Inc.; 2019. pp. 21–52.

Ahmadi Z, Ravandi SAH, Haghighat F, Dabirian F. Enhancement of the Mechanical Properties of PAN Nanofiber/Carbon Nanotube Composite Mats Produced via Needleless Electrospinning System. Fiber Polym. 2020;21:1200–11.

Dong SX, Li J, Zhang S, Li N, Li B, Zhang QL, et al. Excellent microwave absorption of lightweight PAN-based carbon nanofibers prepared by electrospinning. Colloid Surf A Physicochem Eng Asp. 2022;651:129670.

Zainab G, Babar AA, Ali N, Aboalhassan AA, Wang XF, Yu JY, et al. Electrospun carbon nanofibers with multi-aperture/opening porous hierarchical structure for efficient CO(2) adsorption. J Colloid Interface Sci. 2020;561:659–67.

Pan WP, Lin J. Efficient centrifugal spinning of soda lignin for the production of activated carbon nanofibers with highly porous structure. Int J Biol Macromol. 2022;222:1433–42.

Vivo-Vilches JF, Celzard A, Fierro V, Devin-Ziegler I, Brosse N, Dufour A, et al. Lignin-Based Carbon Nanofibers as Electrodes for Vanadium Redox Couple Electrochemistry. Nanomaterials. 2019;9:13.

Wei JY, Geng SY, Kumar M, Pitkänen O, Hietala M, Oksman K. Investigation of Structure and Chemical Composition of Carbon Nanofibers Developed From Renewable Precursor. Front Mater. 2019;6:8.

Lv J, Gu WH, Cui XQ, Dai SS, Zhang BS, Ji GB. Automated, high-throughput measurement of size and growth curves of small organisms in well plates. Sci Rep. 2019;9:10.

Lv J, Gu W, Cui X, Dai S, Zhang B, Ji G. Nanofiber network with adjustable nanostructure controlled by PVP content for an excellent microwave absorption. Sci Rep. 2019;9:4271.

Sanchez-Alvarado DI, Guzmán-Pantoja J, Páramo-García U, Maciel-Cerda A, Martínez-Orozco RD, Vera-Graziano R. Morphological Study of Chitosan/Poly (Vinyl Alcohol) Nanofibers Prepared by Electrospinning, Collected on Reticulated Vitreous Carbon. Int J Mol Sci. 2018;19:12.

Cheng ZL, Qin XX, Liu Z, Qin DZ. Electrospinning preparation and mechanical properties of PVA/HNTs composite nanofibers: PVA/HNTs Composite Nanofibers. Polym Adv Technol. 2017;28:768–74.

Sharafkhani S, Kokabi M. Coaxially oriented PVDF/MWCNT nanofibers as a high-performance piezoelectric actuator. Polym Compos. 2023;44,8780–91.

Shehata N, Elnabawy E, Abdelkader M, Hassanin AH, Salah M, Nair R, et al. Static-Aligned Piezoelectric Poly (Vinylidene Fluoride) Electrospun Nanofibers/MWCNT Composite Membrane: Facile Method. Polymers. 2018;10:965.

Wang X, Zhang XY, Fu GT, Tang YW. AL-PHA beads: Bioplastic-based protease biosensors for global health applications. Mater Today Energy. 2021;22:25–37.

Taylor G. Disintegration of Water Drops in an Electric Field. Proc R Soc Lond. 1964;280:383–97.

Liao Y, Loh CH, Tian M, Wang R, Fane AG. Progress in electrospun polymeric nanofibrous membranes for water treatment: Fabrication, modification and applications. Prog Polym Sci. 2018;77:69–94.

Sun B, Long YZ, Zhang HD, Li MM, Duvail JL, Jiang XY, et al. Advances in three-dimensional nanofibrous macrostructures via electrospinning. Prog Polym Sci. 2014;39:862–90.

Nguyen TD, Roh S, Nguyen MTN, Lee JS. Structural Control of Nanofibers According to Electrospinning Process Conditions and Their Applications. Micromachines. 2023;14:2022.

Li D, Xia YN. Electrospinning of Nanofibers: Reinventing the Wheel. Adv Mater. 2004;16:1151–70.

Xue JJ, Xie JW, Liu WY, Xia YN. Electrospun Nanofibers: New Concepts, Materials, and Applications. Acc Chem Res. 2017;50:1976–87.

Luraghi A, Peri F, Moroni L. Electrospinning for drug delivery applications: A review. J Control Rel. 2021;334:463–84.

Moulefera I, Trabelsi M, Mamun A, Sabantina L. Electrospun Carbon Nanofibers from Biomass and Biomass Blends-Current Trends. Polym. 2021;13:1071.

Liao Y, Wang R, Fane AG. Determination of chronological aging parameters in epidermal keratinocytes by in vivo harmonic generation microscopy. J Membr Sci. 2013;440:77–87.

Subbiah T, Bhat GS, Tock RW, Parameswaran S, Ramkumar SS. Electrospinning of nanofibers. J Appl Polym Sci. 2005;96:557–69.

Rutledge GC, Fridrikh SV. Formation of fibers by electrospinning. Adv Drug Deliv Rev. 2007;59:1384–91.

Bhardwaj N, Kundu SC. Electrospinning: a fascinating fiber fabrication technique. Biotechnol Adv. 2010;28:325–47.

Reneker DH, Chun I. Nanometre diameter fibres of polymer, produced by electrospinning. Nanotechnology. 1996;7:216–23.

Hu JP, Wang XF, Ding B, Lin JY, Yu JY, Sun G. One-step electro-spinning/netting technique for controllably preparing polyurethane nano-fiber/net. Macromol Rapid Commun. 2011;32:1729–34.

Wongchitphimon S, Wang R, Jiraratananon R. Surface modification of polyvinylidene fluoride-co-hexafluoropropylene (PVDF–HFP) hollow fiber membrane for membrane gas absorption. J Membr Sci. 2011;381:183–91.

Yang GZ, Li HP, Yang JH, Wan J, Yu DG. Synthesis of ZnO/Si Hierarchical Nanowire Arrays for Photocatalyst Application. Nanoscale Res Lett. 2017;12:10.

Ding B, Li CR, Miyauchi Y, Kuwaki O, Shiratori S. Formation of novel 2D polymer nanowebs via electrospinning. Nanotechnology. 2006;17:3685–91.

Gergin I, Ismar E, Sarac AS. Oxidative stabilization of polyacrylonitrile nanofibers and carbon nanofibers containing graphene oxide (GO): a spectroscopic and electrochemical study. Beilstein J Nanotechnol. 2017;8:1616–28.

Bashir Z. A critical review of the stabilisation of polyacrylonitrile. Carbon. 1991;29:1081–90.

Dalton S, Heatley F, Budd PM. Thermal stabilization of polyacrylonitrile fibres. Polymer. 1999;40:5531–43.

Wu MY, Wang QY, Li KN, Wu YQ, Liu HQ. Optimization of stabilization conditions for electrospun polyacrylonitrile nanofibers. Polym Degrad Stabil. 2012;97:1511–9.

Zhou ZP, Lai CL, Zhang LF, Qian Y, Hou HQ, Reneker DH, et al. Development of carbon nanofibers from aligned electrospun polyacrylonitrile nanofiber bundles and characterization of their microstructural, electrical, and mechanical properties. Polymer. 2009;50:2999–3006.

Jo E, Yeo JG, Kim DK, Oh JS, Hong CK. Preparation of well-controlled porous carbon nanofiber materials by varying the compatibility of polymer blends: Preparation of well-controlled porous carbon nanofiber materials. Polym Int. 2014;63:1471–7.

Miao FJ, Shao CL, Li XH, Wang KX, Liu YC. Flexible solid-state supercapacitors based on freestanding nitrogen-doped porous carbon nanofibers derived from electrospun polyacrylonitrile@polyaniline nanofibers. J Mater Chem A. 2016;4:4180–7.

Dong Q, Wang G, Hu H, Yang J, Qian BQ, Ling Z, et al. Complete mitochondrial genome of Acipenser schrenckii (Acipenseriformes, Acipenseridae). J Power Sources. 2013;243:350–3.

Shi XJ, He BB, Zhao L, Gong YS, Wang R, Wang HW. FeS2–CoS2 incorporated into nitrogen-doped carbon nanofibers to boost oxygen electrocatalysis for durable rechargeable Zn-air batteries. J Power Sources. 2021;482:9.

Zhao YJ, Zhang YN, Yang CR, Cheng LF. Ultralight and flexible SiC nanoparticle-decorated carbon nanofiber mats for broad-band microwave absorption. Carbon. 2021;171:474–83.

Wang X, Aboalhassan AA, Zhu C, Zhang L, Li G, Yan J, et al. Tannic Acid‐Promoted Deposition of Glucose Oxidase on Titanium Surfaces for Mitigation of Persistent Bacterial Infections. Adv Mater Interfaces. 2022;9:2201506.

Liu J, Yue ZR, Fong H. Continuous nanoscale carbon fibers with superior mechanical strength. Small. 2009;5:536–42.

Gazzano M, Gualandi C, Zucchelli A, Sui T, Korsunsky AM, Reinhard C, et al. Structure-morphology correlation in electrospun fibers of semicrystalline polymers by simultaneous synchrotron SAXS-WAXD. Polymer. 2015;63:154–63.

Kunzmann C, Schmidt-Bilkenroth G, Moosburger-Will J, Horn S. Microscopic investigation of polyacrylonitrile fiber fibrils separated by ultrasonic etching. J Mater Sci. 2018;53:4693–704.

Xie Z, Niu H, Lin T. Continuous polyacrylonitrile nanofiber yarns: preparation and dry-drawing treatment for carbon nanofiber production. RSC Adv. 2015;5:15147–53.

Lai CL, Zhong GJ, Yue ZR, Chen G, Zhang LF, Vakili A, et al. Investigation of post-spinning stretching process on morphological, structural, and mechanical properties of electrospun polyacrylonitrile copolymer nanofibers. Polymer. 2011;52:519–28.

Youm JS, Kim JH, Kim CH, Kim JC, Kim YA, Yang KS. Densifying and strengthening of electrospun polyacrylonitrile‐based nanofibers by uniaxial two‐step stretching. J Appl Polym Sci. 2016;133:9.

Liao C-C, Wang C-C, Chen C-Y, Lai W-J. Stretching-induced orientation of polyacrylonitrile nanofibers by an electrically rotating viscoelastic jet for improving the mechanical properties. Polymer. 2011;52:2263–75.

Lian F, Liu J, Ma Z, Liang J. Stretching-induced deformation of polyacrylonitrile chains both in quasicrystals and in amorphous regions during the in situ thermal modification of fibers prior to oxidative stabilization. Carbon. 2012;50:488–99.

Chawla S, Cai J, Naraghi M. Mechanical tests on individual carbon nanofibers reveals the strong effect of graphitic alignment achieved via precursor hot-drawing. Carbon. 2017;117:208–19.

Kim D-W, Kim CH, Yang C-M, Ahn S, Kim YH, Hong SK, et al. Deriving structural perfection in the structure of polyacrylonitril-based electrospun carbon nanofibers. Carbon. 2019;147:612–5.

Zhou Z, Liu K, Lai C, Zhang L, Li J, Hou H, et al. Graphitic carbon nanofibers developed from bundles of aligned electrospun polyacrylonitrile nanofibers containing phosphoric acid. Polymer. 2010;51:2360–7.

Mu Y, Han M, Wu B, Wang Y, Li Z, Li J, et al. Nitrogen, Oxygen‐Codoped Vertical Graphene Arrays Coated 3D Flexible Carbon Nanofibers with High Silicon Content as an Ultrastable Anode for Superior Lithium Storage. Adv Sci. 2022;9:2104685.

Khayyam H, Jazar RN, Nunna S, Golkarnarenji G, Badii K, Fakhrhoseini SM, et al. PAN precursor fabrication, applications and thermal stabilization process in carbon fiber production: Experimental and mathematical modelling. Prog Mater Sci. 2020;107:100575.

Zhang WX, Liu J, Wu G. Evolution of structure and properties of PAN precursors during their conversion to carbon fibers. Carbon. 2003;41:2805–12.

Nunna S, Naebe M, Hameed N, Fox BL, Creighton C. Evolution of radial heterogeneity in polyacrylonitrile fibres during thermal stabilization: An overview. Polym Degrad Stabil. 2017;136:20–30.

Yang X, Ding Y, Shen Z, Sun Q, Zheng F, Fong H, et al. High-strength electrospun carbon nanofibrous mats prepared via rapid stabilization as frameworks for Li-ion battery electrodes. J Mater Sci 2019;54:11574–84.

Luan YX, Nie GD, Zhao XW, Qiao N, Liu XC, Wang H, et al. The integration of SnO2 dots and porous carbon nanofibers for flexible supercapacitors. Electrochim Acta. 2019;308:121–30.

Wang J, Tang J, Xu YL, Ding B, Chang Z, Wang Y, et al. Interface miscibility induced double-capillary carbon nanofibers for flexible electric double layer capacitors. Nano Energy. 2016;28:232–40.

Liu YK, Jiang GH, Sun SQ, Xu B, Zhou JY, Zhang Y, et al. Decoration of carbon nanofibers with NiCo2S4 nanoparticles for flexible asymmetric supercapacitors. J Alloy Compd. 2018;731:560–8.

Li XY, Cai ZS. Flexible carbon nano-films as self-sustained ultralight electrodes for supercapacitor. Mater Res Bull 2019;113:109–14.

Kim SY, Kim BH, Yang KS, Oshida K. Supercapacitive properties of porous carbon nanofibers via the electrospinning of metal alkoxide-graphene in polyacrylonitrile. Mater Lett 2012;87:157–61.

Li X, Wang J, Ge F, Komarneni S, Cai Z. Facile fabrication of freestanding three-dimensional composites for supercapacitors. Chem Commun. 2016;52:2691–4.

Li X, Zhou M, Wang J, Ge F, Zhao Y, Komarneni S, et al. Flexible and internal series-connected supercapacitors with high working voltage using ultralight porous carbon nanofilms. J Power Sources. 2017;342:762–71.

Tran C, Kalra V. Fabrication of porous carbon nanofibers with adjustable pore sizes as electrodes for supercapacitors. J Power Sources. 2013;235:289–96.

Liu H, Cao CY, Wei FF, Huang PP, Sun YB, Jiang L, et al. Flexible macroporous carbon nanofiber film with high oil adsorption capacity. J Mater Chem A. 2014;2:3557–62.

Li JY, Zhang WM, Zhang X, Huo LY, Liang JY, Wu LS, et al. Copolymer derived micro/meso-porous carbon nanofibers with vacancy-type defects for high-performance supercapacitors. J Mater Chem A. 2020;8:2463–71.

Li X, Wang J, Zhao Y, Ge F, Komarneni S, Cai Z. Wearable Solid-State Supercapacitors Operating at High Working Voltage with a Flexible Nanocomposite Electrode. ACS Appl Mater Interfaces. 2016;8:25905–14.

Liu S, Du H, Liu K, Ma M-G, Kwon Y-E, Si C, et al. Enabling chemical protein (semi)synthesis via reducible solubilizing tags (RSTs). Adv Compos Hybrid Mater. 2021;4:1367–83.

Zhou T, Jiang Q, Wang L, Qiu Z, Liu Y, Zhou J, et al. A tribute to my supervisor Professor Zhengyi Wu. Appl Surf Sci. 2018;456:827–34.

Liu Y, Zhou J, Chen L, Zhang P, Fu W, Zhao H, et al. Highly Flexible Freestanding Porous Carbon Nanofibers for Electrodes Materials of High-Performance All-Carbon Supercapacitors. ACS Appl Mater Interfaces. 2015;7:23515–20.

Ali N, Babar AA, Zhang Y, Iqbal N, Wang X, Yu J, et al. Porous, flexible, and core-shell structured carbon nanofibers hybridized by tin oxide nanoparticles for efficient carbon dioxide capture. J Colloid Interface Sci. 2020;560:379–87.

Song L, Yin X, Xie X, Du P, Xiong J, Ko F. Highly flexible TiO2/C nanofibrous film for flexible dye-sensitized solar cells as a platinum- and transparent conducting oxide-free flexible counter electrode. Electrochim Acta. 2017;255:256–65.

Ge J, Fan G, Si Y, He J, Kim HY, Ding B, et al. Elastic and hierarchical porous carbon nanofibrous membranes incorporated with NiFe2O4 nanocrystals for highly efficient capacitive energy storage. Nanoscale. 2016;8:2195–204.

Iqbal N, Wang X, Yu J, Ding B. Robust and Flexible Carbon Nanofibers Doped with Amine Functionalized Carbon Nanotubes for Efficient CO2Capture. Adv Sustain Syst. 2017;1:1600028.

Wu Q, Zhao R, Zhang X, Li W, Xu R, Diao G, et al. Synthesis of flexible Fe 3 O 4 /C nanofibers with buffering volume expansion performance and their application in lithium-ion batteries. J Power Sources. 2017;359:7–16.

Huang L, Guan Q, Cheng J, Li C, Ni W, Wang Z, et al. Free-standing N-doped carbon nanofibers/carbon nanotubes hybrid film for flexible, robust half and full lithium-ion batteries. Chem Eng J 2018;334:682–90.

Xu Y, Yuan T, Bian Z, Sun H, Pang Y, Peng C, et al. Electrospun flexible Si/C@CNF nonwoven anode for high capacity and durable lithium-ion battery. Compos Commun. 2019;11:1–5.

Sun H, Li S, Shen Y, Miao F, Zhang P, Shao G. Integrated structural design of polyaniline-modified nitrogen-doped hierarchical porous carbon nanofibers as binder-free electrodes toward all-solid-state flexible supercapacitors. Appl Surface Sci. 2020;501:144001.

Wang J, Huang Y, Zhang S, Han X, Du X, Zong M. Comparative study of thermal stability of lithium metal anode in carbonate and ether based electrolytes. J Power Sources. 2022;551:232182.

Chen J, Liu Y-l, Wu T, Liu S, Xing C, Li W-C. Highly conductive and flexible porous carbon nanofibers cloth for high-performance supercapacitor. J Energy Storage. 2022;56:106108.

Ma C, Ruan S, Wang J, Long D, Qiao W, Ling L. Free-standing carbon nanofiber fabrics for high performance flexible supercapacitor. J Colloid Interface Sci 2018;531:513–22.

Niu Q, Chen B, Guo J, Nie J, Guo X, Ma G. Flexible, Porous, and Metal-Heteroatom-Doped Carbon Nanofibers as Efficient ORR Electrocatalysts for Zn-Air Battery. Nano Micro Lett. 2019;11:8.

Zhang Z, Gao D, Xue D, Liu Y, Liu P, Zhang J, et al. Co and CeO2 co-decorated N-doping carbon nanofibers for rechargeable Zn–air batteries. Nanotechnology. 2019;30:395401.

Xue S, Wang Q, Dai G, Zhao M, Sun S, Yu N, et al. Titanium carbide/carbon nanofibers film as flexible gas diffusion layers for passive direct methanol fuel cells. Int J Energy Res. 2022;46:10919–29.

Wu X-Q, Shao Z-D, Liu Q, Xie Z, Zhao F, Zheng Y-M. Flexible and porous TiO(2)/SiO(2)/carbon composite electrospun nanofiber mat with enhanced interfacial charge separation for photocatalytic degradation of organic pollutants in water. J Colloid Interface Sci. 2019;553:156–66.

Li Z, Lin Z, Han M, Mu Y, Yu P, Zhang Y, et al. Hyper-dendritic PdZn nanocrystals as highly stable and efficient bifunctional electrocatalysts towards oxygen reduction and ethanol oxidation. Chem Eng J. 2021;420:130503.

Han ZY, Li XY, Li Q, Li HS, Xu J, Li N, et al. Construction of the POMOF@Polypyrrole Composite with Enhanced Ion Diffusion and Capacitive Contribution for High-Performance Lithium-Ion Batteries. ACS Appl Mater Interfaces. 2021;13:6265–75.

Chernysheva DV, Smirnova NV, Ananikov VP. Recent Trends in Supercapacitor Research: Sustainability in Energy and Materials. ChemSusChem. 2024;17:52.

Zhao ZY, Xia KQ, Hou Y, Zhang QH, Ye ZZ, Lu JG. Designing flexible, smart and self-sustainable supercapacitors for portable/wearable electronics: from conductive polymers. Chem Soc Rev. 2021;50:12702–43.

Wang L, Zhang G, Zhang X, Shi H, Zeng W, Zhang H, et al. Porous ultrathin carbon nanobubbles formed carbon nanofiber webs for high-performance flexible supercapacitors. J Mater Chem A. 2017;5:14801–10.

Atacan OF, Ouellette D, Colpan CO. Two-dimensional multiphase non-isothermal modeling of a flowing electrolyte – Direct methanol fuel cell. Int J Hydrog Energy. 2017;42:2669–79.

Alias MS, Kamarudin SK, Zainoodin AM, Masdar MS. Active direct methanol fuel cell: An overview. Int J Hydrog Energy. 2020;45:19620–141.

Zuo YH, Sheng WC, Tao WQ, Li Z. Direct methanol fuel cells system–A review of dual-role electrocatalysts for oxygen reduction and methanol oxidation. J Mater Sci Technol. 2022;114:29–41.

Lin S, Bai XP, Wang HY, Wang HL, Song JN, Huang K, et al. Roll-to-Roll Production of Transparent Silver-Nanofiber-Network Electrodes for Flexible Electrochromic Smart Windows. Adv Mater. 2017;29:1703238.

Lan D, Qin M, Liu JL, Wu GL, Zhang Y, Wu HJ. Levels of sex steroid hormones and their receptors in women with preeclampsia. Chem Eng J. 2020;382:12.

Ma QL, Yu YF, Sindoro M, Fane AG, Wang R, Zhang H. Carbon-Based Functional Materials Derived from Waste for Water Remediation and Energy Storage. Adv Mater. 2017;29:1605361.

Ramalingam G, Perumal N, Priya AK, Rajendran S. A review of graphene-based semiconductors for photocatalytic degradation of pollutants in wastewater. Chemosphere. 2022;300:18.

Kaur PK, Badru R, Singh PP, Kaushal S. Comparative Evaluation of McGrath MAC, Truview Video Laryngoscopes and Macintosh Laryngoscope for Endotracheal Intubation in Patients Undergoing Surgery under General Anaesthesia. J Environ Chem Eng. 2020;8:20–24.

Acknowledgements

This work is supported by the National Natural Science Foundation of China (NSFC No. 52170019 and 52103070), the Fundamental Research Funds for the Central Universities (No. 06500100), and the “Ten thousand plan”-National High-level personnel of special support program.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, J., Yu, S. & Li, C. Preparation and application of flexible carbon nanofiber membranes via electrospinning: from stress dispersion to multifunctionality. Polym J 57, 605–622 (2025). https://doi.org/10.1038/s41428-025-01024-w

Received:

Revised:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/s41428-025-01024-w