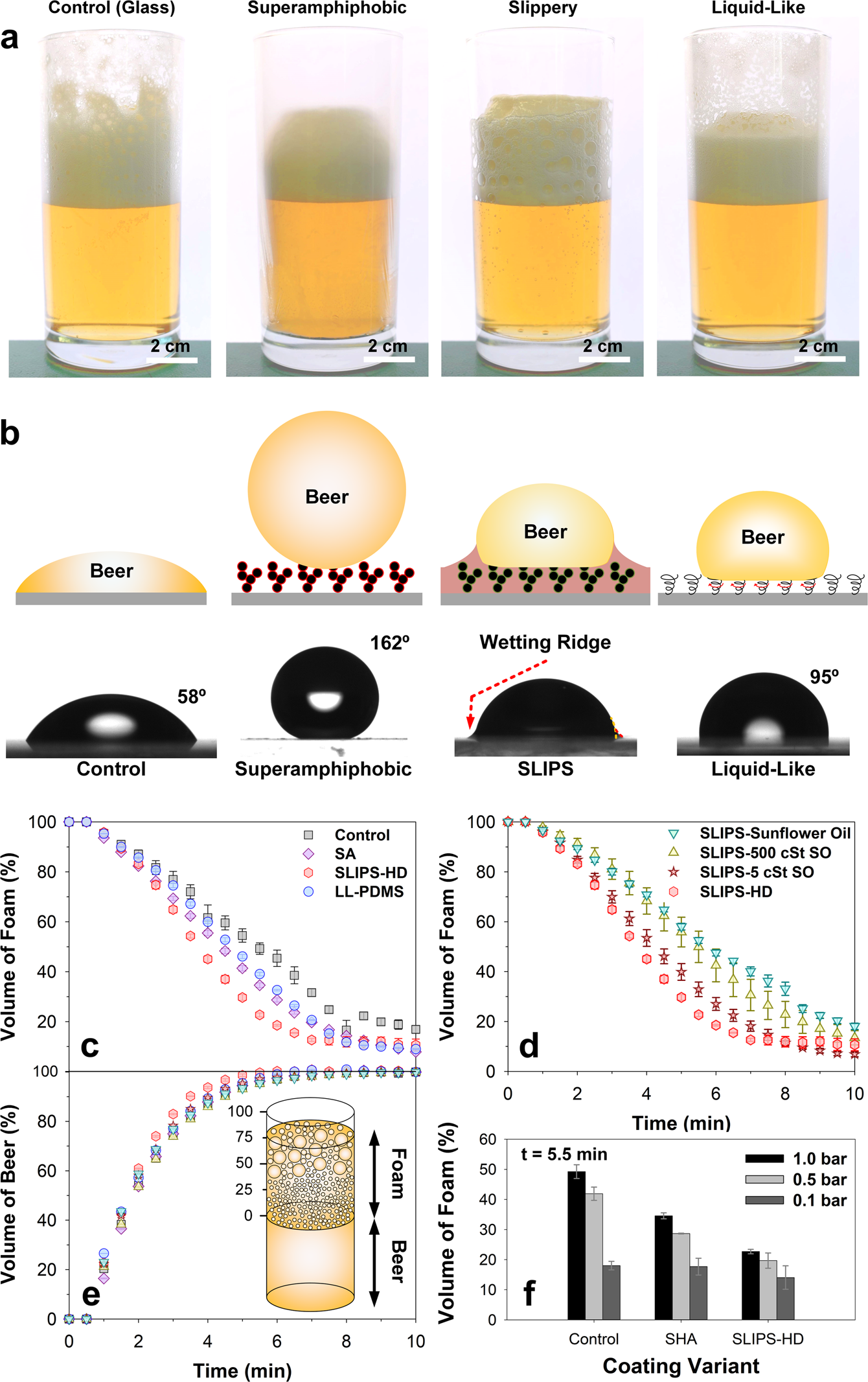

Fig. 1: Evaluation of super liquid-repellent surfaces for defoaming.

From: Super liquid repellent surfaces for anti-foaming and froth management

a Unmodified glass (control), superamphiphobic surface (SA), slippery liquid-infused porous surfaces (SLIPS), and liquid-like PDMS (LL-PDMS) 5 min after deposition. All surfaces were coated inside glass cups. As the wet liquid foam, commercially procured beer (Bitburger Pilsner) was used. b Schematic and optical image of a drop of beer (schematized as yellow) on test surfaces. The static, advancing, and receding contact angles were: (1) Control: 58°, 71°, 15°; (2) superamphiphobic: 164°, 180°45, 162°; (3) SLIPS: apparent contact angle of 74°, (4) liquid-like surface: 95°, 100°, 15°. Defoaming of foam generated from 1.0 bar pressure-dispensed beer. Analysis of (c) foam and (e) beer volume with test surfaces. d A comparison of various liquid-infused surfaces. f Volume of foam for three dispensing pressures using control, superamphiphobic and hexadecane-infused SLIPS glasses after 5.5 min. HD refers to hexadecane, SO refers to silicone oil. All data are presented in mean ± standard deviations.