Abstract

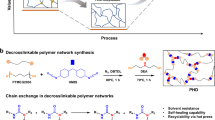

Dynamic covalent chemistry (DCC) allows the development of thermally (re)processable and recyclable polymer networks, which is a highly attractive feature for new generations of thermoset materials. However, despite a surge in academic interest wherein soon almost any imaginable DCC platform may have been applied in a thermoset formulation, dynamic or reversible covalent polymer networks have so far found only few industrial applications. This Review provides a perspective on the main strategies for the application of DCC in the design and development of bulk thermoset materials, and it presents some of the key hurdles for their industrial implementation. The polymer design strategies and associated chemistries are viewed from the perspective of how ‘close to market’ their development pathway is, thus providing a roadmap to achieve high-volume breakthrough applications.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Coates, G. W. & Getzler, Y. D. Y. L. Chemical recycling to monomer for an ideal, circular polymer economy. Nat. Rev. Mater. 5, 501–516 (2020).

Hinsken, H., Moss, S., Pauquet, J. R. & Zweifel, H. Degradation of polyolefins during melt processing. Polym. Degrad. Stab. 34, 279–293 (1991).

Miranda, R., Yang, J., Roy, C. & Vasile, C. Vacuum pyrolysis of PVC I. Kinetic study. Polym. Degrad. Stab. 64, 127–144 (1999).

Kartalis, C. N., Papaspyrides, C. D., Pfaendner, R., Hoffmann, K. & Herbst, H. Closed loop recycling of bottle crates using the restabilization technique. Macromol. Mater. Eng. 288, 124–136 (2003).

Oblak, P., Gonzalez-Gutierrez, J., Zupančič, B., Aulova, A. & Emri, I. Processability and mechanical properties of extensively recycled high density polyethylene. Polym. Degrad. Stab. 114, 133–145 (2015).

Rahimi, A. & García, J. M. Chemical recycling of waste plastics for new materials production. Nat. Rev. Chem. 1, 0046 (2017).

Rodríguez Lamar, Y., Noboa, J., Torres Miranda, A. S. & Almeida Streitwieser, D. Conversion of PP, HDPE and LDPE plastics into liquid fuels and chemical precursors by thermal cracking. J. Polym. Environ. 29, 3842–3853 (2021).

Nguyen, T. Q. & Kausch, H. H. in Mechanical Properties and Testing of Polymers 143–150 (Springer Nature, 1999).

Weerasinghe, M. A. S. N. et al. Educational series: turning monomers into crosslinked polymer networks. Polym. Chem. 14, 4503–4514 (2023).

Rajawasam, C. W. H. et al. Educational series: characterizing crosslinked polymer networks. Polym. Chem. 15, 219–247 (2023).

Li, H. et al. Expanding plastics recycling technologies: chemical aspects, technology status and challenges. Green Chem. 24, 8899–9002 (2022).

Schyns, Z. O. G. & Shaver, M. P. Mechanical recycling of packaging plastics: a review. Macromol. Rapid Commun. 42, 1–27 (2021).

Jehanno, C. et al. Critical advances and future opportunities in upcycling commodity polymers. Nature 603, 803–814 (2022).

Ragaert, K., Delva, L. & Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 69, 24–58 (2017).

Utekar, S., Suriya, V. K., More, N. & Rao, A. Comprehensive study of recycling of thermosetting polymer composites — driving force, challenges and methods. Compos. B Eng. 207, 108596 (2021).

Law, K. L. & Narayan, R. Reducing environmental plastic pollution by designing polymer materials for managed end-of-life. Nat. Rev. Mater. 7, 104–116 (2022).

Geyer, R., Jambeck, J. R. & Law, K. L. Production, use, and fate of all plastics ever made. Sci. Adv. 3, 25–29 (2017).

Van Lijsebetten, F., Debsharma, T., Winne, J. M. & Du Prez, F. E. A highly dynamic covalent polymer network without creep: mission impossible? Angew. Chem. Int. Ed. 61, e202210405 (2022).

Wu, S. & Chen, Q. Advances and new opportunities in the rheology of physically and chemically reversible polymers. Macromolecules 55, 697–714 (2022).

Winne, J. M., Leibler, L. & Du Prez, F. E. Dynamic covalent chemistry in polymer networks: a mechanistic perspective. Polym. Chem. 10, 6091–6108 (2019).

Shieh, P. et al. Cleavable comonomers enable degradable, recyclable thermoset plastics. Nature 583, 542–547 (2020).

Naqvi, S. R. et al. A critical review on recycling of end-of-life carbon fibre/glass fibre reinforced composites waste using pyrolysis towards a circular economy. Resour. Conserv. Recycl. 136, 118–129 (2018).

Lehn, J. M. Dynamers: dynamic molecular and supramolecular polymers. Prog. Polym. Sci. 30, 814–831 (2005).

Lei, Z., Chen, H., Jin, Y. & Zhang, W. Dynamic covalent chemistry toward wearable electronics. Cell Rep. Phys. Sci. 4, 101336 (2023).

Park, H. Y., Kloxin, C. J., Scott, T. F. & Bowman, C. N. Covalent adaptable networks as dental restorative resins: stress relaxation by addition–fragmentation chain transfer in allyl sulfide-containing resins. Dent. Mater. 26, 1010–1016 (2010).

Zhang, V., Kang, B., Accardo, J. V. & Kalow, J. A. Structure–reactivity–property relationships in covalent adaptable networks. J. Am. Chem. Soc. 144, 22358–22377 (2022).

Van Zee, N. J. & Nicolaÿ, R. in Macromolecular Engineering 1–38 (Wiley, 2022).

Zou, W., Dong, J., Luo, Y., Zhao, Q. & Xie, T. Dynamic covalent polymer networks: from old chemistry to modern day innovations. Adv. Mater. 29, 1606100 (2017).

Chakma, P. & Konkolewicz, D. Dynamic covalent bonds in polymeric materials. Angew. Chem. Int. Ed. 58, 9682–9695 (2019).

Deng, Y., Zhang, Q. & Feringa, B. L. Dynamic chemistry toolbox for advanced sustainable materials. Adv. Sci. 2308666, 1–22 (2024).

Wanasinghe, S. V., Dodo, O. J. & Konkolewicz, D. Dynamic bonds: adaptable timescales for responsive materials. Angew. Chem. Int. Ed. 61, e202206938 (2022).

Lei, Z. et al. New advances in covalent network polymers via dynamic covalent chemistry. Chem. Rev. 124, 7829–7906 (2024).

Elling, B. R. & Dichtel, W. R. Reprocessable cross-linked polymer networks: are associative exchange mechanisms desirable? ACS Cent. Sci. 6, 1488–1496 (2020).

Denissen, W., Winne, J. M. & Du Prez, F. E. Vitrimers: permanent organic networks with glass-like fluidity. Chem. Sci. 7, 30–38 (2016).

Guerre, M., Taplan, C., Winne, J. M. & Du Prez, F. E. Vitrimers: directing chemical reactivity to control material properties. Chem. Sci. 11, 4855–4870 (2020).

Alabiso, W. & Schlögl, S. The impact of vitrimers on the industry of the future: chemistry, properties and sustainable forward-looking applications. Polymers 12, 1660 (2020).

Kloxin, C. J., Scott, T. F., Adzima, B. J. & Bowman, C. N. Covalent adaptable networks (CANs): a unique paradigm in cross-linked polymers. Macromolecules 43, 2643–2653 (2010).

Montarnal, D., Capelot, M., Tournilhac, F. & Leibler, L. Silica-like malleable materials from permanent organic networks. Science 334, 965–968 (2011).

Kloxin, C. J. & Bowman, C. N. Covalent adaptable networks: smart, reconfigurable and responsive network systems. Chem. Soc. Rev. 42, 7161–7173 (2013).

Van Zee, N. J. & Nicolaÿ, R. Vitrimers: permanently crosslinked polymers with dynamic network topology. Prog. Polym. Sci. 104, 101233 (2020).

Bowman, C. N. & Kloxin, C. J. Covalent adaptable networks: reversible bond structures incorporated in polymer networks. Angew. Chem. Int. Ed. 51, 4272–4274 (2012).

Scheutz, G. M., Lessard, J. J., Sims, M. B. & Sumerlin, B. S. Adaptable crosslinks in polymeric materials: resolving the intersection of thermoplastics and thermosets. J. Am. Chem. Soc. 141, 16181–16196 (2019).

Dobson, A. L., Bongiardina, N. J. & Bowman, C. N. Combined dynamic network and filler interface approach for improved adhesion and toughness in pressure-sensitive adhesives. ACS Appl. Polym. Mater. 2, 1053–1060 (2020).

Sowan, N., Dobson, A., Podgorski, M. & Bowman, C. N. Dynamic covalent chemistry (DCC) in dental restorative materials: implementation of a DCC-based adaptive interface (AI) at the resin–filler interface for improved performance. Dent. Mater. 36, 53–59 (2020).

Aldana, A. A. et al. Biomimetic double network hydrogels: combining dynamic and static crosslinks to enable biofabrication and control cell‐matrix interactions. J. Polym. Sci. 59, 2832–2843 (2021).

Tobolsky, A. V., Prettyman, I. B. & Dillon, J. H. Stress relaxation of natural and synthetic rubber stocks. J. Appl. Phys. 15, 380–395 (1944).

Craven, J. M. Cross-linked thermally reversible polymers produced from condensation polymers with pendant furan groups cross-linked with maleimides. US patent WO 3435003 (1969).

Frich, D., Goranov, K., Schneggenburger, L. & Economy, J. Novel high-temperature aromatic copolyester thermosets: synthesis, characterization, and physical properties. Macromolecules 29, 7734–7739 (1996).

Lehn, J. M. From supramolecular chemistry towards constitutional dynamic chemistry and adaptive chemistry. Chem. Soc. Rev. 36, 151–160 (2007).

Chen, X., Wudl, F., Mal, A. K., Shen, H. & Nutt, S. R. New thermally remendable highly cross-linked polymeric materials. Macromolecules 36, 1802–1807 (2003).

Rowan, S. J., Cantrill, S. J., Cousins, G. R. L., Sanders, J. K. M. & Stoddart, J. F. Dynamic covalent chemistry. Angew. Chem. Int. Ed. 41, 898–952 (2002).

Taynton, P. et al. Heat- or water-driven malleability in a highly recyclable covalent network polymer. Adv. Mater. 26, 3938–3942 (2014).

Jin, Y., Yu, C., Denman, R. J. & Zhang, W. Recent advances in dynamic covalent chemistry. Chem. Soc. Rev. 42, 6634–6654 (2013).

Denissen, W. et al. Vinylogous urethane vitrimers. Adv. Funct. Mater. 25, 2451–2457 (2015).

De Alwis Watuthanthrige, N., Chakma, P. & Konkolewicz, D. Designing dynamic materials from dynamic bonds to macromolecular architecture. Trends Chem. 3, 231–247 (2021).

Capelot, M., Montarnal, D., Tournilhac, F. & Leibler, L. Metal-catalyzed transesterification for healing and assembling of thermosets. J. Am. Chem. Soc. 134, 7664–7667 (2012).

Capelot, M., Unterlass, M. M., Tournilhac, F. & Leibler, L. Catalytic control of the vitrimer glass transition. ACS Macro Lett. 1, 789–792 (2012).

Poutrel, Q.-A., Blaker, J. J., Soutis, C., Tournilhac, F. & Gresil, M. Dicarboxylic acid-epoxy vitrimers: influence of the off-stoichiometric acid content on cure reactions and thermo-mechanical properties. Polym. Chem. 11, 5327–5338 (2020).

Altuna, F. I., Hoppe, C. E. & Williams, R. J. J. Shape memory epoxy vitrimers based on DGEBA crosslinked with dicarboxylic acids and their blends with citric acid. RSC Adv. 6, 88647–88655 (2016).

Li, L., Chen, X., Jin, K. & Torkelson, J. M. Vitrimers designed both to strongly suppress creep and to recover original cross-link density after reprocessing: quantitative theory and experiments. Macromolecules 51, 5537–5546 (2018).

Self, J. L., Dolinski, N. D., Zayas, M. S., Read de Alaniz, J. & Bates, C. M. Brønsted-acid-catalyzed exchange in polyester dynamic covalent networks. ACS Macro Lett. 7, 817–821 (2018).

Han, J. et al. A catalyst-free epoxy vitrimer system based on multifunctional hyperbranched polymer. Macromolecules 51, 6789–6799 (2018).

Han, J. et al. Hyperbranched polymer assisted curing and repairing of an epoxy coating. Ind. Eng. Chem. Res. 58, 6466–6475 (2019).

Yang, S. et al. Direct and catalyst-free ester metathesis reaction for covalent adaptable networks. J. Am. Chem. Soc. 145, 20927–20935 (2023).

Altuna, F. I., Hoppe, C. E. & Williams, R. J. J. Epoxy vitrimers with a covalently bonded tertiary amine as catalyst of the transesterification reaction. Eur. Polym. J. 113, 297–304 (2019).

Li, Y. et al. Catalyst-free vitrimer elastomers based on a dimer acid: robust mechanical performance, adaptability and hydrothermal recyclability. Green Chem. 22, 870–881 (2020).

Hao, C. et al. Recyclable CFRPs with extremely high Tg: hydrothermal recyclability in pure water and upcycling of the recyclates for new composite preparation. J. Mater. Chem. A 10, 15623–15633 (2022).

Qiu, J. et al. Upcycling of polyethylene terephthalate to continuously reprocessable vitrimers through reactive extrusion. Macromolecules 54, 703–712 (2021).

Zhou, Y., Goossens, J. G. P., Sijbesma, R. P. & Heuts, J. P. A. Poly(butylene terephthalate)/glycerol-based vitrimers via solid-state polymerization. Macromolecules 50, 6742–6751 (2017).

Zhou, Y., Groote, R., Goossens, J. G. P., Sijbesma, R. P. & Heuts, J. P. A. Tuning PBT vitrimer properties by controlling the dynamics of the adaptable network. Polym. Chem. 10, 136–144 (2019).

Demongeot, A. et al. Cross-linking of poly(butylene terephthalate) by reactive extrusion using Zn(II) epoxy-vitrimer chemistry. Macromolecules 50, 6117–6127 (2017).

Ng, K. W. J. et al. A facile alternative strategy of upcycling mixed plastic waste into vitrimers. Commun. Chem. 6, 158 (2023).

Berzelius, J. J. Rapport annuel sur les progrès de la chimie (Swedish Royal Academy of Science, 1847).

Sandler, S. R. & Karo, W. (eds). in Polymer Syntheses 29, Ch. 5 (Elsevier, 1977).

Delahaye, M., Winne, J. M. & Du Prez, F. E. Internal catalysis in covalent adaptable networks: phthalate monoester transesterification as a versatile dynamic cross-linking chemistry. J. Am. Chem. Soc. 141, 15277–15287 (2019).

Bender, M. L., Chloupek, F. & Neveu, M. C. Intramolecular catalysis of hydrolytic reactions. III. Intramolecular catalysis by carboxylate ion in the hydrolysis of methyl hydrogen phthalate 1,2. J. Am. Chem. Soc. 80, 5384–5387 (1958).

Thanassi, J. W. & Bruice, T. C. Neighboring carboxyl group participation in the hydrolysis of monoesters of phthalic acid. The dependence of mechanisms on leaving group tendencies. J. Am. Chem. Soc. 88, 747–752 (1966).

Hernández, A. et al. Design and continuous (re)processing of thermally resilient poly(styrene-co-maleic maleate)-based covalent adaptable networks. Chem. Mater. 36, 7487–7503 (2024).

Delebecq, E., Pascault, J., Boutevin, B. & Ganachaud, F. On the versatility of urethane/urea bonds: reversibility, blocked isocyanate, and non-isocyanate polyurethane. Chem. Rev. 113, 80–118 (2013).

Offenbach, J. A. & Tobolsky, A. V. Chemical relaxation of stress in polyurethane elastomers. J. Colloid Sci. 11, 39–47 (1956).

Colodny, P. C. & Tobolsky, A. V. Chemorheological study of polyurethan elastomers 1. J. Am. Chem. Soc. 79, 4320–4323 (1957).

Wicks, D. A. & Wicks, Z. W. Blocked isocyanates III: part A. Mechanisms and chemistry. Prog. Org. Coat. 36, 148–172 (1999).

Wicks, D. A. & Wicks, Z. W. Blocked isocyanates III — part B: uses and applications of blocked isocyanates. Prog. Org. Coat. 41, 1–83 (2001).

Maes, S., Van Lijsebetten, F., Winne, J. M. & Du Prez, F. E. N-Sulfonyl urethanes to design polyurethane networks with temperature-controlled dynamicity. Macromolecules 56, 1934–1944 (2023).

Camberlin, Y., Michaud, P., Pesando, C. & Pascault, J. P. Isocyanate blocking agents use in polyurethane processing. Makromol. Chem. Macromol. Symp. 25, 91–99 (1989).

Chen, X., Hu, S., Li, L. & Torkelson, J. M. Dynamic covalent polyurethane networks with excellent property and cross-link density recovery after recycling and potential for monomer recovery. ACS Appl. Polym. Mater. 2, 2093–2101 (2020).

Elizalde, F., Aguirresarobe, R. H., Gonzalez, A. & Sardon, H. Dynamic polyurethane thermosets: tuning associative/dissociative behavior by catalyst selection. Polym. Chem. 11, 5386–5396 (2020).

Stern, M. D. & Tobolsky, A. V. Stress-time-temperature relations in polysulfide rubbers. J. Chem. Phys. 14, 93–100 (1946).

Osthoff, R. C., Bueche, A. M. & Grubb, W. T. Chemical stress-relaxation of polydimethylsiloxane elastomers. J. Am. Chem. Soc. 76, 4659–4663 (1954).

Zheng, P. & McCarthy, T. J. A surprise from 1954: siloxane equilibration is a simple, robust, and obvious polymer self-healing mechanism. J. Am. Chem. Soc. 134, 2024–2027 (2012).

Ramdani, N., Zaimeche, H. & Derradji, M. Biobased thermally-stable aromatic cyanate ester thermosets: a review. React. Funct. Polym. 168, 105037 (2021).

Lei, Z. et al. Recyclable and malleable thermosets enabled by activating dormant dynamic linkages. Nat. Chem. 14, 1399–1404 (2022).

Van Lijsebetten, F., Maes, S., Winne, J. M. & Du Prez, F. E. Thermoswitchable catalysis to inhibit and promote plastic flow in vitrimers. Chem. Sci. 15, 7061–7071 (2024).

Unal, K. et al. Foam-to-elastomer recycling of polyurethane materials through incorporation of dynamic covalent TAD–indole linkages. ACS Appl. Polym. Mater. 6, 2604–2615 (2024).

Van Lijsebetten, F., Holloway, J. O., Winne, J. M. & Du Prez, F. E. Internal catalysis for dynamic covalent chemistry applications and polymer science. Chem. Soc. Rev. 49, 8425–8438 (2020).

Wink, R., Majumdar, S., van Benthem, R. A. T. M., Heuts, J. P. A. & Sijbesma, R. P. RNA-inspired phosphate diester dynamic covalent networks. Polym. Chem. 14, 4294–4302 (2023).

Majumdar, S. et al. Efficient exchange in a bioinspired dynamic covalent polymer network via a cyclic phosphate triester intermediate. Macromolecules 54, 7955–7962 (2021).

Peerman, D., Tolberg, W. & Floyd, D. Reaction of polyamide resins and epoxy resins. Ind. Eng. Chem. 49, 1091–1094 (1957).

Huang, K., Xia, J., Yang, X., Li, M. & Ding, H. Properties and curing kinetics of C21-based reactive polyamides as epoxy-curing agents derived from tung oil. Polym. J. 42, 51–57 (2010).

Van Lijsebetten, F., Maiheu, T., Winne, J. M. & Du Prez, F. E. Epoxy adhesives with reversible hardeners: controllable thermal debonding in bulk and at interfaces. Adv. Mater. 35, 1–11 (2023).

Miller, I. K. Amide‐exchange reactions in mixtures of N‐alkyl amides and in polyamide melt blends. J. Polym. Sci. Polym. Chem. Ed. 14, 1403–1417 (1976).

Smith, M. E. & Adkins, H. The relative reactivity of amines in the aminolysis of amides 1. J. Am. Chem. Soc. 60, 657–663 (1938).

Van Lijsebetten, F., Spiesschaert, Y., Winne, J. M. & Du Prez, F. E. Reprocessing of covalent adaptable polyamide networks through internal catalysis and ring-size effects. J. Am. Chem. Soc. 143, 15834–15844 (2021).

Chen, Y. et al. Dynamic polyamide networks via amide–imide exchange. Macromolecules 54, 9703–9711 (2021).

Michael, A. & Schulthess, O. Ueber die addition von natriumacetessig‐ und Natriummalonsäureäthern zu den Aethern ungesättigter Säuren. J. Prakt. Chem. 45, 55–63 (1892).

Boynton, N. R. et al. Accessing pluripotent materials through tempering of dynamic covalent polymer networks. Science 383, 545–551 (2024).

Van Herck, N. et al. Covalent adaptable networks with tunable exchange rates based on reversible thiol–yne cross‐linking. Angew. Chem. Int. Ed. 59, 3609–3617 (2020).

Fischer, S. M., Kaschnitz, P. & Slugovc, C. Tris(2,4,6-trimethoxyphenyl)phosphine — a Lewis base able to compete with phosphazene bases in catalysing oxa-Michael reactions. Catal. Sci. Technol. 12, 6204–6212 (2022).

Fischer, S. M., Schallert, V., Uher, J. M. & Slugovc, C. Sequential dual-curing of electron-deficient olefins and alcohols relying on oxa-Michael addition and anionic polymerization. Polym. Chem. 14, 1081–1084 (2023).

Mather, B. D., Viswanathan, K., Miller, K. M. & Long, T. E. Michael addition reactions in macromolecular design for emerging technologies. Prog. Polym. Sci. 31, 487–531 (2006).

Genest, A., Portinha, D., Fleury, E. & Ganachaud, F. The aza-Michael reaction as an alternative strategy to generate advanced silicon-based (macro)molecules and materials. Prog. Polym. Sci. 72, 61–110 (2017).

González, G., Fernández-Francos, X., Serra, À., Sangermano, M. & Ramis, X. Environmentally-friendly processing of thermosets by two-stage sequential aza-Michael addition and free-radical polymerization of amine-acrylate mixtures. Polym. Chem. 6, 6987–6997 (2015).

Wang, J., Zhang, C., Ye, W., Zhou, X. & Xue, Z. Amine-acrylate Michael addition: a versatile platform for fabrication of polymer electrolytes with varied cross-linked networks. ACS Appl. Polym. Mater. 6, 2041–2048 (2024).

Baruah, R. et al. Recyclable thermosets based on dynamic amidation and aza-Michael addition chemistry. Macromolecules 49, 7814–7824 (2016).

Taplan, C., Guerre, M. & Du Prez, F. E. Covalent adaptable networks using β-amino esters as thermally reversible building blocks. J. Am. Chem. Soc. 143, 9140–9150 (2021).

Berne, D. et al. Taking advantage of β-hydroxy amine enhanced reactivity and functionality for the synthesis of dual covalent adaptable networks. Polym. Chem. 13, 3806–3814 (2022).

Engelen, S., Van Lijsebetten, F., Aksakal, R., Winne, J. M. & Du Prez, F. E. Enhanced viscosity control in thermosets derived from epoxy and acrylate monomers based on thermoreversible aza-Michael chemistry. Macromolecules 56, 7055–7064 (2023).

Stricker, L., Taplan, C. & Du Prez, F. E. Biobased, creep-resistant covalent adaptable networks based on β-amino ester chemistry. ACS Sustain. Chem. Eng. 10, 14045–14052 (2022).

Ivaldi, C. et al. Exploiting β-amino ester chemistry to obtain methacrylate-based covalent adaptable networks. Polymer 293, 126636 (2024).

Nguyen, L. T., Portone, F. & Du Prez, F. E. β-Amino amide based covalent adaptable networks with high dimensional stability. Polym. Chem. 15, 11–16 (2023).

del Rector, F., Blount, W. W. & Leonard, D. R. Applications for acetoacetyl chemistry in thermoset coatings. J. Coat. Technol. 61, 31–37 (1989).

De Bruycker, K. et al. Triazolinediones as highly enabling synthetic tools. Chem. Rev. 116, 3919–3974 (2016).

Fortman, D. J., Brutman, J. P., Cramer, C. J., Hillmyer, M. A. & Dichtel, W. R. Mechanically activated, catalyst-free polyhydroxyurethane vitrimers. J. Am. Chem. Soc. 137, 14019–14022 (2015).

Bakkali-Hassani, C. et al. Polyhydroxyurethane covalent adaptable networks: looking for suitable catalysts. Polym. Chem. 14, 3610–3620 (2023).

Monie, F. et al. Chemo- and regioselective additions of nucleophiles to cyclic carbonates for the preparation of self-blowing non-isocyanate polyurethane foams. Angew. Chem. Int. Ed. 59, 17033–17041 (2020).

Monie, F., Grignard, B. & Detrembleur, C. Divergent aminolysis approach for constructing recyclable self-blown nonisocyanate polyurethane foams. ACS Macro Lett. 11, 236–242 (2022).

Purwanto, N. S., Chen, Y., Wang, T. & Torkelson, J. M. Rapidly synthesized, self-blowing, non-isocyanate polyurethane network foams with reprocessing to bulk networks via hydroxyurethane dynamic chemistry. Polymer 272, 125858 (2023).

Zhao, X. L., Li, Y. D. & Zeng, J. B. Progress in the design and synthesis of biobased epoxy covalent adaptable networks. Polym. Chem. 13, 6573–6588 (2022).

Wu, X. et al. A facile access to stiff epoxy vitrimers with excellent mechanical properties: via siloxane equilibration. J. Mater. Chem. A 6, 10184–10188 (2018).

Debsharma, T. et al. Fast dynamic siloxane exchange mechanism for reshapable vitrimer composites. J. Am. Chem. Soc. 144, 12280–12289 (2022).

Debsharma, T., Engelen, S., De Baere, I., Van Paepegem, W. & Du Prez, F. Resorcinol-derived vitrimers and their flax fiber-reinforced composites based on fast siloxane exchange. Macromol. Rapid Commun. 44, 1–5 (2023).

Putnam-Neeb, A. A. et al. Oligosiloxane-based epoxy vitrimers: adaptable thermosetting networks with dual dynamic bonds. ACS Appl. Polym. Mater. 6, 14229–14234 (2024).

Rekondo, A. et al. Catalyst-free room-temperature self-healing elastomers based on aromatic disulfide metathesis. Mater. Horiz. 1, 237–240 (2014).

Li, B., Zhu, G., Hao, Y. & Ren, T. An investigation on the performance of epoxy vitrimers based on disulfide bond. J. Appl. Polym. Sci. 139, e51589 (2022).

Azcune, I. & Odriozola, I. Aromatic disulfide crosslinks in polymer systems: self-healing, reprocessability, recyclability and more. Eur. Polym. J. 84, 147–160 (2016).

Ruiz de Luzuriaga, A. et al. Chemical control of the aromatic disulfide exchange kinetics for tailor-made epoxy vitrimers. Polymer 239, 124457 (2022).

Ruiz De Luzuriaga, A. et al. Epoxy resin with exchangeable disulfide crosslinks to obtain reprocessable, repairable and recyclable fiber-reinforced thermoset composites. Mater. Horiz. 3, 241–247 (2016).

Schenk, V. et al. Exploring the limits of high-Tg epoxy vitrimers produced through resin-transfer molding. ACS Appl. Mater. Interfaces 15, 46357–46367 (2023).

Ruiz de Luzuriaga, A. et al. Aero grade epoxy vitrimer towards commercialization. Polymers 14, 3180 (2022).

Guggari, S. et al. Vanillin-based epoxy vitrimers: looking at the cystamine hardener from a different perspective. ACS Sustain. Chem. Eng. 11, 6021–6031 (2023).

Li, L., Chen, X. & Torkelson, J. M. Covalent adaptive networks for enhanced adhesion: exploiting disulfide dynamic chemistry and annealing during application. ACS Appl. Polym. Mater. 2, 4658–4665 (2020).

Li, B., Zhu, G., Hao, Y. & Ren, T. Effect of cross-link density on the performance of polyimine/epoxy vitrimers. Smart Mater. Struct. 33, 025014 (2024).

Guerre, M., Taplan, C., Nicolaÿ, R., Winne, J. M. & Du Prez, F. E. Fluorinated vitrimer elastomers with a dual temperature response. J. Am. Chem. Soc. 140, 13272–13284 (2018).

Taplan, C., Guerre, M., Winne, J. M. & Du Prez, F. E. Fast processing of highly crosslinked, low-viscosity vitrimers. Mater. Horiz. 7, 104–110 (2020).

Van Lijsebetten, F., De Bruycker, K., Spiesschaert, Y., Winne, J. M. & Du Prez, F. E. Suppressing creep and promoting fast reprocessing of vitrimers with reversibly trapped amines. Angew. Chem. Int. Ed. 61, e202113872 (2022).

Van Lijsebetten, F., De Bruycker, K., Winne, J. M. & Du Prez, F. E. Masked primary amines for a controlled plastic flow of vitrimers. ACS Macro Lett. 11, 919–924 (2022).

Soavi, G. et al. Phenoxy resin-based vinylogous urethane covalent adaptable networks. React. Funct. Polym. 191, 105681 (2023).

Spiesschaert, Y. et al. Dynamic curing agents for amine-hardened epoxy vitrimers with short (re)processing times. Macromolecules 53, 2485–2495 (2020).

Adjaoud, A., Puchot, L. & Verge, P. Polybenzoxazine-based covalent adaptable networks: a mini-review. Polymer 287, 126426 (2023).

Luo, J. et al. Highly recyclable and tough elastic vitrimers from a defined polydimethylsiloxane network. Angew. Chem. Int. Ed. 62, e202310989 (2023).

Vozzolo, G., Ximenis, M., Mantione, D., Fernández, M. & Sardon, H. Thermally reversible organocatalyst for the accelerated reprocessing of dynamic networks with creep resistance. ACS Macro Lett. 12, 1536–1542 (2023).

Martins, M. L. et al. Viscoelasticity of polymers with dynamic covalent bonds: concepts and misconceptions. Macromolecules 56, 8688–8696 (2023).

Fortman, D. J., Snyder, R. L., Sheppard, D. T. & Dichtel, W. R. Rapidly reprocessable cross-linked polyhydroxyurethanes based on disulfide exchange. ACS Macro Lett. 7, 1226–1231 (2018).

Slone, R. V. Methacrylic ester polymers. Encycl. Polym. Sci. Technol. 3, 249–277 (2001).

Lessard, J. J. et al. Catalyst-free vitrimers from vinyl polymers. Macromolecules 52, 2105–2111 (2019).

Lessard, J. J. et al. Block copolymer vitrimers. J. Am. Chem. Soc. 142, 283–289 (2020).

Lessard, J. J., Scheutz, G. M., Hughes, R. W. & Sumerlin, B. S. Polystyrene-based vitrimers: inexpensive and recyclable thermosets. ACS Appl. Polym. Mater. 2, 3044–3048 (2020).

Lossada, F., Jiao, D., Yao, X. & Walther, A. Waterborne methacrylate-based vitrimers. ACS Macro Lett. 9, 70–76 (2020).

Chen, J., Jiang, S., Gao, Y. & Sun, F. Reducing volumetric shrinkage of photopolymerizable materials using reversible disulfide-bond reactions. J. Mater. Sci. 53, 16169–16181 (2018).

Takahashi, A., Goseki, R., Ito, K. & Otsuka, H. Thermally healable and reprocessable bis(hindered amino)disulfide-cross-linked polymethacrylate networks. ACS Macro Lett. 6, 1280–1284 (2017).

Maes, S., Scholiers, V. & Du Prez, F. E. Photo‐crosslinking and reductive decrosslinking of polymethacrylate‐based copolymers containing 1,2‐dithiolane rings. Macromol. Chem. Phys. 224, 2100445 (2023).

Cuthbert, J., Wanasinghe, S. V., Matyjaszewski, K. & Konkolewicz, D. Are RAFT and ATRP universally interchangeable polymerization methods in network formation? Macromolecules 54, 8331–8340 (2021).

Lepage, M. L. & Wulff, J. E. Mixed plastics upcycled dynamically. Nature 616, 663–664 (2023).

Acknowledgements

The authors express their gratitude to all the experts who provided valuable insights and perspectives that greatly enriched this Review: G. Bouquet (principal research scientist at Trinseo in Terneuzen), M. Guerre (CNRS Researcher at Université de Toulouse), L. Imbernon (R&D engineer at Carpenter Co. Wetteren), R. Sijbesma (full professor at TU Eindhoven), A. Slark (Professorial Fellow at the University of Sheffield), P. Taynton (CEO at Mallinda Inc.), F. G. Tournilhac (Research Director at C3M in CNRS and ESPCI Paris-PSL) and T. Xie (Qiushi Chair Professor at Zhenjiang University in China). F.E.D.P would like to thank the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation program (CiMaC project — grant agreement no. 101021081).

Author information

Authors and Affiliations

Contributions

The manuscript was written through contributions of all authors. All authors have given approval to the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Reviews Chemistry thanks the anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Related links

ASTP Innovations: https://www.atspinnovations.com/

Mallinda Incorporated: https://mallinda.com/

Toyobo MC Corporation, Limited: https://www.toyobo-mc.jp

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Maes, S., Badi, N., Winne, J.M. et al. Taking dynamic covalent chemistry out of the lab and into reprocessable industrial thermosets. Nat Rev Chem 9, 144–158 (2025). https://doi.org/10.1038/s41570-025-00686-7

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41570-025-00686-7

This article is cited by

-

Dynamic decrosslinking enables self-healing, reprocessability, and upcycling in polyurethane networks

Nature Communications (2026)

-

Synthesis of poly(ester disulfide)s from S8-involved step-growth addition polymerization at ambient temperature

Nature Communications (2026)

-

Beyond durability: the transformative journey of carbon fiber reinforced epoxy composites through advanced interfacial engineering, self-healing, and vitrimer-enabled recycling

Advanced Composites and Hybrid Materials (2026)

-

Self-healing crystals

Nature Reviews Chemistry (2025)

-

En route to realistic sustainable structural fiber-reinforced polymers in a circular economy

Advanced Composites and Hybrid Materials (2025)