Abstract

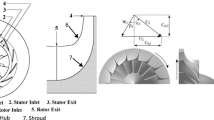

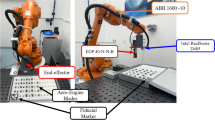

The uncertainty in blade machining deviations leads to the offset in the average performance and the performance scatter of aero-engine compressors, posing a threat to the safe operation of engines. Therefore, quantifying the uncertainty effects of machining deviations is critically important. However, due to factors such as prolonged inspection cycles and high costs, geometric data on blade machining deviations remain scarce. Most uncertainty quantification analyses are conducted under assumed statistical distributions of deviations, making it difficult to guarantee the accuracy of the quantification. In this paper, a dataset of measured machining deviations of 100 compressor rotor blades is presented. And it includes 7 types of machining deviations of 13 blade sections from blade root to tip. The work fills a critical gap in available geometric deviation data for compressor rotor blades, and provides a reliable foundation for subsequent uncertainty quantification investigation.

Similar content being viewed by others

Data availability

The data can be accessed at https://doi.org/10.57760/sciencedb.27122.

Code availability

No custom code is generated for this research. The measurement and analysis procedures comply with the corresponding manual, and the statistical methods employed are conventional.

References

Villarrazo, N., Martínez de Pisson, G., Fernández, P., Pereira, O. & López de Lacalle, L. N. Titanium blade milling with minimum piece deformation based on tool orientation. MM Sci. J. https://doi.org/10.17973/mmsj.2023_11_2023117 (2023).

Zha, J. et al. Accuracy evolution method applied to five-axis machining of curved surfaces. Int. J. Adv. Manuf. Technol. 125(7), 3475–3487, https://doi.org/10.1007/s00170-023-10864-w (2023).

Villarrazo, N. et al. Effect of tool orientation on surface roughness and dimensional accuracy in ball end milling of thin-walled blades. Int. J. Adv. Manuf. Technol. 136(1), 383–395, https://doi.org/10.1007/s00170-024-14523-6 (2025).

Pereira, O. et al. CO2 cryogenic milling of Inconel 718: cutting forces and tool wear. J. Mater. Res. Technol. 9(4), 8459–8468, https://doi.org/10.1016/j.jmrt.2020.05.118 (2020).

González, H. et al. Flank-milling of integral blade rotors made in Ti6Al4V using Cryo CO2 and minimum quantity lubrication. J. Manuf. Sci. Eng. 143(9), 091011, https://doi.org/10.1115/1.4050548 (2021).

Dang, J., Wu, B., Cui, Q., Zhang, Z. & Zhang, Y. A machining error prediction approach without iteration for thin-walled part in flank milling. J. Manuf. Process. 124, 399–418, https://doi.org/10.1016/j.jmapro.2024.06.038 (2024).

Deng, W. et al. Multi-dimensional simulations for extensive off-design conditions of gas turbines by iterative-coupled methods using different characteristic maps of coaxial compressor and turbine. Case Stud. Therm. Eng. 72, 106290, https://doi.org/10.1016/j.csite.2025.106290 (2025).

Wang, H., Gao, L., Yang, G. & Wu, B. A data-driven robust design optimization method and its application in compressor blade. Phys. Fluids. 35(6), 066114, https://doi.org/10.1063/5.0150040 (2023).

Suriyanarayanan, V., Rendu, Q., Vahdati, M. & Salles, L. Effect of manufacturing tolerance in flow past a compressor blade. J. Turbomach. 144(4), 041005, https://doi.org/10.1115/1.4052600 (2022).

Dan, Y., Li, R., Gao, L., Yu, H. & Hao, Y. Twist angle error statistical analysis and uncertain influence on aerodynamic performance of three-dimensional compressor rotor. Aerospace. 11(8), 614, https://doi.org/10.3390/aerospace11080614 (2024).

Ju, Y., Liu, Y., Jiang, W. & Zhang, C. Aerodynamic analysis and design optimization of a centrifugal compressor impeller considering realistic manufacturing uncertainties. Aerosp. Sci. Technol. 115, 106787, https://doi.org/10.1016/j.ast.2021.106787 (2021).

Fan, L., Ren, Y., Tan, M., Wu, B. & Gao, L. Exploratory factor analysis for machining error data of compressor blades based on dimensionality-reduced statistical analysis method. J. Manuf. Sci. Eng. 146(10), 101007, https://doi.org/10.1115/1.4066183 (2024).

Li, N. et al. A multi-feature dataset of coated end milling cutter tool wear whole life cycle. Sci. Data. 12, 16, https://doi.org/10.1038/s41597-024-04345-2 (2025).

Gao, L., Ma, C. & Cai, Y. A Robust Blade Design Method based on Non-Intrusive Polynomial Chaos Considering Profile Error. J. Therm. Sci. 28(5), 875–885, https://doi.org/10.1007/s11630-019-1185-6 (2019).

Lejon, M., Andersson, N., Ellbrant, L. & Mårtensson, H. The impact of manufacturing variations on performance of a transonic axial compressor rotor. J. Turbomach. 142(8), 081009, https://doi.org/10.1115/1.4046617 (2020).

Wang, J. & Zheng, X. Review of geometric uncertainty quantification in gas turbines. J. Eng. Gas Turbines Power. 142(7), 070801, https://doi.org/10.1115/1.4047179 (2020).

Montomoli, F. et al. Uncertainty quantification in computational fluid dynamics and aircraft engines. Springer. 74–75 (2019).

Hu, X., Chen, X., Parks, G. T. & Yao, W. Review of improved Monte Carlo methods in uncertainty-based design optimization for aerospace vehicles. Prog. Aerosp. Sci. 86, 20–27, https://doi.org/10.1016/j.paerosci.2016.07.004 (2016).

Karimi, M. S., Salehi, S., Raisee, M., Hendrick, P. & Nourbakhsh, A. Probabilistic CFD computations of gas turbine vane under uncertain operational conditions. Appl. Therm. Eng. 148, 754–767, https://doi.org/10.1016/j.applthermaleng.2018.11.072 (2019).

Huang, M., Li, Z., Li, J. & Song, L. Efficient uncertainty quantification and sensitivity analysis on the aerothermal performance of turbine blade squealer tip. J. Turbomach. 144(5), 051014, https://doi.org/10.1115/1.4054067 (2022).

Luo, J. & Liu, F. Statistical evaluation of performance impact of manufacturing variability by an adjoint method. Aerosp. Sci. Technol. 77, 471–484, https://doi.org/10.1016/j.ast.2018.03.030 (2018).

Zhang, Q., Xu, S., Meng, D., Wang, D. & Huang, X. Efficient quantification of aerodynamic performance uncertainty due to geometric variability using an adjoint method. Proceedings of the ASME Turbo Expo 2024: Multidisciplinary Design Approaches, Optimization, and Uncertainty Quantification; Radial Turbomachinery Aerodynamics; Unsteady Flows in Turbomachinery, London, UK, Paper GT2024-127703, https://doi.org/10.1115/GT2024-127703 (2024).

Garzon, V. E. & Darmofal, D. L. Impact of geometric variability on axial compressor performance. J. Turbomach. 125(4), 692–703, https://doi.org/10.1115/1.1622715 (2003).

Lamb, C. M. Probabilistic performance-based geometric tolerancing of compressor blades. Massachusetts Institute of Technology. (2006).

Duffner, J. D. The effects of manufacturing variability on turbine vane performance. Massachusetts Institute of Technology. (2008).

Wang, J. et al. Compressor geometric uncertainty quantification under conditions from near choke to near stall. Chin. J. Aeronaut. 36(3), 16–29, https://doi.org/10.1016/j.cja.2022.10.012 (2023).

Ma, C., Gao, L., Wang, H., Li, R. & Wu, B. Influence of leading edge with real manufacturing error on aerodynamic performance of high subsonic compressor cascades. Chin. J. Aeronaut. 34(6), 220–232, https://doi.org/10.1016/j.cja.2020.08.018 (2021).

Lange, A., Voigt, M., Vogeler, K., Schrapp, H., Johann, E. & Gümmer, V. Probabilistic CFD simulation of a high-pressure compressor stage taking manufacturing variability into account. ASME Turbo Expo 2010: Power for Land, Sea, and Air, Glasgow, UK, Paper GT2010-22484, https://doi.org/10.1115/GT2010-22484 (2010).

Lange, A., Voigt, M., Vogeler, K. & Johann, E. Principal component analysis on 3D scanned compressor blades for probabilistic CFD simulation. 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, Principal component analysis on 3D scanned compressor blades for probabilistic CFD simulation USA, Paper AIAA 2012-1762, https://doi.org/10.2514/6.2012-1762 (2012).

Panizza, A., Rubino, D. T. & Tapinassi, L. Efficient uncertainty quantification of centrifugal compressor performance using polynomial chaos. ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, Paper GT2014-25081, https://doi.org/10.1115/GT2014-25081 (2014).

Liu, B., Liu, J., Yu, X. & An, G. A novel decomposition method for manufacture variations and the sensitivity analysis on compressor blades. Aerospace. 9(10), 542, https://doi.org/10.3390/aerospace9100542 (2022).

Guo, Z. & Chu, W. Stochastic aerodynamic analysis for compressor blades with manufacturing variability based on a mathematical dimensionality reduction method. Proceedings of the Institution of Mechanical Engineers, Part C, J. Mech. Eng. Sci. 236(10), 5719–5735, https://doi.org/10.1177/09544062211062452 (2021).

Dow, E. A. & Wang, Q. The implications of tolerance optimization on compressor blade design. ASME J. Turbomach. 137(10), 101008, https://doi.org/10.1115/1.4030791 (2015).

Xiong, F., Li, Z., Liu, Y. & Xiahou, T. Review of characterization methods for parameter uncertainty in engineering design based on numerical simulation. Acta Aero. Astro. Sinica. 44(22), 92–123, https://doi.org/10.7527/S1000-6893.2023.28611 (2023).

Labbe, S. G., Gilbert, M. G. & Kehoe, M. W. Possible deficiencies in predicting transonic aerodynamics on the X-43A. NASA. No. LF99-8657 (2009).

Gao, L. et al. Research progress on uncertainty effect of compressor blade machining deviation. Acta Aero. Astro. Sinica. 45(19), 7–28, https://doi.org/10.7527/S1000-6893.2024.30386 (2024).

Gao, L., Dan, Y., Wang, H., Li, R. & Yang, G. Measured machining deviation data of aero-engine compressor blades, SciDB. https://doi.org/10.57760/sciencedb.27122 (2026).

Wang, H., Gao, L. & Wu, B. Critical sample-size analysis for uncertainty aerodynamic evaluation of compressor blades with stagger-angle errors. Aerospace. 10(12), 990, https://doi.org/10.3390/aerospace10120990 (2023).

Li, P. Effect of blade machining error and data transfer on compressor aerodynamic performance. Xi’an, Northwestern Polytechnical University. (2015).

Yang, G., Gao, L., Tu, P. & Dan, Y. Effects of uniform profile tolerance on aerodynamic performance eligibility of high subsonic cascade. Aerosp. Sci. Technol. 160, 110028, https://doi.org/10.1016/j.ast.2025.110028 (2025).

Wang, H., Gao, L., Yang, G., Li, R. & Wu, B. A preconditioner-based data-driven polynomial expansion method, application to compressor blade with leading edge uncertainty. J. Eng. Gas Turbines Power. 146(11), 111004, https://doi.org/10.1115/1.4065787 (2024).

Dan, Y. et al. Uncertainty quantification of leading-edge radius machining error of compressor cascade considering statistical characteristics of skewness and kurtosis. Acta Aero. Astro. Sinica. 45(19), 89–99, https://doi.org/10.7527/S1000-6893.2024.30366 (2024).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 92152301), the National Natural Science Foundation of China (No. U2241249), the National Science and Technology Major Project (No. J2019-II-0016-0037) and the Foundation of Rotor Aerodynamics Key Laboratory (No. RAL202402-5).

Author information

Authors and Affiliations

Contributions

Limin Gao and Yue Dan contributed to data collection and processing. Haohao Wang contributed to the data analyzing. Ruiyu Li and Guang Yang reviewed the statements of data records. All authors have read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Gao, L., Dan, Y., Wang, H. et al. A dataset of measured machining deviations of compressor rotor blades. Sci Data (2026). https://doi.org/10.1038/s41597-026-06846-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41597-026-06846-8