Abstract

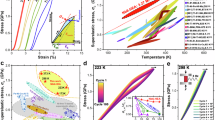

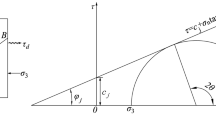

It is well-known that materials behavior changes with strain rate and temperature. The changes are described by an equation known as material model. The model involves a number of constants which are normally determined by experiment. In this study, the constants of Zerilli-Armstrong model are identified using dynamic indentation test combined with numerical simulation and an optimization technique. The specimens made of a steel alloy are subjected to indentation tests at four different strain rates and four temperatures and the experimental load-depth curve is recorded. The dynamic indentation test is simulated using Ls-dyna hydro code and the numerical load-depth is obtained. Attempts are made to optimize the error between the experimental and the numerical load-depth curves. This is accomplished using Surrogate model. The results are validated using the stress–strain curves obtained from Hopkinson bar tests. The study shows that the method yields acceptable results. The results obtained using artificial neural network and optimization technique, based on a quadratic polynomial, which have been reported in the previous works for Johnson–Cook model are reproduced here for Zerilli-Armstrong model for comparison purposes.

Similar content being viewed by others

Data availability

All data generated or analysed during this study are included in this published article.

References

Zerilli, F. J. & Armstrong, R. W. Dislocation-mechanics-based constitutive relation for material dynamic calculation. J. Appl. Phys. 61, 1816–1825. https://doi.org/10.1063/1.338024 (1987).

Majzoobi, G. H. & Pourolajal, S. Determination of stress–strain curves of materials at high strain rates using dynamic indentation technique. J. Strain Anal. Eng. Res. 56, 327–336. https://doi.org/10.1177/0309324720948646 (2020).

Renger, A. & Johnson, K. L. Contact Mechanics Vol. 170, 452–460 (Cambridge University Press, 1989).

Giannakopoulos, A. & Larsson, P. Analysis of pyramid indentation of pressure-sensitive hard metals and ceramics. Mech. Mater. 25, 1–35. https://doi.org/10.1016/S0167-6636(96)00051-8 (1997).

Hernandez, C., Blanco, D. L. & Maranon, A. An inverse method to estimate Cowper-Symonds material model parameters from a single split Hopkinson pressure bar test. J. Dyn. Behav. Mater. 9, 167–178. https://doi.org/10.1007/s40870-022-00364-5 (2023).

Jakkula, P. et al. Strain rate sensitivity of the additive manufacturing material scalmalloy. J. Dyn. Behav. Mater. 7, 518–525. https://doi.org/10.1007/s40870-021-00298-4 (2021).

Scapin, M. et al. Effect of strain-rate and temperature on mechanical response of pure tungsten. J. Dyn. Behav. Mater. 5, 296–308. https://doi.org/10.1007/s40870-019-00221-y (2019).

Peroni, M. & Solomos, G. Advanced experimental data processing for the identification of thermal and strain-rate sensitivity of a nuclear steel. J. Dyn. Behav. Mater. 5, 251–265. https://doi.org/10.1007/s40870-019-00207-w (2019).

Nakai, K. & Yokoyama, T. Uniaxial compressive response and constitutive modeling of selected polymers over a wide range of strain rates. J. Dyn. Behav. Mater. 1, 15–27. https://doi.org/10.1007/s40870-015-0003-9 (2015).

Faisal, N. & Ahmed, R. A review of patented methodologies in instrumented indentation residual stress measurements. Recent Patent Mech. Eng. 4, 138–152. https://doi.org/10.2174/1874477X11104020138 (2011).

Suresh, S. & Giannakopoulos, A. A new method for estimating residual stresses by instrumented sharp indentation. Acta Mater. 46, 5755–5767. https://doi.org/10.1016/S1359-6454(98)00226-2 (1998).

Carlsson, S. & Larsson, P. On the determination of residual stress and strain fields by sharp indentation testing: Part 1, theoretical and numerical analysis. Acta Mater. 49, 2179–2191. https://doi.org/10.1016/S1359-6454(01)00122-7 (2001).

Dao, M., Chollacoop, N., Vliet, K. V., Venkatesh, T. & Suresh, S. Computational modeling of the forward and reverse problems in instrumented sharp indentation. Acta Mater. 49, 3899–3918. https://doi.org/10.1016/S1359-6454(01)00295-6 (2001).

Chollacoop, N., Dao, M. & Suresh, S. Depth-sensing instrumented indentation with dual Shar framework. Acta Mater. 51, 3713–3729. https://doi.org/10.1016/S1359-6454(03)00186-1 (2003).

Min, L., Wei-Min, C., Nai-Gang, L. & Ling-Dong, W. A numerical study of indentation using indenters of different geometry. J. Mater. Res. 19, 73–78. https://doi.org/10.1557/jmr.2004.19.1.73 (2004).

Antunes, J., Menezes, L. & Fernandes, J. Influence of Vickers tip imperfection on depth sensing indentation tests. Int. J. Solids Struct. 43, 784–806. https://doi.org/10.1016/j.ijsolstr.2006.08.017 (2006).

Antunes, J., Fernandes, J., Menezes, L. & Chaparro, B. A new approach for reverse analyses in depth-sensing indentation using numerical simulation. Acta Mater. 55, 69–81. https://doi.org/10.1016/j.actamat.2006.08.019 (2007).

Sakharova, N., Fernandes, J., Antunes, J. & Oliveria, M. Cmparison between Berkovich, Vickers and conical indentation tests: A three-dimensional numerical simulation study. Int. J. Solids Struct. 46, 1095–1104. https://doi.org/10.1016/j.ijsolstr.2008.10.032 (2009).

Sanosh, K., Balakrishnan, A., Francis, L. & Kim, T. Vickers and Knoop micro-hardness behavior of coarse and ultrafine-grained titanium. J. Mater. Sci. Technol. 26, 904–907. https://doi.org/10.1016/S1005-0302(10)60145-4 (2010).

Johnson, K. L. The correlation of indentation experiments. J. Mech. Phys. Solids 18(2), 115–126. https://doi.org/10.1016/0022-5096(70)90029-3 (1970).

Liang, J., Xu, Z.-H. & Li, X. Whisker nucleation in indentation residual stress field on tin plated component leads. J. Mater. Sci. Mater. Electron. 18(6), 599–604. https://doi.org/10.1007/s10854-007-9153-4 (2007).

Long, X. et al. Reverse analysis of surface strain in elasto-plastic materials by nanoindentation. Int. J. Appl. Mech. 13, 2150106. https://doi.org/10.1142/S1758825121501064 (2021).

Long, X. et al. Calibration of a constitutive model from tension and nanoindentation for lead-free solder. Micromachines https://doi.org/10.3390/mi9110608 (2018).

Jennet, N. M. & Nun, J. High resolution measurement of dynamic Nano indentation impact energy, a step towards the determination of indentation fracture resistance. Philos. Mag. 91, 1200–1220. https://doi.org/10.1080/14786435.2010.485585 (2010).

Majzoobi, G.-H., Hosseinkhani, A. R. & Lahmi, S. Determination of the constants of material models at high strain rates and elevated temperatures using shot impact test. J. Strain Anal. Eng. Des. https://doi.org/10.1177/0309324720948646 (2013).

BullS, D. J., Spearing, M. & Sinclair, I. Investigation of the response to low velocity impact and quasi-static indentation loading of particle-toughened carbon-fiber composite materials. Compos. A Appl. Sci. Manuf. 74, 38–46. https://doi.org/10.1016/j.compositesa.2015.03.016 (2015).

Forrester, A. I. J. & Keane, A. J. Why surrogate models are necessary in engineering design and optimization. https://doi.org/10.2514/1.38901 (2009).

Jones, D. R., Schonlau, M. & Welch, W. J. Efficient global optimization of expensive black-box functions. J. Glob. Optim. https://doi.org/10.1023/A:1008306431147 (1998).

Liu, H. et al. A survey of adaptive sampling for global metamodeling in support of simulation-based complex engineering design. J. Tribol. https://doi.org/10.1115/1.4039143 (2018).

Queipo, N. V. et al. Surrogate-based analysis and optimization. Prog. Aerosp. Sci. https://doi.org/10.1016/j.paerosci.2005.02.001 (2005).

Wang, G. G. & Shan, S. A comparative study of metamodeling methods for multiobjective optimization in engineering design. https://doi.org/10.1115/1.2423027 (2007).

Hastie, T., Tibshirani, R. & Friedman, J. Elements of Statistical Learning: Data Mining, Inference, and Prediction (Springer Science & Business Media, 2009).

Forrester, A. I., Sobester, A. & Keane, A. J. Engineering Design through Surrogate Modeling: A Practical Guide (John Wiley & Sons, 2008).

Jin, R., Chen, W. & Simpson, T. W. Comparative studies of metamodeling techniques under multiple modeling criteria. J. Struct. Multidiscip. Optim. 23(1), 1–13 (2001).

Sinyavskii, V. S. & Kalinin, V. D. Marine corrosion and protection of aluminum alloys according to their composition and structure. Prot. Met. 41, 317–328. https://doi.org/10.1007/s11124-005-0046-8 (2005).

Pourolajal, S. & Majzoobi, G. H. Determination of the parameters of material models using dynamic indentation test and artificial neural network. J. Strain Eng. Des. 56(5), 327–336. https://doi.org/10.1177/03093247221140981 (2022).

Golshan, M., Ebrahimi, P. & Avari, A. Choosing the best interpolation method for annual average zoning of Iran. Geogr. Environ. Sustain. https://doi.org/10.3390/rs14112632 (2014).

Payandehpeyman, J., Majzoobi, G. H. & Bagheri, R. Determination of the extended Drucker-Prager parameters using the surrogate-based optimization method for polypropylene nanocomposites. J. Strain Anal. Eng. Des. 51(3), 220–232. https://doi.org/10.1177/0309324715627564 (2016).

Mack, Y., Goel, T., Shyy, W. & Haftka, R. Surrogate Model-Based Optimization Framework: A Case Study in Aerospace Design (Springer, 2007).

MüLler, J., Shoemaker, C. A. & Piché, R. SO-MI: A surrogate model algorithm for computationally expensive nonlinear mixed-integer black-box global optimization problems. Comput. Oper. Res. 40(5), 1383–1400. https://doi.org/10.1007/s10898-013-0101-y (2013).

Amininejad, S. Determination of dynamic and static behavior of epoxy composites reinforced with carbon fibers and nanographene. PhD thesis, Buali Sina University. https://doi.org/10.22075/macs.2023.29813.1475 (2018).

Malek Mohammadi, H. Study of the mechanical and ballistic behavior of polycarbonate-nanoclay/graphene nanocomposites. PhD thesis, Buali Sina University (2018).

McKay, M. D., Beckman, R. J. & Conover, W. J. A comparison of three methods for selecting values of input variables in the analysis of output from a computer code. Technometrics 21(2), 239–245. https://doi.org/10.1080/00401706.1979.10489755 (1979).

Author information

Authors and Affiliations

Contributions

S.P. was my Phd student and has done the experiments, prepared the figures and tables. G.H.M. was the supervisor of S.P. He has supervised the thesis and written the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Majzoobi, G.H., Pourolajal, S. Determination of the parameters of a material constitutive relation using the surrogate model along with dynamic indentation test. Sci Rep (2026). https://doi.org/10.1038/s41598-025-06192-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-06192-6