Abstract

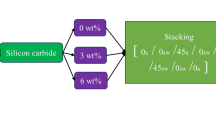

This study presents an experimental investigation into the mechanical, vibrational, and acoustic properties of carbon/glass fibre-reinforced epoxy hybrid laminates embedded with varying weight percentages of silicon carbide (SiC) nanoparticles. The laminates were fabricated using compression moulding, with a six-layer alternating stacking sequence of carbon and glass fibres. A comprehensive series of tests was conducted to assess flexural strength, tensile behaviour, impact resistance, free-vibration characteristics, and sound-absorption performance. Mechanical tests revealed that the laminate with 3 wt% SiC achieved the highest tensile strength of 258.8 MPa, flexural strength of 292.6 MPa, Young’s modulus of 19.13 GPa, and impact strength of 67.9 kJ/m2, indicating optimal reinforcement and efficient stress transfer due to uniform nanoparticle dispersion. These values correspond to improvements of approximately 19.05%, 15.22%, 15.37%, and 7.65%, respectively, compared to the unreinforced (0 wt%) composite. SEM analysis substantiated the improved fibre–matrix interaction and the minimal microstructural defects at the optimal filler content. Conversely, the 5 wt% SiC specimens exhibited reduced mechanical performance, attributed to particle agglomeration and weakened interfacial bonding. Vibration analysis indicated a peak in stiffness and natural frequency at 3 wt% SiC, while damping behaviour declined with increasing filler loading. Acoustic testing showed enhanced transmission loss with increasing SiC content, with 5 wt% yielding the best sound-attenuation performance. The study concludes that incorporating SiC nanoparticles into carbon/glass hybrid composites significantly improves their multifunctional performance when the filler content is optimized, with the 3 wt% SiC composition offering the best balance between strength, stiffness, and acoustic efficiency.This advances SDG 9 (Industry, Innovation and Infrastructure) by developing resilient, lightweight composites for sustainable aerospace/transport infrastructure, reducing emissions via efficiency gains.

Similar content being viewed by others

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Mallick, P. K. Fiber- Reinforced Composites Materials, Manufacturing and Design 3rd edn (CRC Press Taylor & Francis Group, 2007). https://doi.org/10.3144/expresspolymlett.2007.115.

Pai, Y., Dayananda Pai, K. & Vijaya Kini, M. Effect of ageing conditions on the low velocity impact behavior and damage characteristics of aramid-basalt/epoxy hybrid interply composites. Eng. Fail. Anal. 152, 107492. https://doi.org/10.1016/j.engfailanal.2023.107492 (2023).

Shaikh, F., Monis, N., Pai, Y. & Pai, D. G. ‘Examining the impact of moisture on the mechanical and vibrational characteristics of quasi isotropic kevlar- basalt / epoxy hybrid composites’, 2024, https://doi.org/10.1080/23311916.2024.2417686

Agarwal, S., Pai, Y., Pai, D. & Mahesha, G. T. Assessment of ageing effect on the mechanical and damping characteristics of thin quasi-isotropic hybrid carbon-Kevlar/epoxy intraply composites. Cogent Eng. 10(1). https://doi.org/10.1080/23311916.2023.2235111 (2023).

Bazli, M., Ashrafi, H. & Oskouei, A. V. Effect of harsh environments on mechanical properties of GFRP pultruded profiles. Compos. Part. B: Eng. 99, 203–215. https://doi.org/10.1016/j.compositesb.2016.06.019 (2016).

Dong, C. ‘Carbon and glass fibre-reinforced hybrid composites in flexure’, Hybrid Adv. 10, 100471. https://doi.org/10.1016/j.hybadv.2025.100471 (2025).

Ishtiaq, S., Saleem, M. Q., Naveed, R., Harris, M. & Khan, S. A. Glass–Carbon–Kevlar fiber reinforced hybrid polymer composite (HPC): part (A) mechanical and thermal characterization for high GSM laminates. Compos. Part. C: Open. Access. 14, 100468. https://doi.org/10.1016/j.jcomc.2024.100468 (2024).

Bhushan, B. Handbook on Nano technology (2017).

Eun Jung, J. P. et al. and ‘Nanoparticle characterization: State of the art, challenges, and emerging technologies. Springer Briefs Appl. Sci. Techno. 10, 17–29. https://doi.org/10.1007/978-3-319-03958-9_3 (2014).

Li, X. et al. Study on the mechanical and toughness behavior of epoxy nano-composites with zero-dimensional and two-dimensional nano-fillers. Polymers. https://doi.org/10.3390/polym14173618 (2022).

Xie, M., Zhan, L., Ma, B. & Hui, S. Classification of fiber metal laminates (FMLs), adhesion theories and methods for improving interfacial adhesion: A review. Thin-Walled Struct. 198, 111744. https://doi.org/10.1016/j.tws.2024.111744 (2024).

Laurent, S. et al. ‘Erratum: Magnetic iron oxide nanoparticles: Synthesis, stabilization, vectorization, physicochemical characterizations, and biological applications (Chemical Reviews (2008) 108 (2064)). Chem. Rev. 110(4), 2574. https://doi.org/10.1021/cr900197g(2010).

Mittal, G., Dhand, V., Rhee, K. Y., Park, S. J. & Lee, W. R. A review on carbon nanotubes and graphene as fillers in reinforced polymer nanocomposites. J. Ind. Eng. Chem. 21, 11–25. https://doi.org/10.1016/j.jiec.2014.03.022 (2015).

Ye, H. Z. et al. Mechanical properties and production quality of hand-layup and vacuum infusion processed hybrid composite materials for GFRP marine structures. Industrial Robot: Int. J. 5(3), 1–2. https://doi.org/10.1017/CBO9781107415324.004 (2016).

Zare, Y. Study of nanoparticles aggregation/agglomeration in polymer particulate nanocomposites by mechanical properties. Compos. Part A: Appl. Sci. Manufac. 84, 158–164. https://doi.org/10.1016/j.compositesa.2016.01.020 (2016).

Sánchez, M., Campo, M., Jiménez-Suárez, A. & Ureña, A. Effect of the carbon nanotube functionalization on flexural properties of multiscale carbon fiber/epoxy composites manufactured by VARIM. Compos. Part. B: Eng. 45(1), 1613–1619. https://doi.org/10.1016/j.compositesb.2012.09.063 (2013).

Rezvani, M. B., Atai, M., Hamze, F. & Hajrezai, R. The effect of silica nanoparticles on the mechanical properties of fiber-reinforced composite resins. J. Dent. Res. Dent. Clin. 10(2), 112–117. https://doi.org/10.15171/joddd.2016.018 (2016). Dental Prospects.

Vaggar, G. B., Kamate, S. C. & Badyankal, P. V. A study on thermal conductivity enhancement of silicon carbide filler glass fiber epoxy resin hybrid composites Materials Today: Proceedings A study on thermal conductivity enhancement of silicon carbide filler glass fiber epoxy resin hybrid composites. Mater. Today 35, 330–334. https://doi.org/10.1016/j.matpr.2020.02.008 (2021).

Loeffen, A., Cree, D. E., Sabzevari, M. & Wilson, L. D. Effect of graphene oxide as a reinforcement in a bio-epoxy composite. J. Compos. Sci. 5(3), 1–19. https://doi.org/10.3390/jcs5030091 (2021).

Naveen Kumar, G., Naga Durga Rao, G., Durga Prasad, J., Avinash kumar, K. & Eswara Manikanta, J. Hybrid polymer nano fillers on mechanical properties for current applications: An overview. Mater. Today. https://doi.org/10.1016/j.matpr.2023.04.505 (2023).

Rajesh, D. et al. Investigations on the mechanical properties of tungsten carbide reinforced aluminium metal matrix composites by stir casting. Mater. Today 46, 3618–3620. https://doi.org/10.1016/j.matpr.2021.01.634 (2020).

Girimurugan, R., Arunraja, K. M., Shanmugam, A., Saranya, S. & Vigneshwaran, M. The effects of nano-alumina particles on the enrichment of tensile, flexural and impact properties of carbon fiber-reinforced epoxy composites. Materi Today (2023). https://doi.org/10.1016/j.matpr.2023.04.053

Huang, B. et al. Investigation on the fundamental mechanical properties and probabilistic characteristics of unidirectional carbon fiber reinforced polymer composite plates. Polym. Test. 131, 108355. https://doi.org/10.1016/j.polymertesting.2024.108355 (2024).

Chisholm, N., Mahfuz, H., Rangari, V. K., Ashfaq, A. & Jeelani, S. Fabrication and mechanical characterization of carbon/SiC-epoxy nanocomposites. Composite Structures 67(1), 115–124. https://doi.org/10.1016/j.compstruct.2004.01.010 (2005).

Megahed, M., Megahed, A. A. & Agwa, M. A. The influence of incorporation of silica and carbon nanoparticles on the mechanical properties of hybrid glass fiber reinforced epoxy. J. Ind. Text. 49(2), 181–199. https://doi.org/10.1177/1528083718775978 (2019).

Vaggar, G. B., Kamate, S. C. & Badyankal, P. V. A study on thermal conductivity enhancement of silicon carbide filler glass fiber epoxy resin hybrid composites. Mater. Today 35, 330–334. https://doi.org/10.1016/j.matpr.2020.02.008 (2019).

Krishnasamy Karthik, B. S. et al. Experimental investigation of the mechanical properties of carbon/basalt/SiC nanoparticle/polyester hybrid composite materials. Crystals 11(13), 145. https://doi.org/10.3390/cryst13030415 (2023).

Shahabaz, S. M. et al. Effect of Al2O3 and SiC Nano-Fillers on the mechanical properties of carbon Fiber-Reinforced epoxy hybrid composites. J. Compos. Sci. 7(4). https://doi.org/10.3390/jcs7040133 (2023).

Araújo Mendonça, F. et al. Development and characterization of graphene-reinforced epoxy nanocomposites optimized via Box-Behnken design. J. Mater. Res. Technol. 39, 3137–3155. https://doi.org/10.1016/j.jmrt.2025.10.045 (2025).

D792-20. Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement (ASTM International, 2020).

ASTM D3039/D3039M-14. Standard Test Method for Tensile Properties of Polymer Matrix Composite’ (ASTM International, 2017).

ASTM D7264/D7264M-07. Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials (ASTM International, 2021).

ISO 179-1. Plastics—Determination of Charpy Impact properties; Part 1: Non-instrumented Impact Test (International Organisation for Standardization, 2023).

ASTM E756-05. Standard test method for measuring Vibration-Damping properties of Materials’, Annual book of ASTM standards. No Reapproved. 05, 14. https://doi.org/10.1520/E0756-05R17.2 (2023).

ISO-10534. ‘Determination of sound absorption coefficient and impedance in impedance tubes’, vol. ISO 10534, 1–27 (2023).

Costa, U. O. et al. ‘Mechanical properties of composites with graphene oxide functionalization of either epoxy matrix or curaua fiber reinforcement. J. Mater. Res. Technol. 9(6), 13390–13401. https://doi.org/10.1016/j.jmrt.2020.09.035 (2020).

Dhilipkumar, T., Rashia, M. V. S. & Sathyaseelan, B. P. Evaluation of acoustic and structural behavior of banana fiber reinforced polymer composites. Fibers Polym. 25, 2303–2314. https://doi.org/10.1007/s12221-024-00582-9 (2024).

Acknowledgements

The authors wish to acknowledge Advanced Material Testing Lab & Vibrations and Acoustics Lab, School of Mechanical Engineering, Manipal Institute of Technology, Manipal Academy of Higher Education, Manipal, India, for facilitating to carry out the testing of specimens.

Funding

Open access funding provided by Manipal Academy of Higher Education, Manipal

Author information

Authors and Affiliations

Contributions

Suhas K S : Writing – original draft, Software, Methodology, Formal analysis, Conceptualization. Vamsi Krishna Reddy: Writing – original draft, Methodology, Formal analysis. Yeturi Thirumanas Reddy: Writing – original draft, Software, Resources. Yogeesha Pai: Writing – review & editing, Supervision, Software, Resources.All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Suhas, K.S., Reddy, V.K., Reddy, Y.T. et al. Effects of silicon carbide nanoparticles on mechanical and vibrational characteristics of carbon glass epoxy hybrid composites. Sci Rep (2026). https://doi.org/10.1038/s41598-026-39559-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-026-39559-4