Abstract

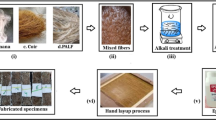

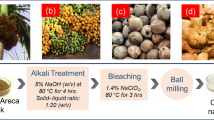

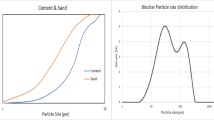

This study examined the effect of biochar by macadamia nut shell waste on the mechanical behaviour of ramie fibre reinforced epoxy composite. Controlled pyrolysis was used to prepare biochar at 350 °C, followed by ball milling to produce a mesoporous carbon structure with a crystallinity index of 40.5%, a crystallite size of 1.6 nm, a Brunauer–Emmett–Teller (BET) surface area of 326 m2/g and an average pore size of 3.8 nm. Fourier Transform Infrared Spectroscopy (FTIR) and X-ray diffraction (XRD) analyses confirmed partial graphitization and the presence of oxygen-containing functional groups, while surface roughness analysis (Ra = 0.2382 µm, Rq = 0.2985 µm) and particle size measurements (7.40 ± 1.92 µm, standard deviation = 1.08 µm) indicated a highly textured morphology with a good dispersion potential. Ramie–epoxy composites with varying biochar loadings (1, 3, and 5 wt%) were fabricated using hand lay-up followed by compression molding. Mechanical testing showed that incorporation of 3 wt% biochar (MR3) showed high improvement in tensile strength by 47.45 MPa (33%), flexural strength by 68.46 MPa (18%), and impact resistance by 3.9 kJ/mm2 (50%) than 1 wt% composite (MR1). These enhancements were attributed to the better interfacial bonding, uniform dispersion of filler and efficient stress transfer. These enhancements were attributed to the improved interfacial bonding, uniform filler dispersion, and efficient stress transfer. Beyond 3 wt% biochar loading, marginal reductions in mechanical properties were observed due to particle agglomeration and void formation. This study demonstrates the effective valorization of macadamia nutshell waste into high-performance, eco-efficient hybrid composites, with potential applications in lightweight structural, automotive, and green engineering systems.

Similar content being viewed by others

Data availability

All data is provided within the article.

References

Dinu, R. & Mija, A. Bio-based composites from industrial by-products and wastes as raw materials. J. Mater. Sci. Res. 9, 29 (2020).

Raj, M. K. A. et al. Study on the mechanical characteristics of a natural fiber-based hybrid polymer composite. Sci. Rep. 15, 45247. https://doi.org/10.1038/s41598-025-29459-4 (2025).

Velmurugan, G. et al. Enhanced performance through hybridization: Mechanical, dynamic mechanical, flammability, and vibration analysis of natural fibres/basalt/SiO2 composites. Polym. Bull. 82, 1413–1446 (2025).

Alrasheedi, N. H., Kumar, P. M., Balaji, D. & Sathishkumar, M. Hybrid natural fiber composites based on cashew apple bagasse and mahogany fruit for multifunctional performance. J. Mater. Res. Technol. 37, 4739–4751 (2025).

Manjulaiah, H. et al. A novel study on the development of sisal-jute fiber epoxy filler–based composites for brake pad application. Biomass Convers. Biorefin 14, 23411–23423 (2024).

Djafar, Z., Renreng, I. & Jannah, M. Tensile and bending strength analysis of ramie fiber and woven ramie reinforced epoxy composite. J. Nat. Fibers 18, 2315–2326 (2021).

Peng, H. et al. Enhancing the interfacial interactions and thermal oxidative mechanical properties of aramid fiber-reinforced epoxy composites through hyperbranched epoxy-grafted multi-walled carbon nanotubes. Polym. Compos. https://doi.org/10.1002/pc.70244 (2025).

Mohan Kumar, A. et al. Investigation of drilling process parameters of palmyra based composite. Adv. Mater. Sci. Eng. 2021(1), 4222344 (2021).

Thiyagu, C. & Narendrakumar, U. Mechanical and ballistic performance of ramie fiber-reinforced polymer composites: A review. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 238, 7661–7675 (2024).

Pratiwi, H. et al. Development and characterization of polyester/ramie fiber hybrid composites reinforced with crystalline5 nanocellulose extracted from durian peel waste. J. Mater. Res. Technol. 34, 1201–1212 (2025).

Ramesh, M., Rajeshkumar, L. & Balaji, D. Mechanical and dynamic properties of ramie fiber-reinforced composites. Mech. Dyn. Propert. Biocompos. https://doi.org/10.1002/9783527822331.CH15 (2021).

Majid, A., Mujiyono & Nurhadiyanto, D. Analysis of tensile strength in Ramie fiber composites with variation in the addition of microcrystalline cellulose as filler. AIP Conf. Proc. 3354 (2025).

Mahapatra, S. K. & Satapathy, A. Development and characterization of titanium oxide filled ramie fiber based hybrid composites. Polym. Compos. 44, 6707–6719 (2023).

Samuel, S. S. & Issac Selvaraj, R. V. Mechanical and vibrational study of raw and surface-treated ramie fiber hybridized carbon fiber epoxy composites. Polym. Compos. 45, 373–387 (2024).

Raja, T. et al. Comparative study of mechanical properties and thermal stability on banyan/ramie fiber-reinforced hybrid polymer composite. Adv. Mater. Sci. Eng. 2021, 5835867 (2021).

Velmurugan, G. et al. Driving into the future: Nano graphene and silicon dioxide enriched Kevlar composites for automotive applications. SILICON 16, 3873–3890 (2024).

G, V., K, B., Nagaraj, M. & Kumar, A. J. P. Investigations of flame retardancy, mechanical and thermal properties of woven hemp/PP hybrid composite for insulating material reinforced with synthetic silicon and zinc oxides. SILICON 15, 4875–4888 (2023).

Velmurugan, G. et al. Exploring mechanical and flammability traits in hybrid composites of crown flower/nano SiO2/4ZnO·B2O3·H2O under cryogenic conditions: An experimental study. SILICON 16, 3281–3295 (2024).

Velmurugan, G., Chohan, J. S., Babu, K., Paramasivam, P. & Maranan, R. Biosynthesis of SiO2 nanoparticles from bamboo leaves for tanning wastewater treatment and mechanical properties of HMPC-SiO2 nanocomposite. Clean Technol. Environ. Policy 27, 2899–2918 (2025).

Zhan, J. et al. Effect of the compatilizer and chemical treatments on the performance of poly(lactic acid)/ramie fiber composites. Compos. Commun. 27, 100843 (2021).

Kumar, S., Mahakur, V. K. & Bhowmik, S. Physico-mechanical and tribological characteristics of flax–ramie fiber reinforced green composites and anticipation of fabricated composites under different loading with sliding constraint. Arab. J. Sci. Eng. 49, 2463–2482 (2024).

Mohanavel, V., Raja, T., Yadav, A., Ravichandran, M. & Winczek, J. Evaluation of mechanical and thermal properties of jute and ramie reinforced epoxy-based hybrid composites. J. Nat. Fibers 19, 8022–8032 (2022).

Matheswaran, M., Suresh, P., Velmurugan, G. & Nagaraj, M. Evaluation of agrowaste/nanoclay/SiO2-based blended nanocomposites for structural applications: Comparative physical and mechanical properties. SILICON 15, 7095–7108 (2023).

Jayabalakrishnan, D. et al. Mechanical, dielectric, and hydrophobicity behavior of coconut shell biochar toughened Caryota urens natural fiber reinforced epoxy composite. Polym. Compos. 43, 493–502 (2022).

Prabhu, P. et al. Mechanical, tribology, dielectric, thermal conductivity, and water absorption behaviour of Caryota urens woven fibre-reinforced coconut husk biochar toughened wood-plastic composite. Biomass Convers. Biorefin. 14, 109–116 (2024).

Salman, S. D. Physico - Mechanical characterization property evaluation of polyvinyl butyral composites filled with macadamia nutshell. J. Ind. Text. 54 (2024).

Khan, M. S., Islam, M. M., Epaarachchi, J. & Shibata, S. Exploring the prospects of macadamia nutshells for bio-synthetic polymer composites: A review. Polymers 15, 4007 (2023).

Nguyen, D. T. C. Chemical constituent, pretreatment, and conversion of macadamia nut waste into bio-based materials. Chem. Pap. https://doi.org/10.1007/S11696-025-04390-0/METRICS (2025).

Dos, L. et al. Approach in Macadamia integrifolia residue based low-density polyethylene composites on mechanical and thermal performance. J. Appl. Polym. Sci. 138, 50613 (2021).

Silva, N. G. S., Cortat, L. I. C. O. & Mulinari, D. R. Effect of alkaline treatment and coupling agent on thermal and mechanical properties of Macadamia Nutshell Residues Based PP Composites. J. Polym. Environ. 29, 3271–3287 (2021).

Zhan, J. et al. Flame-retardant, thermal and mechanical properties of PLA/ramie fiber composites. Polym. Compos. 43, 4244–4254 (2022).

Islam, M. M., Chowdhury, S. & Khan, M. S. Development of novel composite core using powdered macadamia nutshell and its sandwich structures for building and other engineering applications. Materials 18, 4369 (2025).

Ihsanullah, I., Almanassra, I. W. & Abushawish, A. Macadamia nut shell biochar/Mg-Al LDH composite: A sustainable solution for highly effective phosphate ion removal from water. J. Water Process Eng. 67, 106164 (2024).

Sathish, T., Giri, J., Shaik, M. R. & Kumar, A. Comparative investigation of mechanical properties in banana fiber and ramie fiber composites enhanced by SiC nanoparticles. AIP Adv. https://doi.org/10.1063/5.0207560 (2024).

Gebremaryam, G. et al. Influence of layering pattern, fibre architecture, and alkalization on physical, mechanical, and morphological behaviour of banana fibre epoxy composites. Int. J. Polym. Sci. (2023).

Puttaswamygowda, P. H., Sharma, S., Ullal, A. K. & Shettar, M. Synergistic enhancement of the mechanical properties of epoxy-based coir fiber composites through alkaline treatment and nanoclay reinforcement. J. Compos. Sci. https://doi.org/10.3390/jcs8020066 (2024).

Kumar, K. S. et al. Mechanical characterization of sisal fiber-groundnut shell powder reinforced epoxy composites. Sci. Rep. https://doi.org/10.1038/s41598-025-18645-z (2025).

Kumar, K. P. et al. Experimental investigation of mechanical properties and morphology of ramie, bamboo, and ramie-bamboo hybrid composites with silicon carbide and alumina nano-fillers. Mater. Res. Express 12 (2025).

Ahmad, A. et al. Effect of hybridization approach on mechanical performance of jute-hemp/epoxy hybrid composite laminates. J. Nat. Fibers https://doi.org/10.1080/15440478.2022.2064398 (2022).

Pawar, J., Malagi, R. & Jadhav, M. Mechanical characterization of flax-mat reinforced PLA/PBS green composite laminates. J. Chin. Inst. Eng., Trans. Chin. Inst. Eng., Ser. A 48, 342–351 (2025).

Krishnan, A., Paul, S., Midhun Dominic, C. D., Jafrey Daniel James, D. & Manoharan, S. Lignocellulose fiber extraction from Ixora coccinea plants for possible reinforcement in polymer composites. Int. J. Biol. Macromol. https://doi.org/10.1016/j.ijbiomac.2025.141757 (2025).

H, J. R. et al. Effect of chemical treatment on physio-mechanical properties of lignocellulose natural fiber extracted from the bark of Careya arborea tree. Heliyon https://doi.org/10.1016/j.heliyon.2024.e26706 (2024).

Gurupranes, S. V. et al. Preparation, characteristics, and application of biopolymer materials reinforced with lignocellulosic fibres. Int. J. Polym. Sci. https://doi.org/10.1155/2023/1738967 (2023).

Muthukumarasamy, S. & Karthik, K. Experimental analysis of biochar filler effects on the mechanical, water absorption, and viscoelastic properties of novel caryota fiber reinforced polymeric composites: The role of biodegradable reinforcements concentration. Polym. Compos. 46, S119–S134 (2025).

Jubinville, D., Sen, R., Alikiotis, P. & Mekonnen, T. H. Effect of Biochar on the thermal and dimensional stability of Poly(Vinyl Chloride) (PVC) Composites. J. Vinyl Addit. Technol. 31, 1138–1150 (2025).

Beronská, N. et al. Using biochar from kitchen bio-waste as a filler material in polymer matrix composite. J. Compos. Mater. 59, 2409–2424 (2025).

Mozrall, A. M., Hernandez-Charpak, Y. D., Trabold, T. A. & Diaz, C. A. Effect of biochar content and particle size on mechanical properties of biochar-bioplastic composites. Sustain. Chem. Pharm. 35, 101223 (2023).

Hemlata. Mechanical, thermal, morphological, and rheological behavior of recycled polypropylene/pine needle biochar composite: An innovative approach towards circular economy. Polym. Compos. 46, 8490–8507 (2025).

Zhang, R. et al. Effect of biochar content and particle size on mechanical and water absorption properties of landscaping waste/polylactic acid composites. Ind. Crops Prod. 223, 120163 (2025).

Jiang, L. et al. Pyrolytic kinetics of polystyrene particle in nitrogen atmosphere: Particle size effects and application of distributed activation energy method. Polymers https://doi.org/10.3390/polym12020421 (2020).

Rajendran, S. et al. Prosopis juliflora biochar-based hybrid composites: Mechanical property assessment and development prospects. Clean. Eng. Technol. https://doi.org/10.1016/j.clet.2025.100955 (2025).

Jayabalakrishnan, D., Jayaseelan, V., Patil, P. P., Ramesh, B. & Bhaskar, K. Mechanical, wear, and dielectric properties of opuntia cladode fiber and pearl millet biochar-reinforced epoxy composite. Biomass Convers. Biorefin. 14, 13111–13121 (2024).

Velmurugan, G. et al. Evaluation of mechanical, thermal, and flammability properties in biochar-infused polymer composites from bael fruit and cashew shells: A comparative study. Biomass Convers. Biorefin. 15, 12457–12473 (2025).

Ganesan, V. et al. Mechanical and structural characterization of curauá fiber, sugarcane biochar, and poly(lactic acid) hybrid green composites for sustainable biomass utilization. Sugar Tech. https://doi.org/10.1007/s12355-025-01628-9 (2025).

Shah, AurR. et al. Mechanical, thermal, and fire retardant properties of rice husk biochar reinforced recycled high-density polyethylene composite material. Polymers (Basel) https://doi.org/10.3390/polym15081827 (2023).

Gokulraj, S., Saravanan, K. G., Vijayakumar, K. & Arunkumar, K. Thermo-mechanical and mechanical performance of interlaced glass fiber epoxy hybrid composites reinforced with almond biochar biofiller. J. Polym. Res. https://doi.org/10.1007/s10965-025-04400-5 (2025).

Funding

This work was supported and funded by the Deanship of Scientific Research at Imam Mohammad Ibn Saud Islamic University (IMSIU) (grant number IMSIU-DDRSP2602).

Author information

Authors and Affiliations

Contributions

Murugesan Palaniappan: *Conceptualization, Investigation, Writing—original draft.* P. Manoj Kumar: *Conceptualization, Writing-review and editing, Supervision.* Gokulkumar Sivanantham: *Formal analysis, Validation, Visualization, Writing—original draft.* Dawit Tafesse Gebreyohannes: *Methodology, Project administration, Writing-review and editing.*

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Palaniappan, M., Kumar, P.M., Sivanantham, G. et al. Chemical and structural characterization of ramie-based epoxy composites reinforced with macadamia nut shell biochar. Sci Rep (2026). https://doi.org/10.1038/s41598-026-39764-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-026-39764-1