Abstract

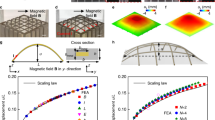

The development of soft electronics requires methods to connect flexible and stretchable circuits. With conventional rigid electronics, vias are typically used to electrically connect circuits with multilayered architectures, increasing device integration and functionality. However, creating vias using soft conductors leads to additional challenges. Here we show that soft vias and planar interconnects can be created through the directed stratification of liquid metal droplets with programmed photocuring. Abnormalities that occur at the edges of a mask during ultraviolet exposure are leveraged to create vertical stair-like architectures of liquid metal droplets within the photoresin. The liquid metal droplets in the uncured (liquid) resin rapidly settle, assemble and then are fully cured, forming electrically conductive soft vias at multiple locations throughout the circuit in a parallel and spatially tunable manner. Our three-dimensional selective stratification method can also form seamless connections with planar interconnects, for in-plane and through-plane electrical integration.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Change history

30 October 2024

In the version of the article initially published, Sungjune Park’s name appeared incorrectly (as Sujgjune Park) in the Peer review information section, and has now been corrected in the HTML and PDF versions of the article.

References

Mack, C. A. Fifty years of Moore’s law. IEEE Trans. Semicond. Manuf. 24, 202–207 (2011).

Lancaster, A. & Keswani, M. Integrated circuit packaging review with an emphasis on 3D packaging. Integration 60, 204–212 (2018).

Gambino, J. P., Adderly, S. A. & Knickerbocker, J. U. An overview of through-silicon-via technology and manufacturing challenges. Microelectron. Eng. 135, 73–106 (2015).

Hensleigh, R. et al. Charge-programmed three-dimensional printing for multi-material electronic devices. Nat. Electron. 3, 216–224 (2020).

Rich, S. I., Wood, R. J. & Majidi, C. Untethered soft robotics. Nat. Electron. 1, 102–112 (2018).

Truby, R. L., Katzschmann, R. K., Lewis, J. A. & Rus, D. Soft robotic fingers with embedded ionogel sensors and discrete actuation modes for somatosensitive manipulation. In Proc. 2019 2nd IEEE International Conference on Soft Robotics (RoboSoft) (ed Ren, H.) 322–329 (IEEE, 2019).

Bhattacharya, S. et al. A chest-conformable, wireless electro-mechanical e-tattoo for measuring multiple cardiac time intervals. Adv. Electron. Mater. 9, 2201284 (2023).

Kim, D.-H. et al. Epidermal electronics. Science 333, 838–843 (2011).

Guo, R. et al. Ni-gain amalgams enabled rapid and customizable fabrication of wearable and wireless healthcare electronics. Adv. Eng. Mater. 20, 1800054 (2018).

Yao, D. et al. Achieving the upper bound of piezoelectric response in tunable, wearable 3D printed nanocomposites. Adv. Funct. Mater. 29, 1903866 (2019).

Zhang, H. & Rogers, J. A. Recent advances in flexible inorganic light emitting diodes: from materials design to integrated optoelectronic platforms. Adv. Opt. Mater. 7, 1800936 (2019).

Park, S., Vosguerichian, M. & Bao, Z. A review of fabrication and applications of carbon nanotube film-based flexible electronics. Nanoscale 5, 1727–1752 (2013).

Sekitani, T. et al. Stretchable active-matrix organic light-emitting diode display using printable elastic conductors. Nat. Mater. 8, 494–499 (2009).

Slee, D., Stepan, J., Wei, W. & Swart, J. Introduction to printed circuit board failures. In Proc. 2009 IEEE Symposium on Product Compliance Engineering, PSES 2009 (ed Nix, D.) 1–8 (IEEE, 2009).

Kim, T. W., Lee, J. S., Kim, Y. C., Joo, Y. C. & Kim, B. J. Bending strain and bending fatigue lifetime of flexible metal electrodes on polymer substrates. Materials 12, 2490 (2019).

Byun, J. et al. A single droplet-printed double-side universal soft electronic platform for highly integrated stretchable hybrid electronics. Adv. Funct. Mater. 27, 1701912 (2017).

Shamkhalichenar, H., Bueche, C. J. & Choi, J. W. Printed circuit board (PCB) technology for electrochemical sensors and sensing platforms. Biosensors 10, 159 (2020).

Zhang, Y., An, M., Yang, P. & Zhang, J. Recent advances in electroplating of through-hole copper interconnection. Electrocatalysis 12, 619–627 (2021).

Dow, W.-P. et al. Through-hole filling by copper electroplating. J. Electrochem. Soc. 155, D750 (2008).

Khoshmanesh, K. et al. Liquid metal enabled microfluidics. Lab Chip 17, 974–993 (2017).

Bartlett, M. D. et al. High thermal conductivity in soft elastomers with elongated liquid metal inclusions. Proc. Natl Acad Sci. USA 114, 2143–2148 (2017).

Dickey, M. D. et al. Eutectic gallium-indium (egain): a liquid metal alloy for the formation of stable structures in microchannels at room temperature. Adv. Funct. Mater. 18, 1097–1104 (2008).

Veerapandian, S. et al. Hydrogen-doped viscoplastic liquid metal microparticles for stretchable printed metal lines. Nat. Mater. 20, 533–540 (2021).

Zheng, Y. et al. Lignin-based encapsulation of liquid metal particles for flexible and high-efficiently recyclable electronics. Adv. Funct. Mater 34, 2310653 (2024).

Dickey, M. D. Stretchable and soft electronics using liquid metals. Adv. Mater. 29, 1606425 (2017).

Wang, X. & Liu, J. Recent advancements in liquid metal flexible printed electronics: properties, technologies, and applications. Micromachines 7, 206 (2016).

Chen, S., Cui, Z., Wang, H., Wang, X. & Liu, J. Liquid metal flexible electronics: past, present, and future. Appl. Phys. Rev. 10, 21308 (2023).

Ford, M. J., Patel, D. K., Pan, C., Bergbreiter, S. & Majidi, C. Controlled assembly of liquid metal inclusions as a general approach for multifunctional composites. Adv. Mater. 32, 2002929 (2020).

Haque, A. T. et al. Electrically conductive liquid metal composite adhesives for reversible bonding of soft electronics. Adv. Funct. Mater. 34, 2304101 (2023).

Lee, W. et al. Universal assembly of liquid metal particles in polymers enables elastic printed circuit board. Science 378, 637–641 (2022).

Wu, D. et al. Fast and facile liquid metal printing via projection lithography for highly stretchable electronic circuits. Adv. Mater. 36, 2307632 (2024).

Liu, S. et al. Ultrasonic-enabled nondestructive and substrate-independent liquid metal ink sintering. Adv. Sci. 10, 2301292 (2023).

Yun, G. et al. Electro-mechano responsive elastomers with self-tunable conductivity and stiffness. Sci. Adv. 9, eadf1141 (2023).

Kim, M. G., Alrowais, H., Pavlidis, S. & Brand, O. Size-scalable and high-density liquid-metal-based soft electronic passive components and circuits using soft lithography. Adv. Funct. Mater. 27, 1604466 (2017).

Ren, P. & Dong, J. Direct fabrication of via interconnects by electrohydrodynamic printing for multi-layer 3d flexible and stretchable electronics. Adv. Mater. Technol. 6, 2100280 (2021).

Marques, D. G., Lopes, P. A., de Almeida, A. T., Majidi, C. & Tavakoli, M. Reliable interfaces for egain multi-layer stretchable circuits and microelectronics. Lab Chip 19, 897–906 (2019).

Liu, S., Shah, D. S. & Kramer-Bottiglio, R. Highly stretchable multilayer electronic circuits using biphasic gallium-indium. Nat. Mater. 20, 851–858 (2021).

Hirsch, A. et al. Intrinsically stretchable biphasic (solid-liquid) thin metal films. Adv. Mater. 28, 4507–4512 (2016).

Yoon, J. et al. Design and fabrication of novel stretchable device arrays on a deformable polymer substrate with embedded liquid-metal interconnections. Adv. Mater. 26, 6580–6586 (2014).

Franssila, S. Introduction to Microfabrication (Wiley, 2010).

Patel, D. K. et al. Highly stretchable and UV curable elastomers for digital light processing based 3D printing. Adv. Mater. 29, 1606000 (2017).

Qi, D., Zhang, K., Tian, G., Jiang, B. & Huang, Y. Stretchable electronics based on PDMS substrates. Adv. Mater. 33, 2003155 (2021).

Llerena Zambrano, B. et al. Soft electronics based on stretchable and conductive nanocomposites for biomedical applications. Adv. Healthc. Mater. 10, 2001397 (2021).

Bartlett, M. D. et al. Stretchable, high-k dielectric elastomers through liquid-metal inclusions. Adv. Mater. 28, 3726–3731 (2016).

Style, R. W. et al. Stiffening solids with liquid inclusions. Nat. Phys. 11, 82–87 (2015).

Markvicka, E. J., Bartlett, M. D., Huang, X. & Majidi, C. An autonomously electrically self-healing liquid metal–elastomer composite for robust soft-matter robotics and electronics. Nat. Materials 17, 618–624 (2018).

Ford, M. J. et al. A multifunctional shape-morphing elastomer with liquid metal inclusions. Proc. Natl Acad. Sci. USA 116, 21438–21444 (2019).

Baum, D. et al. High-throughput segmentation of tiled biological structures using random-walk distance transforms. Integr. Comp. Biol. 59, 1700–1712 (2019).

Cheng, N.-S. Simplified settling velocity formula for sediment particle. J. Hydraul. Eng. 123, 149–152 (1997).

Bogatin, E. Essential principles of signal integrity. IEEE Microw. Mag. 12, 34–41 (2011).

Liu, Y. et al. Synthesis and applications of low dielectric polyimide. Resour. Chem. Mater. 2, 49–62 (2023).

Barron III, E. J., Williams, E. T., Wilcox, B. T., Ho, D. H. & Bartlett, M. D. Liquid metal-elastomer composites for water-resilient soft electronics. J. Polymer Sci. https://doi.org/10.1002/pol.20230616 (2023).

Acknowledgements

D.H.H. and M.D.B. acknowledge support from the Office of Naval Research Young Investigator Program (ONR YIP) (grant no. N000142112699) and the National Science Foundation CAREER award (grant no. 2238754). C.H. and L.L. acknowledge support from Virginia Polytechnic Institute and State University through the COE Faculty Fellowship. C.H. and L.L. also thank D. Baum for the kind assistance in using random-work distance transforms for quantitative microCT analysis.

Author information

Authors and Affiliations

Contributions

D.H.H. and M.D.B. conceived and designed research. D.H.H. conducted research. C.H. and L.L. contributed to measurement and analysis of the microCT scan data. M.D.B. supervised the work. D.H.H. and M.D.B. wrote the paper with contributions from all the authors.

Corresponding author

Ethics declarations

Competing interests

M.D.B. and D.H.H. are inventors on a patent application (US Patent Application no. 63/535,919) on the fabrication approach. The other authors declare no competing interests.

Peer review

Peer review information

Nature Electronics thanks Wedyan Babatain, Sungjune Park and Nanjia Zhou for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes, Figs. 1–21 and Videos 1–6.

Supplementary Video 1

Reconstructed microCT images of LM-STAIR vias.

Supplementary Video 2

LM-STAIR ultrasonic activation.

Supplementary Video 3

Real-time fabrication of LM-STAIR vias inside the photoresin.

Supplementary Video 4

Reconstructed microCT images of planar interconnect.

Supplementary Video 5

Circuit adhesion demonstration.

Supplementary Video 6

Magnetic field interface circuit demonstration.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ho, D.H., Hu, C., Li, L. et al. Soft electronic vias and interconnects through rapid three-dimensional assembly of liquid metal microdroplets. Nat Electron 7, 1015–1024 (2024). https://doi.org/10.1038/s41928-024-01268-z

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41928-024-01268-z

This article is cited by

-

Materials design and integration strategies for soft bioelectronics in digital healthcare

Nature Reviews Materials (2025)

-

Highly foldable and leakage-free electrodes enabled by ultrathin liquid metal micromeshes

npj Flexible Electronics (2025)

-

Electronic fibres via the thermal drawing of liquid-metal-embedded elastomers

Nature Electronics (2025)

-

Rapid interconnects for 3D soft electronics

Nature Electronics (2024)