Abstract

In the past few years, design of mechanical metamaterials has been empowered by computational tools that have allowed the community to overcome limitations of human intuition. By leveraging efficient optimization algorithms and computational physics models, it is now possible to explore vast design spaces, achieving new material functionalities with unprecedented performance. Here, we present our viewpoint on the state of the art of computational metamaterials design, discussing recent advances in topology optimization and machine learning design with respect to challenges in additive manufacturing.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Bertoldi, K., Vitelli, V., Christensen, J. & Van Hecke, M. Flexible mechanical metamaterials. Nat. Rev. Mater. 2, 17066 (2017).

Xia, X., Spadaccini, C. M. & Greer, J. R. Responsive materials architected in space and time. Nat. Rev. Mater. 7, 683–701 (2022).

Lakes, R. Foam structures with a negative poisson’s ratio. Science 235, 1038–1040 (1987).

Lakes, R. Deformation mechanisms in negative poisson’s ratio materials: structural aspects. J. Mater. Sci. 26, 2287–2292 (1991).

Milton, G. W. Composite materials with poisson’s ratios close to – 1. J. Mech. Phys. Solids 40, 1105–1137 (1992).

Sigmund, O. Materials with prescribed constitutive parameters: an inverse homogenization problem. Int. J. Solids Struct. 31, 2313–2329 (1994).

Sigmund, O. Tailoring materials with prescribed elastic properties. Mech. Mater. 20, 351–368 (1995).

Evans, K. E. & Alderson, A. Auxetic materials: functional materials and structures from lateral thinking! Adv. Mater. 12, 617–628 (2000).

Coulais, C., Kettenis, C. & van Hecke, M. A characteristic length scale causes anomalous size effects and boundary programmability in mechanical metamaterials. Nat. Phys. 14, 40–44 (2017).

Florijn, B., Coulais, C. & van Hecke, M. Programmable mechanical metamaterials. Phys. Rev. Lett. 113, 175503 (2014).

Florijn, B., Coulais, C. & van Hecke, M. Programmable mechanical metamaterials: the role of geometry. Soft Matter 12, 8736–8743 (2016).

Rayneau-Kirkhope, D. J. & Dias, M. A. Recipes for selecting failure modes in 2-d lattices. Extreme Mech. Lett. 9, 11–20 (2016).

Gibson, L. J., Ashby, M. F. & Harley, B. A. Cellular Materials in Nature and Medicine (Cambridge Univ. Press, 2010).

Ashby, M. F. The properties of foams and lattices. Philos. Trans. R. Soc. A 364, 15–30 (2006).

Rayneau-Kirkhope, D., Bonfanti, S. & Zapperi, S. Density scaling in the mechanics of a disordered mechanical meta-material. Appl. Phys. Lett. 114, 111902 (2019).

Lin, X. et al. Mechanical fourier transform for programmable metamaterials. Proc. Natl Acad. Sci. USA 120, e2305380120 (2023).

Frenzel, T., Kadic, M. & Wegener, M. Three-dimensional mechanical metamaterials with a twist. Science 358, 1072–1074 (2017).

Fernandez-Corbaton, I. et al. New twists of 3D chiral metamaterials. Adv. Mater. 31, 1807742 (2019).

Wu, W. et al. Mechanical design and multifunctional applications of chiral mechanical metamaterials: a review. Mater. Des. 180, 107950 (2019).

Bertoldi, K., Reis, P. M., Willshaw, S. & Mullin, T. Negative Poisson’s ratio behavior induced by an elastic instability. Adv. Mater. 22, 361–366 (2010).

Zhang, H., Wu, J., Fang, D. & Zhang, Y. Hierarchical mechanical metamaterials built with scalable tristable elements for ternary logic operation and amplitude modulation. Sci. Adv. 7, eabf1966 (2021).

Zhang, X. et al. Kirigami-based metastructures with programmable multistability. Proc. Natl Acad. Sci. USA 119, e2117649119 (2022).

Bendsoe, M. P. & Sigmund, O.Topology Optimization: Theory, Methods, and Applications (Springer Science and Business Media, 2003).

Sigmund, O. & Maute, K. Topology optimization approaches: a comparative review. Struct. Multidiscip. Optim. 48, 1031–1055 (2013).

Bendsøe, M. P. Optimal shape design as a material distribution problem. Struct. Optim. 1, 193–202 (1989).

Zhou, M. & Rozvany, G. The COC algorithm, Part II: topological, geometrical and generalized shape optimization. Comput. Methods Appl. Mech. Eng. 89, 309–336 (1991).

Mlejnek, H.-P. & Schirrmacher, R. An engineer’s approach to optimal material distribution and shape finding. Comput. Methods Appl. Mech. Eng. 106, 1–26 (1993).

Diaz, A. & Sigmund, O. Checkerboard patterns in layout optimization. Struct. Optim. 10, 40–45 (1995).

Jog, C. S. & Haber, R. B. Stability of finite element models for distributed-parameter optimization and topology design. Comput. Methods Appl. Mech. Eng. 130, 203–226 (1996).

Sigmund, O. & Petersson, J. Numerical instabilities in topology optimization: a survey on procedures dealing with checkerboards, mesh-dependencies and local minima. Struct. Optim. 16, 68–75 (1998).

Sigmund, O. On the design of compliant mechanisms using topology optimization. J. Struct. Mech. 25, 493–524 (1997).

Bourdin, B. Filters in topology optimization. Int. J. Numer. Methods Eng. 50, 2143–2158 (2001).

Bruns, T. E. & Tortorelli, D. A. Topology optimization of non-linear elastic structures and compliant mechanisms. Comput. Methods Appl. Mech. Eng. 190, 3443–3459 (2001).

Lazarov, B. S. & Sigmund, O. Filters in topology optimization based on Helmholtz-type differential equations. Int. J. Numer. Methods Eng. 86, 765–781 (2011).

Prager, W. & Taylor, J. E. Problems of optimal structural design. J. Appl. Mech. 35, 102–106 (1968).

Svanberg, K. The method of moving asymptotes-a new method for structural optimization. Int. J. Numer. Methods Eng. 24, 359–373 (1987).

Bourdin, B. & Chambolle, A. Design-dependent loads in topology optimization. ESAIM Control. Optim. Calc. Var. 9, 19–48 (2003).

Wang, M. Y. & Zhou, S. Phase field: a variational method for structural topology optimization. Comput. Model. Eng. Sci. 6, 547–566 (2004).

Garcke, H., Lam, K. F., Nürnberg, R. & Signori, A. Overhang penalization in additive manufacturing via phase field structural topology optimization with anisotropic energies. Appl. Math. Optim. 87, 44 (2023).

Osher, S. & Sethian, J. A. Fronts propagating with curvature-dependent speed: algorithms based on Hamilton-Jacobi formulations. J. Comput. Phys. 79, 12–49 (1988).

Sethian, J. A. & Wiegmann, A. Structural boundary design via level set and immersed interface methods. J. Comput. Phys. 163, 489–528 (2000).

Allaire, G., Gournay, F. D., Jouve, F. & Toader, A.-M. Structural optimization using topological and shape sensitivity via a level set method. Control Cybern. 34, 59–80 (2005).

Van Dijk, N. P., Maute, K., Langelaar, M. & Van Keulen, F. Level-set methods for structural topology optimization: a review. Struct. Multidiscip. Optim. 48, 437–472 (2013).

Shim, P. Y. & Manoochehri, S. Generating optimal configurations in structural design using simulated annealing. Int. J. Numer. Methods Eng. 40, 1053–1069 (1997).

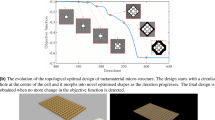

Bonfanti, S., Guerra, R., Font-Clos, F., Rayneau-Kirkhope, D. & Zapperi, S. Automatic design of mechanical metamaterial actuators. Nat. Commun. 11, 4162 (2020).

Beretta, L. et al. Automatic design of chiral mechanical metamaterials. APL Mater. 9, 101112 (2021).

Wu, C.-Y. & Tseng, K.-Y. Topology optimization of structures using modified binary differential evolution. Struct. Multidiscip. Optim. 42, 939–953 (2010).

Kitayama, S., Arakawa, M. & Yamazaki, K. Differential evolution as the global optimization technique and its application to structural optimization. Appl. Soft Comput. 11, 3792–3803 (2011).

Madeira, J. A., Pina, H. & Rodrigues, H. GA topology optimization using random keys for tree encoding of structures. Struct. Multidiscip. Optim. 40, 227–240 (2010).

Zhang, J. & Yanagimoto, J. Density-based topology optimization integrated with genetic algorithm for optimizing formability and bending stiffness of 3d printed cfrp core sandwich sheets. Compos. Part B 225, 109248 (2021).

Mattheck, C. & Burkhardt, S. A new method of structural shape optimization based on biological growth. Int. J. Fatigue 12, 185–190 (1990).

Xie, Y. M. & Steven, G. P. A simple evolutionary procedure for structural optimization. Comput. Struct. 49, 885–896 (1993).

Querin, O. M., Steven, G. P. & Xie, Y. M. Evolutionary structural optimisation (ESO) using a bidirectional algorithm. Eng. Comput. 15, 1031–1048 (1998).

Young, V., Querin, O. M., Steven, G. & Xie, Y. 3D and multiple load case bi-directional evolutionary structural optimization (BESO). Struct. Optim. 18, 183–192 (1999).

Sigmund, O. On the usefulness of non-gradient approaches in topology optimization. Struct. Multidiscip. Optim. 43, 589–596 (2011).

Zhang, S. & Norato, J. A. Finding better local optima in topology optimization via tunneling. In International Design Engineering Technical Conferences and Computers and Information in Engineering Conference Vol. 51760, V02BT03A014 (American Society of Mechanical Engineers, 2018).

Martinez, P., Marti, P. & Querin, O. Growth method for size, topology, and geometry optimization of truss structures. Struct. Multidiscip. Optim. 33, 13–26 (2007).

Zhu, B. et al. Design of compliant mechanisms using continuum topology optimization: a review. Mech. Mach. Theory 143, 103622 (2020).

Yoon, G., Kim, Y., Bendsøe, M. P. & Sigmund, O. Hinge-free topology optimization with embedded translation-invariant differentiable wavelet shrinkage. Struct. Multidiscip. Optim. 27, 139–150 (2004).

Luo, Z., Chen, L., Yang, J., Zhang, Y. & Abdel-Malek, K. Compliant mechanism design using multi-objective topology optimization scheme of continuum structures. Struct. Multidiscip. Optim. 30, 142–154 (2005).

Poulsen, T. A. A simple scheme to prevent checkerboard patterns and one-node connected hinges in topology optimization. Struct. Multidiscip. Optim. 24, 396–399 (2002).

Zhang, W., Zhong, W. & Guo, X. An explicit length scale control approach in simp-based topology optimization. Comput. Methods Appl. Mech. Eng. 282, 71–86 (2014).

Poulsen, T. A. A new scheme for imposing a minimum length scale in topology optimization. Int. J. Numer. Methods Eng. 57, 741–760 (2003).

Seltmann, S. & Hasse, A. Topology optimization of compliant mechanisms with distributed compliance (hinge-free compliant mechanisms) by using stiffness and adaptive volume constraints instead of stress constraints. Mech. Mach. Theory 180, 105133 (2023).

de Assis Pereira, A. & Cardoso, E. L. On the influence of local and global stress constraint and filtering radius on the design of hinge-free compliant mechanisms. Struct. Multidiscip. Optim. 58, 641–655 (2018).

Jonsmann, J., Sigmund, O. & Bouwstra, S. Compliant thermal microactuators. Sens. Actuators A 76, 463–469 (1999).

Jonsmann, J., Sigmund, O. & Bouwstra, S. Compliant electro-thermal microactuators. In Technical Digest. IEEE International MEMS 99 Conference. Twelfth IEEE International Conference on Micro Electro Mechanical Systems 588–593 (IEEE, 1999).

Sigmund, O. Design of multiphysics actuators using topology optimization – Part I: one-material structures. Comput. Methods Appl. Mech. Eng. 190, 6577–6604 (2001).

Sigmund, O. Design of multiphysics actuators using topology optimization – Part II: two-material structures. Comput. Methods Appl. Mech. Eng. 190, 6605–6627 (2001).

Bruns, T. & Sigmund, O. Toward the topology design of mechanisms that exhibit snap-through behavior. Comput. Methods Appl. Mech. Eng. 193, 3973–4000 (2004).

Prasad, J. & Diaz, A. Synthesis of bistable periodic structures using topology optimization and a genetic algorithm. J. Mech. Des. 128, 1298–1306 (2006).

Ohsaki, M. et al. Enumeration of optimal pin-jointed bistable compliant mechanisms with non-crossing members. Struct. Multidiscip. Optim. 37, 645–651 (2009).

Zhang, D., Zhai, X., Liu, L. & Fu, X.-M. An optimized, easy-to-use, open-source gpu solver for large-scale inverse homogenization problems. Struct. Multidiscip. Optim. 66, 207 (2023).

Laman, G. On graphs and rigidity of plane skeletal structures. J. Eng. Math. 4, 331–340 (1970).

Roth, B. Rigid and flexible frameworks. Am. Math. Monthly 88, 6–21 (1981).

Borcea, C. S. & Streinu, I. Periodic frameworks and flexibility. Proc. R. Soc. A 466, 2633–2649 (2010).

Mitschke, H. et al. Finding auxetic frameworks in periodic tessellations. Adv. Mater. 23, 2669–2674 (2011).

Wang, F. & Sigmund, O. 3D architected isotropic materials with tunable stiffness and buckling strength. J. Mech. Phys. Solids 152, 104415 (2021).

Wang, F., Brøns, M. & Sigmund, O. Non-hierarchical architected materials with extreme stiffness and strength. Adv. Funct. Mater. 33, 2211561 (2023).

Clausen, A., Wang, F., Jensen, J. S., Sigmund, O. & Lewis, J. A. Topology optimized architectures with programmable poisson’s ratio over large deformations. Adv. Mater. 27, 5523–5527 (2015).

Rodrigues, H., Guedes, J. M. & Bendsoe, M. P. Hierarchical optimization of material and structure. Struct. Multidiscip. Optim. 24, 1–10 (2002).

Coelho, P. G., Fernandes, P. R., Guedes, J. M. & Rodrigues, H. C. A hierarchical model for concurrent material and topology optimisation of three-dimensional structures. Struct. Multidiscip. Optim. 35, 107–115 (2008).

Bendsøe, M. P. & Kikuchi, N. Generating optimal topologies in structural design using a homogenization method. Comput. Methods Appl. Mech. Eng. 71, 197–224 (1988).

Avellaneda, M. Optimal bounds and microgeometries for elastic two-phase composites. SIAM J. Appl. Math. 47, 1216–1228 (1987).

Francfort, G. A. & Murat, F. Homogenization and optimal bounds in linear elasticity. Arch. Ration. Mech. Anal. 94, 307–334 (1986).

Pantz, O. & Trabelsi, K. A post-treatment of the homogenization method for shape optimization. SIAM J. Control Optim. 47, 1380–1398 (2008).

Pantz, O. & Trabelsi, K. Construction of minimization sequences for shape optimization. In 2010 15th International Conference on Methods and Models in Automation and Robotics 278–283 (IEEE, 2010).

Allaire, G., Geoffroy-Donders, P. & Pantz, O. Topology optimization of modulated and oriented periodic microstructures by the homogenization method. Comput. Math. Appl. 78, 2197–2229 (2019).

Geoffroy-Donders, P., Allaire, G. & Pantz, O. 3-d topology optimization of modulated and oriented periodic microstructures by the homogenization method. J. Comput. Phys. 401, 108994 (2020).

Groen, J. P. & Sigmund, O. Homogenization-based topology optimization for high-resolution manufacturable microstructures. Int. J. Numer. Methods Eng. 113, 1148–1163 (2018).

Groen, J. P., Stutz, F. C., Aage, N., Bærentzen, J. A. & Sigmund, O. De-homogenization of optimal multi-scale 3D topologies. Comput. Methods Appl. Mech. Eng. 364, 112979 (2020).

Woldseth, R. V., Bærentzen, J. A. & Sigmund, O. Phasor noise for dehomogenisation in 2D multiscale topology optimisation. Comput. Methods Appl. Mech. Eng. 418, 116551 (2024).

Jensen, P. D. L., Sigmund, O. & Groen, J. P. De-homogenization of optimal 2D topologies for multiple loading cases. Comput. Methods Appl. Mech. Eng. 399, 115426 (2022).

Träff, E., Sigmund, O. & Groen, J. Simple single-scale microstructures based on optimal rank-3 laminates. Struct. Multidiscip. Optim. 59, 1021–1031 (2019).

Lazarov, B. S., Wang, F. & Sigmund, O. Length scale and manufacturability in density-based topology optimization. Arch. Appl. Mech. 86, 189–218 (2016).

Qian, X. Undercut and overhang angle control in topology optimization: a density gradient based integral approach. Int. J. Numer. Methods Eng. 111, 247–272 (2017).

Zhang, K., Cheng, G. & Xu, L. Topology optimization considering overhang constraint in additive manufacturing. Comput. Struct. 212, 86–100 (2019).

Gaynor, A. T. & Guest, J. K. Topology optimization considering overhang constraints: eliminating sacrificial support material in additive manufacturing through design. Struct. Multidiscip. Optim. 54, 1157–1172 (2016).

Langelaar, M. Topology optimization for additive manufacturing with controllable support structure costs. In 7th European Congress on Computational Methods in Applied Sciences and Engineering 3689–3699 (National Technical University of Athens, 2016).

Langelaar, M. An additive manufacturing filter for topology optimization of print-ready designs. Struct. Multidiscip. Optim. 55, 871–883 (2017).

Luo, Y., Sigmund, O., Li, Q. & Liu, S. Additive manufacturing oriented topology optimization of structures with self-supported enclosed voids. Comput. Methods Appl. Mech. Eng. 372, 113385 (2020).

Sabiston, G. & Kim, I. Y. Void region restriction for additive manufacturing via a diffusion physics approach. Int. J. Numer. Methods Eng. 121, 4347–4373 (2020).

Donoso, A., Aranda, E. & Ruiz, D. A new approach based on spectral graph theory to avoiding enclosed holes in topology optimization. Comput. Methods Appl. Mech. Eng. 393, 114769 (2022).

Gaynor, A. T. & Johnson, T. E. Eliminating occluded voids in additive manufacturing design via a projection-based topology optimization scheme. Addit. Manuf. 33, 101149 (2020).

Xiong, Y., Yao, S., Zhao, Z.-L. & Xie, Y. M. A new approach to eliminating enclosed voids in topology optimization for additive manufacturing. Addit. Manuf. 32, 101006 (2020).

Wang, C. Simultaneous optimization of build orientation and topology for self-supported enclosed voids in additive manufacturing. Comput. Methods Appl. Mech. Eng. 388, 114227 (2022).

Bruggi, M., Laghi, V. & Trombetti, T. Simultaneous design of the topology and the build orientation of wire-and-arc additively manufactured structural elements. Comput. Struct. 242, 106370 (2021).

Mishra, V., Ayas, C., Langelaar, M. & Van Keulen, F. Simultaneous topology and deposition direction optimization for wire and arc additive manufacturing. Manuf. Lett. 31, 45–51 (2022).

Michaleris, P. Modeling metal deposition in heat transfer analyses of additive manufacturing processes. Finite Elem. Anal. Des. 86, 51–60 (2014).

Ranjan, R., Ayas, C., Langelaar, M. & van Keulen, F. Fast detection of heat accumulation in powder bed fusion using computationally efficient thermal models. Materials 13, 4576 (2020).

Ranjan, R., Ayas, C., Langelaar, M. & Keulen, F. V. Controlling local overheating in topology optimization for additive manufacturing. Struct. Multidiscip. Optim. 65, 162 (2022).

Ueda, Y., Fukuda, K., Nakacho, K. & Endo, S. A new measuring method of residual stresses with the aid of finite element method and reliability of estimated values. J. Soc. Nav. Archit. Jpn 1975, 499–507 (1975).

Liang, X., Cheng, L., Chen, Q., Yang, Q. & To, A. C. A modified method for estimating inherent strains from detailed process simulation for fast residual distortion prediction of single-walled structures fabricated by directed energy deposition. Addit. Manuf. 23, 471–486 (2018).

Bihr, M. et al. Part and supports optimization in metal powder bed additive manufacturing using simplified process simulation. Comput. Methods Appl. Mech. Eng. 395, 114975 (2022).

Mishra, V., Ayas, C., Langelaar, M. & van Keulen, F. On controlling microstructure through topology optimization for additive manufacturing. In Proceedings of the ASMO UK12-EU1 Conference Engineering Design Optimization 147 (2022).

Bayat, M. et al. Holistic computational design within additive manufacturing through topology optimization combined with multiphysics multi-scale materials and process modelling. Prog. Mater. Sci. 138, 101129 (2023).

Shi, R. et al. Microstructural control in metal laser powder bed fusion additive manufacturing using laser beam shaping strategy. Acta Mater. 184, 284–305 (2020).

Saghaian, S. E. et al. Effect of hatch spacing and laser power on microstructure, texture, and thermomechanical properties of laser powder bed fusion (L-PBF) additively manufactured NiTi. Opt. Laser Technol. 149, 107680 (2022).

Fu, Z., Ye, J., Franke, M. & Körner, C. A novel approach for powder bed-based additive manufacturing of compositionally graded composites. Addit. Manuf. 56, 102916 (2022).

Liu, Z. et al. Additive manufacturing of metals: microstructure evolution and multistage control. J. Mater. Sci. Technol. 100, 224–236 (2022).

Woldseth, R. V., Aage, N., Bærentzen, J. A. & Sigmund, O. On the use of artificial neural networks in topology optimisation. Struct. Multidiscip. Optim. 65, 294 (2022).

Shin, S., Shin, D. & Kang, N. Topology optimization via machine learning and deep learning: A review. J. Comput. Des. Eng. 10, 1736–1766 (2023).

Zheng, X., Zhang, X., Chen, T.-T. & Watanabe, I. Deep learning in mechanical metamaterials: from prediction and generation to inverse design. Adv. Mater. 35, 2302530 (2023).

Jiao, P., Mueller, J., Raney, J. R., Zheng, X. & Alavi, A. H. Mechanical metamaterials and beyond. Nat. Commun. 14, 6004 (2023).

Mao, Y., He, Q. & Zhao, X. Designing complex architectured materials with generative adversarial networks. Sci. Adv. 6, eaaz4169 (2020).

Andreassen, E., Clausen, A., Schevenels, M., Lazarov, B. S. & Sigmund, O. Efficient topology optimization in matlab using 88 lines of code. Struct. Multidiscip. Optim. 43, 1–16 (2011).

Kollmann, H. T., Abueidda, D. W., Koric, S., Guleryuz, E. & Sobh, N. A. Deep learning for topology optimization of 2D metamaterials. Mater. Des. 196, 109098 (2020).

Sosnovik, I. & Oseledets, I. Neural networks for topology optimization. Russ. J. Numer. Anal. Math. Model. 34, 215–223 (2019).

Joo, Y., Yu, Y. & Jang, I. G. Unit module-based convergence acceleration for topology optimization using the spatiotemporal deep neural network. IEEE Access 9, 149766–149779 (2021).

Kallioras, N. A., Kazakis, G. & Lagaros, N. D. Accelerated topology optimization by means of deep learning. Struct. Multidiscip. Optim. 62, 1185–1212 (2020).

Deng, B. et al. Inverse design of mechanical metamaterials with target nonlinear response via a neural accelerated evolution strategy. Adv. Mater. 34, 2206238 (2022).

Ha, C. S. et al. Rapid inverse design of metamaterials based on prescribed mechanical behavior through machine learning. Nat. Commun. 14, 5765 (2023).

Greminger, M. Generative adversarial networks with synthetic training data for enforcing manufacturing constraints on topology optimization. In International Design Engineering Technical Conferences and Computers and Information in Engineering Conference Vol. 84003, V11AT11A005 (American Society of Mechanical Engineers, 2020).

Oh, S., Jung, Y., Lee, I. & Kang, N. Design automation by integrating generative adversarial networks and topology optimization. In International Design Engineering Technical Conferences and Computers and Information in Engineering Conference Vol. 51753, V02AT03A008 (American Society of Mechanical Engineers, 2018).

Zheng, L., Karapiperis, K., Kumar, S. & Kochmann, D. M. Unifying the design space and optimizing linear and nonlinear truss metamaterials by generative modeling. Nat. Commun. 14, 7563 (2023).

Wang, C., Yao, S., Wang, Z. & Hu, J. Deep super-resolution neural network for structural topology optimization. Eng. Optim. 53, 2108–2121 (2021).

Napier, N., Sriraman, S.-A., Tran, H. T. & James, K. A. An artificial neural network approach for generating high-resolution designs from low-resolution input in topology optimization. J. Mech. Des. 142, 011402 (2020).

Elingaard, M. O., Aage, N., Bærentzen, J. A. & Sigmund, O. De-homogenization using convolutional neural networks. Comput. Methods Appl. Mech. Eng. 388, 114197 (2022).

Hu, Y. Recent progress in field-assisted additive manufacturing: materials, methodologies, and applications. Mater. Horiz. 8, 885–911 (2021).

Lee, R. H., Mulder, E. A. & Hopkins, J. B. Mechanical neural networks: architected materials that learn behaviors. Sci. Robot. 7, eabq7278 (2022).

Dillavou, S. et al. Machine learning without a processor: emergent learning in a nonlinear electronic metamaterial. Proc. Natl Acad. Sci. USA 121, e2319718121 (2023).

Scheidgen, M. et al. NOMAD: a distributed web-based platform for managing materials science research data. J. Open Source Softw. 8, 5388 (2023).

Wilkinson, M. D. et al. The fair guiding principles for scientific data management and stewardship. Sci. Data 3, 160018 (2016).

Acknowledgements

S.H. acknowledges support from the FRASCAL graduate school (German Research Foundation (DFG); 377472739/GRK 2423/2-2023) and the DFG (grant Za 171 14/1) during the early stages of the work. S.H. also acknowledges support from the Humboldt Foundation through the Feodor Lynen fellowship during the later stages of the work. S.B. was partially supported by the European Union Horizon 2020 research and innovation programme under (grant 857470) and from the European Regional Development Fund under the programme of the Foundation for Polish Science International Research Agenda PLUS (grant MAB PLUS/2018/8). R.G. was supported by the PRIN 2022 project TRIEL. S.Z. was supported by the PRIN 2022 project METACTOR. M.Z. and S.Z. also acknowledge support from DFG (Za 171 9/3). R.Z. was supported by the Italian Ministry of Education Universities and Research through PON Ricerca e Innovazione 2014–2020 (DM 1061, 10 August 2021).

Author information

Authors and Affiliations

Contributions

S.B., S.H., R.Z., R.G., M.Z. and S.Z. performed the literature review, assembled the figures and wrote the paper.

Corresponding authors

Ethics declarations

Competing interests

S.B., R.G. and S.Z. have filed a patent application through the University of Milan related to the present work (application number: 102019000021618). The patent concerns a design method for mechanical actuators. All other authors declare no competing interests.

Peer review

Peer review information

Nature Computational Science thanks the anonymous reviewer(s) for their contribution to the peer review of this work. Primary Handling Editor: Fernando Chirigati, in collaboration with the Nature Computational Science team.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bonfanti, S., Hiemer, S., Zulkarnain, R. et al. Computational design of mechanical metamaterials. Nat Comput Sci 4, 574–583 (2024). https://doi.org/10.1038/s43588-024-00672-x

Received:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/s43588-024-00672-x