Abstract

The cold chain is an essential system of temperature-controlled logistics that ensures the quality and safety of perishable goods. Refrigeration technologies in the chain, which mostly use vapour-compression refrigeration, have large direct and indirect negative environmental impacts linked to high energy consumption and the use of refrigerants with high global warming potential. This Review examines the technical and environmental challenges of refrigeration systems used in transport (road, sea and air) and stationary applications (refrigerated warehouses and retail stores). Across applications, refrigerants with low global warming potential, phase-change materials and vacuum-insulation panels could be used to reduce energy consumption and emissions, with some demonstrations showing reductions of 25–86%. In road transport, photovoltaic-powered refrigeration and hybrid cooling systems could be implemented to reduce emissions but adoption is impeded by high costs and safety concerns. Improved thermal insulation and waste-heat recovery for fresh transportation could be used in sea transport. Advanced energy management and renewable energy integration could be leveraged in stationary storage to reduce emissions by up to 60% and enable off-grid refrigeration. In all of these applications, operational reliability must be maintained, which will require coordinated industry efforts and policy support.

Key points

-

Natural refrigerants like R744 (carbon dioxide), R717 (ammonia) and hydrocarbons are increasingly used in stationary and marine-transport refrigeration systems, but their broader adoption is limited by flammability, toxicity and system-efficiency issues, as well as regulatory gaps, especially in transport applications.

-

Phase-change materials can be adopted in both transport and stationary systems to stabilize temperatures and lower energy use, but their effectiveness is limited by challenges such as material stability, supercooling and long-term performance, and in transport applications, their weight and placement may affect vehicle safety and design constraints.

-

Renewable energy, particularly solar photovoltaics, can be integrated into stationary refrigeration and some road-transport applications, although road systems face space and weight constraints that hinder full deployment compared with more adaptable stationary set-ups.

-

Air transport requires lightweight, compact solutions to balance efficiency and safety, relying on technologies such as electric vapour-compression refrigeration systems, phase-change materials, and vacuum insulation panels, facing strict safety regulations, high operational costs, and limited adoption of natural refrigerants owing to flammability concerns and space constraints.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

International dictionary of refrigeration International Institute of Refrigeration https://iifiir.org/en/international-dictionary-of-refrigeration (2025).

Mercier, S., Villeneuve, S., Mondor, M. & Uysal, I. Time–temperature management along the food cold chain: a review of recent developments. Compr. Rev. Food Sci. Food Saf. 16, 647–667 (2017).

Duret, S. et al. Combining quantitative risk assessment of human health, food waste, and energy consumption: the next step in the development of the food cold chain? Risk Anal. 39, 906–925 (2019).

Zhao, X. et al. Study the test method of temperature and humidity monitoring equipment in the cold chain transportation process. J. Phys. Conf. Ser. 2437, 012065 (2023).

She, X. et al. Energy-efficient and -economic technologies for air conditioning with vapor compression refrigeration: a comprehensive review. Appl. Energy 232, 157–186 (2018).

Baha, M., Hammami, S. & Dupont, J. L. The role of refrigeration in the global economy: 3rd edn, 60th IIR Technical Brief on refrigeration technologies. International Institute of Refrigeration https://iifiir.org/en/fridoc/the-role-of-refrigeration-in-the-global-economy-3-lt-sup-gt-rd-lt-sup-gt-150413 (2025).

Sarr, J., Dupont, J.-L. & Guilpart, J. The carbon footprint of the cold chain: 7th Informatory Note on refrigeration and food. International Institute of Refrigeration https://iifiir.org/en/fridoc/the-carbon-footprint-of-the-cold-chain-7-lt-sup-gt-th-lt-sup-gt-informatory-143457 (2021).

Abdelaziz, O. & Cotton, N. Technoeconomic evaluations for energy efficient domestic low GWP refrigeration technologies. Int. J. Refrig. 132, 255–262 (2021).

Zhang, N. et al. A dynamic analysis of the global warming potential associated with air conditioning at a city scale: an empirical study in Shenzhen, China. Environ. Impact Assess. Rev. 81, 106354 (2020).

Ceglia, F., Marrasso, E., Roselli, C. & Sasso, M. An innovative environmental parameter: expanded total equivalent warming impact. Int. J. Refrig. 131, 980–989 (2021).

Amendment to the Montreal Protocol on substances that deplete the ozone layer. United Nations Environment Programme https://treaties.un.org/doc/Publication/CN/2016/CN.872.2016-Eng.pdf (2016).

Regulation (EU) 2024/573 of the European Parliament and of the Council of 7 February 2024 on fluorinated greenhouse gases, amending directive (EU) 2019/1937 and repealing regulation (EU) No 517/2014. The European Parliament and the Council of the European Union https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=OJ:L_202400573 (2024).

Singh, R. R. & Papanastasiou, D. K. Comment on “Scientific basis for managing PFAS as a chemical class”. Environ. Sci. Technol. Lett. 8, 192–194 (2021).

Stoecker, W. F. & Jones, J. W. Refrigeration and Air Conditioning (McGraw-Hill, 1986).

Hwang, Y. & Qian, S. Caloric cooling technologies: 50th Informatory Note on refrigeration technologies. International Institute of Refrigeration https://iifiir.org/en/fridoc/caloric-cooling-technologies-50-lt-sup-gt-th-lt-sup-gt-informatory-note-on-146206 (2022).

Mehling, H. & Cabeza, L. F. Heat and Cold Storage with PCM (Springer, 2008).

Sustainable food cold chains: opportunities, challenges and the way forward. UNEP and FAO https://openknowledge.fao.org/handle/20.500.14283/cc0923en (2022).

Long-haul vs short-haul: what’s the difference for truckers? ATECH https://www.atechlogistics.com/long-haul-vs-short-haul-whats-the-difference-for-truckers/ (8 July 2024).

Yang, Z., Tate, J. E., Morganti, E. & Shepherd, S. P. Real-world CO2 and NOX emissions from refrigerated vans. Sci. Total Environ. 763, 142974 (2021).

Ahmed, M., Meade, O. & Medina, M. A. Reducing heat transfer across the insulated walls of refrigerated truck trailers by the application of phase change materials. Energy Convers. Manag. 51, 383–392 (2010).

Tassou, S. A., De-Lille, G. & Ge, Y. T. Food transport refrigeration — approaches to reduce energy consumption and environmental impacts of road transport. Appl. Therm. Eng. 29, 1467–1477 (2009).

Yildiz, T. CFD characteristics of refrigerated trailers and improvement of airflow for preserving perishable foods. Logistics 3, 11 (2019).

Maiorino, A., Petruzziello, F. & Aprea, C. Refrigerated transport: state of the art, technical issues, innovations and challenges for sustainability. Energies 14, 7237 (2021).

Transport Refrigeration catalog. Daikin https://www.daikin.eu/en_us/product-group/transport-refrigeration.html (2025).

Kehinde, A. G., Ngonda, T., Raji, A. & Kanyarusoke, K. A review of different technologies for refrigerated truck. Mater. Today Proc. 56, 2305–2310 (2022).

Calati, M., Hooman, K. & Mancin, S. Thermal storage based on phase change materials (PCMs) for refrigerated transport and distribution applications along the cold chain: a review. Int. J. Thermofluids 16, 100224 (2022).

Vaitkus, L., Prakopavičius, L. & Balčius, A. Refrigerants for eutectic refrigerating systems — experimental results and future consideration. Int. J. Refrig. 164, 105–116 (2024).

Rai, A. & Tassou, S. A. Environmental impacts of vapour compression and cryogenic transport refrigeration technologies for temperature controlled food distribution. Energy Convers. Manag. 150, 914–923 (2017).

Li, Y. et al. A high efficiency hybrid synchronous motor for electric vehicle. In 12th Energy Conversion Congr. Expo. Asia (ECCE-Asia) 1806–1810 (IEEE, 2021).

Liu, H. et al. Investigation on the potential of high efficiency for internal combustion engines. Energies 11, 513 (2018).

Sun, Z. & Hebbale, K. Challenges and opportunities in automotive transmission control. In Proc. 2005 American Control Conf. 3284–3289 (IEEE, 2005).

Moreno, G. et al. Electric-drive vehicle power electronics thermal management: current status, challenges, and future directions. J. Electron. Packag. 144, 011004 (2021).

Huang, J. et al. A hybrid electric vehicle motor cooling system — design, model, and control. IEEE Trans. Veh. Technol. 68, 4467–4478 (2019).

Maiorino, A., Cilenti, C., Petruzziello, F. & Aprea, C. A review on thermal management of battery packs for electric vehicles. Appl. Therm. Eng. 238, 122035 (2024).

Refrigerant report. BITZER https://www.bitzer.de/shared_media/documentation/a-501-21.pdf (2023).

Colbourne, D. et al. Development of R290 transport refrigeration system. International Institute of Refrigeration https://iifiir.org/en/fridoc/development-of-r290-transport-refrigeration-system-32376 (2017).

Kivevele, T. Propane (HC – 290) as an alternative refrigerant in the food transport refrigeration sector in Southern Africa — a review. Automot. Exp. 5, 75–89 (2022).

Minetto, S., Fabris, F., Marinetti, S. & Rossetti, A. A review on present and forthcoming opportunities with natural working fluids in transport refrigeration. Int. J. Refrig. 152, 343–355 (2023).

Sharma, V., Fricke, B. & Bansal, P. Supermarket refrigeration system charge reduction using cascade systems. In 11th IIR Gustav Lorentzen Conf. Natural Refrigerants: Natural Refrigerants and Environmental Protection 956–962 (International Institute of Refrigeration, 2014).

Das, K. M., Ramgopal, M., Guha, A. & Katu, Y. A. Performance of a refrigeration system with a two-phase CO2-based natural circulation loop for cold storage applications. Therm. Sci. Eng. Prog. 58, 103184 (2025).

Lösch, M., Fallmann, M., Poks, A. & Kozek, M. Simulation-based sizing of a secondary loop cooling system for a refrigerated vehicle. Energies 16, 6459 (2023).

Barta, R. B., Groll, E. A. & Ziviani, D. Review of stationary and transport CO2 refrigeration and air conditioning technologies. Appl. Therm. Eng. 185, 116422 (2021).

Fabris, F. et al. A novel R744 multi-temperature cycle for refrigerated transport applications with low-temperature ejector: experimental ejector characterization and thermodynamic cycle assessment. Int. J. Refrig. 152, 26–35 (2023).

Bahaj, A. S. World’s first solar powered transport refrigeration system. Renew. Energy 15, 572–576 (1998).

Meneghetti, A., Dal Magro, F. & Romagnoli, A. Renewable energy penetration in food delivery: coupling photovoltaics with transport refrigerated units. Energy 232, 120994 (2021).

Rossetti, A., Marinetti, S., Artuso, P., Fabris, F. & Minetto, S. Implementation of a solar aided refrigration unit for refrigerated trucks employing photovoltaic generators. Energy Rep. 8, 7789–7799 (2022).

Maiorino, A., Petruzziello, F., Cilenti, C., Llopis, R. & Aprea, C. Performance evaluation of a hybrid photovoltaic-vapor compression system serving a refrigerated van. Int. J. Refrig. 168, 720–729 (2024).

Petruzziello, F., Cilenti, C., Grilletto, A., Maiorino, A. & Aprea, C. Solar-powered refrigeration for sustainable refrigerated transport. J. Phys. Conf. Ser. 2893, 012118 (2024).

Radebe, T. B., Huan, Z. & Baloyi, J. A simulation study of natural convection airflow pattern for a phase change material chamber. SSRN Electron. J. https://doi.org/10.2139/ssrn.3637981 (2019).

Ndanduleni, A. U. C. & Huan, Z. Thermal energy storage technology for application in transport refrigeration. SSRN Electron. J. https://doi.org/10.2139/ssrn.3656548 (2019).

Selvnes, H., Allouche, Y., Manescu, R. I. & Hafner, A. Review on cold thermal energy storage applied to refrigeration systems using phase change materials. Therm. Sci. Eng. Prog. 22, 100807 (2021).

Cirillo, L., Greco, A. & Masselli, C. A transient analysis of latent thermal energy storage using phase change materials in a refrigerated truck. Energies 17, 2665 (2024).

Ben Taher, M. A., Kousksou, T., Zeraouli, Y., Ahachad, M. & Mahdaoui, M. Thermal performance investigation of door opening and closing processes in a refrigerated truck equipped with different phase change materials. J. Energy Storage 42, 103097 (2021).

Tong, S. et al. A phase change material (PCM) based passively cooled container for integrated road–rail cold chain transportation — an experimental study. Appl. Therm. Eng. 195, 117204 (2021).

Anand, A., Shukla, A., Kumar, A., Buddhi, D. & Sharma, A. Cycle test stability and corrosion evaluation of phase change materials used in thermal energy storage systems. J. Energy Storage 39, 102664 (2021).

Ahmed, S. F. et al. Integration of phase change materials in improving the performance of heating, cooling, and clean energy storage systems: an overview. J. Clean. Prod. 364, 132639 (2022).

Radebe, T. B., Huan, Z. & Baloyi, J. Simulation of eutectic plates in medium refrigerated transport. J. Eng. Des. Technol. 19, 62–80 (2021).

Jeong, J. et al. Numerical analysis of the thermoaeraulic behavior of air during the opening of the door of a refrigerated truck trailer equipped with cold plates. Appl. Therm. Eng. 206, 118057 (2022).

Oh, S. & Jeong, J. Design and simulation of safe truck–cargo matching system for rollover prevention. Int. J. Mech. 16, 128–133 (2022).

Glouannec, P., Michel, B., Delamarre, G. & Grohens, Y. Experimental and numerical study of heat transfer across insulation wall of a refrigerated integral panel van. Appl. Therm. Eng. 73, 196–204 (2014).

Chatzidakis, S. K. & Chatzidakis, K. S. Refrigerated transport and environment. Int. J. Energy Res. 28, 887–897 (2004).

Tao, W.-H., Chang, C.-C. & Lin, J.-Y. An energy-efficiency performance study of vacuum insulation panels. J. Cell. Plast. 36, 441–450 (2000).

Hammond, E. C. & Evans, J. A. Application of vacuum insulation panels in the cold chain — analysis of viability. Int. J. Refrig. 47, 58–65 (2014).

Zdun, K. & Uhl, T. Improvement of properties of an insulated wall for refrigerated trailer — numerical and experimental study. Energies 15, 51 (2021).

Chandran, R., Hasanuzzaman, M., Arıcı, M. & Kumar, L. Energy, economic and environmental impact analysis of phase change materials for cold chain transportation in Malaysia. J. Energy Storage 55, 105481 (2022).

Calati, M. et al. Latent thermal energy storage for refrigerated trucks. Int. J. Refrig. 136, 124–133 (2022).

Umate, T. B. & Sawarkar, P. D. A review on thermal energy storage using phase change materials for refrigerated trucks: active and passive approaches. J. Energy Storage 75, 109704 (2024).

Yang, Y.-C. & Lin, H.-Y. Cold supply chain of longline tuna and transport choice. Mar. Bus. Rev. 2, 349–366 (2017).

Lukasse, L. J. S. et al. Perspectives on the evolution of reefer containers for transporting fresh produce. Trends Food Sci. Technol. 140, 104147 (2023).

Behdani, B., Fan, Y. & Bloemhof, J. M. in Sustainable Food Supply Chains (eds Accorsi, R. & Manzini, R.) 167–183 (Elsevier, 2019).

Kan, A., Wang, T., Zhu, W. & Cao, D. The characteristics of cargo temperature rising in reefer container under refrigeration-failure condition. Int. J. Refrig. 123, 1–8 (2021).

Fitzgerald, W. B., Howitt, O. J. A., Smith, I. J. & Hume, A. Energy use of integral refrigerated containers in maritime transportation. Energy Policy 39, 1885–1896 (2011).

Hafner, I. A., Gabrielii, C. H. & Widell, K. Refrigeration units in marine vessels: alternatives to HCFCs and high GWP HFCs. Nordic Co-operation https://doi.org/10.6027/TN2019-527 (2019).

Fourth GHG Study 2020. International Maritime Organization https://www.imo.org/en/ourwork/environment/pages/fourth-imo-greenhouse-gas-study-2020.aspx (2021).

Fisher, R. et al. Innovative waste heat valorisation technologies for zero-carbon ships — a review. Appl. Therm. Eng. 253, 123740 (2024).

Palomba, V., Dino, G. E., Ghirlando, R., Micallef, C. & Frazzica, A. Decarbonising the shipping sector: a critical analysis on the application of waste heat for refrigeration in fishing vessels. Appl. Sci. 9, 5143 (2019).

Salmi, W., Vanttola, J., Elg, M., Kuosa, M. & Lahdelma, R. Using waste heat of ship as energy source for an absorption refrigeration system. Appl. Therm. Eng. 115, 501–516 (2017).

Zhang, J., Mei, N. & Yuan, H. Design, analysis, and operation optimisation of a shipborne absorption refrigeration — ice thermal storage system based on waste-heat utilization. Therm. Sci. Eng. Prog. 53, 102720 (2024).

Kazil, J. et al. Deposition and rainwater concentrations of trifluoroacetic acid in the United States from the use of HFO‐1234yf. J. Geophys. Res. Atmos. 119, 14059–14079 (2014).

Söylemez, E. et al. Overview of the development and status of carbon dioxide (R-744) refrigeration systems onboard fishing vessels. Int. J. Refrig. 140, 198–212 (2022).

Brodal, E., Jackson, S. & Eiksund, O. Transient model of an RSW system with CO2 refrigeration — a study of overall performance. Int. J. Refrig. 86, 344–355 (2018).

Container refrigeration. Carrier Transicold https://www.carrier.com/container-refrigeration/en/worldwide/products/Container-Units/naturaline/ (2011).

Barta, R. B., Groll, E. A. & Hugenroth, J. J. Modeling and control strategy of a transcritical carbon dioxide cycle for application in multi-temperature refrigerated container systems. In Proc. 13th IIR Gustav Lorentzen Conf. Natural Refrigerants 1116 (International Institute of Refrigeration, 2018).

Lawrence, N., Elbel, S. & Hrnjak, P. S. Design and investigation of a transcritical R744 refrigerated container for military applications. In Proc. 17th Int. Refrigeration and Air Conditioning Conf. Paper 1947 (Purdue Univ., 2018).

Baxter, G. & Kourousis, K. Temperature controlled aircraft unit load devices: the technological response to growing global air cargo cool chain requirements. J. Technol. Manag. Innov. 10, 157–172 (2015).

Ritchie, H. Very little of global food is transported by air; this greatly reduces the climate benefits of eating local. Our World In Data https://ourworldindata.org/food-transport-by-mode (2020).

Our solutions — when patients count on you, you can count on us. Envirotainer https://www.envirotainer.com/our-solutions/ (2024).

Bulk air cargo. CSafe https://csafeglobal.com/bulk-air-cargo/ (2024).

Sales, M. The Air Logistics Handbook: Air Freight and the Global Supply Chain (Routledge, 2013).

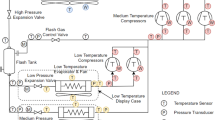

Tachajapong, W., Wiratkasem, K., Kammuang-lue, N. & Pattana, S. Preliminary study on specific energy consumption of cold storage room in Thailand’s cold chain. Energy Rep. 8, 336–341 (2022).

Wu, Q., Zhang, X. & Wu, H. Research progress on cold store technology in the context of dual carbon. J. Energy Storage 86, 111291 (2024).

Pearson, A. in Sustainable Retail Refrigeration (eds Evans, J. A. & Foster, A. M.) 179–197 (Wiley, 2015).

Bagarella, G., Lazzarin, R. & Noro, M. Annual energy analysis of a water-loop self-contained refrigeration plant and comparison with multiplex systems in supermarkets. Int. J. Refrig. 45, 55–63 (2014).

Eid, E. et al. Modelling energy consumption in a Paris supermarket to reduce energy use and greenhouse gas emissions using EnergyPlus. Int. J. Refrig. 168, 1–8 (2024).

Franco, A. & Cillari, G. Energy sustainability of food stores and supermarkets through the installation of PV integrated plants. Energies 14, 5678 (2021).

Evans, J. A., Maidment, G. G., Brown, T., Hammond, E. & Foster, A. M. in Refrigeration Science and Technology (eds Cleland, D. et al.) 316–323 (International Institute of Refrigeration, 2016).

2018 Ashrae handbook — refrigeration. ASHRAE https://www.ashrae.org/technical-resources/ashrae-handbook/description-2018-ashrae-handbook-refrigeration (2018).

Verma, S. & Singh, H. Vacuum insulation panels for refrigerators. Int. J. Refrig. 112, 215–228 (2020).

Zhang, Y. & Wang, R. Sorption thermal energy storage: concept, process, applications and perspectives. Energy Storage Mater. 27, 352–369 (2020).

Suman, S., Khan, Mohd, K. & Pathak, M. Performance enhancement of solar collectors — a review. Renew. Sustain. Energy Rev. 49, 192–210 (2015).

Gao, P. et al. Solar-driven compression-assisted desorption chemisorption refrigeration/cold energy storage system. Energy Convers. Manag. 258, 115474 (2022).

Roy, Z. & Halder, G. Replacement of halogenated refrigerants towards sustainable cooling system: a review. Chem. Eng. J. Adv. 3, 100027 (2020).

ISO 5149-4:2022. Refrigerating systems and heat pumps — safety and environmental requirements. Operation, maintenance, repair and recovery. BSI https://standardsdevelopment.bsigroup.com/projects/2021-00380 (2022).

Domanski, P. A., Brignoli, R., Brown, J. S., Kazakov, A. F. & McLinden, M. O. Low-GWP refrigerants for medium and high-pressure applications. Int. J. Refrig. 84, 198–209 (2017).

Shanmugam, S. K. G. & Mital, M. An ultra-low ammonia charge system for industrial refrigeration. Int. J. Refrig. 107, 344–354 (2019).

Regulation (EU) No 517/2014 of the European Parliament and of the Council of 16 April 2014 on fluorinated greenhouse gases and repealing regulation (EC) No 842/2006. European Environment Agency https://www.eea.europa.eu/policy-documents/regulation-eu-no-517-2014 (2014).

Mota-Babiloni, A. et al. Commercial refrigeration — an overview of current status. Int. J. Refrig. 57, 186–196 (2015).

Catalán-Gil, J., Sánchez, D., Llopis, R., Nebot-Andrés, L. & Cabello, R. Energy evaluation of multiple stage commercial refrigeration architectures adapted to F-gas regulation. Energies 11, 1915 (2018).

World guide to transcritical CO2 refrigeration. Shecco https://issuu.com/shecco/docs/r744-guide/60 (2020).

Llopis, R. et al. Worldwide performance of CO2 booster systems with auxiliary compressor. In Proc. 14th IIR Gustav Lorentzen Conf. Refrigeration Science and Technology 518–523 (International Institute of Refrigeration, 2020).

Queiroz, M. V. A. et al. Experimental comparison between R134a/R744 and R438A/R744 (drop‐in) cascade refrigeration systems based on energy consumption and greenhouse gases emissions. Energy Sci. Eng. 9, 2281–2297 (2021).

Messineo, A. R744-R717 cascade refrigeration system: performance evaluation compared with a HFC two-stage system. Energy Proc. 14, 56–65 (2012).

Aprea, C. & Maiorino, A. An experimental evaluation of the transcritical CO2 refrigerator performances using an internal heat exchanger. Int. J. Refrig. 31, 1006–1011 (2008).

Sánchez, D. et al. New positions for an internal heat exchanger in a CO2 supercritical refrigeration plant. Experimental analysis and energetic evaluation. Appl. Therm. Eng. 63, 129–139 (2014).

Torrella, E., Sánchez, D., Llopis, R. & Cabello, R. Energetic evaluation of an internal heat exchanger in a CO2 transcritical refrigeration plant using experimental data. Int. J. Refrig. 34, 40–49 (2011).

Liu, S. et al. Alternative positions of internal heat exchanger for CO2 booster refrigeration system: thermodynamic analysis and annual thermal performance evaluation. Int. J. Refrig. 131, 1016–1028 (2021).

Deng, J., Jiang, P., Lu, T. & Lu, W. Particular characteristics of transcritical CO2 refrigeration cycle with an ejector. Appl. Therm. Eng. 27, 381–388 (2007).

Fangtian, S. & Yitai, M. Thermodynamic analysis of transcritical CO2 refrigeration cycle with an ejector. Appl. Therm. Eng. 31, 1184–1189 (2011).

Elbarghthi, A. F. A., Hafner, A., Banasiak, K. & Dvorak, V. An experimental study of an ejector-boosted transcritical R744 refrigeration system including an exergy analysis. Energy Convers. Manag. 238, 114102 (2021).

Pardiñas, Á. Á., Selvnes, H., Banasiak, K. & Hafner, A. Next generation of ejector-supported R744 booster systems for commercial refrigeration at all climates. Int. J. Refrig. 148, 168–178 (2023).

Chesi, A., Esposito, F., Ferrara, G. & Ferrari, L. Experimental analysis of R744 parallel compression cycle. Appl. Energy 135, 274–285 (2014).

Gullo, P., Elmegaard, B. & Cortella, G. Advanced exergy analysis of a R744 booster refrigeration system with parallel compression. Energy 107, 562–571 (2016).

Sacasas, D., Vega, J. & Cuevas, C. An annual energetic evaluation of booster and parallel refrigeration systems with R744 in food retail supermarkets. A Chilean perspective. Int. J. Refrig. 133, 326–336 (2022).

Llopis, R., Nebot-Andrés, L., Sánchez, D., Catalán-Gil, J. & Cabello, R. Subcooling methods for CO2 refrigeration cycles: a review. Int. J. Refrig. 93, 85–107 (2018).

Nebot-Andrés, L., Calleja-Anta, D., Sánchez, D., Cabello, R. & Llopis, R. Experimental assessment of dedicated and integrated mechanical subcooling systems vs parallel compression in transcritical CO2 refrigeration plants. Energy Convers. Manag. 252, 115051 (2022).

Llopis, R., Atencia, J., Catalan, J., Nishikawa, T. & Nebot-Andres, L. Thermodynamic optimization and field tests of advanced CO2 booster systems with integrated mechanical subcooling. In Proc. 16th IIR Gustav Lorentzen Conf. Natural Refrigerants (GL2024) (International Institute of Refrigeration, 2024).

Niu, B. & Zhang, Y. Experimental study of the refrigeration cycle performance for the R744/R290 mixtures. Int. J. Refrig. 30, 37–42 (2007).

Tobaly, P., Terrier, M. F. & Bouteiller, P. CO2+ propane mixture as working fluid for refrigeration in hot climates. Experimental results of energy efficiency tests. In Proc. 13th IIR Gustav Lorentzen Conf. Natural Refrigerants (GL2018) (International Institute of Refrigeration, 2018).

Massuchetto, L. H. P., Nascimento, R. B. C., do, Carvalho, S. M. R., de, Araújo, H. Vde & d’Angelo, J. V. H. Thermodynamic performance evaluation of a cascade refrigeration system with mixed refrigerants: R744/R1270, R744/R717 and R744/RE170. Int. J. Refrig. 106, 201–212 (2019).

Sánchez, D., Vidan-Falomir, F., Nebot-Andrés, L., Llopis, R. & Cabello, R. Alternative blends of CO2 for transcritical refrigeration systems. Experimental approach and energy analysis. Energy Convers. Manag. 279, 116690 (2023).

Martínez-Ángeles, M. et al. Evaluation of CO2-doped blends in single-stage with IHX and parallel compression refrigeration architectures. Int. J. Refrig. 151, 50–62 (2023).

Vaccaro, G., Milazzo, A. & Talluri, L. Thermodynamic assessment of trans-critical refrigeration systems utilizing CO2-based mixtures. Int. J. Refrig. 147, 61–70 (2023).

Sánchez, D., Vidan-Falomir, F., Larrondo-Sancho, R., Llopis, R. & Cabello, R. Alternative CO2-based blends for transcritical refrigeration systems. Int. J. Refrig. 152, 387–399 (2023).

Sánchez, D., Larrondo, R., Vidan-Falomir, F. & Cabello, R. Experimental evaluation of the CO2-based mixtures CO2/R32, CO2/R1234yf and CO2/R1270 in a transcritical refrigerating plant considering the effect of the internal heat exchanger (IHX). Appl. Therm. Eng. 236, 121473 (2024).

Martínez-Ángeles, M. et al. New phase separation phenomena in refrigeration plants working with CO2-based mixtures. Experimental approach. Int. J. Refrig. 172, 75–86 (2025).

Brendel, L. P. M. et al. High-glide refrigerant blends in high-temperature heat pumps: Part 1 — coefficient of performance. Int. J. Refrig. 165, 84–96 (2024).

Brendel, L. P. M. et al. Experimental performance comparison of high-glide hydrocarbon and synthetic refrigerant mixtures in a high-temperature heat pump. Energies 17, 1981 (2024).

Yelishala, S. C. et al. Performance maximization by temperature glide matching in energy exchangers of cooling systems operating with natural hydrocarbon/CO2 refrigerants. Int. J. Refrig. 119, 294–304 (2020).

Jige, D., Nobunaga, M., Nogami, T. & Inoue, N. Boiling heat transfer of binary and ternary mixtures in multiple rectangular microchannels. Appl. Therm. Eng. 229, 120613 (2023).

Yan, S., Nie, F., Dong, X. & Gong, M. Experimental investigation on flow condensation heat transfer of methane/ethylene mixture inside a horizontal smooth tube. Heat. Transf. Res. 54, 19–37 (2023).

System considerations for refrigerant blends with temperature glide. Theory and practical retrofit guidance. Parker Hannifin Corporation https://www.parker.com/content/dam/Parker-com/Literature/Sporlan/Sporlan-pdf-files/Sporlan-pdf-Educational/Form-5-492-Refrig-Blends.pdf (2017).

Ullah, K. R., Saidur, R., Ping, H. W., Akikur, R. K. & Shuvo, N. H. A review of solar thermal refrigeration and cooling methods. Renew. Sustain. Energy Rev. 24, 499–513 (2013).

Del Pero, C. et al. Characterization and monitoring of a self-constructible photovoltaic-based refrigerator. Energies 9, 749 (2016).

Petruzziello, F., Cilenti, C., Grilletto, A., Aprea, C. & Maiorino, A. Sun-powered refrigerator: design, testing, and limitations. Int. J. Heat. Technol. 42, 1598–1604 (2024).

Sabry, A. H. & Ker, P. J. Improvement on energy consumption of a refrigerator within PV system including battery storage. Energy Rep. 7, 430–438 (2021).

Abdelkareem, M. A. et al. Environmental aspects of batteries. Sustain. Horiz. 8, 100074 (2023).

Padhye, M. S. & Agrawal, N. Integration of phase change materials (PCMs) in freezer of a domestic refrigerator: a comparative study. J. Inst. Eng Ser. C 104, 1057–1064 (2023).

Aslam, J. & Santhappan, J. S. Phase change materials (PCMs) for the use of solar energy in cooling applications. AIP Conf. Proc. 3042, 020001 (2024).

Joseph Sekhar, S., Saif Al Maqbali, F. & Aslam, J. Phase change materials (PCM) for a zero-carbon food preservation technology in remote areas. IOP Conf. Ser. Earth Environ. Sci. 1365, 012009 (2024).

Zhou, D. Y., Shi, C. P. & Yuan, W. H. Applied research of cool storage and energy conservation technology on cold storage. Appl. Mech. Mater. 71–78, 4744–4747 (2011).

Oró, E., Miró, L., Farid, M. M., Martin, V. & Cabeza, L. F. Energy management and CO2 mitigation using phase change materials (PCM) for thermal energy storage (TES) in cold storage and transport. Int. J. Refrig. 42, 26–35 (2014).

Natarajan, B., Chellachi Kathiresan, A. & Subramanium, S. K. Development and performance evaluation of a hybrid portable solar cold storage system for the preservation of vegetables and fruits in remote areas. J. Energy Storage 72, 108292 (2023).

Maiorino, A., Petruzziello, F., Grilletto, A., Cilenti, C. & Aprea, C. Achieving off-grid refrigeration in remote areas: a solar-powered vapor compression refrigerator prototype with PCM integration. Int. J. Refrig. 169, 267–278 (2025).

Ouaouja, Z., Ousegui, A., Toublanc, C., Rouaud, O. & Havet, M. Phase change materials for cold thermal energy storage applications: a critical review of conventional materials and the potential of bio-based alternatives. J. Energy Storage 110, 115339 (2025).

Ben-Abdallah, R. et al. Analysis of phase change material integration in retail display cabinets for energy management. Appl. Therm. Eng. 187, 116459 (2021).

Alzuwaid, F., Ge, Y. T., Tassou, S. A., Raeisi, A. & Gowreesunker, L. The novel use of phase change materials in a refrigerated display cabinet: an experimental investigation. Appl. Therm. Eng. 75, 770–778 (2015).

Yilmaz, D., Mancuhan, E. & Yılmaz, B. Experimental investigation of PCM location in a commercial display cabinet cooled by a transcritical CO2 system. Int. J. Refrig. 120, 396–405 (2020).

Javeri-Shahreza, I., Fakhroleslam, M. & Sadrameli, S. M. Application of phase change materials for performance enhancement of open-display supermarket refrigerators: numerical simulation and parametric study. J. Energy Storage 66, 107506 (2023).

Ben-Abdallah, R. et al. Experimental investigation of the use of PCM in an open display cabinet for energy management purposes. Energy Convers. Manag. 198, 111909 (2019).

Alzuwaid, F. A., Ge, Y. T., Tassou, S. A. & Sun, J. The novel use of phase change materials in an open type refrigerated display cabinet: a theoretical investigation. Appl. Energy 180, 76–85 (2016).

Lu, Y. L. et al. Experimental study of heat transfer intensification by using a novel combined shelf in food refrigerated display cabinets (experimental study of a novel cabinets). Appl. Therm. Eng. 30, 85–91 (2010).

Purohit, N. & Dasgupta, M. S. Thermal storage material enhanced refrigerated display cabinet. Mater. Today Proc. 28, 510–514 (2020).

Agreement on the international carriage of perishable foodstuffs and on the special equipment to be used for such carriage (ATP). UNECE https://unece.org/transport/road-transport/text-and-status-agreement (2024).

Guidelines for the International Packaging and Shipping of Vaccines 6th edn (World Health Organization, 2020).

Santos, A. F., Gaspar, P. D. & de Souza, H. J. L. Refrigeration of COVID-19 vaccines: ideal storage characteristics, energy efficiency and environmental impacts of various vaccine options. Energies 14, 1849 (2021).

ISO 817:2024. Refrigerants — designation and safety classification. International Organization for Standardization (ISO) https://www.iso.org/standard/83452.html (2024).

EN 378-1:2016+A1:2020. Refrigerating systems and heat pumps — safety and environmental requirements — part 1: basic requirements, definitions, classification and selection criteria. European Committee for Standardization (CEN) https://standards.iteh.ai/catalog/standards/cen/f789dd0a-6149-419f-b138-78414b221ea5/en-378-1-2016a1-2020 (2020).

EN 378-2:2016. Refrigerating systems and heat pumps — safety and environmental requirements — part 2: design, construction, testing, marking and documentation. European Committee for Standardization (CEN) https://standards.iteh.ai/catalog/standards/cen/480c2099-de30-4ca7-8b6d-7b1a7d4fc23b/en-378-2-2016 (2016).

LXE10E specifications & options. Daikin https://www.Ref.Daikin.Com/-/Media/Project/Daikin/Ref_daikin_com/Site222/Wp-Content/Uploads/LXE_brochure-Pdf.Pdf (2015).

SG-5000 series — high performance generator set range for marine containers. Thermoking https://www.thermoking.com/content/dam/thermoking/documents/marketing/TK80051_SG5000.pdf (2024).

Envirotainer product manual: RKN E1 and RAP E2. Envirotainer https://www.envirotainer.com/our-solutions/pallets/e-tech/#specificationsblock (2025).

Acknowledgements

P.G.-P. acknowledges grant CIACIF/2021/182, funded by the Generalitat Valenciana (GV) and the European Social Fund (ESF).

Author information

Authors and Affiliations

Contributions

F.P., A.G., C.C., A.M. and C.A. contributed equally to all aspects of the article. M.M.-A., P.G.-P., A.D.S., A.M.-B. and R.L. contributed substantially to discussion of the content and reviewed and edited the manuscript before submission.

Corresponding author

Ethics declarations

Competing interests

A.D.S. is the General Manager at Idal Group SpA (Salerno, Italy). The other authors declare no competing interests.

Peer review

Peer review information

Nature Reviews Clean Technology thanks Riley Bartar, Cheng Zheng and Alessandro Giampieri for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Glossary

- Barocaloric effect

-

Change in the temperature of a material, caused by a pressure change.

- CO2 equator

-

Ambient temperature (between 30 °C and 35 °C) limit, above which CO2 refrigeration systems lose efficiency because of transcritical operation.

- Coefficient of performance

-

Ratio measuring the efficiency of a refrigeration system, defined as the cooling effect produced divided by the input energy.

- Cold plate

-

A thermally conductive plate, typically containing phase-change materials, that transfers energy to products.

- Elastocaloric effect

-

Change in temperature of a material caused by the application or removal of mechanical stress and strain.

- Electrocaloric effect

-

Change in temperature of a material caused by the application or removal of an electric field.

- Hermetic compressor

-

A compressor that is fully sealed within the motor housing, preventing refrigerant leaks.

- Magnetocaloric effect

-

Change in temperature of a material caused by the application or removal of a magnetic field.

- Open compressor

-

The compressor and the motor are separated, allowing for maintenance but increasing leakage risks.

- Phase-change material

-

A substance able to absorb or release heat during phase change.

- Pull-down time

-

The time needed for a refrigeration system to cool a refrigerated space from ambient temperature to the setpoint.

- Transport refrigeration unit

-

A refrigeration system designed to operate in vehicles transporting perishable products.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Petruzziello, F., Grilletto, A., Cilenti, C. et al. Refrigeration technologies to increase cold chain sustainability. Nat. Rev. Clean Technol. 1, 604–620 (2025). https://doi.org/10.1038/s44359-025-00094-6

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s44359-025-00094-6

This article is cited by

-

Looking backwards and forwards

Nature Reviews Clean Technology (2026)