Abstract

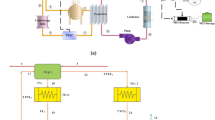

Ammonia has potential to play a key role in large-scale, long-term storage and transport of renewable energy. Renewable energy generation, particularly from solar and wind sources, has increased substantially but faces challenges such as intermittency and decentralization. Energy storage technologies are vital for addressing these issues, with chemical energy storage, especially ammonia, offering long-term (weeks) and large-scale (10–1,000 MW) energy storage. In this Review, we explore the role of ammonia in the energy landscape, focusing on its synthesis and utilization. Ammonia has advantages over hydrogen, such as higher volumetric energy density (12.7 MJ l−1) and simpler storage requirements (readily liquefied at ~10 bar or −33 °C). It can be synthesized using renewable electricity and later decomposed to release hydrogen or used directly in fuel cells, including direct-ammonia fuel cells, indirect-ammonia fuel cells and ammonia solid-oxide fuel cells. We show that although decentralized ammonia synthesis under mild conditions offers potential for localized, low-carbon production, it remains limited by high energy costs and scalability challenges, underscoring the need for breakthroughs in catalyst efficiency and system design. The successful integration of ammonia into renewable energy systems will require coordinated efforts across technology development, policy support and infrastructure expansion.

Key points

-

Ammonia is a promising carbon-free energy carrier with high volumetric energy density and ease of storage, suitable for large-scale and long-duration renewable energy storage and transport.

-

Mild-condition ammonia synthesis, including electrochemical, plasma-catalytic and tandem plasma-electrocatalytic routes, offers potential for decentralized and flexible production using renewable electricity.

-

Metal-mediated electrochemical nitrogen reduction has demonstrated high selectivity and stability, but scaling to industrial current densities and lifetimes remains a key challenge.

-

Plasma-based and tandem plasma-electrocatalytic approaches enable operation under ambient conditions and modular deployment, but energy efficiency and catalyst performance need further improvement.

-

Ammonia can be decomposed to supply hydrogen for fuel cells or combustion, with ongoing efforts focused on lowering the reaction temperature and replacing costly ruthenium-based catalysts.

-

Realizing cost-competitive, sustainable ammonia production and its full potential as a carbon-free energy carrier will require integrated advances in catalysts, reactors and system-level design, supported by policy and infrastructure to drive scalable deployment.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Al-Shetwi, A. Q., Abidin, I. Z., Mahafzah, K. A. & Hannan, M. A. Feasibility of future transition to 100% renewable energy: recent progress, policies, challenges, and perspectives. J. Clean. Prod. 478, 143942 (2024).

Valera-Medina, A., Xiao, H., Owen-Jones, M., David, W. I. F. & Bowen, P. J. Ammonia for power. Prog. Energy Combust. Sci. 69, 63–102 (2018).

Gür, T. M. Review of electrical energy storage technologies, materials and systems: challenges and prospects for large-scale grid storage. Energy Environ. Sci. 11, 2696–2767 (2018).

MacFarlane, D. R. et al. A roadmap to the ammonia economy. Joule 4, 1186–1205 (2020).

Yapicioglu, A. & Dincer, I. A review on clean ammonia as a potential fuel for power generators. Renew. Sustain. Energy Rev. 103, 96–108 (2019).

Guo, J. P. & Chen, P. Catalyst: NH3 as an energy carrier. Chem 3, 709–712 (2017).

Spatolisano, E., Pellegrini, L. A., de Angelis, A. R., Cattaneo, S. & Roccaro, E. Ammonia as a carbon-free energy carrier: NH3 cracking to H2. Ind. Eng. Chem. Res. 62, 10813–10827 (2023).

David, W. I. F. et al. 2023 roadmap on ammonia as a carbon-free fuel. JPhys Energy 6, 021501 (2024).

The Royal Society. Ammonia: Zero-Carbon Fertiliser, Fuel and Energy Store (The Royal Society, 2020).

Kobayashi, H., Hayakawa, A., Somarathne, K. D. K. A. & Okafor, E. C. Science and technology of ammonia combustion. Proc. Combust. Inst. 37, 109–133 (2019).

Westhead, O. et al. Near ambient N2 fixation on solid electrodes versus enzymes and homogeneous catalysts. Nat. Rev. Chem. 7, 184–201 (2023).

Iriawan, H. et al. Methods for nitrogen activation by reduction and oxidation. Nat. Rev. Methods Primers 1, 56 (2021).

Chang, W. S., Jain, A., Rezaie, F. & Manthiram, K. Lithium-mediated nitrogen reduction to ammonia via the catalytic solid-electrolyte interphase. Nat. Catal. 7, 231–241 (2024).

Li, S., Fu, X., Nørskov, J. K. & Chorkendorff, I. Towards sustainable metal-mediated ammonia electrosynthesis. Nat. Energy 9, 1344–1349 (2024).

Wang, Y. et al. Shielding protection by mesoporous catalysts for improving plasma-catalytic ambient ammonia synthesis. J. Am. Chem. Soc. 144, 12020–12031 (2022).

Fu, X. B., Zhang, J. H. & Kang, Y. J. Recent advances and challenges of electrochemical ammonia synthesis. Chem. Catal. 2, 2590–2613 (2022).

Fu, X. & Chorkendorff, I. Prospects and challenges in electrochemical nitrogen activation for ammonia synthesis. Sci. China Chem. 67, 3510–3514 (2024).

Erisman, J. W., Sutton, M. A., Galloway, J., Klimont, Z. & Winiwarter, W. How a century of ammonia synthesis changed the world. Nat. Geosci. 1, 636–639 (2008).

Li, K. et al. Enhancement of lithium-mediated ammonia synthesis by addition of oxygen. Science 374, 1593–1597 (2021).

Fernández, C. A., Chapman, O., Brown, M. A., Alvarez-Pugliese, C. E. & Hatzell, M. C. Achieving decentralized, electrified, and decarbonized ammonia production. Environ. Sci. Technol. 58, 6964–6977 (2024).

Ithisuphalap, K. et al. Photocatalysis and photoelectrocatalysis methods of nitrogen reduction for sustainable ammonia synthesis. Small Methods 3, 1800352 (2019).

Gao, W. B. et al. Production of ammonia via a chemical looping process based on metal imides as nitrogen carriers. Nat. Energy 3, 1067–1075 (2018).

Tanifuji, K. & Ohki, Y. Metal-sulfur compounds in N2 reduction and nitrogenase-related chemistry. Chem. Rev. 120, 5194–5251 (2020).

Andersen, S. Z. et al. A rigorous electrochemical ammonia synthesis protocol with quantitative isotope measurements. Nature 570, 504–508 (2019).

Mehta, P. et al. Overcoming ammonia synthesis scaling relations with plasma-enabled catalysis. Nat. Catal. 1, 269–275 (2018).

Han, G.-F. et al. Mechanochemistry for ammonia synthesis under mild conditions. Nat. Nanotechnol. 16, 325–330 (2021).

Choi, J. et al. Identification and elimination of false positives in electrochemical nitrogen reduction studies. Nat. Commun. 11, 5546 (2020).

Lazouski, N., Schiffer, Z. J., Williams, K. & Manthiram, K. Understanding continuous lithium-mediated electrochemical nitrogen reduction. Joule 3, 1127–1139 (2019).

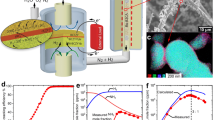

Fu, X. et al. Continuous-flow electrosynthesis of ammonia by nitrogen reduction and hydrogen oxidation. Science 379, 707–712 (2023).

Westhead, O. et al. The role of ion solvation in lithium mediated nitrogen reduction. J. Mater. Chem. A 11, 12746–12758 (2023).

Fu, X. B. et al. Calcium-mediated nitrogen reduction for electrochemical ammonia synthesis. Nat. Mater. 23, 101–107 (2024).

Lazouski, N., Chung, M. J., Williams, K., Gala, M. L. & Manthiram, K. Non-aqueous gas diffusion electrodes for rapid ammonia synthesis from nitrogen and water-splitting-derived hydrogen. Nat. Catal. 3, 463–469 (2020).

Schwalbe, J. A. et al. A combined theory–experiment analysis of the surface species in lithium-mediated NH3 electrosynthesis. ChemElectroChem 7, 1542–1549 (2020).

Cai, X. Y. et al. Membrane electrode assembly design for lithium-mediated electrochemical nitrogen reduction. Energy Environ. Sci. 16, 3063–3073 (2023).

Li, S. et al. Electrosynthesis of ammonia with high selectivity and high rates via engineering of the solid-electrolyte interphase. Joule 6, 2083–2101 (2022).

Du, H. L. et al. Electroreduction of nitrogen with almost 100% current-to-ammonia efficiency. Nature 609, 722–727 (2022).

Fu, X. Lithium-mediated nitrogen reduction for electrochemical ammonia synthesis: from batch to flow reactor. Mater. Today Catal. 3, 100031 (2023).

Fu, X. B. et al. Phenol as proton shuttle and buffer for lithium-mediated ammonia electrosynthesis. Nat. Commun. 15, 2417 (2024).

Cai, X. Y. et al. Lithium-mediated electrochemical nitrogen reduction: mechanistic insights to enhance performance. iScience 24, 103105 (2021).

Li, K. et al. Increasing current density of Li-mediated ammonia synthesis with high surface area copper electrodes. ACS Energy Lett. 7, 36–41 (2022).

Gao, L. F. et al. Domino effect: gold electrocatalyzing lithium reduction to accelerate nitrogen fixation. Angew. Chem. Int. Ed. 60, 5257–5261 (2021).

Li, S. F. et al. Long-term continuous ammonia electrosynthesis. Nature 629, 92–97 (2024).

Suryanto, B. H. R. et al. Nitrogen reduction to ammonia at high efficiency and rates based on a phosphonium proton shuttle. Science 372, 1187–1191 (2021).

Tsuneto, A., Kudo, A. & Sakata, T. Efficient electrochemical reduction of N2 to NH3 catalyzed by lithium. Chem. Lett. 22, 851–854 (1993).

Hyung et al. Utilizing water as a proton source for sustainable Li-mediated electrochemical ammonia synthesis. Chem. Eng. J. 497, 154644 (2024).

Farghali, M. et al. Strategies for ammonia recovery from wastewater: a review. Environ. Chem. Lett. 22, 2699–2751 (2024).

Lee, G., Kim, K., Chung, J. & Han, J.-I. Electrochemical ammonia accumulation and recovery from ammonia-rich livestock wastewater. Chemosphere 270, 128631 (2021).

Lee, G., Kim, D. & Han, J.-I. Gas-diffusion-electrode based direct electro-stripping system for gaseous ammonia recovery from livestock wastewater. Water Res. 196, 117012 (2021).

Iddya, A. et al. Efficient ammonia recovery from wastewater using electrically conducting gas stripping membranes. Environ. Sci. Nano 7, 1759–1771 (2020).

Fu, X. What insights can we learn from dimensionally stable anodes (DSAs)? Carbon Future 1, 9200027 (2024).

Wang, Y. et al. Engineering Ni–Co bimetallic interfaces for ambient plasma-catalytic CO2 hydrogenation to methanol. Chem 10, 2590–2606 (2024).

Chen, J. G. et al. Beyond fossil fuel-driven nitrogen transformations. Science 360, eaar6611 (2018).

Kim, H.-H., Teramoto, Y., Ogata, A., Takagi, H. & Nanba, T. Atmospheric-pressure nonthermal plasma synthesis of ammonia over ruthenium catalysts. Plasma Process. Polym. 14, 1600157 (2017).

Akay, G. & Zhang, K. Process intensification in ammonia synthesis using novel coassembled supported microporous catalysts promoted by nonthermal plasma. Ind. Eng. Chem. Res. 56, 457–468 (2017).

Rouwenhorst, K. H. R., Mani, S. & Lefferts, L. Improving the energy yield of plasma-based ammonia synthesis with in situ adsorption. ACS Sustain. Chem. Eng. 10, 1994–2000 (2022).

Peng, P. et al. Atmospheric plasma-assisted ammonia synthesis enhanced via synergistic catalytic absorption. ACS Sustain. Chem. Eng. 7, 100–104 (2018).

Winter, L. R. & Chen, J. G. N2 fixation by plasma-activated processes. Joule 5, 300–315 (2021).

Abdelaziz, A. A., Teramoto, Y., Nozaki, T. & Kim, H.-H. Performance of high-frequency spark discharge for efficient NO production with tunable selectivity. Chem. Eng. J. 470, 144182 (2023).

Liu, H. et al. Low-coordination rhodium catalysts for an efficient electrochemical nitrate reduction to ammonia. ACS Catal. 13, 1513–1521 (2023).

Liu, W. et al. Efficient ammonia synthesis from the air using tandem non-thermal plasma and electrocatalysis at ambient conditions. Nat. Commun. 15, 3524 (2024).

Guo, X. et al. Highly stable perovskite oxides for electrocatalytic acidic NOx− reduction streamlining ammonia synthesis from air. Angew. Chem. Int. Ed. 63, e202410517 (2024).

Liu, H., Bai, L., Bergmann, A., Cuenya, B. R. & Luo, J. Electrocatalytic reduction of nitrogen oxide species to ammonia. Chem 10, 2963–2986 (2024).

Hermawan, A., Alviani, V. N., Wibisono & Seh, Z. W. Fundamentals, rational catalyst design, and remaining challenges in electrochemical NOx reduction reaction. iScience 26, 107410 (2023).

Smith, C., Hill, A. K. & Torrente-Murciano, L. Current and future role of Haber–Bosch ammonia in a carbon-free energy landscape. Energy Environ. Sci. 13, 331–344 (2020).

Rafiqul, I., Weber, C., Lehmann, B. & Voss, A. Energy efficiency improvements in ammonia production—perspectives and uncertainties. Energy 30, 2487–2504 (2005).

Erfani, N., Baharudin, L. & Watson, M. Recent advances and intensifications in Haber–Bosch ammonia synthesis process. Chem. Eng. Process. 204, 109962 (2024).

Jin, D. L., Chen, A. Q. & Lin, B. L. What metals should be used to mediate electrosynthesis of ammonia from nitrogen and hydrogen from a thermodynamic standpoint? J. Am. Chem. Soc. 146, 12320–12323 (2024).

Kim, K. et al. Electrochemical synthesis of ammonia from water and nitrogen: a lithium-mediated approach using lithium-ion conducting glass ceramics. ChemSusChem 11, 120–124 (2018).

Murphy, E. et al. Elucidating electrochemical nitrate and nitrite reduction over atomically-dispersed transition metal sites. Nat. Commun. 14, 4554 (2023).

Ge, X. et al. Controlling the reaction pathways of mixed NOxHy reactants in plasma-electrochemical ammonia synthesis. J. Am. Chem. Soc. 146, 35305–35312 (2024).

Buchner, G. A., Zimmermann, A. W., Hohgräve, A. E. & Schomäcker, R. Techno-economic assessment framework for the chemical industry—based on technology readiness levels. Ind. Eng. Chem. Res. 57, 8502–8517 (2018).

Rezaie, F., Læsaa, S., Sahin, N. E., Catalano, J. & Dražević, E. Low-temperature electrochemical ammonia synthesis: measurement reliability and comparison to Haber–Bosch in terms of energy efficiency. Energy Technol. 11, 2300410 (2023).

Li, X. et al. Synergistic catalysis of the synthesis of ammonia with Co-based catalysts and plasma: from nanoparticles to a single atom. ACS Appl. Mater. Interfaces 13, 52498–52507 (2021).

Li, L. et al. Efficient nitrogen fixation to ammonia through integration of plasma oxidation with electrocatalytic reduction. Angew. Chem. Int. Ed. 60, 14131–14137 (2021).

Wu, A. et al. Direct ammonia synthesis from the air via gliding arc plasma integrated with single atom electrocatalysis. Appl. Catal. B 299, 120667 (2021).

Sun, J. et al. A hybrid plasma electrocatalytic process for sustainable ammonia production. Energy Environ. Sci. 14, 865–872 (2021).

Zheng, J. et al. Enhanced NH3 synthesis from air in a plasma tandem-electrocatalysis system using plasma-engraved N-doped defective MoS2. JACS Au 3, 1328–1336 (2023).

Fernandez, C. A. & Hatzell, M. C. Economic considerations for low-temperature electrochemical ammonia production: achieving Haber–Bosch parity. J. Electrochem. Soc. 167, 143504 (2020).

Gomez, J. R. & Garzon, F. Preliminary economics for green ammonia synthesis via lithium mediated pathway. Int. J. Energy Res. 45, 13461–13470 (2021).

Lazouski, N. et al. Cost and performance targets for fully electrochemical ammonia production under flexible operation. ACS Energy Lett. 7, 2627–2633 (2022).

Chen, X. et al. Technical and economic analysis of renewable energy systems with hydrogen–ammonia energy storage: a comparison of different ammonia synthesis methods. J. Energy Storage 113, 115549 (2025).

Wang, W., Wang, Y. & Tu, X. Tandem plasma electrocatalysis: an emerging pathway for sustainable ammonia production. Curr. Opin. Green Sustain. Chem. 51, 100986 (2025).

Ganley, J. C., Thomas, F. S., Seebauer, E. G. & Masel, R. I. A priori catalytic activity correlations: the difficult case of hydrogen production from ammonia. Catal. Lett. 96, 117–122 (2004).

Choudhary, T. V., Sivadinarayana, C. & Goodman, D. W. Catalytic ammonia decomposition: COx-free hydrogen production for fuel cell applications. Catal. Lett. 72, 197–201 (2001).

Yin, S. F. et al. Investigation on the catalysis of CO-free hydrogen generation from ammonia. J. Catal. 224, 384–396 (2004).

Wijayanta, A. T., Oda, T., Purnomo, C. W., Kashiwagi, T. & Aziz, M. Liquid hydrogen, methylcyclohexane, and ammonia as potential hydrogen storage: comparison review. Int. J. Hydrog. Energy 44, 15026–15044 (2019).

Lucentini, I., Garcia, X., Vendrell, X. & Llorca, J. Review of the decomposition of ammonia to generate hydrogen. Ind. Eng. Chem. Res. 60, 18560–18611 (2021).

Lee, J. E., Lee, J., Jeong, H., Park, Y.-K. & Kim, B.-S. Catalytic ammonia decomposition to produce hydrogen: a mini-review. Chem. Eng. J. 475, 146108 (2023).

Babar, P. & Botte, G. G. Recent advances in ammonia electrolysis for sustainable hydrogen generation. ACS Sustain. Chem. Eng. 12, 13030–13047 (2024).

Zecher-Freeman, N., Zong, H., Xie, P. & Wang, C. Catalytic cracking of ammonia toward carbon-neutral liquid fuel. Curr. Opin. Green Sustain. Chem. 44, 100860 (2023).

Trangwachirachai, K., Rouwenhorst, K., Lefferts, L. & Faria Albanese, J. A. Recent progress on ammonia cracking technologies for scalable hydrogen production. Curr. Opin. Green Sustain. Chem. 49, 100945 (2024).

Andriani, D. & Bicer, Y. A review of hydrogen production from onboard ammonia decomposition: maritime applications of concentrated solar energy and boil-off gas recovery. Fuel 352, 128900 (2023).

Cao, C.-F. et al. Electronic metal–support interaction enhanced ammonia decomposition efficiency of perovskite oxide supported ruthenium. Chem. Eng. Sci. 257, 117719 (2022).

Mukherjee, S., Devaguptapu, S. V., Sviripa, A., Lund, C. R. F. & Wu, G. Low-temperature ammonia decomposition catalysts for hydrogen generation. Appl. Catal., B 226, 162–181 (2018).

Schüth, F., Palkovits, R., Schlögl, R. & Su, D. S. Ammonia as a possible element in an energy infrastructure: catalysts for ammonia decomposition. Energy Environ. Sci. 5, 6278–6289 (2012).

Boisen, A., Dahl, S., Norskov, J. & Christensen, C. Why the optimal ammonia synthesis catalyst is not the optimal ammonia decomposition catalyst. J. Catal. 230, 309–312 (2005).

Yin, S. F., Xu, B. Q., Wang, S. J., Ng, C. F. & Au, C. T. Magnesia–carbon nanotubes (MgO–CNTs) nanocomposite: novel support of Ru catalyst for the generation of COx-free hydrogen from ammonia. Catal. Lett. 96, 113–116 (2004).

David, W. I. F. et al. Hydrogen production from ammonia using sodium amide. J. Am. Chem. Soc. 136, 13082–13085 (2014).

Guo, J. et al. Electronic promoter or reacting species? The role of LiNH2 on Ru in catalyzing NH3 decomposition. Chem. Commun. 51, 15161–15164 (2015).

Wu, Z.-W. et al. Ammonia decomposition over SiO2-supported Ni–Co bimetallic catalyst for COx-free hydrogen generation. Int. J. Hydrog. Energy 45, 15263–15269 (2020).

Duan, X., Qian, G., Zhou, X., Chen, D. & Yuan, W. MCM-41 supported CoMo bimetallic catalysts for enhanced hydrogen production by ammonia decomposition. Chem. Eng. J. 207–208, 103–108 (2012).

Fu, E. et al. Enhanced NH3 decomposition for H2 production over bimetallic M(M = Co, Fe, Cu)Ni/Al2O3. Fuel Process. Technol. 221, 106945 (2021).

Guo, J. et al. Lithium imide synergy with 3d transition-metal nitrides leading to unprecedented catalytic activities for ammonia decomposition. Angew. Chem. Int. Ed. 54, 2950–2954 (2015).

Xie, P. et al. Highly efficient decomposition of ammonia using high-entropy alloy catalysts. Nat. Commun. 10, 4011 (2019).

Boisen, A., Dahl, S. & Jacobsen, C. J. H. Promotion of binary nitride catalysts: isothermal N2 adsorption, microkinetic model, and catalytic ammonia synthesis activity. J. Catal. 208, 180–186 (2002).

Ogasawara, K. et al. Ammonia decomposition over CaNH-supported Ni catalysts via an NH2–-vacancy-mediated Mars–van Krevelen mechanism. ACS Catal. 11, 11005–11015 (2021).

Strasser, P. et al. Lattice-strain control of the activity in dealloyed core–shell fuel cell catalysts. Nat. Chem. 2, 454–460 (2010).

Sayas, S. et al. High pressure ammonia decomposition on Ru–K/CaO catalysts. Catal. Sci. Technol. 10, 5027–5035 (2020).

Zhai, L., Liu, S. & Xiang, Z. Ammonia as a carbon-free hydrogen carrier for fuel cells: a perspective. Ind. Chem. Mater. 1, 332–342 (2023).

Kanaan, R., Nóbrega, P. H. A., Achard, P. & Beauger, C. Economical assessment comparison for hydrogen reconversion from ammonia using thermal decomposition and electrolysis. Renew. Sustain. Energy Rev. 188, 113784 (2023).

Mehta, P., Barboun, P., Go, D. B., Hicks, J. C. & Schneider, W. F. Catalysis enabled by plasma activation of strong chemical bonds: a review. ACS Energy Lett. 4, 1115–1133 (2019).

Zeng, X. et al. Energy-efficient pathways for pulsed-plasma-activated sustainable ammonia synthesis. ACS Sustain. Chem. Eng. 11, 1110–1120 (2023).

Li, J. et al. Utilizing full-spectrum sunlight for ammonia decomposition to hydrogen over GaN nanowires-supported Ru nanoparticles on silicon. Nat. Commun. 15, 7393 (2024).

Zhang, K. et al. Energy-efficient and cost-effective ammonia electrolysis for converting ammonia to green hydrogen. Cell Rep. Phys. Sci. 5, 102171 (2024).

Hatton, L., Bañares-Alcántara, R., Sparrow, S., Lott, F. & Salmon, N. Assessing the impact of climate change on the cost of production of green ammonia from offshore wind. Int. J. Hydrog. Energy 49, 635–643 (2024).

Zhang, H., Wang, L., van Herle, J., Maréchal, F. & Desideri, U. Techno-economic comparison of green ammonia production processes. Appl. Energy 259, 114135 (2020).

Oh, S., Mun, H., Park, J. & Lee, I. Techno-economic comparison of ammonia production processes under various carbon tax scenarios for the economic transition from grey to blue ammonia. J. Clean. Prod. 434, 139909 (2024).

Lee, B. et al. Pathways to a green ammonia future. ACS Energy Lett. 7, 3032–3038 (2022).

Cloete, S., Khan, M. N., Nazir, S. M. & Amini, S. Cost-effective clean ammonia production using membrane-assisted autothermal reforming. Chem. Eng. J. 404, 126550 (2021).

Devkota, S. et al. Techno-economic and environmental assessment of hydrogen production through ammonia decomposition. Appl. Energy 358, 122605 (2024).

Sen, R. & Bhattacharyya, S. C. Off-grid electricity generation with renewable energy technologies in India: an application of HOMER. Renew. Energy 62, 388–398 (2014).

Sørensen, R. Z. et al. Promoted Ru on high-surface area graphite for efficient miniaturized production of hydrogen from ammonia. Catal. Lett. 112, 77–81 (2006).

Gyak, K.-W. et al. 3D-printed monolithic SiCN ceramic microreactors from a photocurable preceramic resin for the high temperature ammonia cracking process. React. Chem. Eng. 4, 1393–1399 (2019).

Badakhsh, A. et al. A compact catalytic foam reactor for decomposition of ammonia by the Joule-heating mechanism. Chem. Eng. J. 426, 130802 (2021).

Liu, W. et al. Innovative internal Joule-heated reactor design: toward enhanced efficiency in hydrogen production via ammonia decomposition. Chem. Eng. Sci. 315, 121906 (2025).

Lutz, A. E., Larson, R. S. & Keller, J. O. Thermodynamic comparison of fuel cells to the Carnot cycle. Int. J. Hydrog. Energy 27, 1103–1111 (2002).

Chan, Y. T., Siddharth, K. & Shao, M. Investigation of cubic Pt alloys for ammonia oxidation reaction. Nano Res. 13, 1920–1927 (2020).

Jiao, F. & Xu, B. Electrochemical ammonia synthesis and ammonia fuel cells. Adv. Mater. 31, 1805173 (2019).

Bunce, N. J. & Bejan, D. Mechanism of electrochemical oxidation of ammonia. Electrochim. Acta 56, 8085–8093 (2011).

Lee, S. A., Lee, M. G. & Jang, H. W. Catalysts for electrochemical ammonia oxidation: trend, challenge, and promise. Sci. China Mater. 65, 3334–3352 (2022).

Novell-Leruth, G., Valcárcel, A., Pérez-Ramírez, J. & Ricart, J. M. Ammonia dehydrogenation over platinum-group metal surfaces. Structure, stability, and reactivity of adsorbed NHx species. J. Phys. Chem. C 111, 860–868 (2007).

Daramola, D. A. & Botte, G. G. Theoretical study of ammonia oxidation on platinum clusters—adsorption of ammonia and water fragments. Comput. Theor. Chem. 989, 7–17 (2012).

Katsounaros, I. et al. On the mechanism of the electrochemical conversion of ammonia to dinitrogen on Pt(100) in alkaline environment. J. Catal. 359, 82–91 (2018).

Rouwenhorst, K. H. R., Van der Ham, A. G. J., Mul, G. & Kersten, S. R. A. Islanded ammonia power systems: technology review & conceptual process design. Renew. Sustain. Energy Rev. 114, 109339 (2019).

Cai, A. & Rozario, Z. Direct ammonia fuel cells: a general overview, current technologies and future directions. Johns. Matthey Technol. Rev. 66, 479–489 (2022).

Halseid, R., Vie, P. J. S. & Tunold, R. Effect of ammonia on the performance of polymer electrolyte membrane fuel cells. J. Power Sources 154, 343–350 (2006).

Li, J. et al. Ammonia and hydrogen blending effects on combustion stabilities in optical SI engines. Energy Convers. Manage. 280, 116827 (2023).

Jeerh, G., Zhang, M. & Tao, S. Recent progress in ammonia fuel cells and their potential applications. J. Mater. Chem. A 9, 727–752 (2021).

Yang, J. et al. A stability study of Ni/yttria-stabilized zirconia anode for direct ammonia solid oxide fuel cells. ACS Appl. Mater. Interfaces 7, 28701–28707 (2015).

Akimoto, W. et al. Ni–Fe/Sm-doped CeO2 anode for ammonia-fueled solid oxide fuel cells. Solid State Ion. 256, 1–4 (2014).

Song, Y. et al. Infiltrated NiCo alloy nanoparticle decorated perovskite oxide: a highly active, stable, and antisintering anode for direct-ammonia solid oxide fuel cells. Small 16, 2001859 (2020).

Meng, G., Jiang, C., Ma, J., Ma, Q. & Liu, X. Comparative study on the performance of a SDC-based SOFC fueled by ammonia and hydrogen. J. Power Sources 173, 189–193 (2007).

Hashinokuchi, M., Zhang, M., Doi, T. & Inaba, M. Enhancement of anode activity and stability by Cr addition at Ni/Sm-doped CeO2 cermet anodes in NH3-fueled solid oxide fuel cells. Solid State Ion. 319, 180–185 (2018).

Wan, Z., Tao, Y., Shao, J., Zhang, Y. & You, H. Ammonia as an effective hydrogen carrier and a clean fuel for solid oxide fuel cells. Energy Convers. Manage. 228, 113729 (2021).

Zhu, L. et al. Ammonia-fed reversible protonic ceramic fuel cells with Ru-based catalyst. Commun. Chem. 4, 121 (2021).

Müller, M., Pfeifer, M., Holtz, D. & Müller, K. Comparison of green ammonia and green hydrogen pathways in terms of energy efficiency. Fuel 357, 129843 (2024).

Wen, D. & Aziz, M. Techno-economic analyses of power-to-ammonia-to-power and biomass-to-ammonia-to-power pathways for carbon neutrality scenario. Appl. Energy 319, 119272 (2022).

Lin, Z., Li, D. & Zou, Y. Energy efficiency of lithium-ion batteries: influential factors and long-term degradation. J. Energy Storage 74, 109386 (2023).

Xie, Q. et al. Non-thermal atmospheric plasma synthesis of ammonia in a DBD reactor packed with various catalysts. J. Phys. D 53, 064002 (2020).

Li, S., van Raak, T. & Gallucci, F. Investigating the operation parameters for ammonia synthesis in dielectric barrier discharge reactors. J. Phys. D 53, 014008 (2020).

Hu, X., Zhu, X., Wu, X., Cai, Y. & Tu, X. Plasma-enhanced NH3 synthesis over activated carbon-based catalysts: effect of active metal phase. Plasma Process. Polym. 17, 2000072 (2020).

Wang, Y. et al. Plasma-enhanced catalytic synthesis of ammonia over a Ni/Al2O3 catalyst at near-room temperature: insights into the importance of the catalyst surface on the reaction mechanism. ACS Catal. 9, 10780–10793 (2019).

Liu, Y. et al. Synergistic effect of Co–Ni bimetal on plasma catalytic ammonia synthesis. Plasma Chem. Plasma Process. 42, 267–282 (2022).

Zhu, X. et al. Plasma-catalytic synthesis of ammonia over Ru-based catalysts: insights into the support effect. J. Energy Inst. 102, 240–246 (2022).

Acknowledgements

X.F. acknowledges support from the National University of Singapore start-up grant. P.X. acknowledges funding from National Key Research and Development Program of China (2023YFA1508103) and the National Natural Science Foundation of China (22278365). X.T. acknowledges funding from the European Union’s Horizon Europe Research and Innovation Programme under grant agreement no. 101083905 and the UK Research and Innovation Horizon Europe Guarantee Fund (no. 10055396).

Author information

Authors and Affiliations

Contributions

Introduction (X.F. and Z.W.); Ammonia as an energy carrier (X.F. and Z.W.); Ammonia synthesis under mild conditions (X.F., X.T., Z.W. and Y.W.); Ammonia decomposition for hydrogen production (P.X., K.W. and X.F.); Ammonia fuel cells (P.X., B.H. and X.F.); Overview of the review (X.F., P.X. and X.T.). All authors discussed and edited the full manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Reviews Clean Technology thanks Hoang-Long Du, Kwiyong Kim, Chenglin Yan and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wen, Z., Huang, B., Wang, Y. et al. Ammonia as a renewable energy carrier from synthesis to utilization. Nat. Rev. Clean Technol. 1, 755–770 (2025). https://doi.org/10.1038/s44359-025-00102-9

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s44359-025-00102-9