Abstract

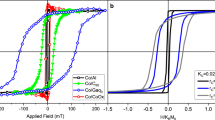

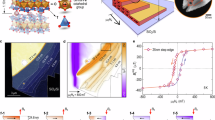

The stability of data bits in magnetic recording media1,2 at ultra-high densities is compromised by the thermal ‘flips’—magnetic spin reversals—of nano-sized spin domains3, which erase the stored information. Media that are magnetized perpendicular to the plane of the film, such as ultrathin cobalt films or multilayered structures4,5, are more stable against thermal self-erasure2,6 than conventional memory devices. In this context, magneto-optical memories seem particularly promising for ultrahigh-density recording on portable disks, and bit densities of ∼100 Gbit inch-2 (ref. 7) have been demonstrated using recent advances in the bit writing and reading techniques7,8,9,10,11. But the roughness and mobility of the magnetic domain walls12,13 prevents closer packing of the magnetic bits, and therefore presents a challenge to reaching even higher bit densities. Here we report that the strain imposed by a linear defect in a magnetic thin film can smooth rough domain walls over regions hundreds of micrometres in size, and halt their motion. A scaling analysis of this process, based on the generic physics of disorder-controlled elastic lines14,15,16,17, points to a simple way by which magnetic media might be prepared that can store data at densities in excess of 1 Tbit inch-2.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Daniel, E. D., Mee, C. D. & Clark, M. H. (eds) Magnetic Recording: The First Hundred Years (IEEE Press, New York, 1998).

Thompson, D. A. & Best, J. S. The future of magnetic data storage technology. IBM J. Res. Develop. 44, 311–322 (2000).

Hubert, A. & Schäfer, R. Magnetic Domains (Springer, New York, 1998).

Kirby, R. D., Shen, J. X., Hardy, R. J. & Sellmyer, D. J. Magnetization reversals in nanoscale films with perpendicular anisotropy. Phys. Rev. B 65, R10810–R10813 (1994).

Allenspach, R., Stampanoni, M. & Bischof, A. Magnetic domains in thin epitaxial Co/Au(111) films. Phys. Rev. Lett. 65, 3344–3347 (1990).

Weller, D. & Moser, A. Thermal effect limits in ultrahigh density magnetic recording. IEEE Trans. Magn. 35, 4423–4439 (1999).

Partovi, A. Optical near-field aperture storage technique for high density, high performance data storage applications. SPIE 3864, 352–354 (1999).

Awano, H. & Ohta, N. Magnetooptical recording technology toward 100 Gb/in2. IEEE J. Select. Topics Quantum Electron. 4, 815–820 (1998).

Betzig, E., Trautman, J. K., Harris, T. D., Weiner, J. S. & Kostelak, R. L. Breaking the diffraction barrier: optical microscopy on a nanometer scale. Science 251, 1468–1470 (1991).

Partovi, A. et al. High-power laser light source for near-field optics and its application to high-density optical data storage. Appl. Phys. Lett. 75, 1515–1517 (1999).

Kaneko, M. Magnetic multilayer films for high density magneto-optical recording. J. Magn. Magn. Mater. 148, 351–356 (1995).

Han, S. K., Yu, S.-C. & Rao, K. V. Domain wall jaggedness induced by the random anisotropy orientation in magneto-optic materials: A computer simulation study. J. Appl. Phys. 79, 4260–4264 (1996).

Lemerle, S. et al. Domain wall creep in an Ising ultrathin magnetic film. Phys. Rev. Lett. 80, 849–852 (1998).

Halpin-Healy, T. & Zhang, Y.-C. Kinetic roughening phenomena, stochastic growth, directed polymers and all that. Phys. Rep. 254, 215–414 (1995).

Hwa, T. From vortices to genomics. Nature 399, 17–18 (1999).

Blatter, G., Feigel'man, M. V., Geshkenbein, V. B., Larkin, A. I. & Vinokur, V. M. Vortices in high-temperature superconductors. Rev. Mod. Phys. 66, 1125–1388 (1994).

Krusin-Elbaum, L. et al. Superconductivity enhanced by Hg fission. Nature 389, 243–244 (1997).

Heanue, J. F., Bashaw, M. C. & Hasselink, L. Volume holographic storage and retrieval of digital data. Science 265, 749–752 (1994).

Binnig, G. K., Rohrer, H. & Vettiger, P. Mass-storage applications of local probe arrays. US Patent 5,835,477 (1998).

Nakamura, J., Miyamoto, M., Hosaka, S. & Koyanagi, H. High-density thermomagnetic recording method using a scanning tunneling microscope. J. Appl. Phys. 77, 779–781 (1995).

Argyle, B. E. & McCord, J. G. New laser illumination method for Kerr microscopy. J. Appl. Phys. 87, 6487–6489 (2000).

Weller, D. et al. Ion induced magnetization reorientation in Co/Pt multilayers for patterned media. J. Appl. Phys. 87, 5768–5770 (2000).

Deng, H., Jarratt, J. D., Minor, M. K. & Barnard, J. A. Artificially controlled stress anisotropy and magnetic properties of FeTaN thin films. J. Appl. Phys. 81, 4510–4512 (1997).

Feigel'man, M. V., Geshkenbein, V. B., Larkin, A. I. & Vinokur, V. M. Theory of collective flux creep. Phys. Rev. Lett. 63, 2303–2306 (1989).

Chuang, D. S., Ballentine, C. A. & O'Handley, R. C. Surface and step magnetic anisotropy. Phys. Rev. B 49, 15084–15095 (1994).

Acknowledgements

We thank J. Slonczewski, V. Vinokur, G. Blatter, and G. Zimanyi for useful discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Krusin-Elbaum, L., Shibauchi, T., Argyle, B. et al. Stable ultrahigh-density magneto-optical recordings using introduced linear defects. Nature 410, 444–446 (2001). https://doi.org/10.1038/35068515

Received:

Accepted:

Issue date:

DOI: https://doi.org/10.1038/35068515

This article is cited by

-

Spin-engineering magnetic media

Nature (2002)