Abstract

Bricks are widely used in ancient constructions throughout the world. However, weathering patterns such as cracking, flaking, and powdering are common among them and conservation interventions are thus necessary. In this paper, the alcoholic solution of calcium hydroxy glycolate was investigated as a novel protectant. It features good penetration and controllability. The consolidation of the bricks can be achieved by successively introducing the alcoholic solution of calcium hydroxy glycolate and water. The consolidation mechanism was studied by scanning electron microscopy, energy dispersive spectroscopy, Fourier transform infrared spectroscopy, X-ray diffraction, and thermogravimetric analysis. The protection effect was evaluated by determination of penetration depth, water absorption, porosity, water vapor permeability, mechanical strength, and color change. The results show that the consolidation is due to the reaction of calcium hydroxy glycolate with carbon dioxide in the air and active silicon in the brick (25 °C, RH = 60%, 1 atm). The cohesive calcite and calcium silicate phases are thus generated and weathering fragments are reunited together. After treatment, the mechanical strength and weathering resistance of the samples are improved greatly. The porosity, water absorption, and color, however, are affected insignificantly, indicating good compatibility. These satisfying results suggest a promising application prospect of the proposed method in the conservation of heritage brick constructions.

Similar content being viewed by others

Introduction

The weathering patterns such as cracking, flaking, and powdering are common among the bricks in the construction heritages1,2,3. They are, in essence, the results of natural weathering, including water erosion, freezing-thawing, salt crystallization, and so on4,5. These damages have been aggravated by the industrial emission of carbon, nitrogen, and sulfur oxides from the combustion of fossil fuels6. As a typical brick construction, Xi’an City Wall of Ming Dynasty is no exception. From the survey results shown in Fig. 1, the powdering and peeling damages of bricks can be observed.

In order to protect the brick construction heritages, both organic and inorganic materials have been tested in recent years. Organic polymers such as acrylic7, organic silicon8, epoxy9, and fluoropolymer resins10 have been proven to be effective in enhancing strength and waterproofing. Nonetheless, there are significant differences between organic polymers and inorganic bricks in chemical composition and physical properties. The unsuitable application of organic polymers even led to the accelerated weathering of construction heritages, which was called “protective destruction” by some conservators11,12. In addition, the service life of organic polymers is generally insufficient due to thermal, light, and microbial degradation in the open air13,14.

Owing to the similar chemical composition and physical properties, inorganic substances are regarded as more suitable for protecting brick constructions. Among them, the primary subjects were silicon and calcium materials. For example, the aqueous solution of silicate was studied as a protectant agent for weathered bricks15. Although effective, the co-introduction of massive soluble salts like potassium or sodium carbonate may lead to the risk of “salt damage”16. In contrast, no soluble salt products but only amorphous silica were generated when silica sol was used alternatively, showing better safety. However, its consolidation capacity is far from satisfactory17. Lime water was traditionally adopted as a protectant. However, due to its low solubility (0.02 mol/L at 20 °C18), lime water is inefficient as a consolidant. Frequently, over 150 penetration operations are essential for attaining a satisfactory consolidation outcome19. To solve this problem, the suspension of nano lime in alcohol solvent has been developed in recent years20. Its application concentration is as high as 0.07 mol/L, which is more than three times that of lime water. As a consequence, a much higher application efficiency can be achieved. However, the surface deposition of nano lime was usually found in practice, leading to the whitening of the treated objects21. This is primarily attributed to the aggregation of the nano lime, thereby resulting in the reduction of the suspension’s permeability22. So, high application concentration and permeability are both necessary for an ideal consolidant.

In this study, calcium hydroxy glycolate was explored as a novel consolidant for weathered ancient bricks. The alcoholic solution of calcium hydroxy glycolate has a solubility of 2.0 mol/L23, almost 30 times the suspension concentration of nano lime. Besides, the alcoholic solution of calcium hydroxy glycolate has a high permeability of up to 20 mm24, which exceeds the thickness of the weathered layer of most ancient bricks. In practice application, calcium hydroxy glycolate solution and water were introduced into the bricks in succession. The reactions among calcium hydroxy glycolate, water, carbon dioxide, and the active silicon within bricks give rise to cohesive C–S-H and calcite, which serve as consolidants. The consolidation mechanism was studied by scanning electron microscopy, energy dispersive spectroscopy, Fourier transform infrared spectroscopy, X-ray diffraction, and thermogravimetric analysis. Porosity, penetration depth, water vapor permeability, mechanical strength, and color change were used to verify the protective effect. The highly positive results indicate that calcium hydroxyl glycolate as a solution-treating agent exhibits a promising prospect in the conservation of bricks.

Laboratory experiments

Materials and methods

Samples

Calcium oxide, ethylene glycol, anhydrous ethanol, ammonium dihydrogen phosphate, magnesium nitrate hexahydrate, and phenolphthalein were all purchased from Sinopharm Chemical Reagent Co., Ltd, China. All of them were analytical grade and used without further purification. Deionized water was used in the experiments. The brick powder with a particle size of 0.07–0.10 mm was prepared from the local abandoned old gray bricks. The composition of the brick powder was analyzed using an X-ray fluorescence spectrometer (XRF, Bruker, Germany). The results in Table 1 indicate that the main components of the sample are SiO2, Fe2O3, and Al2O3.

Simulated weathering samples were prepared according to the literature17: first, distilled water was evenly mixed with brick powder by a ratio of 1 to 5. Then, the mixture was placed into cylindrical molds (⌀30 mm) and compacted with a hydraulic machine (QYL 20 T, Haiyan Guangyao Hydraulic Technology Co., Ltd., Zhejiang, China) at a pressure of 0.2 MPa. The size of Φ30 mm × 8 mm was used for performance experiments, while the size of Φ30 mm × 20 mm was used for phenolphthalein test. Finally, the sample was taken out and dried naturally (25 °C, RH = 50%) to a constant weight prior to use.

Preparation of consolidant

Calcium hydroxy glycolate was synthesized through the reaction of calcium oxide and ethylene glycol. According to the literature23, 2.24 g of calcium oxide and 20 ml of ethylene glycol were left to react at 25 °C for 5 h, then centrifuged at 8000 rpm for 8 min to obtain a clear solution of calcium hydroxy glycolate, as shown in Fig. 2a.

Consolidation treatment

As shown in Fig. 2b, the brick sample was treated with 2 mL of calcium hydroxy glycolate solution from the front side, and the treatment area was ~2.25π cm2. Two days later (for the evaporation of ethanol), 1 mL of distilled water was added. The interval between two drip infiltration was 5 days. The samples treated by 1–4 times were recorded as T1, T2, T3, and T4, respectively. After the consolidation treatment, the samples were left to stand under conditions (25 °C, RH = 60%) for 14 days.

Characterization

Composition and structure

The morphology of samples was observed by scanning electron microscopy (SEM, VEGA-3XMU, TESCAN, Czech Republic, SE mode 20 kV). The elemental composition and distribution were examined by X-ray fluorescence spectrometer (XRF, Bruker, Germany) and energy spectroscopy (EDX, Genesis 2000 XMS, EDAX, USA). The crystal phase of the samples was determined using an X-ray diffractometer (XRD, scanning range 5–90°, step length 0.01°, scanning speed 10° min−1, voltage 40 kV, current 150 mA). Fourier transform infrared spectroscopy (FT-IR, Bruker, Germany, scanning wave number 4000–500 cm−1, resolution 4 cm−1, scanning times 16 times) was used to analyze the composition of the samples. A thermogravimetric analyzer (TGA-DSC3 + , METTLER TOLEDO, USA, N2 atmosphere 50.0 ml min−1, heating rate of 10 K min−1, from 30 to 1000 °C) was used to investigate the composition and content of the samples.

Conservation effect assessment

The surface hardness of the samples was measured using a hardness tester (LX-D-1, Dongguan Sanliang Measurement Co., Ltd., Dongguan, China), and the test point was taken at the center of the sample.

Surface cohesion of the sample was assessed by scotch-tape test (STT). The tape was 2.5 cm wide. The surface of each sample was successively adhered five times, and the mass variations of the tape were recorded. Stripping mass per unit area of the tape was negatively correlated to the surface cohesion of the samples.

Strength variation of samples across the thickness was measured by a drilling resistance measurement system (DRMS Cordless, Italy). The drilling rate was 5 mm/min and the rotation speed was 100 rpm.

Water absorption, porosity, and density were determined using a densitometer (MZ-C300, Mayzun, Shenzhen, China). Water absorption (W), open porosity (P) and density (D) was calculated as:

where m0 refers to the weight of the dry sample. m1 is the suspended weight of a saturated sample in water. m2 is the weight of the fully saturated sample.

Water vapor permeability was tested by the wet cup method25: The containers were filled with saturated ammonium dihydrogen phosphate solution, and the gap between the samples and the container was sealed with plastic wrap so that water vapor could only be exchanged through the samples. The device was placed in a closed laboratory environment and weighed at a 24 h interval for 7 days. Water vapor transmission rate W and the moisture permeability coefficient δ were calculated as:

where G refers to the water vapor flow rate, that is, the mass change per unit time. G was calculated as G = ∆m/∆t. A is the area of moisture permeability (2.25 πcm2). PS is the experimental ambient saturated vapor pressure (2.335 × 103 Pa). R1 is the ambient relative humidity inside the cup containing ammonium dihydrogen phosphate solution (93%), R2 is the ambient relative humidity, which was controlled by a saturated magnesium nitrate hexahydrate solution (50%) and d is the thickness of the sample (8 mm).

Color change of samples was investigated by a colorimeter (WSC-2B, Shanghai INESA Optical Instrument Co., Ltd.). The overall color difference (ΔE) was calculated as follows:

The salt resistance of samples was tested according to the literature method26: samples were immersed in a mixture of 5% sodium chloride and 5% sodium sulfate for 2 h and then dried in an oven at 105 °C for 16 h. The operation was repeated for 15 cycles.

Freeze–thaw resistance was evaluated using the method described in the literature27: samples were first soaked in water for 24 h, then frozen at −20 ± 2 °C for 3 h, and finally thawed in water at 20 ± 2 °C for 3 h. The 6 h were counted as one freeze–thaw cycle. The procedure mentioned above was repeated 15 times.

For each parameter, five parallel samples were tested throughout the experiment, and the average value was reported.

Results and discussion

Conservation mechanism

The surface morphology of the samples before and after treatment was observed by SEM. As shown in Fig. 3a, the surface of the blank sample is rough, loose, and porous, exhibiting a typical state of severe weathering28. After consolidation treatment with calcium hydroxy glycolate solution, the large pores are filled (with small hole retention). The loose fragments are integrated by some gel-like materials, resulting in a compact surface of the sample (Fig. 3b). This can also be observed in the polished cross-section images of the samples in Fig. 3c, d. Obviously, these changes are mainly due to the introduction of the calcium hydroxy glycolate protectant, which leads to the generation of the new gel-like continuous phase. The final state of protectant is closely related to the consolidation effect. In the case of isolated particles, only the pore-filling effect can be obtained, and the consolidation one is not pronounced generally29. In contrast, both the pore filling and integral consolidation can be gained for the state of continuous phase30. Due to the bridging function of the continuous phase, the weathering particles are integrated31. The composition and formation mechanism of the gel-like continuous phase will be discussed later in detail.

Figure 4 shows the EDX plane scanning results of the samples. Si, Al, Fe, O, and Ca elements are identified in the blank brick sample, which is consistent with the results of the XRF analysis. After treatment with calcium hydroxy glycolate protectant, the at% of Si is reduced from 20.38 to 9.23%, while the one of Ca is significantly increased from 0.59 to 5.02%. The uniform distribution of Ca in Fig. 4b, f indicates the homogenous introduction of calcium hydroxy glycolate protectant. In addition, the at% of C is also increased from 5.14 to 17.11% exhibiting uniform distribution of the sample surface, which may be due to the carbonization of calcium hydroxy glycolate. According to Wang et al.23, calcium carbonate is from the reaction between calcium hydroxy glycolate and carbon dioxide in the air. The reduce of Si in at% is mainly due to the increase of Ca and C.

To investigate the distribution of the calcium hydroxy glycolate protectant along the cross-section of the sample, the SEM elemental maps were conducted, and the results are shown in Fig. 5. In contrast to the untreated sample (Fig. 5c–f), Ca, C, and O elements increased and distributed evenly throughout the treated samples (Fig. 5g–j). The one of Si is reduced accordingly. These results indicate the good penetration of the calcium hydroxy glycolate solution, which can be proved further by the result of the phenolphthalein test in Fig. 6. Figure 6a is the cross-section of the blank sample. After infiltration treatment by calcium hydroxy glycolate solution, the sample was cut open, and its cross-section became wet and exhibited a darker appearance (Fig. 6b). Through further treatment by phenolphthalein, the red color appeared throughout the cross-section in Fig. 6c, more clearly showing the penetration depth of calcium hydroxy glycolate solution in the sample. The solution nature and the suitable reactivity of calcium hydroxy glycolate are mainly responsible for the good permeability. First, the solute and solvent in the solution are both small molecules, giving an innate advantage of high permeability for the solutions, especially when alcohol is used as a solvent. Second, calcium hydroxy glycolate can remain in the solution state within 24 h at 60% RH23, since it is inert in the air but reacts with carbon dioxide in the presence of enough water, which makes it a good permeating agent. The good permeability of the protectants is vital for consolidation treatment, for it can prevent the stress damage caused by the accumulation of the consolidants on the surface layer of the objects32.

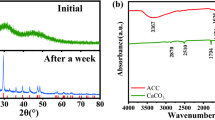

FT-IR analysis was performed to confirm the composition of samples. In Fig. 7ai, the asymmetric and symmetric stretching vibrations of the Si–O bond at 1078 cm−1, 1163 cm−1, 792 cm−1, 774 cm−1, and 690 cm−1 (see ref. 33) indicate that silicon dioxide is the main component of the brick sample34. After infiltration treatment, new absorption peaks are present in Fig. 7aii. The broad band at 3350 cm−1 is ascribed to the O–H stretching of the hydroxyl group35. The absorption peaks at 2879 cm−1, 2947 cm−1, and 874 cm−1 come from the C–H stretching vibration of the ethyl group36. The absorption peaks at 1086 cm−1 and 1041 cm−1 correspond to the C–O single bond of glycolate37. These results confirm the successful introduction of calcium hydroxy glycolate consolidant into the brick sample. In addition, the peaks at 1647 cm−1 and 1300 cm−1 are the characteristic adsorptions of calcium alkyl carbonate. According to the study of Wang et al.23, calcium alkyl carbonate is the product of the insertion of CO2 into the Ca–O bond of calcium hydroxy glycolate. As shown in Fig. 7aiii, 15 days later after the treatment, the characteristic peaks of calcium hydroxy glycolate are invisible. New asymmetric stretching ν3, out-of-plane bending ν2, and in-plane bending vibrations ν4 of the C–O bond from CO32− at 1442 cm−1, 874 cm−1, and 712 cm−1 appear, indicating the presence of calcium carbonate25. Calcium carbonate is the hydrolysis product of calcium alkyl carbonate38. Compared with the blank samples in Fig. 7ai, the asymmetric and symmetric stretching vibrations of the Si–O bond are broadened and shifted to a lower wavelength. These changes are common when silica and alkaline calcium are used as the precursors of C–S–H. In this case, both calcium hydroxy glycolate and its hydrolysis product of calcium hydroxide are alkaline. Calcium hydroxide even has a pH of 12.5 at room temperature and can combine with active silicon in the brick and generate C–S–H39. The adsorption bands near 515 cm−1 from the internal deformation vibration of SiO4 tetrahedra further prove the presence of C–S–H40.

The XRD results of the blank and treated samples are shown in Fig. 7b. The main mineral composition of the blank sample is quartz, with typical characteristic peaks at 20.9°, 26.6°,36.5°, 39.5°, 40.3°, 42.5°, 45.8°, 50.1°, 54.9°, 60°, and 68.14°41. After treatment, the new characteristic peaks at 29.2°, 32.1°, 50.1°, and the enhancement of the background diffraction peak in the range of 5–30° indicate the presence of C–S–H42,43. The characteristic peaks at 23.1°, 29.4°, 35.9°, 39.4°, and 43.2° are from the calcite type of calcium carbonate38. The XRD results for C–S-H and calcium carbonate products are consistent with the ones of FT-IR.

To identify the reaction products more clearly, thermal analysis was performed, and the results are shown in Fig. 8. Samples before and after treatment both show a small drop at around 100–150 °C, which is attributed to the elimination of physically bonded water41. The weight loss occurring in the ranges 577–684 °C is due to the decomposition of calcium carbonate44. In contrast, the change in mass for the treated sample is more pronounced within this range. It is due to the introduction of calcium carbonate from the carbonation of calcium hydroxy glycolate protectant. Similarly, the gravimetric loss rate and exothermic peaks of the treated samples are more pronounced between 870 and 980 °C, indicating that C–S–H is also the reaction product of the consolidant45. These results can be verified mutually with the FT-IR results in Fig. 7. In the study of Yi et al.46, C–S–H was also found to be the product of the pozzolanic reaction between lime and soil. However, the reaction is very slow because of the weak activity of the silica in the soil. In contrast, the pozzolanic reactivity of the silica in brick is enhanced remarkably after high-temperature firing41. So, in this case, the formation of C–S–H is faster and more significant.

Conservation effect evaluation

The mechanical properties of the samples were characterized by surface hardness, adhesion resistance, and drilling resistance. Figure 9a shows the surface hardness results before and after treatment. The surface hardness of the blank samples is only 0.3 HD, which is increased to 21.3 HD, 32.2 HD, 46.6 HD, and 47.9 HD after 1–4 times of treatment, respectively.

Figure 9b shows the outcomes of the STT test. The amount of stripping per unit area can reflect the cohesion of the samples to be tested. For blank samples, the stripping amount is 3.41 mg/cm2. It is reduced gradually with the increase of the treating times. For example, when the treatment reaches 4 times, it is merely 0.67 mg/cm2, decreasing up to 80%.

The drilling resistance results are shown in Fig. 9c. The average drilling resistance of the untreated brick sample is 0.42 N. After consolidation treatment of 1–4 times, it increases to 4.75 N, 5.94 N, 8.37 N, and 9.66 N, respectively.

The above results show that the mechanical properties of samples can be effectively enhanced. This is due to the introduction of calcium carbonate and C–S–H consolidants. On one hand, the weathering pores and cracks47 in the sample are filled. On the other hand, the weathering fragments are reintegrated. As shown in the SEM results in Fig. 3, a denser structure is obtained, showing the desirable consolidation effect48.

Water absorption, open porosity and density of the samples were tested for compatibility evaluation, and the results are shown in Table 2. For the blank sample, the porosity and water absorption are 40.51% and 29.73%. After consolidation treatment by 1–4 times, the water absorption of the samples decreases to 28.19%, 28.02%, 27.44%, and 26.72%, respectively. As for the porosity, the variation trend is almost synchronized. It is reduced to 40.08%, 39.85%, 39.72%, and 39.10%, respectively. Accordingly, the density of the samples shows an increasing trend. As mentioned earlier, the alterations stem from the generation of C–S–H and calcium carbonate. In general, low porosity and water absorption are beneficial for bricks, which means a better resistance to water-related damage.

Water vapor permeability is one of the basic properties of bricks49. From Table 2, the water vapor permeability coefficient (δ) of the blank sample was 8.78 × 10−8 g/(m⋅s⋅Pa), which is consistent with its high porosity. After 1–4 times of treatment, it decreases to 8.18 × 10−8 g/(m⋅s⋅Pa), 7.99 × 10−8 g/(m⋅s⋅Pa), 7.79 × 10-8 g/(m⋅s⋅Pa) and 7.50 × 10−8 g/(m⋅s⋅Pa), respectively. The decrease in vapor diffusion is actually the consequence of the consolidation treatment50. Due to the generation of calcium carbonate and C–H–S, the samples become denser in structure. Fortunately, the decrease in δ is less than 15%, indicating that the water vapor exchange capacity of the sample is not significantly affected51 and the “breathing function” is maintained52.

Figure 10 shows the color difference of the samples. The maximum value of ∆L for the treated samples is 2.27, and the minimum one is 1.60, while Δa and Δb are both less than 0.5. It is stated that the loss of brightness is the most significant factor in the appearance change of the samples. ΔE between the treated samples and the blank ones are all less than 3.0, which is below the visible threshold of the human eyes53. Besides, ΔE among the samples after different treating cycles is tiny, which allows the selection of suitable consolidation dosages according to the actual protection requirement.

Weather resistance evaluation

Salt-resistance test

The salt-resistance results of the samples are shown in Fig. 11. From Fig. 11a, the blank sample disintegrates after the first immersion in saline solution, indicating poor water resistance. After 1–3 times of consolidation treatment, the salt resistance of the samples increases gradually. The sample treated three times can maintain its original shape even after 15 cycles of testing. However, the sample treated by four times shows a decrease in salt resistance. It begins to disintegrate after 15 cycles of testing. It may be due to the excessive introduction of the consolidant54.

Analysis of data from Fig. 11b shows a mass loss of 72% for the sample after one treatment, while that of the sample treated two times is 42%. After three treatments, the sample has a slight weight increase, which may be due to the uptake of the soluble salts55. The mass loss of 36% of the sample treated four times is from its disintegration. Consequently, it is essential to select a suitable dosage of consolidant, especially in a high-salt environment56. After the test of salt resistance, the color differences of samples are all below 5, showing an acceptable appearance change in the field of cultural relic conservation.

Freeze–thaw test

The results of the freeze–thaw test of samples are shown in Fig. 12. From Fig. 12a, the blank sample collapses totally in the immersion test and has little resistance to water. The consolidation treatment can improve the freeze–thaw resistance of the samples greatly. The samples treated three times even can remain intact after 15 freeze–thaw cycles. However, four times of treatment brings a negative effect, and cracks appear after 5 cycles of testing. So, the excessive usage of the consolidant should be avoided57.

The changes in mass and color of the samples are shown in Fig. 12b. The trend of mass loss is highly consistent with the ones of the appearance integrity for the samples. The sample treated by three times has the least mass loss of 0.5% even after 15 cycles of test, exhibiting the best performance in freeze–thaw resistance. Meanwhile, the color differences (ΔE) of the samples are all less than 3.0 and cannot be recognized by the naked eye, showing ideal aesthetic compatibility21.

Application

The Xi’an City Wall was built in the early Ming Dynasty. The weathered brick of Xi’an City Wall was treated with calcium hydroxy glycolate solution for in situ consolidation. It can be seen from Fig. 13 that the brick becomes slightly denser after treatment (135×). The color difference ΔE is 2.21, indicating that the treatment cannot affect the original appearance of the brick. This concurs with laboratory simulation outcomes and proves that the method is feasible for practical application.

Conclusion

In this study, a novel consolidant of calcium hydroxy glycolate was explored and evaluated for the conservation of the weathered brick construction heritages. Its action mechanism and performance were investigated, and the conclusion can be drawn as follows.

First, the consolidation mechanism is from the reaction of calcium hydroxy glycolate with the brick, carbon dioxide and water. The resultant cohesive calcium carbonate and C–S-H can fill the weathering pores and cracks, reestablish the bond between the weathered fragments and act as a consolidant.

Second, the reactions between calcium hydroxy glycolate, carbon dioxide, and brick can only be triggered by the introduction of enough water. This indicates that the introduction of protectants and the consolidation of the bricks can be separated, showing a good controllability of the conservation method.

Last but not least, the strength and weathering resistance of the samples can be improved significantly. Meanwhile, the inherent physical properties such as porosity, water vapor permeability and appearance are not affected significantly, showing good compatibility and treating repeatability.

Therefore, this study provides important insight for the development of new consolidants and the proposed calcium hydroxy glycolate consolidant holds a broad application prospect in the field of brick heritage conservation.

Data availability

No datasets were generated or analysed during the current study.

References

Vijayan, D. S., Mohan, A., Revathy, J., Parthiban, D. & Varatharajan, R. Evaluation of the impact of thermal performance on various building bricks and blocks: a review. Environ. Technol. Innov. 23, 101577 (2021).

Ma, S., Wu, Y. & Bao, P. Experimental study on the properties of modern blue clay brick for Kaifeng People’s Conference Hall. Sci. Rep. 11, 20631 (2021).

Pu, J. J., Zhang, Y., Wang, S., Yang, X. G. & Zhang, M. L. Characterization of the superficial weathering of bricks on the City Wall of Xi’an, China. Constr. Build Mater. 149, 139–148 (2017).

Matsukura, Y., Oguchi, C. T. & Kuchitsu, N. Salt damage to brick kiln walls in Japan: spatial and seasonal variation of efflorescence and moisture content. Bull. Eng. Geol. Environ. 63, 167–176 (2004).

Yuan, Y. et al. Evaluation of the organosilicon materials for ancient grey bricks preservation. Int. J. Conserv. Sci. 9, 641–652 (2018).

Ottosen, L., Damoe, A. & Rörig-Dalgaard, I. Salt-related problems in brick masonry and electrokinetic removal of salts. J. Build. Appraisal 3, 181–194 (2007).

Singh, T. D., Prakash, S. & Manohar, S. Assessment of the performance and compatibility of acrylic polymer and silane based consolidants on deteriorated heritage masonry units subjected to salt weathering. J. Build 77, 107490 (2013).

Franzoni, E., Pigino, B., Leemann, A. & Lura, P. Use of TEOS for fired-clay bricks consolidation. Mater. Struct. 47, 1175–1184 (2013).

Zhou, Y., Zhang, F. & Wang, S. L. Structural protection of ancient masonry pagodas based on modified epoxy resin infiltration. J. N. Mat. Electr. Syst. 23, 13–19 (2020).

He, L., Zhen, G. & Zhou, W. Q. The deterioration and consolidation of Dayan Pagoda and Famen Temple. Sci. Conserv. Archaeol. 16, 33–39 (2004).

Liu, Q. & Zhang, B. J. Assessment of damage from organic protective coating treatments to historic stone buildings and sculptures. Appl. Mech. Mater. 44-47, 610–613 (2011).

Chen, Z. R. et al. Application of epoxy resin in cultural relics protection. Chin. Chem. Lett. 35, 109194 (2024).

Moustafa Ibrahim, M., Mohamed, W. & Mohamed, H. Evaluation of the efficacy of traditional and nano paraloid B72 for pottery consolidation. Int. J. Conserv. Sci. 13, 15–30 (2022).

Zhang, H., Liu, Q., Liu, T. & Zhang, B. J. The preservation damage of hydrophobic polymer coating materials in conservation of stone relics. Prog. Org. Coat. 76, 1127–1134 (2013).

Li, G. H., Zhou, S. L. & Wu, W. Conservation materials for the Pagoda Forest in the Shaolin Temple, Henan, China. Stud. Conserv. 59, S246–S247 (2014).

Lourenço, P. B., van Hees, R., Fernandes, F. & Lubelli, B. Characterization and damage of brick masonry. Structural Rehabilitation of Old. Buildings 2, 109–130 (2013).

Fang, X. X., Zhang, B. J., Li, J. J., Hu, L. L. & Chen, W. X. A significant comparison between magnesium-based binder and other inorganic cementitious materials for the restoration of brick-carved cultural relics. Constr. Build Mater. 411, 134788 (2024).

Girginova, P. I., Galacho, C., Veiga, R., Santos Silva, A. & Candeias, A. Inorganic nanomaterials for restoration of cultural heritage: synthesis approaches towards nano consolidants for stone and wall paintings. ChemSusChem 11, 4168–4182 (2018).

Slížková, Z., Drdácký, M. & Viani, A. Consolidation of weak lime mortars by means of saturated solution of calcium hydroxide or barium hydroxide. J. Cult. Herit. 16, 452–460 (2015).

Navarro-Moreno, D. et al. Nanolime, ethyl silicate and sodium silicate: advantages and inconveniences in consolidating ancient bricks (XII-XIII century). Constr. Build Mater. 277, 122240 (2021).

Borsoi, G., Lubelli, B., van Hees, R., Veiga, R. & Silva, A. S. Optimization of nanolime solvent for the consolidation of coarse porous limestone. Appl Phys. A 122, 846 (2016).

Borsoi, G., Lubelli, B., van Hees, R., Veiga, R. & Silva, A. S. Evaluation of the effectiveness and compatibility of nanolime consolidants with improved properties. Constr. Build Mater. 142, 385–394 (2017).

Wang, L. et al. Preparation of infiltrating calcium carbonate layer in gypsum substrate using novel calcium precursor: the implication for the protection of the surface weathered carbonate heritages from water erosion damage. Surf. Interfaces 44, 103685 (2024).

Daniele, V. & Taglieri, G. Synthesis of Ca (OH)2 nanoparticles with the addition of Triton X-100. Protective treatments on natural stones: Preliminary results. J. Cult. Herit. 13, 40–46 (2012).

Liu, Z. D., Zhu, L. G. & Zhang, B. J. In-situ formation of an aluminum phosphate coating with high calcite-lattice matching for the surface consolidation of limestone relics. Constr. Build Mater. 392, 131836 (2023).

Han, X., Rong, B., Huang, X. & Luo, H. Bridged siloxanes as novel potential hybrid consolidants for ancient Qin terracotta. Prog. Org. Coat. 101, 416–422 (2016).

Yue, J. W. et al. Study on deterioration of Gray Brick with different moisture contents under freeze-thaw environment. Materials 15, 1819 (2022).

Cultrone, G. & Sebastián, E. Laboratory simulation showing the influence of salt efflorescence on the weathering of composite building materials. Environ. Geol. 56, 729–740 (2008).

Sena da Fonseca, B., Ferreira Pinto, A. P., Piçarra, S. & Montemor, M. F. Alkoxysilane-based sols for consolidation of carbonate stones: proposal of methodology to support the design and development of new consolidants. J. Cult. Herit. 43, 51–63 (2020).

Chen, W. W., Zhang, Y. M., Zhang, J. K. & Dai, P. F. Consolidation effect of composite materials on earthen sites. Constr. Build Mater. 187, 730–737 (2018).

Sena da Fonseca, B., Ferreira Pinto, A. P., Rodrigues, A., Rucha, M. & Montemor, M. F. Ability of novel consolidants to improve cohesion of carbonate stones: dependence on pore-shape, aging conditions and treatment procedures. J. Cult. Herit. 55, 95–106 (2022).

Franzoni, E. et al. Solvent-based ethyl silicate for stone consolidation: influence of the application technique on penetration depth, efficacy and pore occlusion. Mater. Struct. 48, 3503–3515 (2015).

Chen, H. S., Sun, Z. Y. & Shao, J. C. Investigation on FT-IR spectroscopy for eight different sources of SiO2. Bull. Chin. Ceram. Soc. 30, 934–937 (2011).

Li, T. Z. et al. Methyl-modified silica hybrid fluorinated Paraloid B-72 as hydrophobic coatings for the conservation of ancient bricks. Constr. Build Mater. 299, 123906 (2021).

Das, P., Das, P. K. & Arunan, E. Conformational stability and intramolecular hydrogen bonding in 1, 2- ethanediol and 1, 4-butanediol. J. Phys. Chem. A 119, 3710–3720 (2015).

Rodriguez-Navarro, C., Vettori, I. & Ruiz-Agudo, E. Kinetics and mechanism of calcium hydroxide conversion into calcium alkoxides: Implications in heritage conservation using nanolimes. Langmuir 32, 5183–5194 (2016).

Ossola, F. et al. New calcium alkoxides for consolidation of carbonate rocks. Influence of precursors’ characteristics on morphology, crystalline phase and consolidation effects. N. J. Chem. 36, 2618–2624 (2012).

Wang, L. et al. A novel immersive calcium carbonate coating for conservation of limestone relics with gypsum crust. N. J. Chem. 46, 15967–15974 (2022).

Dodson, V. H. Pozzolans and the pozzolanic reaction. Concr. Admix. 7, 159–201 (1990).

Yu, P., Kirkpatrick, R., Poe, B., McMillan, P. & Cong, X. Structure of calcium silicate hydrate (C‐S‐H): near‐, mid‐, and far‐infrared spectroscopy. J. Am. Ceram. Soc. 82, 742–748. (2004).

Navrátilová, E. & Rovnaníková, P. Pozzolanic properties of brick powders and their effect on the properties of modified lime mortars. Constr. Build Mater. 120, 530–539 (2016).

Wu, J. F., Liao, H. Q., Ma, Z. H., Song, H. P. & Cheng, F. Q. Effect of different initial CaO/SiO2 molar ratios and curing times on the preparation and formation mechanism of calcium silicate hydrate. Materials 26, 717 (2023).

Chang, J., Fang, Y. F. & Li, Y. Effects of calcium to silicon ratios on accelerating carbonation of calcium silicate hydrate. J. Chin. Ceram. Soc. 42, 1377–1382 (2014).

Maddalena, R., Li, K., Chater, P. A., Michalik, S. & Hamilton, A. Direct synthesis of a solid calcium-silicate-hydrate (C-S-H). Constr. Build Mater. 223, 554–565 (2019).

Miao, J. S., Li, X. Y., Cheng, R. K. & Lu, B. S. A preliminary investigation of cementing materials used in ancient China. J. Chin. Ceram. Soc. 9, 120–126 (1981).

Yi, S. Y., Wei, G. F., Zhang, B. J. & Liu, X. B. Experimental study on the recipes of the traditional Tabia of China. J. Northwest Minzu Univ. (Nat. Sci.) 40, 31–41 (2019).

Thiry, M., Fernandes, P., Milnes, A. & Raynal, J. P. Driving forces for the weathering and alteration of silica in the regolith: implications for studies of prehistoric flint tools. Earth Sci. Rev. 136, 141–154 (2014).

Theodoridou, M., Charalambous, E., Maravelaki-Kalaitzaki, P. & Ioannou, I. Amelioration of crushed brick-lime composites using nano-additives. Cem. Concr. Compos 68, 77–87 (2016).

Dean, S. et al. Correlation between water vapor and air permeability of building materials: experimental observations. J. ASTM Int. 8, 102924 (2011).

Anna, A. & Giuseppe, C. The water transfer properties and drying shrinkage of aerial lime-based mortars: an assessment of their quality as repair rendering materials. Environ. Earth Sci. 71, 1699–1710 (2014).

Zhao, J. et al. TEOS/PDMS-OH hybrid material for the consolidation of damaged pottery. Herit. Sci. 1, 12 (2013).

Defreece Emery, S. N. & Charola, A. E. Coatings on Brick Masonry: are they protective or can they enhance deterioration? J. Am. Inst. Conserv. 46, 39–52 (2007).

García, O. & Malaga, K. Definition of the procedure to determine the suitability and durability of an anti-graffiti product for application on cultural heritage porous materials. J. Cult. Herit. 13, 77–82 (2012).

Manohar, S., Santhanam, M. & Chockalingam, N. Performance and microstructure of bricks with protective coatings subjected to salt weathering. Constr. Build Mater. 226, 94–105 (2019).

Guo, S. Y. et al. Conservation of the weathering bricks in historical buildings using the alcoholic solution of barium hydroxide. Constr. Build Mater. 452, 138887 (2024).

Benavente, D., Cueto, N., Martínez-Martínez, J., García del Cura, M. A. & Cañaveras, J. C. The influence of petrophysical properties on the salt weathering of porous building rocks. Environ. Geol. 52, 215–224. (2007).

Graziani, G., Sassoni, E. & Franzoni, E. Experimental study on the salt weathering resistance of fired clay bricks consolidated by ethyl silicate. Mater. Struct. 49, 2525–2533 (2015).

Acknowledgements

This study was supported by the Natural Science Foundation of China (B050121975202, 52108031), the Shaanxi Provincial Natural Science Foundation General Program (2023-JC-YB-097), and the Open Project of the Academic Prosperity Program of Archaeology of Northwest University in 2022.

Author information

Authors and Affiliations

Contributions

Conceptualization: F.Y.; methodology: F.Y. and H.Y.; validation: H.Y.; formal analysis: H.Y., L.W., and Z.W.; investigation: H.Y., G.H., and Y.X.; resources: G.H., Y.X., F.Y., Y.L., and K.Z.; data curation: H.Y. and L.W.; writing—original draft preparation: H.Y.; writing—review and editing: F.Y., H.Y., Y.L., and M.S.; supervision: F.Y., G.H., and Y.X.; project administration: F.Y.; funding acquisition: G.H., Y.X., F.Y., and Z.W. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yang, H., Wang, L., Wang, Z. et al. Conservation of the weathered bricks in ancient constructions using a novel protectant of calcium hydroxy glycolate. npj Herit. Sci. 13, 81 (2025). https://doi.org/10.1038/s40494-025-01570-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s40494-025-01570-9