Abstract

Salt weathering significantly degrades building materials, necessitating a thorough understanding of influencing factors. While prior research has focused on relative humidity (RH), temperature effects on salt crystallisation and dissolution remain less explored. This study examines selected single salts and mixtures, using the ECOS/RUSALT thermodynamic model to assess equilibrium behaviour across temperatures from 1 °C to 50 °C and RH values from 15% to 98%. Results show that crystallisation and dissolution RH generally decrease with rising temperature. Single salts exhibit monotonic changes, whereas mixtures behave variably. Calcium-rich mixtures have lower mutual crystallisation and dissolution RH than sulfate-rich ones, with further reductions in magnesium-containing mixtures. Lower temperatures promote the formation of more output salts. Model limitations are acknowledged to explain discrepancies between predictions and real-world observations. These findings enhance understanding of salt behaviour under climatic variations, aiding strategies to mitigate salt damage in building materials.

Similar content being viewed by others

Introduction

The cumulative impact of salt mixtures on architectural heritage is undeniable, as evidenced by the wide range of damage observed1. The loss of structural integrity, surface deterioration, and erosion of intricate architectural details paint a grim picture of the consequences of salt-induced deterioration2,3. The loss of original architectural details is a distressing consequence of salt-induced deterioration. Intricate carvings, mouldings, and ornate features that define the historical character of buildings can be eroded by the corrosive action of salts. Salt solutions can enter the smallest crevices, expanding upon recrystallisation and gradually wearing away delicate elements that once showcased the artistry of craftsmen4,5.

Salt mixtures significantly contribute to the degradation of various construction materials in heritage and architectural contexts, for example, affecting stone structures in coastal areas where salt deposition (with over 85% of the composition being NaCl) occurs primarily through the deposition of marine aerosols6. Additionally, salt efflorescence, resulting from moisture-carrying salts migrating to surfaces during evaporation, impacts materials such as bricks and mortar7,8, even unavoidably affecting contemporary buildings9. Furthermore, the “salt attack" poses a significant threat to concrete structures in regions with saline soils, where salts migrating through materials compromise structural integrity, leading to microcracks and corrosion10,11. There are also other important sources of salts except sea salt. For example, salts from the ground transported with rising damp are not a problem of cement structures in saline soils but are frequently found in old buildings2,12. Also, air pollution with pollutants such as sulfur dioxide and nitrogen oxides is an important source leading to salt accumulation when reacting with the materials such as stone and brick13.

To mitigate these effects and ensure the preservation of architectural heritage, a holistic understanding of salt mixture behaviour, coupled with innovative conservation strategies, is imperative. The recent cases highlighted underscore the urgency of implementing proactive conservation strategies14,15. By integrating monitoring, preventive measures, and innovative restoration techniques, architectural heritage can be safeguarded for the enrichment of future generations. The urgency of addressing salt-related challenges becomes apparent when considering the monumental loss of the world’s architectural legacy caused by these pervasive mixtures.

Other studies focus on the variation of RH at a fixed temperature, but in reality, a combination of RH and temperature fluctuations is relevant. It is true that temperature has been of less concern, but often with some salts, the effect is large so cannot be neglected16. The aim of this study is to identify and understand the crystallisation and dissolution behaviour of common salt mixtures found in the built environment under various climatic conditions. Specific focuses include exploring the effect of temperature on crystallisation behaviour, and comparing behaviour of single salts and mixtures.

Methods

Data preparation

Four frequently occurring mixtures, as identified by Godts et al.17, were selected to investigate salt mixture behaviour. These mixtures include sodium (Na+), potassium (K+), nitrate (NO3−), chloride (Cl−), and calcium (Ca2+)) or sulfate (SO42−)), and may include or exclude magnesium (Mg2+). The ion mixtures were identified through ion chromatography analysis of 11,412 drill samples conducted by the Monuments Laboratory of the Royal Institute for Cultural Heritage (KIK-IRPA)18. These samples originated from 338 different monuments, archaeological sites, mural paintings, and sculptures, mostly located in Belgium and primarily constructed between the 10th and 20th centuries. The associated building materials included traditional brick, lime-based mortar, natural stone, cement, and plaster. The salt compositions were compiled using ion data expressed as mole fractions to derive mean ion values, which facilitated the comparison between mixtures with different total moles (Table 1). From these mixtures, ten common salts were selected to compare their crystallisation and dissolution behaviour within the mixtures.

For salt mixtures, they were classified into two types of mixture compositions commonly found in the built environment according to the criteria outlined by Godts et al.18:

-

Type 1 (T1): A sulfate−rich mixture that includes an excess of sulfate ions, with respect to gypsum removal. The most important ions of this mixture type (median) derived from the dataset in order of magnitude are SO42−, Na+, K+, NO3−, Cl−, and Mg2+. Two T1 mixtures, T1v and T1vi, were studied, where v and vi represent mixtures with 5 and 6 ions, respectively.

-

Type 2 (T2): A calcium-rich mixture that includes an excess of calcium ions, with respect to gypsum removal. The most important ions of this mixture type (median) derived from the dataset in order of magnitude are NO3−, Ca2+, Cl−, Na+, K+, and Mg2+. Two T2 mixtures, T2v and T2vi, were studied, where v and vi represent mixtures with 5 and 6 ions, respectively.

ECOS/RUNSALT and the follow-up calculation

The values in Table 1 were used as direct input for a graphical user interface software RUNSALT based on a chemical equilibrium model ECOS (Environmental Control of Salts) originally from the molality-based thermodynamic approach of the ion interaction model of Pitzer, as described in Price et al.19. Each single salt has its specific deliquescence relative humidity (DRH) at a certain temperature and dissolves in the solution when the surrounding RH is higher than its DRH. Conversely, crystallisation occurs when the surrounding RH is lower than its DRH20. However, salt mixtures instead of single salts are present in reality. The Pitzer’s thermodynamic model21 is one of the most widely used models to understand the behaviour of mixed salt solutions and their effect on each other’s solubility. The extended use of this model includes determining the environmental conditions needed to decrease salt damage in porous materials and was documented in different published works22. ECOS/RUNSALT predicts the behaviour of salt mixtures under varying environmental conditions such as RH and temperature.

The RUNSALT programme allows users to simply input the cation and anion content with the environmental parameters in the window interface and use the single-click functionality to generate the results of salt behaviour. In this study, the output of all samples was produced to identify common solids as a percentage. For each sample, sixteen iterations were run to achieve a resolution of 0.1% RH, thus for each 5% interval (since the data results were automatically and systematically computed for 50 datapoints within a chosen interval) between 15% and 98% RH (removing duplicates), for every integer of temperature from 1 °C to 50 °C. Under a resolution of 0.1% RH, the thermodynamically calculated RH points of interest could be computed more accurately. Moreover, a narrower range of the RH interval could clarify certain artefacts and uncertainties in the data23.

ECOS/RUNSALT produces a visual output, from which the plot data in textual format was exported for further modifications. The crystallisation behaviour of the sample is presented with the specified RH range on the x-axis and the amount of substance (mol) on the y-axis. The values generated in the y-axis array are stacked, which means that the amount of the first salt is subtracted from the second to obtain the absolute value of each salt.

The above analysis procedure was executed automatically by R to simulate mouse clicks and keyboard input actions24. Initially, it retrieved the composition of the salt solution from an external file, similar to the format illustrated in Table 1, and inputted the parameters into RUNSALT for each salt sample. Subsequently, the primary loop iterated through every 5%-interval of RH, ranging from 15% to 98%, and across each degree Celsius from 1 °C to 50 °C, generating a list of substance amounts which were then stored in individual text files. These text files corresponding to the same sample were then consolidated into a single .CSV file, with columns representing temperature, RH, and substance amounts for each output salt. Lastly, the absolute values of substance amounts were computed from the stacked data.

As has been discussed elsewhere, the limitations of the ECOS/RUNSALT programme are known23, but it remains an essential tool. Without employing thermodynamic modelling, the experimental work necessary to explore the complete range of environmental conditions (a full expansion of 15% ≤ RH ≤ 98% and 1 °C ≤ T ≤ 50 °C) would have been impractical. The limitations of the ECOS/RUNSALT model particularly pertain to the accuracy of the results for certain hydrate salts and issues created by the output resolution. The interpretation of the model output and corresponding chemical phenomena acknowledges these issues and corrects for them when possible, supplementing with references to the literature when possible to substantiate the findings.

Mutual crystallisation and dissolution RH

The procedures commonly adopted in the literature to describe and detect the crystallisation process of mixed salt systems are shown as follows23:

-

1.

To find the mutual crystallisation and dissolution RH, the appearance of a solid is considered from a more humid environment (upper limit of RH 98%) to a dry environment (lower limit of RH 15%). The solid crystallises when its amount of substance appears in the plot data (i.e. its value greater than 0). The corresponding RH is defined as the point of the first mutual crystallisation RH. The solution at this point is saturated with respect to that specific solid. As the crystallisation of the first solid takes place, remaining ions can still be present in the solution and are getting more concentrated until the second and more solids start to crystallise. Similarly, that point of RH is regarded as the mutual crystallisation RH of that solid. Therefore, each solid has its own mutual crystallisation RH.

-

2.

As the condition gets dryer, the solid amount can increase over a RH range. If the amount remains unchanged before a certain RH, that point is considered as the mutual dissolution RH, which is the start of dissolution when coming from a dry to a humid environment.

-

3.

The mutual crystallisation and dissolution RH points for each integer of temperature from 1 °C to 50 °C are determined for each solid from the RUNSALT outputs. The RH ranges are compared to the RH equilibrium of the individual solids to obtain the range of crystallisation and dissolution RH points of salts in a mixture over the range of temperature.

The term ‘mutual’ is included above since the behaviour of each solid output is affected by the mixture composition. For single salts, there is only one value usually known as DRH. Additionally, salt transitions in the salt mixtures, including phase change (hydration and dehydration), decomposition, and formation (addition) of solids under both wetting and drying conditions, are not explained in detail in this study.

Graphical illustration

Graphs of (mutual) crystallisation RH and (mutual) dissolution RH with RH on y-axis and temperature on x-axis for each single salt and salt mixture were plotted to illustrate changes in RH across different temperatures. All the output solids that appeared during the crystallisation process in a single salt or salt mixture were presented on the same graph to display any interaction among them. For comparison between single salts and salt mixtures, the common output salts from both salt mixtures and single salts were put in a single graph to illustrate the behaviour differences among them.

Results

Single salt

The output solids fall into one of three categories: (1) identical to the original salt, (2) a hydrated form of the original salt, whose molecular formula is presented with the suffix “ • nH2O”, where n is the number of water molecules, or (3) the original salt and its hydrated forms, with only one solid appearing under varying RH conditions.

In the first group of five single salts, KNO3, NaCl, NaNO3 and KCl remain anhydrous, while Mg(NO3)2 forms as nitromagnesite (Mg(NO3)2 ⋅ 6H2O). The critical crystallisation RH (also known as DRH) decreases steadily with temperature for all five salts (Fig. 1). An attempt was made to model the relationship between RH (as response variable) and temperature (as explanatory variable) by fitting a quadratic equation to the data for each single salt. The changes in percentage (and range, i.e. maximum - minimum of crystallisation RH within 1 °C and 50 °C, shown in the bracket) of crystallisation RH from 1 °C to 50 °C are −11.9% (11.5) for KNO3, −1.3% (1) for NaCl, −12.9% (10.2) for NaNO3, −8.5% (7.5) for KCl, and −23.1% (14) for nitromagnesite, respectively. As expected25, the effect of temperature on the crystallisation RH of NaCl is nearly negligible as the critical RH values were within a narrow range around 75%. Most of them start to crystallise at a higher value of RH of approximately 70% or above while nitromagnesite crystallises at a relatively drier level of 60% or below, but not less than 45%. The findings are consistent with literature data as given in Steiger et al.26, Steiger27.

Critical RH values of crystallisation of five single salts with only one solid output from 1 °C to 50 °C and RH 15% to 98%, fitted with quadratic regression equation with all R2 (coefficient of determination) greater than 0.99. The values of crystallisation RH at 1 °C and 50 °C are displayed at the beginning and the end of the line.

Another group of five single salts, Na2SO4, MgSO4, K2SO4, Ca(NO3)2 and CaSO4, include hydrate phases in the outputs under the investigated conditions. Their crystallisation behaviour is more complex as the change of crystallisation RH is no longer a quadratic relationship with temperature since different hydrates appear under different RH or temperature. The hydrates tend to appear at lower temperatures. For example, mirabilite (Na2SO4 ⋅ 10H2O) (Fig. 2a) appears at 32 °C or below as it is not stable at higher temperatures28. The critical RH value of crystallisation of mirabilite decreases from 98% (the upper limit of this study’s RH range) to 87.9% when the temperature rises from 1 °C to 32 °C. On the other hand, the transition RH of mirabilite to thenardite (Na2SO4) increases significantly from 61.8% to 87.2% in this temperature range. Thenardite is then substituted for mirabilite and the critical RH value of crystallisation continues to rise slightly from 87.5% to 88.6% until 50 °C. The case for CaSO4 (Fig. 2b) is similar as gypsum (CaSO4 ⋅ 2H2O) appears at 43 °C or below and transits to CaSO4 at lower RH.

In the cases of MgSO4, K2SO4 and Ca(NO3)2, Godts et al.23 has identified some discrepancies between the ECOS/RUNSALT outputs and the findings of some present studies.

For K2SO4 (Fig. 3a), the ECOS/RUNSALT output shows that its monohydrate K2SO4 ⋅ H2O appears between 5 °C and 40 °C. Nevertheless, Archer and Kirklin29 suggests that the monohydrate phase does not occur below 9 °C, and is also less likely to happen at higher temperatures if stable at all. Moreover, the crystallisation RH should decrease with decreasing temperature but the ECOS/RUNSALT output shows the opposite at lower temperatures, with a reducing amount of monohydrate. Therefore, the crystallisation RH of arcanite should substitute the area of monohydrate beyond 9 °C and be revised to between 98% and 96.9% from 9 °C to 40 °C.

For Ca(NO3)2 (Fig. 3b), the ECOS/RUNSALT output shows that nitrocalcite Ca(NO3)2 ⋅ 4H2O only appears at 31 °C or below. Its critical RH value of crystallisation decreases gradually from 61.6% to 44.8% as the temperature rises from 1 °C to 31 °C. At the same time, the transition RH of nitrocalcite to Ca(NO3)2 increases quite linearly from 27.2% to 44.4%. Then the critical RH value of crystallisation of Ca(NO3)2 keeps rising slightly from 44.7% to 46.6% starting from 32 °C until the end. However, Steiger et al.2 suggested nitrocalcite is stable up to 42.7 °C. The corrected crystallisation RH values of nitrocalcite from 0 °C to 42.7 °C (solid line in Fig. 3b) and Ca(NO3)2 ⋅ 3H2O from 42.7 °C to 50 °C (dotted line in Fig. 3b) are shown in the figure. The salt system includes further hydrates neglected in ECOS/RUNSALT. As the lower hydrates are stable at relatively low RH, their formation under ambient climatic conditions is unlikely and the kinetically hindered crystallisation of nitrocalcite from solution can lead to high supersaturations20. More investigation is needed to find out the in-pore effects here under realistic climatic conditions23.

The scenario of MgSO4 hydrates is more complicated (Fig. 4). Four hydrates, epsomite (MgSO4 ⋅ 7H2O), hexahydrite (MgSO4 ⋅ 6H2O), starkeyite (MgSO4 ⋅ 4H2O), and kieserite (MgSO4 ⋅ 1H2O) are predicted in the temperature range of 1 °C to 50 °C. Nonetheless, there is a known error for MgSO4 hydrates present in ECOS/RUNSALT. According to the experimental results and improved thermodynamic calculations in Steiger et al.30, some key deviations specifically concerning starkeyite were determined. It shows that the values used in ECOS/RUNSALT for this phase are incorrect within the above-mentioned temperature range. The only stable phases are kieserite, hexahydrite and epsomite. Also, kieserite is kinetically hindered, thus often resulting in starkeyite as detected in reality. The corrected figures are shown by the dotted line regions in Fig. 4. The corrected crystallisation RH of epsomite decreases linearly from 94.4% to 83.4% from 1 °C to 48 °C. The transition RH of hexahydrite to kieserite increases from 36.7% to 64.8% from 1 °C to 50 °C. Hexahydrite only appears at higher temperatures. The corrected transition RH of epsomite to hexahydrite starts at 46.9% and increases to 83.2% from 20.3 °C to 48 °C. In addition to the described issues above, it is important to note that certain phases can be metastable and kinetically hindered30, while ECOS/RUNSALT is thermodynamics.

Crystallisation of MgSO4 from 1 °C to 50 °C and RH 15% to 98% computed by ECOS/RUNSALT. The colour shaded area represents the RH range of the solid form of the salts. The upper edge of the colour shaded area is regarded as the critical RH values of crystallisation. The dotted line represents the corrected crystallisation RH suggested by Steiger et al.30.

Salt mixtures

The solids formed within the range of RH of 15% and 98% and temperature of 1 °C and 50 °C are summarized in Table 2 for salt mixtures. Different double salts and hydrated salts are found in the salt mixtures, with the possibility of more than one solid present at one time. Halite (NaCl) and nitre (KNO3) are the common salts found in all four salt mixtures. The total number of solids formed are 5, 6, 7, and 11 in mixtures T2v, T1v, T2vi and T1vi across the full temperature and RH ranges, respectively. According to the phase rule, a maximum of four and five solids can coexist at a given temperature and RH within the five- and six-ion mixtures.

Table 2 shows the output salts that appear in the mixtures within the climate conditions of this study. The salts formed in type 1 (sulfate-rich) mixtures are typically more hydrated and less hygroscopic. In contrast, those in type 2 (calcium-rich) mixtures tend to be more hygroscopic by nature with the presence of more nitrate and chloride ions together with calcium18. Magnesium appears in both mixture types but is seen less frequently. The ions with higher concentration in the mixture will considerably affect the mutual crystallisation and dissolution RH. The results validate the rank of the most important ions that occur in the built environment2.

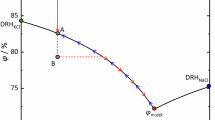

Figure 5 gives an overall view of all four salt mixtures. The first mutual crystallisation RH values (solid lines) of all of them decrease with increasing temperature. The trends are 94.8% to 89.6% for mixture T1v, 85.6% to 71.0% for mixture T1vi, 81.4% to 56.3% for mixture T2v, and 75.2% to 51.0% for mixture T2vi, respectively. Type 1 mixtures always have a higher RH than type 2 mixtures at the same temperature level. Within the same type, the mixtures with magnesium ions (T1vi and T2vi) have a lower RH than mixtures without magnesium ions. In type 2 mixtures, there are turning points at 13 °C and 14 °C for mixtures T2vi and T2v, respectively. From these temperatures onwards, the RH value decreases very slowly. For mixture T1vi, a turning point is also found at 37 °C, while mixture T1v keeps decreasing steadily along the temperature.

The trends of mutual dissolution RH (dotted lines in Fig. 5) across the full temperature are 70.0% to 53.3% for mixture T1v, 67.7% to 44.6% for mixture T1vi, 32.5% to 29.8% for mixture T2v, and 31.1% to 21.5% for mixture T2vi, respectively. Similarly to mutual crystallisation, type 1 mixtures have a much higher RH of mutual dissolution than type 2 mixtures for all the temperatures. However, mixture T2v shows a slight upward trend during 7 °C and 26 °C while other mixtures go down monotonically. Compared to the amplitude of the changes along the temperature, type 2 mixtures change more steadily than type 1 mixtures, especially mixture T1vi has a steep drop after 46 °C.

Type 1 mixtures

Mixture T1v

Figure 6 shows the change of crystallisation and dissolution RH of the solids formed along the temperature in mixture T1v. More solids are formed at the very low temperatures than the higher temperatures. Starting from a more humid environment, mirabilite is the first solid to crystallise, followed by aphthitalite between 1 °C and 3 °C. Aphthitalite becomes the first solid to crystallise starting from 4 °C. When RH goes further down, nitre crystallises. When RH is under 70%, halite crystallises. Halite is formed earlier than nitre when drying starting from 14 °C. Darapskite and thenardite are identified as the products of some solid state reactions occurring in a range of moderate RH (i.e. around 40% and 70%). Their behaviour are beyond the scope of this study.

Mirabilite is present only between 1 °C and 7 °C. Its crystallisation RH drops from a very humid level of 94.8% to 89.3% in the said temperature range. At 5 °C, it is absent in the range of RH 68.2% and 71.8% inclusively, but it is believed to be an artefact. This temperature is also the turning point of its dissolution RH as it gradually decreases from 70.0% to 68.8% when the temperature rises from 1 °C to 4 °C, then jumps up to 78.1% at 5 °C and goes up further to 86.7% and 86.2% at 6 °C and 7 °C, respectively. These sudden change is also believed to be an artefact. In summary, mirabilite appears in the very humid and low temperature conditions.

The crystallisation RH of nitre drops significantly from 87.0% at 1 °C to 67.4% at 13 °C, then goes down steadily to 55.5% until 50 °C. Moreover, the crystallisation RH values of both halite and aphthitalite decrease very slowly from 70.0% to approximately 67.0%, and 93.9% to 89.6% in the full temperature range, respectively. The paths of dissolution RH of nitre and halite are the same. Both start from 70.0% at 1 °C and then decrease to 53.3% until 50 °C. Furthermore, the path of dissolution RH of aphthitalite is close to them and has only 0.1 to 0.2 percent point difference from them. In summary, halite has the same crystallisation and dissolution RH at very low temperatures (1 °C to 4 °C). Nitre has crystallisation RH close to dissolution RH starting from 13 °C, with approximately a 2 percent point difference.

Mixture T1vi

Figure 7 shows the change of crystallisation and dissolution RH of the solids formed along the temperature in mixture T1vi. Beginning from a more humid environment, picromerite is the first solid to crystallise, followed by hexahydrite. When RH goes further down, picromerite decomposes and nitre is formed. Some solids are only formed at very low temperatures. For example, aphthitalite and mirabilite only appear at 1 °C. The crystallisation and dissolution RH are 68.2% and 67.8% for aphthitalite, and 79.2% and 74.9% for mirabilite, respectively. Then, halite is formed in a further dryer condition. After that, MgSO4 ⋅ nH2O is identified as the product of some solid-state reactions occurred (see section 3.1).

Complex interactions among the output salts happen when the temperature increases. The appearance order of the output salts changes when drying as shown below:

-

Starting from 12 °C, bloedite appears and crystallises before the formation of halite.

-

Starting from 18 °C, bloedite crystallises earlier than nitre.

-

Starting from 27 °C, bloedite crystallises earlier than MgSO4 ⋅ nH2O.

-

Starting from 37 °C, bloedite crystallises earlier than picromerite.

-

Starting from 38 °C, halite crystallises earlier than nitre. Also, picromerite stops to form.

-

Starting from 44 °C, sylvite appears and crystallises before the formation of nitre.

-

Starting from 49 °C, halite crystallises earlier than MgSO4 ⋅ nH2O.

The path of crystallisation RH of bloedite is different from the other output salts. It starts from 64.9% at 12 °C, goes up to a maximum of 71.8% at 36 °C, and eventually ends at 71.0% at 50 °C. For dissolution RH, most output salts have a very similar path. Halite, nitre and MgSO4 ⋅ nH2O have the same path from 67.7% to 44.6% across the full temperature. Sylvite has a similar path from 54.7% to 45.2% between 44 °C and 50 °C. Bloedite has a similar path during 12 °C and 37 °C but decreases at a slower rate from 57.5% at 38 °C to 56.8% at 50 °C. However, the dissolution RH of K2SO4 ⋅ MgSO4 ⋅ nH2O (leonite / picromerite) is different from them. It shows an overall downward trend but fluctuats along the temperature. But the fluctuation is considered as an artefact and is being smoothed in Fig. 7. During 1 °C and 17 °C, its path is close to the crystallisation RH of nitre. After that, it falls and reaches 56.4% at 50 °C.

Type 2 mixtures

Both Ca(NO3)2 and nitre are seen in the output solids of type 2 mixture. However, the system with Ca(NO3)2 and nitre are not calculated correctly due to missing Ca(NO3)2 phases and the wrong phase of Ca(NO3)2 in most calculations, mostly the anhydrous salt. The model also uses a not proven solid MgCa(NO3)4 ⋅ 10H2O to handle this issue with extreme high concentrations of the solution. Ca(NO3)2 is also known to form double salts with KNO3, i.e. Ca(NO3)2 ⋅ KNO3 ⋅ 3H2O and 5Ca(NO3)2 ⋅ KNO3 ⋅ 10H2O when above 33 °C31.

Mixture T2v

Figure 8 shows the change of crystallisation and dissolution RH of the solids formed along the temperature in mixture T2v. Starting from a more humid environment, nitre is the first solid to crystallise, followed by halite. Then nitre decomposes in a narrow range of RH within 30% and 37% in a dry condition, while sylvite crystallises at the same time. Next, nitrocalcite is formed when nitre disappears in a further dryer condition. Finally, Ca(NO3)2 is formed and replaces nitrocalcite in a further dryer condition. Nitrocalcite does not appear starting from 7 °C. Halite becomes the first solid to crystallise, instead of nitre starting from 14 °C. Nitre only crystallises until 27 °C.

The crystallisation RH of halite drops slowly from 62.7% to 56.3% throughout the whole temperature range of this study. That of sylvite increases from 35.0% at 1 °C and reaches the highest level of 42.9% at 28 °C, then goes down to 29.8% at 50 °C. For Ca(NO3)2 ⋅ 4H2O (nitrocalcite), its crystallisation RH decreases slightly from 32.5% to 30.3% between 1 °C and 7 °C. Then it goes up to the highest value of 31.8% at 26 °C and falls to 29.8% at 50 °C.

The dissolution RH values of halite, sylvite and nitrocalcite follow a coherent path, which coincides with the crystallisation RH of nitrocalcite. For nitre, its dissolution RH increases from 35.1% to 42.9% in its existence of temperature between 1 °C and 27 °C, which is very close to the trajectory of the crystallisation RH of sylvite in the same temperature range.

Mixture T2vi

Figure 9 shows the change of crystallisation and dissolution RH of the solids formed along the temperature in mixture T2vi. Beginning from a more humid environment, nitre is the first solid to crystallise, followed by halite. When RH drops below 40%, nitre dissolves in a drying condition, while carnallite crystallises at the same time. Next, nitrocalcite is formed in a further dryer condition. When RH is further down to near 30%, MgCa(NO3)4 ⋅ 10H2O is formed. After that, Ca(NO3)2 is formed and replaces nitrocalcite in a further dryer condition. Finally, nitromagnesite is formed and replaces MgCa(NO3)4 ⋅ 10H2O in a further dryer condition. Some complex interactions among the output salts happen when the temperature increases as follows:

-

Starting from 3 °C, nitre is absent within a narrow range of dry conditions around 30%, i.e. absent between 30.1% and 31.9% at 3 °C. The gap becomes wider with increasing temperature. (Grey region of the left figure in Fig. 9) Nitre reappears in the dryer condition.

-

Starting from 6 °C, nitrocalcite stops to form.

-

Starting from 11 °C, MgCa(NO3)4 ⋅ 10H2O stops to form.

-

Starting from 13 °C, halite becomes the first solid to crystallise, instead of nitre.

-

During 41 °C and 50 °C, the solid amount of all output salts is unsteady between their own dissolution RH and 28%, especially nitre appears on and off in this range.

The crystallisation RH values of most output salts do not vary too much throughout the whole temperature range of this study. Halite, carnallite, nitrocalcite, and nitromagnesite decrease moderately from 55.3% to 51.0%, 38.8% to 30.6%, 32.6% to 29.2%, and 31.1% to 21.5%, respectively. For dissolution RH, they almost have the same path from 31.1% at 1 °C descending to 21.5% at 50 °C, with a very minor RH difference of less than 0.5 percent points at several low temperature levels.

The behaviour of nitre is complicated and believed to be an artefact of the ECOS/RUNSALT calculations. The results shows nitre disappears in the mid-range of RH. The crystallisation RH of nitre drops from 75.2% at 1 °C to 53.3% at 13 °C. Then it continues to fall at a lower rate to 32.5% at 50 °C. Its dissolution RH decreases from 31.1% at 1 °C to 30.7% at 2 °C. Then it rises up to 39.0% at 3 °C but goes down again to 30.7% at 50 °C, which is similar to the path of crystallisation RH of carnallite. During 3 °C and 50 °C, its re-crystallisation RH starts from 30.1% and ends at 25.0%. Its re-dissolution RH is roughly the same as the re-crystallisation RH. In the unstable section between 41 °C and 50 °C, there is a very narrow range between RH 26% and 28% of its appearance. All these on and off dissolution and crystallisation are inherent to the solution properties as the concentration increases, nitre dissolves again due to its solubility influenced by the surrounding ion concentration.

Comparison between single salts and salt mixtures

Halite and nitre involve in the single salt samples and appear in all four mixtures, while sylvite involves in the single salt sample and mixtures T1vi and T2v, respectively (Fig. 10). The crystallisation RH in mixtures is always lower than that of single salts. For halite, the mixtures with magnesium ions (T1vi and T2vi) have a much lower RH range than those without (T1v and T2v) in both type 1 and type 2 mixtures, respectively. All of them show an overall decline in RH along the temperature. The dissolution RH is much higher in type 1 mixtures than in type 2s. They all show a downward trend along the temperature.

For nitre, both crystallisation and dissolution RH show a downward trend along the temperature in type 1 mixtures. Higher RH value in mixture with magnesium ions is observed except the temperature between 7 °C and 16 °C in crystallisation. In type 2 mixtures, nitre only crystallises in lower temperature up to 27 °C in mixture T2v (without magnesium ions). Moreover, it reappears in dryer condition between 3 °C and 50 °C in mixture T2vi, as discussed in the previous section. Their crystallisation RH values (first appearance for mixture T2vi) show a downward trend with increasing temperature. However, dissolution RH of mixture T2v goes up along the temperature range, while that of mixture T2vi (first dissolution) rises a bit in the very low temperature then drops steadily.

For sylvite, it only crystallises in high temperature between 44 °C and 50 °C in mixture T1vi. Both crystallisation and dissolution RH show a downward trend with increasing temperature. The crystallisation and dissolution RH of mixture T2v are the lowest. Furthermore, its crystallisation RH goes up in the low temperatures and then goes down in the high temperatures. Its dissolution RH fluctuates in a small amplitude along the temperature.

Discussion

This study highlights significant findings regarding salt mixture behaviour at varying temperatures, an aspect often neglected in most studies. By leveraging the ECOS/RUNSALT model, this study is able to explore a wide range of environmental conditions, including factorial outputs for multiple combinations of temperature and RH, which would be impractical to achieve through experimental settings alone. This allows to systematically assess the interplay between temperature and RH on both single salts and mixtures, providing insights that are critical for understanding salt crystallisation and dissolution behaviour. The general trends of decreasing critical RH with increasing temperature is seen and the decreasing rate is different for different salts and mixture compositions. However, some observations highlight the inadequacies of ECOS/RUNSALT and aspects that should be carefully checked. Moreover, this study offers insights into the significant influence of temperature and enhances comprehension of the formation of double salts, although some double salts with nitrates or sulfates of potassium and calcium are not included in the model. These results could still guide future research initiatives, develop a solid foundation for heritage conservation and management plans aimed at preventing the potential damages caused by salts under changing climatic conditions, and facilitate refinement and validation of theoretical models to advance analytical methodologies.

In previous studies, salt weathering has primarily been estimated by the individual action of a single salt composition, mainly focusing on RH. The presented analysis takes into account that the crystallisation and dissolution behaviour of the salt mixtures depend on environmental conditions and different ion concentrations. Type 1 mixtures include more hydrating and double salts which would cause visible efflorescence and sub/crypto-florescence with severe powdering, material disintegration and/or delamination under a certain range of RH fluctuations. On the other hand, type 2 mixtures are more likely to result in moisture stains and/or surface powdering caused by a relatively lower RH range where cycles become possible. The value of RH is even lower with increasing temperature. Godts et al.17 identified 14 common salts that occur most frequently in these two common mixture types and discussed their behaviour. Solids in type 1, excluding kieserite, show a mutual crystallization median RH greater than 60%, while they remain below this value for solids in type 2. The median trends of all solids between mutual dissolution RH and mutual crystallization RH are 61% and 72% for type 1, and 28% and 46% for type 2, respectively. It is also important to consider these for each individual solid in the given mixture separately, when the phase transitions shown for sodium and magnesium sulfate can exist as either the specific phase given or a phase transition can occur in the mixture. The modelling of carbonates in these complex mixtures is still a work in progress, however, mixtures containing an important content of carbonates related to an excess of sodium or potassium fall within 3% of 7946 samples identified as type 1. Moreover, for estimating and quantifying the damage risk for salt mixtures under changing climate conditions, further investigation is needed for certain hydrating salts and double salt phases as the presence of other salts or different porous materials could affect their formation and deterioration processes32,33.

The proposed methodology uses ECOS/RUNSALT model to simulate temperature and RH for selected single salts and salt mixtures, which are chosen from the large open-source database of soluble salt mixtures in the various built environments over centuries. ECOS/RUNSALT is currently the only widely used model with the most relevant salt phases found in built heritage. Not many studies focused on the temperature effect on the salt behaviour using ECOS/RUNSALT since the RH effect is more dominant in such behaviour. In real environments, temperature changes often alter RH, which in turn affects salt crystallisation and dissolution. Since both temperature and RH strongly influence salt behaviour, their effects become intertwined, making it hard to pinpoint temperature’s contribution without accounting for RH variations. Menéndez34,35 used a 3D representation of the salt volume as a function of temperature and RH for the selected salt mixture. These papers concluded that most salt damage (defined as the salt volume change) take place when temperature and RH are low. However, this result is limited to a particular salt mixture only as the study was based on a mortar sample (0.1 g) of the “Préfecture de Police” building in Paris. In contrast, although this analysis primarily draws on a large sample dataset from Belgium, the findings are generalisable beyond this limited geographic scope. The dataset’s focus on Belgian heritage sites does not limit its broader applicability, as the ions detected are representative of those found in stone materials globally17, with the substitution of bicarbonates for nitrate (due to anthropogenic sources), reflecting common sources such as groundwater, atmospheric deposition, and pollution. While regional geological contexts (e.g. areas with elevated magnesium levels) and climatic conditions can influence the kinetics of salt decay, the primary ionic contributors and their role in salt weathering are consistent across diverse environments. This global relevance is further supported by similarities in groundwater ion profiles worldwide, indicating that the findings can be extrapolated with consideration of local climatic and material-specific factors. Further, if there is significant local variation in salt mixture compositions, this work underscores the importance of considering the influence of temperature on their equilibrium behaviour. Finally, the range of conditions studied (a full expansion of 15% ≤ RH ≤ 98% and 1 °C ≤ T ≤ 50 °C) represents a much wider variation of environmental conditions than are typically expected in Belgium alone. These results can thus be extrapolated to hotter and drier climates. There is further research needed to understand the influence of temperature in sub-zero conditions, which cannot accurately be modelled in ECOS/RUNSALT. Nevertheless, the results in this study are coherent with those in the previous studies, i.e. the temperature effect does exist, especially at low temperatures. Moreover, this effect behaves differently in different salt mixtures. Therefore, ions in the mixtures also play an important role in the behaviour.

The results presented emphasise the importance of considering the influence of temperature on critical RH values for crystallisation and dissolution processes. It is not by chance that the critical value often considered in preventive conservation advice is that for NaCl present as a single salt (approximately RH 75%, see Fig. 1): this value is very stable across the range of ambient temperatures, thus neglecting the need to consider the influence of temperature. However, the influence of temperature is significant in almost every realistic case of salt mixtures found in the built environment. Thus, preventive conservation advice developed from models such as ECOS/RUNSALT, or experimentally derived, should consider the influence of temperature. The potential increased risks of not doing so are significant. For example, for sulphate-rich (Type 1) mixtures, at 20 °C have critical values between RH of 60% and 65%. On this evaluation, a dehumidifier may be advised to turn on when the RH is greater than 65% independent of temperature. However, lower temperatures (<10 °C) are often found in unconditioned internal environments such as tombs, crypts, and in some cases historic houses. At these conditions, the critical RH values are higher for these mixture types, approximately 67% to 70%. Thus, the introduction of this dehumidification unit operating at the specified parameters could introduce several opportunities for dissolution processes to occur, particularly in colder periods when humidities also tend to be higher. Best practice would be to ensure that any preventive conservation advice given for the management of salt-related risks considers equilibrium behaviour at several temperatures, representative of the range of expected ambient conditions accounting also for seasonal variation.

The ECOS/RUNSALT model, as recently discussed by Godts et al.23, operates within a framework that offers numerous advantages, though certain aspects are not included due to the model’s inherent focus. For example, kinetics is not considered, as thermodynamic calculations logically exclude kinetic factors since they represent distinct processes. However, it is important to note that kinetics can significantly influence crystal growth. In real-world scenarios, kinetic barriers may lead to delayed crystallisation, metastable phase formation, or supersaturation. Additionally, the model may not account for the extremely high concentrations that can occur in hygroscopic mixtures, such as calcium-rich (type 2) mixtures, at very low RH. Furthermore, while ECOS/RUNSALT includes many common salts, certain solid phases that could play a crucial role in crystallisation and deterioration processes are currently not included in its database. For instance, soluble carbonate salts are absent from the model, which can be a limitation in specific cases12,36,37,38,39,40,41. Menéndez34 pointed out that carbonate and bicarbonate anions are important in the degradation of calcareous stones, mortars, and other artificial cement materials. This issue was further discussed in studies focusing on mixed salt systems in the built environment, where mixtures containing carbonates were identified, albeit in a small percentage of samples18.

Similarly, gypsum (CaSO4 ⋅ 2H2O) is excluded from the model, meaning that double salts containing calcium sulfate are not accounted for42. This exclusion requires users to manually correct ion data for the presence of gypsum when using ECOS/RUNSALT. The model is not currently capable of systematically integrating the presence of equimolar amounts of calcium and sulfate ions. In rare cases where gypsum is included, significant changes in phase transitions can occur, such as the replacement of darapskite (NaNO3 ⋅ Na2SO4 ⋅ H2O) with complex gypsum double salts like glauberite (Na2SO4 ⋅ CaSO4) and gorgeyite (K2SO4 ⋅ 5CaSO4 ⋅ H2O). The solubility of gypsum can increase up to four times when mixed with sodium chloride, potentially leading to extensive damage43,44,45,46. Gypsum is one of the most ubiquitous compounds found both in nature and on buildings and sculptures and has been detected in almost all samples from Belgian monuments, archaeological sites, and sculptures47. Furthermore, some special salts formed by specific ions are not included in ECOS/RUNSALT due to their rarity or lack of data at the time the model was parameterized. For example, humberstonite, as mentioned by Benavente et al.48, is not considered in the model. Despite these exclusions, ECOS/RUNSALT remains a valuable tool for predicting salt crystallisation processes in porous materials. Its focus on thermodynamically stable phases allows for accurate predictions under a wide range of environmental conditions, and ongoing updates aim to incorporate additional salts as new data become available.

As it was shown, for some salt systems that include different hydrates like the magnesium sulfate system and Ca(NO3)2 system, ECOS calculations do not predict the correct phase but it has already been addressed in this study. While it is acknowledged that the ECOS/RUNSALT outputs may be susceptible to incorrect interpretations due to inherent limitations, they can still be considered reliable provided the user is cognizant of these limitations. In practical conservation scenarios, conservation strategies based solely on ECOS/RUNSALT results may not adequately account for slower or intermittent salt damage processes to address the full range of damage mechanisms, if excluding kinetics or certain salt phases. However, these limitations often do not significantly impact the final decisions aimed at preventing decay over time in the given climatic conditions. Therefore, it is important to examine other possible factors that can cause deviations from the modelled crystallisation behaviour, such as salt kinetics, thermal expansion, in-pore situations, and chemical alteration. Furthermore, running sensitivity analyses to simulate across a range of input conditions, such as slight variations in ion composition or temperature intervals, can help identify robust patterns and assess the impact of potential uncertainties. This study acknowledges the reliance on the ECOS/RUNSALT model for theoretical predictions. Incorporating future experimental designs would greatly enhance the robustness of the results. Proposing experiments to validate the impact of temperature on mixed salt crystallization, such as the influence of varying temperature gradients on specific salt mixtures, would provide empirical support and continue in line with changing temperatures in the future to further increase the validity of this theoretical study. Godts et al.49 carried out experimental work with changing RH to confirm the phases predicted from ECOS/RUNSALT using micro-Raman spectroscopy, X-ray diffraction (XRD), and elemental mapping via energy-dispersive X-ray spectroscopy (EDX). Their findings showed a strong correlation between phase transition kinetics and RH change rates under different scenarios of RH changes, proving the accuracy of the model, but also revealing the need for kinetic considerations in future models and risk assessments as significant deviations mainly due to kinetic factors, such as supersaturation.

Data availability

No datasets were generated or analysed during the current study.

References

Doehne, E. Salt weathering: a selective review. Geol. Soc., Lond., Spec. Publ. 205, 51–64 (2002).

Steiger, M., Charola, A. E. & Sterflinger, K. Weathering and Deterioration, 225–316 (Springer Berlin Heidelberg, Berlin, Heidelberg, 2014).

Diaz Gonçalves, T. Salt decay and salt mixtures in the architectural heritage: A review of the work of Arnold and Zehnder. Int. J. Archit. Herit. 18, 125–149 (2024).

Steiger, M. Crystal growth in porous materials — I: The crystallization pressure of large crystals. J. Cryst. growth 282, 455–469 (2005).

Caruso, F., Wangler, T. & Flatt, R. J. Easy illustration of salt damage in stone. J. Chem. Educ. 95, 1615–1620 (2018).

Zezza, F. & Macrì, F. Marine aerosol and stone decay. Sci. Total Environ. 167, 123–143 (1995).

Cultrone, G. & Sebastian, E. Laboratory simulation showing the influence of salt efflorescence on the weathering of composite building materials. Environ. Geol. 56, 729–740 (2008).

Brocken, H. & Nijland, T. G. White efflorescence on brick masonry and concrete masonry blocks, with special emphasis on sulfate efflorescence on concrete blocks. Constr. Build. Mater. 18, 315–323 (2004).

Mahmood, T., Gulzar, S. & Awan, M. Y. An analytical study of colonial and contemporary bricks from the buildings of Lahore, Pakistan. J. Res. Archit. Plan. 24, 26–33 (2018).

Xu, T. et al. Damage mechanism of pier concrete subjected to combined compressive stress, freeze-thaw, and salt attacks in saline soil. Constr. Build. Mater. 324, 126567 (2022).

Long, Z. et al. Mechanism analysis of strength evolution of concrete structure in saline soil area based on 15-year service. Constr. Build. Mater. 332, 127281 (2022).

Arnold, A. & Zehnder, K. Monitoring wall paintings affected by soluble salts (Getty Conservation Institute, Marina Del Rey, CA, USA, 1991).

Steiger, M. Air Pollution Damage to Stone, chap. Chapter 3, 65–102 (Imperial College Press, London, UK, 2016).

Germinario, L., Oguchi, C. T., Tamura, Y., Ahn, S. & Ogawa, M. Taya caves, a Buddhist marvel hidden in underground Japan: stone properties, deterioration, and environmental setting. Herit. Sci. 8, 1–20 (2020).

Cardell, C. et al. Salt-induced decay in calcareous stone monuments and buildings in a marine environment in SW France. Constr. Build. Mater. 17, 165–179 (2003).

Benavente, D., Brimblecombe, P. & Grossi, C. Thermodynamic calculations for the salt crystallisation damage in porous built heritage using PHREEQC. Environ. Earth Sci. 74, 2297–2313 (2015).

Godts, S. et al. Salt mixtures in stone weathering. Sci. Rep. 13, 13306 (2023).

Godts, S. et al. Charge balance calculations for mixed salt systems applied to a large dataset from the built environment. Sci. Data 9, 324 (2022).

Price, C. et al. An expert chemical model for determining the environmental conditions needed to prevent salt damage in porous materials: protection and conservation of the European cultural heritage. European Commission Research Report (2000).

Steiger, M. Salts in porous materials: Thermodynamics of phase transitions, modeling and preventive conservation. Restor. Build. Monum. 11, 419–432 (2005).

Pitzer, K. S. Ion interaction approach: theory and data correlation. In Activity coefficients in electrolyte solutions, 75–153 (CRC Press, Boca Raton, FL, USA, 1991).

Bionda, D. A graphical user interface to the ecos thermodynamic model for the prediction of the behaviour of salt mixtures under changing climate conditions. (2005). http://science.sdf-eu.org/runsalt/. (Accessed: 1 October 2024).

Godts, S. et al. Modeling salt behavior with ECOS/RUNSALT: Terminology, methodology, limitations, and solutions. Heritage 5, 3648–3663 (2022).

R Core Team. R: A Language and Environment for Statistical Computing. R Foundation for Statistical Computing, Vienna, Austria (2021). https://www.R-project.org/.

Greenspan, L. Humidity fixed points of binary saturated aqueous solutions. J. Res. Natl Bur. Stand. Sect. A, Phys. Chem. 81A, 89–96 (1977).

Steiger, M., Kiekbusch, J. & Nicolai, A. An improved model incorporating Pitzer’s equations for calculation of thermodynamic properties of pore solutions implemented into an efficient program code. Constr. Build. Mater. 22, 1841–1850 (2008).

Steiger, M. The geochemistry of nitrate deposits: I. thermodynamics of Mg(NO3)2–H2O and solubilities in the Na+–Mg2+–NO3−–SO42-–H2O system. Chem. Geol. 436, 84–97 (2016).

Steiger, M. & Asmussen, S. Crystallization of sodium sulfate phases in porous materials: The phase diagram Na2SO4–H2O and the generation of stress. Geochim. et. Cosmochim. Acta 72, 4291–4306 (2008).

Archer, D. G. & Kirklin, D. R. Enthalpies of solution of sodium chloride and potassium sulfate in water. thermodynamic properties of the potassium sulfate+ water system. J. Chem. Eng. Data 47, 33–46 (2002).

Steiger, M., Linnow, K., Ehrhardt, D. & Rohde, M. Decomposition reactions of magnesium sulfate hydrates and phase equilibria in the MgSO4–H2O and Na+–Mg2+–Cl−–SO42-–H2O systems with implications for Mars. Geochim. et. Cosmochim. Acta 75, 3600–3626 (2011).

Flatt, R. & Bocherens, P. Le système ternaire Ca++—K+—H+—NO3−—H2O. Helvetica Chim. Acta 45, 198–212 (1962).

Clercq, H., Jovanović, M., Linnow, K. & Steiger, M. Performance of limestones laden with mixed salt solutions of Na2SO4–NaNO3 and Na2SO4–K2SO4. Environ. Earth Sci. 5, 1751–1761 (2013).

Godts, S., Hendrickx, R. & De Clercq, H. The crystallization behavior of sodium magnesium sulfate in limestone. In Proceedings of the third international conference on salt weathering of buildings and stone sculptures (SWBSS 2014), Aedificatio Publishers, Brussels, 167–182 (2014).

Menéndez, B. Estimation of salt mixture damage on built cultural heritage from environmental conditions using ECOS-RUNSALT model. J. Cult. Herit. 24, 22–30 (2017).

Menéndez, B. Estimators of the impact of climate change in salt weathering of cultural heritage. Geosciences 8, 401 (2018).

Charola, A. E. & Lewin, S. Efflorescences on building stones—SEM in the characterization and elucidation of the mechanisms of formation. Scanning Electron. Microsc. 1, 378–386 (1979).

Arnold, A. & Kueng, A. Crystallization and habits of salt efflorescences on walls. part I: methods of investigation and hahits. In Fifth International Congress on the Deterioration and Conservation of Stone, 255–267 (Presses Polytechniques Romandes, Lausanne, 1985).

Bionda, D. Modelling indoor climate and salt behaviour in historical buildings: a case study. Ph.D. thesis, ETH (2006).

Siedel, H. Salt efflorescence as indicator for sources of damaging salts on historic buildings and monuments: a statistical approach. Environ. Earth Sci. 77, 572 (2018).

Erić, S. et al. The origin of Mg sulphate and other salts formed on pure calcium carbonate substrate — tufa stone blocks built into the Gradac Monastery, Serbia. Constr. Build. Mater. 98, 25–34 (2015).

Morillas, H., Maguregui, M., Trebolazabala, J. & Madariaga, J. M. Nature and origin of white efflorescence on bricks, artificial stones, and joint mortars of modern houses evaluated by portable raman spectroscopy and laboratory analyses. Spectrochim. Acta Part A: Mol. Biomol. Spectrosc. 136, 1195–1203 (2015).

Morillas, H. et al. The role of marine aerosol in the formation of (double) sulfate/nitrate salts in plasters. Microchem. J. 123, 148–157 (2015).

Price, C. & Brimblecombe, P. Preventing salt damage in porous materials. Stud. Conserv. 39, 90–93 (1994).

Charola, A. E., Pühringer, J. & Steiger, M. Gypsum: a review of its role in the deterioration of building materials. Environ. Geol. 52, 339–352 (2007).

Klenz Larsen, P. The salt decay of medieval bricks at a vault in Brarup church, Denmark. Environ. Geol. 52, 375–383 (2007).

Sawdy, A. & Heritage, A. Evaluating the influence of mixture composition on the kinetics of salt damage in wall paintings using time lapse video imaging with direct data annotation. Environ. Geol. 52, 303–315 (2007).

Godts, S., Hayen, R. & De Clercq, H. Investigating salt decay of stone materials related to the environment, a case study in the St. James church in Liège, Belgium. Stud. Conserv. 62, 329–342 (2017).

Benavente, D., de Jongh, M. & Cañaveras, J. C. Weathering processes and mechanisms caused by capillary waters and pigeon droppings on porous limestones. Minerals 11, 18 (2021).

Godts, S. et al. Modeled versus experimental salt mixture behavior under variable humidity. ACS Omega 9, 20454–20466 (2024).

Author information

Authors and Affiliations

Contributions

S.G. and S.A.O. devised the project and outline. V.C.W.C. wrote the main manuscript text and prepared figures and tables. S.G., A.S., M.S. and S.A.O. reviewed the manuscript. All authors agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chan, V.C.W., Godts, S., Stahlbuhk, A. et al. Influence of temperature on crystallisation and dissolution of salts and salt mixtures in built environment. npj Herit. Sci. 13, 123 (2025). https://doi.org/10.1038/s40494-025-01659-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s40494-025-01659-1