Abstract

This study develops a silica-coated nanoscale calcium carbonate composite using sodium silicate and ethyl cellulose/n-butanol to address vinegar syndrome in triacetate films. The modified material enhances dispersibility and acid resistance, applied via brushing to degraded films. Post-treatment, film pH rises from 4 to >6.5, surface becomes hydrophobic (contact angle confirmed), and thermal/molecular stability improves (TGA/XRD verified). The mechanical strength exhibits a substantial enhancement, with stress rising from 27.35 to 86.43 MPa and strain improving from 4.32% to 5.53%, while demonstrating sustained stability following aging treatment. The composite mitigates surface roughness and optical defects while preserving image clarity. Comparative tests confirm its effectiveness in deacidification, structural reinforcement, and delayed degradation, demonstrating promising potential for conserving acetate-based cultural heritage affected by vinegar syndrome.

Similar content being viewed by others

Introdution

Photosensitive images, which contain a wealth of archival information, are a valuable cultural heritage in modern human history. They are characterized by their low cost, high sensitivity, and excellent fidelity, and continue to hold irreplaceable value in the digital imaging era. The main components of photosensitive images include the support layer, emulsion layer, protective layer, and other functional layers1,2. Since its introduction in the 1950s, triacetyl cellulose (TAC)-based film has been widely used due to its unique advantages. However, due to the inherent properties of cellulose triacetate, combined with the instability of storage conditions such as temperature and humidity, most films are prone to developing a condition known as “vinegar syndrome” over time. “Vinegar syndrome” is closely related to the substrate material TAC, which is commonly used as an optical film. In the field of photosensitive images, the triacetate substrate has replaced the flammable nitrate substrate, offering both high strength and flexibility. However, under high temperature and humidity, TAC is easily hydrolyzed, producing acetic acid, which releases a pungent odor. Acetic acid catalyzes the hydrolysis reaction, initiating a self-reinforcing cycle3,4. As cellulose acetate degrades, the film’s mechanical properties deteriorate, resulting in distortion, deformation, and the loss of plasticizer5,6,7. Furthermore, the image quality deteriorates, exhibiting scratches and blurring. Eventually, the film becomes damaged and loses its functional value. To mitigate the occurrence of autocatalytic reactions, researchers have begun exploring various approaches.

The treatment of materials undergoing autocatalytic reactions is typically divided into passive inhibition and active intervention8. A significant number of studies have focused on controlling the temperature and humidity within storage environments to reduce degradation. The paper suggests that the optimal humidity should be between 20–50%, and the temperature should range from −10 °C to −20 °C9. However, implementing these strict conditions is costly and not feasible for widespread application. In 2019, Ida R. Ahmad’s team10 developed a mathematical model to predict the occurrence of vinegar syndrome. They found that existing models may overestimate the preservation life of acetic acid films at low temperatures, and that refrigerated environments, by reducing air circulation, actually promote autocatalytic reactions. Additionally, a variety of adsorbent materials, such as desiccants, molecular sieves, tea11, sodium carbonate, and sodium polyacrylate12, are used as acid absorbents and dehumidifiers. These adsorbents primarily target water vapor and acetic acid gas, but their effect is limited, and excessively low humidity can damage the film emulsion layer13. Thus, it is clear that environmental control measures cannot effectively inhibit the hydrolysis reaction. Active intervention typically involves applying alkaline nanomaterials directly to the material via spraying, brushing, or soaking. As early as 2002, Rodorico Diorg14 applied nano-calcium hydroxide non-aqueous solution to paper deacidification. In 2010, there were reports of using nano-barium hydroxide to reinforce mural cultural relics15. In 2015, Adam16 compared the deacidification effects of nano-sized magnesium hydroxide under different methods, concluding that spraying allowed for more even distribution of the deacidifier. However, the higher alkalinity of the hydroxide could lead to the depolymerization of cellulose, and the strong alkaline environment might cause secondary damage to photosensitive materials16,17. Malesic17 and Bicchieri18 applied nano-calcium carbonate for file deacidification and found that its lower pH and better photothermal stability made it a superior material, particularly for films requiring higher light transmission.

Nano-calcium carbonate refers to superfine calcium carbonate particles with sizes ranging from 1 to 100 nm. These particles possess several advantages, including a large specific surface area, excellent biocompatibility, and detoxification properties. Due to their extremely small size and the abundance of hydrophilic hydroxyl groups on their surface, nano-calcium carbonate exhibits poor dispersion in lipophilic organic substances and is prone to aggregation19. To improve its properties, nano-calcium carbonate can be modified using dry, wet, or in-situ methods20,21. Common modifiers include coupling agents, surfactants, organic polymers, and inorganic substances22,23,24. In this study, inorganic silica was used to modify the surface of nano-calcium carbonate, thereby reducing its high surface energy, increasing its surface potential, and enhancing its adhesion to organic polymer matrices. Additionally, the steric hindrance introduced by the inorganic silica prevented direct interaction between acidic ions and the calcium carbonate surface, thereby improving its dispersibility and acid resistance25,26.

The management of vinegar syndrome has undergone decades of research, leading to certain conclusions and methods3,6,10,11,12,27,28. Direct methods for deacidifying film materials are still lacking, and there have been limited reports on the development of effective deacidification materials. In this paper, we aim to address this gap by presenting a novel approach to mitigate vinegar syndrome. Specifically, we prepare a microemulsion consisting of modified calcium carbonate and an ethyl cellulose/n-butyl alcohol solution, which does not react with the film material. This microemulsion is designed to both deacidify and reinforce archival films, offering a new method and perspective for the treatment of vinegar syndrome.

Results

TEM of SiO2-NCC complexes

Figure 1 presents transmission electron microscopy (TEM) images and particle size distribution histograms for nano-CaCO3 and the SiO2-NCC composite materials. Figure 1A, B show the irregular granular morphology of nano-CaCO3, with particle sizes ranging from 20 to 30 nm and a lattice spacing of approximately 0.2623 nm. Figure 1C, D depict the morphology of the SiO2-NCC composite, which largely retains the structure of nanoscale calcium carbonate, with particle diameters around 30 nm. The lattice spacing, calculated from the lattice fringes, is 0.2207 nm.

Energy-dispersive X-ray spectroscopy (EDS) analysis indicates that, in contrast to nano-CaCO3, the SiO2-NCC composite features a uniformly distributed silicon element. Additionally, the particle size distribution histogram suggests that a silica shell layer, with a thickness ranging from approximately 0.1 to 0.3 nm, forms on the surface of CaCO3.

Infrared spectrum of SiO2-NCC complexes

The infrared spectra of SiO2-NCC composites, nano-CaCO3, and nano-SiO2 were measured within the wavelength range of 450–4000 cm−¹. As shown in the Fig. 2A, characteristic peaks at 1790 cm−¹, 1456 cm−¹, 872 cm−¹ and 711 cm−¹ correspond to CaCO3. Specifically, the peak at 1790 cm−¹ represents the C = O stretching vibration of CaCO3. 1456 cm−1 is the characteristic absorption peak of CO32- of CaCO3. For SiO2, the characteristic peaks appear at 1631 cm−¹, 1105 cm−¹, and 805 cm−¹. Notably, the asymmetric stretching vibration of the Si-O-Si bond is observed at 1105 cm−¹, and the bending vibration of the Si-O bond is observed at 805 cm−¹.

In the infrared spectrum of the SiO2-NCC composite, both the characteristic absorption peaks of CaCO3 and SiO2 are present. The SiO2 peaks show a redshift, with the asymmetric stretching vibration of the Si-O-Si bond shifting from 1105 cm−¹ to 1090 cm−¹, and the bending vibration of the Si-O bond shifting from 805 cm−¹ to 801 cm−1 26,29 Furthermore, the characteristic peak at 1450 cm−¹ for SiO2-NCC is slightly broader than that of nano-CaCO3, suggesting that CaCO3 and SiO2 are not merely physically mixed but are chemically bonded.

XRD&XPS of SiO2-NCC complexes

Figure 3 shows the XRD patterns of nano-CaCO₃, nano-SiO₂, and SiO₂-NCC composites. Compared with the standard PDF card for calcium carbonate, the characteristic diffraction peaks of unmodified nano-CaCO₃ appear at 23.02°, 29.41°, 35.97°, 31.42°, 39.41°, 43.15°, 47.49°, and 48.51°, indicating that the sample is of the calcite type of CaCO₃. The X-ray diffraction pattern of SiO₂ shows no sharp, distinct diffraction peaks, but features a broad hump at 2θ = 20°–25°, which corresponds to the amorphous characteristic peak of SiO₂30. The diffraction peaks and crystal plane spacings of the modified SiO₂-NCC composite are nearly identical to those of the unmodified nano-CaCO₃ pattern. However, the intensity of the characteristic diffraction peaks is reduced to some extent, and a small broad hump also appears at 2θ = 20°–25°. This suggests that the SiO₂ generated is coating the surface of the CaCO₃ in an amorphous form, providing a shielding effect. There is no change in the original crystal structure31.

The crystallite size was determined via the Scherrer formula (Eq. (3)).

D: grain size

Κ: Scherrer constant, 0.89

λ: X-ray wavelength, 0.15406 nm

β: sample diffraction peak half-height width

θ: diffraction Angle

Through calculation, the grain size of uncoated CaCO3 is about 28.31 nm, and the grain size of coated SiO2-NCC complex is about 29.38 nm. The grain size is still less than 30 nm, and the particle performance will not be affected by the size change.

To further investigate the interactions between silica and the surface of calcium carbonate, XPS analysis was conducted on the C, O, Ca, and Si elements of Nano-CaCO3, Nano-SiO2, and SiO2-NCC. In the C 1 s spectra, the carbonate component peaks at 289.4 eV and 589.5 eV are observed in Nano-CaCO3 and SiO2-NCC, showing a chemical shift of 0.1 eV. The O 1 s spectrum of Nano-CaCO3 exhibits a symmetric peak, while the XPS peak fitting analysis of O 1 s in SiO2-NCC (Fig. 4) results in two binding energies at 531.9 eV and 532.9 eV, corresponding to the O 1 s peak of CaCO3 and the Si–O–Si peak of SiO232,33,34. Compared to Nano-CaCO3, the O 1 s binding energy in SiO2-NCC shifts toward a higher energy level by approximately 0.5 eV. A comparison of the Ca2p XPS spectra of pure CaCO3 and SiO2-coated CaCO3 (SiO2-NCC) clearly shows that silica coating leads to a significant reduction in the intensity of the calcium peaks in SiO2-NCC. In terms of binding energy, the Ca2p binding energy of uncoated CaCO3 is 347.1 eV, while after silica coating, this binding energy increases to 347.9 eV, a shift of 0.8 eV. This chemical shift is attributed to the change in binding energy due to the different chemical environments of the atoms in the molecule. Additionally, the binding energy of the Si 2p orbitals shifts from 103.8 eV to 103.4 eV, with the chemical shift mainly caused by potential changes due to the transfer of valence electrons. The transfer of valence electrons is closely related to the electronegativity of the corresponding elements. These results suggest that a new chemical bond, Ca–O–Si, is formed at the interface between the calcium carbonate surface and the silica shell, tightly binding the core and the shell together.

Optimization of SiO2-NCC/EC/BuOH (NEB) composites

Figure 5 shows the absorbance and relative absorbance after 24 hours of storage for the NCC/BuOH, SiO2-NCC/BuOH, and SiO2-NCC/EC/BuOH composite solutions (with SiO2-NCC concentration at 0.5% and EC concentration at 3%). The calculation method for relative absorbance is Eq. (4)

The absorbance of the SiO2-NCC/EC/BuOH solution is significantly higher than that of the other two solutions, and its relative absorbance decreases the least over time. After 24 hours, the relative absorbance values for the three solutions are 23%, 53%, and 78%, respectively. This can be attributed to two factors: firstly, ethyl cellulose (EC) increases the viscosity of butanol, which improves the stability of the solution; secondly, the dispersion of SiO2-NCC particles is better. These two factors help prevent nanoparticle aggregation and sedimentation, enhancing the stability of the dispersed solution. This, in turn, favors the uniform distribution of SiO2-NCC particles on the membrane surface after film formation, resulting in consistent acid removal performance.

The mechanical properties of the coatings (Fig. 6A) and the contact angle (Fig. 6B) were tested. The results indicate that with the increase in EC concentration, both the tensile strength and fold resistance of the film gradually improved. However, when the EC concentration reached 8%, the tensile strength began to decrease, and the fold resistance leveled off, showing no further significant improvement. In addition, contact angle measurements were conducted on the films, and the contact angles at 0 s, 30 s, 60 s, and 90 s were plotted as a line graph (Fig. 6B). As the EC concentration increased, the contact angle at 0 s rose from 90.5° to 106.1°. After the EC concentration reached 6%, further increases in EC concentration led to a reduction in the contact angle. The hydrophobicity of the film largely depends on the impact of surface morphology on surface chemical heterogeneity35,36,37. As the EC concentration increased, the viscosity of the liquid also increased, leading to stronger intermolecular forces and a smoother surface, which in turn reduced the overall hydrophobicity of the film. Based on these results, it was found that an EC concentration of 6% was optimal.

In this study, SiO2-NCC composites at varying concentrations are dispersed as deacidifiers, and the resulting dispersion solution is applied to acetate film. The pH (Fig. 7A), substrate transmittance, and reflectance (Fig. 7B) are then measured. From the figure, it can be observed that the average pH of the film is 6.65 when the SiO2-NCC concentration is 1.5%. Additionally, within the wavelength range of 350–800 nm, the film demonstrates a transmittance ranging from 74.71% to 94.66%, while its reflectance varies between 4.31% and 7.56%. Besides functioning as a deacidifier to reduce the film’s acidity, the SiO2-NCC material also acts as a filler for surface scratches, which helps reduce light scattering and reflection, thereby improving light transmittance. However, a concentration that is too high can increase the whiteness of the film, leading to reduced transmittance and increased reflectivity.

In summary, the concentrations of EC and SiO2-NCC in the NEB composites are 6% and 1.5%, respectively.

Performance evaluation of SiO2-NCC/EC/BuOH (NEB) composites

(1) Surface topography analysis

The surface morphology of film samples exhibiting “vinegar syndrome” and those treated with deacidification and hardening was examined. The 2D and 3D surface morphologies, observed using a scanning electron microscope (1000x magnification) and a laser confocal microscope, revealed numerous scratches, bubbles, dimpling, and mottling on the surface of the films at the early stages of “acetic acid syndrome” (Fig. 8B, E). These surface features were linked to frictional damage, degradation of the film base, and aging of the emulsion layer during storage. As acetic acid syndrome progressed, crystalline plasticizer precipitated from the film base (Fig. 8A, D), which was identified as triphenyl phosphate through X-ray diffraction (XRD) analysis. The plasticizer crystals varied in size and shape and were broadly distributed on the surface of the film base, contributing to a shading effect on the film38. The n-butanol solution used in NEB does not react with cellulose triacetate ester-based films, enabling the removal of plasticizers and other contaminants without causing damage. After coating, the surface morphology of the film (Fig. 8C, F) appeared relatively smooth, with nanoparticles uniformly distributed and encapsulated within the film. The surface height differences for the three samples were 106.796 μm, 14.599 μm, and 0.032 μm, respectively. Surface roughness analysis (Fig. 8G) indicated that all parameters for the coated film were lower than those for the film exhibiting “acetic acid syndrome.” This further demonstrated that the composite deacidification material had excellent film-forming properties, effectively eliminating scratches and bumps across the surface, leaving only slight directional paint marks.

Figure 9 shows a scanning electron microscope (SEM) image of a cross-section of the film strip reinforced with NEB material. From the image, it can be observed that the NEB film is tightly bonded to the film strip, with a thickness of approximately 5 μm. The elemental distribution map reveals a significant presence of Ca and Si elements in the NEB layer.

(2) Thermal stability analysis

Thermogravimetric analysis (TGA) was conducted on the films before and after coating. The TG curve reveals that the decomposition of the cellulose acetate (CTA) membrane occurs in three stages: The first stage primarily involves the evaporation of free water and some impurities in the system, with little change in mass. The second stage, occurring between 300 °C and 480 °C, represents a thermal decomposition process during which a large amount of deacetylation and chain scission reactions take place in the CTA, producing carbon dioxide and small molecular products, leading to a reduction in mass. The third stage is the carbonization phase, where the remaining products continue to carbonize at high temperatures between 33 °C and 35 °C39,40,41. The final mass residues for Sample 1, Sample 2, Sample 5, and Sample 6 are approximately 8.8%, 28.4%, 16.8%, and 16.0%, respectively. Sample 1 reaches its maximum decomposition rate around 440 °C, while Sample 2, Sample 5, and Sample 6 show their maximum decomposition rates near 442 °C. The results indicate that a portion of the NCC within the composite deacidification material reacts with acetic acid, resulting in a reduction of the residual mass. Concurrently, the decomposition temperature and the maximum decomposition rate of the film substrate exhibited no significant alterations. This observation confirms that the composite material does not compromise the film’s performance and exerts a certain retarding effect on the film’s degradation process. Figure 10C, D display the TG and DTG curves for nano-CaCO3 and SiO2-NCC. Nano-CaCO3 decomposes between 500 °C and 850 °C, forming calcium oxide and carbon dioxide, with a residue of approximately 38.5% at 1200 °C. The modified SiO2-NCC shows mass loss starting at 400 °C, possibly due to some impurities in the solid, with a mass residue of approximately 47.7% at 1200 °C. Due to the influence of the silica shell, the maximum decomposition rate shifts from 800 °C to 820 °C42 The composite deacidification material can improve the thermal stability of the film to a certain extent, and can delay the degradation and aging of the film.Overall, the composite deacidification material can improve the thermal stability of the film to a certain extent, and can delay the degradation and aging of the film.

(3) Durability of NEB composites

The XRD pattern (Fig. 11) shows that the film without “vinegar syndrome” retains its basic diffraction characteristics. Specifically, there are no significant peaks, but a strong broad peak appears at 2θ = 9°, along with a superimposed peak corresponding to the cellulose type II structure in the 2θ range of 15°–23°. The crystallinity, calculated to be 30.4%, suggests that the macromolecular chains in the film are arranged in a regular manner, with good crystallinity. Crystallinity was determined using the Scherrer formula (Eq. (3)).

After coating, the film structure does not undergo significant changes, with crystallinities of 28.1% and 27.9%, respectively. However, the presence of “vinegar syndrome” leads to the degradation of the polymer matrix, causing the loss of side-chain groups and precipitation of the plasticizer, which disrupts the interactions between the polymers43,44. The crystallity decreased to 20.9%, and there were obvious characteristic peaks at 2θ = 10.6° and 2θ = 21.6°. Compared with PDF card, the characteristic peaks of triphenyl phosphate, a plasticizer precipitate, were also consistent with the results observed by SEM.

It is worth noting that the film after coating exhibits a weak characteristic peak at 2θ = 29°–30°, which is smaller and broader than the characteristic peak of calcium carbonate. Comparison confirms that this is the diffraction peak from the (104) crystal plane of nano-calcium carbonate (NCC), indicating that the crystallinity is lower after the silica coating modification45. During the acetic acid aging process, SiO2-NCC continuously reacts with acetic acid gas, which is reflected in the XRD pattern as the disappearance of this weak peak. The diffraction peaks of ethyl cellulose and triacetate cellulose are essentially overlapped, and no additional diffraction peaks appear during the process, suggesting that the NEB composite material does not affect the structure of the film.

According to the stress-strain curve of the sample (Fig. 12A), It can be observed that the ultimate tensile strength of the film without degradation is 86.43 MPa, with a corresponding strain of 5.53%. After the onset of “vinegar syndrome”, the degradation of the film’s base material causes the molecular chains to break, leading to a reduction in the mechanical strength of the film. As a result, the stress and strain decrease to 27.35 MPa and 4.32%, respectively, which are significantly lower than those of the undamaged film. After undergoing wet heat aging and acetic acid aging, the tensile strength of the film decreases but remains higher than that of the unprotected film. The stress and strain of the film after wet and thermal aging are 79.60 MPa and 5.33%, respectively, while the stress and strain after acetic acid aging are 73.30 MPa and 5.27%. Table 1 Comparison of mechanical properties of films.

Additionally, the water absorption of the film was tested both before and after coating. The results showed that the average water absorption of the coated film was significantly higher than that of the uncoated film. This suggests that the NEB composite material can prevent the film surface from coming into direct contact with water molecules, reducing the risk of glucose chain breakage and alleviating the occurrence of “vinegar syndrome”. Furthermore, under the same conditions, the water absorption rate after removing the emulsion layer is lower than that of the film without removal. This is because the main component of the emulsion layer is gelatin, which has strong water-absorbing properties, contributing to the occurrence of “vinegar syndrome”.

The structure of motion picture film is generally divided into emulsion layer, film base and other functional structures .The surface of the emulsion layer is coated with a protective layer made of photographic gelatin. Table 2 shows the physical and chemical properties of untreated film as well as NEB composite-reinforced films at various stages of acetic aging. During the aging process, acetic acid catalyzes the ‘deacetylation’ of the film base, breaking the long-chain molecules of cellulose triacetate and precipitating plasticizers. The macroscopic effects include a reduction in mechanical strength, a decrease in pH, and an increase in hydrophilicity.

Additionally, under high humidity conditions, the gelatin in the protective layer degrades, liquefies, and deteriorates. This results in a roughened surface of both the protective layer and the film base, leading to increased scattering and absorption of incident light. The degree of fog also increases, indicating a decrease in the film’s transparency and imaging properties46,47. However, when treated with the NEB dispersion solution, surface defects such as scratches are filled, and the roughness of the film decreases. The protective layer and substrate are insulated from water molecules and airborne pollutants, which reduces fogging and improves imaging clarity. Specific improvements include: (1) After NEB treatment, the fogging increase after 28 days of aging is reduced, and the clarity improves. The NEB liquid, when applied to the film surface, fills depressions and smooths out protrusions, thereby reducing reflection and scattering losses and improving transparency. (2) During the aging process, the rate of pH reduction is slower in treated films. After aging with NEB deacidification and strengthening, the pH of the deteriorated film reaches 5.80, which remains within the safe range (above 5.5). SiO2-NCC particles, evenly distributed on the film surface by EC/BuOH, neutralize acetic acid molecules, raising the pH of the film. The SiO2 coating on the NCC surface protects it from direct contact with acetic acid, water, and other acidic gases, thus enhancing the acid resistance of the NCC particles and maintaining the film’s pH in a safe range over time. (3) The formation of the NEB-treated film increases its contact angle, transitioning it from hydrophilic to hydrophobic. After aging, the contact angle remains greater than 90°, contributing to the film’s hydrophobicity. This property helps to isolate the film from direct contact with water in the air, thereby preventing reactions between acetic acid molecules, water, and the protective layer, emulsion layer, and film base.

Discussion

In this study, nano-calcium carbonate was modified with an inorganic substance through a wet coating process. The resulting products were characterized using X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), Fourier-transform infrared spectroscopy (FT-IR), and field-emission scanning electron microscopy (TEM). The findings revealed that the SiO2-NCC composite silica, synthesized via a countercurrent method, is amorphous and adheres to the surface of calcium carbonate particles, which are approximately 29–30 nm in size. The NEB composite solution was prepared by grafting with a mixed n-butanol/ethyl cellulose solution, which was then coated onto the surface of the film affected by vinegar syndrome for deacidification and reinforcement. The performance of the coated film was evaluated as follows:

-

1.

The NEB film reduced surface roughness, enhancing transmittance to a range of 74.71% to 94.66%, and effectively filled in scratches, thereby improving image clarity.

-

2.

The SiO2-NCC composite, when combined with ethyl cellulose, forms an evenly distributed network structure on the film surface, enhancing its thermal stability.

-

3.

The NEB film acts as a barrier, preventing water molecules from reaching the film’s emulsion layer and base, thereby improving the mechanical properties of the coated film. The mechanical properties of the film, after acetic acid aging and wet heat aging, were found to be superior to those of films affected by vinegar syndrome. Water absorption was reduced by approximately 40%.

-

4.

Film samples treated with various methods were subjected to aging tests. The clarity (fog), acidity, and contact angle of the samples protected by the NEB film were all superior to those of the untreated films. The NEB composite material was found to mitigate the effects of vinegar syndrome on film properties and showed potential in both the prevention and treatment of vinegar syndrome.

Methods

Materials and instruments

Scrap film (Xi’an Film Database); Nanometer Calcium Carbonate; Liquid Sodium Silicate (34%, Gulf Group); Sulfuric Acid; N-Butanol (Sinopharm Chemical Reagent Co., Ltd); Ethyl Cellulose (Sinopharm Chemical Reagent Co., Ltd); Sodium Hypochlorite (Sinopharm Chemical Reagent Co., Ltd).

Field emission ultra-high resolution transmission electron microscope (STEM, JEOL); Tungsten Filament Scanning Electron Microscope (SEM, HITACHI); X-ray Diffractometer (XRD, Rigaku Electronics Corporation); Fourier Trsnsform Infrared Spectrscopy (FT-IR, Thermo Fisher); Laser Confocal Scanning Microscope (Keenes Japonica); pH Meter (Mettler Toledo Instrument); Universal Material Testing Machine (Gaotai Instrument); UV-VIS Spectrophotometer (UV-Vis, Perkin-Elmer); Thermogravimetric Analyzer (TG, Setram); Optical Contact Angle Tester (KRUSS, Germany); Humidity-Heat Aging Chamber (Memmert (Shanghai) Trading Co., Ltd.)

Preparation of nano-CaCO 3 modified by SiO 2

SiO₂-NCC Preparation: SiO₂-NCC was prepared by coating silica onto the surface of nano-calcium carbonate (NCC) particles using sodium silicate and sulfuric acid as raw materials, employing a countercurrent method.

Experimental Procedure: The coated sample was prepared using the countercurrent method as follows: 10 g of nano-calcium carbonate (NCC) was dispersed in ultrapure water to form a 10% solid content suspension, which was then stirred evenly. The NCC suspension was heated in a water bath at 90 °C. Sodium silicate was added, followed by the controlled addition of sulfuric acid solution at a rate of 2 mL/min. After the acid was completely added, the solution was heated and stirred for 1 hour, then allowed to settle for 24 hours. The resulting mixture was filtered, washed three times with water, and the nano-calcium carbonate composite was obtained by drying.

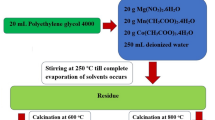

Preparation of SiO2-NCC/EC/BuOH (NEB) composites

Ethyl cellulose (EC) has excellent film-forming properties48. When blended with an n-butanol (BuOH) solution, the resulting mixture exhibits good leveling, fast film formation, strong adhesion, and excellent hydrophobicity. After drying, the film forms a dense, smooth protective network with a thickness ranging from 5 to 10 μm on the surface.

The dry SiO₂-NCC powder was added to the EC/BuOH composite solution and stirred vigorously for 1 hour, followed by ultrasonic dispersion for 2 hours. During this process, SiO₂-NCC particles were grafted onto the EC surface, forming a stable SiO₂-NCC/EC composite structure. The resulting NEB composite material was then uniformly coated onto the surface of the film and treated to remove any acid residues.The preparation process of NEB composite material is shown in Fig. 13. Figure 13 Preparation flow chart of SiO2-modified nano-CaCO3&SiO2-NCC /EC/BuOH (NEB) composites.

Treatment and aging of film samples

The samples and treatment methods used in the experiment are as follows:

The film samples used in this study were discarded films from the Xi’an Film Archive. Wet-heat aging and acetic acid aging were performed on the film samples both before and after coating, with identical aging conditions and durations for all samples. Table 3 Film samples used.

(1) Humidity-heat aging

Temperature and humidity are the main factors affecting the lifespan of films. In the experiment, the aging process of the film was accelerated by exposing it to a high-temperature and high-humidity environment. The samples were placed in an HCP humidity and heat aging chamber with a temperature of 50 °C, relative humidity of 80%, and an aging duration of 28 days. (This is equivalent to natural storage for 10.5 to 14 years in an environment with 20 ± 2 °C and 65 ± 5% relative humidity).

(2) Acetic acid aging

The experiment accelerated the aging process of the film by increasing the acetic acid concentration in the environment. The film samples, before and after coating, were placed in a closed environment with an acetic acid concentration of 2 g/L and a relative humidity of 70 ± 5%, where they were aged for 28 days.

Analytical methods

Infrared spectroscopy testing

The nano-CaCO₃ and SiO₂-NCC samples were analyzed using a PE-Frontier Fourier-transform infrared (FTIR) spectrometer under the following conditions: a wavelength range of 500–4000 cm−¹, transmission mode, spectral resolution better than 0.4 cm−¹, and 16 scans.

X-ray diffraction testing

The samples were examined using a SmartLab (9) high-resolution X-ray diffractometer, with a scanning angle range of 2θ = 5° to 60° and a step size of 0.02° per step. The X-ray generator has a power of 3 kW, and is equipped with a new 9 kW rotating target.

TEM characterization of SiO₂-NCC composites

The microstructure and lattice fringes of the SiO₂-NCC composites were characterized using JEM-2800 Transmission Electron Microscopy (TEM) at an acceleration voltage of 200 kV. The lattice resolution of TEM was approximately 0.1 nm, while the resolutions of Scanning Transmission Electron Microscopy (STEM) and Scanning Electron Imaging (SEI) were approximately 0.16 nm and 0.5 nm, respectively. The magnification range for TEM was from 500× to 2 M×, whereas for STEM and SEI, the magnification ranged from 100× to 150 M×.

XPS testing

XPS analysis was performed using an Escalab Xi+ X-ray photoelectron spectrometer (Thermo Fisher Scientific) to characterize the surface composition of both coated and uncoated calcium carbonate (CaCO₃) samples. Wide scan spectra were acquired over a binding energy range of 0–5000 eV with an adjustable X-ray spot size of 20–900 μm.

Dispersion and stability testing of SiO₂-NCC/EC/BuOH (NEB) composites

Lambda 950 UV-Vis spectroscopy was employed to measure the absorbance of the dispersion at 600 nm after standing for different periods. The relative change in absorbance was used to assess the stability of the dispersion.

Surface morphology characterization of acetate film samples

Material were characterized using a SU3500 Tungsten Filament Scanning Electron Microscope (SEM). The SEM provided resolutions of 2.5 nm at 15 kV (SE), 4 nm at 3 kV (SE), and 5 nm at 1.0 kV (SE), and operated within an acceleration voltage range of 0.1 kV to 30 kV. The magnification range of the instrument spanned from 1× to 300,000×. Additionally, VK-X250 laser confocal microscopy was employed to complement the morphological analysis.The roughness parameters analyzed included Sa, Sz, Str, Spc, and Sdr.

Thermal stability testing

A 5–10 mg sample was placed in an α-Al₂O₃ crucible, and thermal stability testing was performed using Themys One thermogravimetric analyzer. The heating rate was set to 20 °C/min, with nitrogen as the carrier gas, and the temperature range was 20–600 °C.

pH testing

A 1.0 g sample was cut into pieces measuring 1 mm × 1 mm. These pieces were placed into a wide-mouth bottle, to which 100 mL of ultrapure water was added. The mixture was stirred in a water bath at 38 °C for 24 hours. Afterward, the supernatant was collected, and its pH value was measured using Model S210 pH meter.

Mechanical testing

The film was cut into samples measuring 15.0 mm × 180 mm using a paper cutter. The samples were then mounted vertically between two grips and tested using a KC-136PC universal material testing machine under the conditions of a 100 mm gauge length and a tensile speed of 20 mm/min. The tensile strength at break is calculated using the Eq. (1)

F—The tensile force applied to the sample at the point of fracture, N.

A—The initial cross-sectional area of the sample, mm2.

Determination of contact angle of samples

KRUSS-DSA100 optical contact angle meter was used to measure the contact angle on the surface of the film under conditions where the droplet volume was 2 μL and the droplet residence time on the sample surface was 120 seconds.

Water absorption of samples

The samples were dried in an oven at 50 °C for 24 hours. After cooling to room temperature, the initial mass of each sample (m₁) was measured with an accuracy of 0.1 mg. The samples were then immersed in ultrapure water for 24 hours, after which they were removed and quickly blotted to remove surface water. The mass of each sample (m₂) was measured again, accurate to 0.1 mg. Subsequently, the samples were returned to the oven and dried until their mass became stable, after which the final dried mass (m₃) was recorded. The water absorption percentage relative to the initial mass for each sample was calculated using the Eq. (2)

Data availability

No datasets were generated or analysed during the current study.

Code availability

No custom code was generated or used in this study.

References

Knotek, V., Ďurovič, M., Dolenský, B. & Hrdlička, Z. Influence of Disinfection Methods on Cinematographic Film. Materials16, 3493 https://doi.org/10.3390/ma16093493 (2023).

Nunes, S. et al. A diagnostic tool for assessing the conservation condition of cellulose nitrate and acetate in heritage collections: quantifying the degree of substitution by infrared spectroscopy. Heritage Sci. https://doi.org/10.1186/s40494-020-00373-4 (2020).

Allen, N. S. et al. Degradation of historic cellulose triacetate cinematographic film: The vinegar syndrome. Polym. Degrad. Stab.19, 379–387 https://doi.org/10.1016/0141-3910(87)90038-3 (1987).

Soleymani, S. & Russ, L. Naphthalene Syndrome and Vinegar Syndrome Affected Films: An International Survey of Audiovisual Conservation Practitioners. Stud. Conserv. 66, 154–166 https://doi.org/10.1080/00393630.2020.1792205 (2021).

Takahashi, K., Sasaki, M., Hayakawa, H., Yajima, H. & Oda, Y. Composition of the white precipitate formed on the surface of damaged triacetyl cellulose-based motion picture films. Sci. Rep.11, 1502 https://doi.org/10.1038/s41598-020-80498-5 (2021).

Allen, N. S. et al. Acid-catalysed degradation of historic cellulose triacetate, cinematographic film: Influence of various film parameters. Eur. Polym. J. 24, 707–712, https://doi.org/10.1016/0014-3057(88)90002-x (1988).

Edge, M., Allen, N. S., Jewitt, T. S. & Horie, C. V. Fundamental aspects of the degradation of cellulose triacetate base cinematograph film. Polym. Degrad. Stab. 25, 345–362 https://doi.org/10.1016/s0141-3910(89)81016-x (1989).

Shashoua, Y. Inhibiting the inevitable; current approaches to slowing the deterioration of plastics. Macromol. Symposia 238, 67–77 https://doi.org/10.1002/masy.200650610 (2006).

Guo, C., Lan, L., Liu, Y., Meng, N. & Li, C. Comparison of environmental criteria for conservation and storage of collections: A comprehensive literature review. Build. Environ. 243. https://doi.org/10.1016/j.buildenv.2023.110665 (2023).

Ahmad, I. R. et al. Are we overestimating the permanence of cellulose triacetate cinematographic films? A mathematical model for the vinegar syndrome. Polym. Degrad. Stab. 172. https://doi.org/10.1016/j.polymdegradstab.2019.109050 (2019).

Bell, J., Newnham, M. & Nel, P. Tea: An Alternative Adsorbent for the Preservation of Cellulose Triacetate Film. Aiccm Bulletin. 103–113. https://doi.org/10.1080/10344233.2017.1402413 (2017).

Yamamoto, D., Ishii, T., Hashimoto, A. & Matsui, K. Use of sodium carbonate and sodium polyacrylate for the prevention of vinegar syndrome. Imaging Sci. J. 67, 171–178 https://doi.org/10.1080/13682199.2019.1577594 (2019).

Zheng, X., Ge, T. S. & Wang, R. Z. Recent progress on desiccant materials for solid desiccant cooling systems. Energy 74, 280–294 https://doi.org/10.1016/j.energy.2014.07.027 (2014).

Giorgi, R., Dei, L., Ceccato, M., Schettino, C. & Baglioni, P. Nanotechnologies for conservation of cultural heritage: Paper and canvas deacidification. Langmuir 18, 8198–8203 https://doi.org/10.1021/la025964d (2002).

Giorgi, R., Ambrosi, M., Toccafondi, N. & Baglioni, P. Nanoparticles for Cultural Heritage Conservation: Calcium and Barium Hydroxide Nanoparticles for Wall Painting Consolidation. Chem.-a Eur. J. 16, 9374–9382 https://doi.org/10.1002/chem.201001443 (2010).

Wojciak, A. Washing, Spraying and Brushing. A Comparison of Paper Deacidification by Magnesium Hydroxide Nanoparticles. Restaur.-Int. J. Preservation Libr. Archival Mater. 36, 3–23 https://doi.org/10.1515/res-2014-0010 (2015).

Malesic, J., Kadivec, M., Kunaver, M., Skalar, T. & Cigic, I. K. Nano calcium carbonate versus nano calcium hydroxide in alcohols as a deacidification medium for lignocellulosic paper. Herit. Sci. 7. https://doi.org/10.1186/s40494-019-0294-6 (2019).

Bicchieri, M., Valentini, F., Calcaterra, A. & Talamo, M. Newly Developed Nano-Calcium Carbonate and Nano-Calcium Propanoate for the Deacidification of Library and Archival Materials. J. Anal. Methods Chem. 2017, 2372789 https://doi.org/10.1155/2017/2372789 (2017).

Qiu, J. et al. Review on Preparation, Modification and Application of Nano-Calcium Carbonate. Part. Part. Syst. Characterization.https://doi.org/10.1002/ppsc.202400097 (2024).

Yang, L. et al. Progress in Synthesis, Surface Modification and Application of Nanometer Calcium Carbonate. Guangdong Chem. Ind. 46, 124–125 (2019).

Nan, L. et al. Optimization of in-situ Surface Modification Process of Nanometer Calcium Carbonate Prepared by Calcium Carbide Slag. Non-Metallic Mines. 41, 25–27 (2018).

Han, C., Hu, Y., Wang, K. & Luo, G. Preparation and in-situ surface modification of CaCO3 nanoparticles with calcium stearate in a microreaction system. Powder Technol. 356, 414–422 https://doi.org/10.1016/j.powtec.2019.08.054 (2019).

Li, C.-q et al. Surface modification of calcium carbonate: A review of theories, methods and applications. J. Cent. South Univ. 28, 2589–2611 https://doi.org/10.1007/s11771-021-4795-6 (2021).

Barhoum, A. et al. Effect of Cationic and Anionic Surfactants on the Application of Calcium Carbonate Nanoparticles in Paper Coating. ACS Appl. Mater. Interfaces 6, 2734–2744 https://doi.org/10.1021/am405278j (2014).

Meng, D. et al. Influencing Factors and Evaluation Methods of Modification Effect of Nano Calcium Carbonate. Bull. Chin. Ceram. Soc. 42, 123–132 (2023).

dos Santos, V. H. J. M. et al. Application of Fourier Transform infrared spectroscopy (FTIR) coupled with multivariate regression for calcium carbonate (CaCO3) quantification in cement. Construct. Buil. Mater. 313. https://doi.org/10.1016/j.conbuildmat.2021.125413 (2021).

Giorgi, R., Baglioni, M., Berti, D. & Baglioni, P. New Methodologies for the Conservation of Cultural Heritage: Micellar Solutions, Microemulsions, and Hydroxide Nanoparticles. Acc. Chem. Res. 43, 695–704 https://doi.org/10.1021/ar900193h (2010).

Nagai, M. L. E., de Souza Santos, P., Otubo, L., Oliveira, M. J. A. & Vasquez, P. A. S., Gamma and electron beam irradiation effects for conservation treatment of cellulose triacetate photographic and cinematographic films. Radiat. Phys. Chem. https://doi.org/10.1016/j.radphyschem.2021.109395 (2021).

Wan, C., Wang, L.-T., Sha, J.-Y. & Ge, H.-H. Effect of Carbon Nanoparticles on the Crystallization of Calcium Carbonate in Aqueous Solution. Nanomaterlals 9, 179 https://doi.org/10.3390/nano9020179 (2019).

Awadh, S. M. & Yaseen, Z. M. Investigation of silica polymorphs stratified in siliceous geode using FTIR and XRD methods. Mater. Chem. Phys. 228, 45–50 https://doi.org/10.1016/j.matchemphys.2019.02.048 (2019).

Xiaohong, L. I. U. et al. Study on synthesis of silica coating nano calcium carbonate. J. Nanchang Univ.(Eng. Technol.) 38, 12–15+59 https://doi.org/10.13764/j.cnki.ncdg.2016.01.003 (2016).

Aghaei, R. & Eshaghi, A. Optical and superhydrophilic properties of nanoporous silica-silica nanocomposite thin film. J. Alloys Compounds. https://doi.org/10.1016/j.jallcom.2016.12.327. (2017)

Garbassi, F., Balducci, L., Chiurlo, P. & Deiana, L. A study of surface modification of silica using XPS, DRIFT and NMR. Appl. Surf. Sci. https://doi.org/10.1016/0169-4332(94)00469-2 (1995).

Ni, M. & Ratner, B. D. Differentiating calcium carbonate polymorphs by surface analysis techniques-an XPS and TOF-SIMS study. Surf. Interface Anal. 40, 1356–1361 https://doi.org/10.1002/sia.2904 (2008).

Kim, E.-K., Yeong Kim, J. & Sub Kim, S. Synthesis of superhydrophobic SiO2 layers via combination of surface roughness and fluorination. J. Solid State Chem. https://doi.org/10.1016/j.jssc.2012.08.017 (2013).

Chan, L. W., Chow, K. T. & Heng, P. W. S. Investigation of wetting behavior of nonaqueous ethylcellulose gel matrices using dynamic contact angle. Pharm. Res. 23, 408–421 https://doi.org/10.1007/s11095-005-9259-4 (2006).

Lin, Y. et al. A naturally tailored small molecule for the preparation of ethyl cellulose supramolecular composite film. Cellulose. https://doi.org/10.1007/s10570-020-03532-9 (2020).

Zhongying, X. U., Tian, L. I. & Xingrong, Z. Preparation and Property of Flame Retardant ABS by Epoxy Resin/Triphenyl Phosphate. China Plast. Ind. 34, 44–46 (2006).

Sairam, M., Sreedhar, B., Rao, D. V. M. & Palaniappan, S. Synthesis and thermal degradation kinetics of cellulose esters. Polym. Adv. Technol. 14, 477–485 https://doi.org/10.1002/pat.358 (2003).

Jianxin, H. E., Yuyuan, T. & Shanyuan, W. Crystalline structure and thermal property of cellulose acetate. J. Text. Res. 29, 12–16 (2008).

El-Sakhawy, M. et al. THERMAL PROPERTIES OF CARBOXYMETHYL CELLULOSE ACETATE BUTYRATE. Cellul. Chem. Technol. 53, 667–675 https://doi.org/10.35812/CelluloseChemTechnol.2019.53.65 (2019).

Gamelas, J. A. F., Lourenco, A. F., Ferreira, P. J. New modified filler obtained by silica formed by sol–gel method on calcium carbonate. J. Sol-Gel Sci. Technol. https://doi.org/10.1007/s10971-011-2456-1 (2011).

Del Gaudio, I. et al. Water sorption and diffusion in cellulose acetate: The effect of plasticisers. Carbohydr. Polym. 267, 118185 https://doi.org/10.1016/j.carbpol.2021.118185 (2021).

Bamba, M. et al. Preparation and Characterization of Cellulose Triacetate from Cocoa Pod Husk. Bioresources 18, 1684–1698 https://doi.org/10.15376/biores.18.1.1684-1698 (2023).

Yu, Y., Zhang, J., Wang, H. & Xin, Z. Silanized Silica-Encapsulated Calcium Carbonate@Natural Rubber Composites Prepared by One-Pot Reaction. Polymers 12, 2668 https://doi.org/10.3390/polym12112668 (2020).

Yuan, Z. et al. Improvement of the functional properties of cellulose acetate film by incorporating with glycerol and n-propanol. Cellulose 29, 7823–7836 https://doi.org/10.1007/s10570-022-04752-x (2022).

Zhou, Y. et al. Preparation and Characterization of Cellulose Nanocrystal-Doped Cellulose Triacetate Optical Films by Sol-Gel Process. Chemistryselect, 9. https://doi.org/10.1002/slct.202400262 (2024).

Alekseeva, O. V., Noskov, A. V. & Agafonov, A. V. Structure, physicochemical properties, and adsorption performance of the ethyl cellulose/bentonite composite films. Cellulose 29, 3947–3961 https://doi.org/10.1007/s10570-022-04546-1 (2022).

Acknowledgements

The authors are grateful to the China Film Archive for the support with the samples for this research. This research was supported by the National Natural Science Foundation of China (22072083), State Archives Administration key science and technology project (2024-Z-010).

Author information

Authors and Affiliations

Contributions

X.D. (Xujia Dong): writing-original draft, investigation, funding acquisition.Y.Z. (Yajun Zhou): funding acquisition. X.C. (Xiaolian Chao): writing-review, funding acquisition. Y.L. (Yuhu Li): supervision.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Dong, X., Li, Y., Chao, X. et al. Silica nano CaCO3 ethylcellulose N-butanol composite system for film preservation vinegar syndrome eradication. npj Herit. Sci. 13, 220 (2025). https://doi.org/10.1038/s40494-025-01679-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s40494-025-01679-x