Abstract

The domestication of horses, originating from the Eurasian steppe, profoundly impacted early Chinese societies. While late Shang horses and horse-drawn chariots have been widely studied, other representations of horses in material culture remain less explored. This study analyzed China’s earliest bronze horse sculptures, unearthed from a late Shang tomb on the Loess Plateau. The work involved in-situ examination of the crafting traces and subsequent laboratory analysis. The findings enhanced our comprehension of the technical characteristics and potential casting locations of the bronze horses. Comparative evidence identifies the two horses as paired drinking vessels imitating the animal shape, combining local and Central Plains styles. They were likely locally cast on the Loess Plateau utilizing metal raw materials and technologies directly or indirectly imported from the Central Plains. This study offers insights into local bronze handicraft industry and interactions between the Central Plains and surrounding regions during the late Shang period.

Similar content being viewed by others

Introduction

Horses played an important role in the early stages of human civilization. Serving as representatives of strategic resources and productivity, they have significantly altered the patterns and pace of human interactions across the pan-Eurasian continent1,2,3. Given the high value placed on this crucial animal, ancient peoples frequently incorporated horses into burial and sacrificial rituals4,5, and depicted them in various forms of artistic expression6,7. Currently, morphological and genetic analyses of unearthed horse bones have emerged as the primary means of understanding the relationship between humans and horses8,9,10. Additionally, scholars have also undertaken explorations of horse-related archaeological remains and horse-shaped artworks11,12.

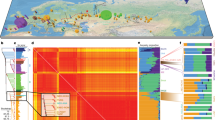

In 2005, two realistically shaped bronze horse sculptures were unearthed from a destroyed late Shang tomb on the Loess Plateau in China (Yanjiagou Village, Ganquan County, Shaanxi Province), representing the earliest independent round-sculpted horse artworks found in the country and the sole example of its kind in Shang Dynasty bronze artifacts (Figs.1, 2a, b). Hiroki Kikuchi and his colleagues, from the perspective of zooarchaeology, highlighted that these two bronze horses are among the rare archaeological findings discovered outside Anyang, the capital of the late Shang Dynasty, which depict human-horse relationships distinct from those represented by horse bones found in other contexts13.

The red and black dots represent sites where late Shang remains associated with horses have been discovered. Dots within the blue region correspond to sites of the Shang culture, while those within the red region indicate sites belonging to its neighboring powers. The yellow triangles denote the locations from which the reference samples come. (1: Yanjiagou; 2: Anyang; 3: Xujianian; 4: Yujiawan; 5: Nianzipo; 6: Hejia; 7: Heidouzui; 8: Laoniupo; 9: Xicha; 10: Linzheyu; 11: Xinzhuang; 12: Zhaigou; 13: Lijiaya; 14: Waizhuangcun; 15: Caojiayuan; 16: Shangdongcun; 17: Jingjie; 18: Qiaobei; 19: Jiuwutou; 20: Xiaohucun; 21: Tianhu; 22: Ximufo; 23: Beizhuangzi; 24: Chenshantou; 25: Houqianyi; 26: Donghangezhuang; 27: Liujiazhuang; 28: Subutun; 29: Qianzhangda; 30: Lijia; 31: Zaolinhetan; 32: Heimugou; 33: Peijiamao; 34: Houma; 35: Guanzhuang).

a The GQ744-1 bronze horse. b The GQ744-2 bronze horse, its right front leg exhibits a stratified structure, comprising an outer layer of metal, followed by dark-red and yellowish-brown hardened substances, and finally filling soil. c Some other bronze artifacts unearthed, including vessels (Ding, Gui, Yan, Gu, You) and weapons (Yue, Ge, sword, knife).

Nearly 70 artifacts, predominantly bronze items such as food containers, drinking vessels, and weapons (Fig. 2c), were excavated from the tomb, along with a small assortment of gold foil decorations, turquoise ornaments, bone arrowheads, and animal teeth. The tomb was initially dated to the late stage of the second phase through the fourth phase of the Yin Ruins period (approximately 1191-1046 BCE) and is associated with the Lijiaya culture14, which is commonly linked to the powerful state “Guifang” on the northwest of the Shang Dynasty15. The Yanjiagou tomb, with the highest number of unearthed artifacts and the most diverse contents among similar tombs in the Loess Plateau during the Late Shang period, has garnered widespread interest from scholars since its discovery. Archaeologists have engaged in thorough discussions regarding significant issues such as the dating of the tomb, typological features of artifacts, the assemblage of vessels, as well as the cultural elements and regional interactions they reflect, ultimately reaching a certain consensus16,17,18.

At the close of 2020, Northwest University commenced the scientific conservation and restoration of the bronze artifacts unearthed from Yanjiagou tomb, presenting an opportunity to conduct a preliminary analysis of the alloy composition and metallographic structure of various vessels, including Ding, Gui, Yan, You, and Gu19. Subsequently, Yangxinghe Liu systematically analyzed the alloy composition, metallographic structure, trace elements, and lead isotope ratios of these bronzes. Within the framework of the “Oxford Research System”20, she conducted multidimensional comparisons with materials from surrounding areas to explore issues such as metal flowing patterns and raw material sources21.

However, there is currently insufficient research on the two bronze horses, and our understanding of them remains limited14. The existing knowledge primarily includes: (1) The objects are solid in form with no internal cavities; (2) They depict the appearance of Equus przewalskii; (3) They depict the appearance of the earliest saddles; (4) It is possible that they were used for burial or sacrificial purposes. In Yangxinghe Liu’s work, only in-situ elemental composition data and rust samples’ lead isotope data were acquired21. The former exhibits exceptionally high lead content due to the influence of surface corrosion products, posing challenges in accurately reflecting the material information of the objects. Their reference value is limited, making it difficult to delve into a comprehensive discussion.

In the field of metallurgical archaeology, clay molds and cores have always been highly valued. Scholars typically conduct analyses from the perspectives of major and trace element composition, mineral composition, and petrographic structure of the samples, comparing them with other molds, cores, pottery sherds, soil, etc. to explore the production technologies and potential casting locations of bronze artifacts22,23,24,25,26,27. In this study, a comprehensive sampling and analysis was conducted on the residual casting cores of the bronze horses, alongside an examination of the alloying and casting technologies employed in creating the artifacts. Based on these findings, we combined existing archaeological materials to conduct a discussion on the technical features, functions, and sources of the bronze horses, to reveal valuable additional information about these precious artifacts.

Methods

Overview of objects and samples

The two bronze horses share a similar form and are depicted in a standing posture. Apart from the parallel lines that represent the mane and tail hair, there are no other additional decorative elements. The surface is completely covered with red and green corrosion products and encrusted soil. The bronze horse GQ744-1 is slightly taller and is characterized by the absence of its left ear and front legs. Similarly, the GQ744-2 bronze horse displays missing front legs and the right hind leg. Residual casting clay cores were found inside all of their extant hooves. Except for the right front leg of GQ744-2, which is suspected to be connected to the horse’s abdomen, all other broken legs are in a closed state (Fig. 2a, b).

Collection and pretreatment of samples

In this study, we mainly sampled and analyzed the residual casting clay cores, the filling soil, as well as the inner surface hardened substance of the bronze horses. Additionally, we sampled the bronze horses’ metal body, buried soil, and other bronze artifacts’ casting clay cores for comparative analysis. The sampling procedure adheres to the principle of minimal intervention, aiming to minimize any impact on the value of the artifacts and their subsequent restoration work. Detailed sampling information is presented in Table 1.

It is important to highlight that the piece-shaped samples preserve their original structural morphology, enabling us to selectively excise and analyze specific parts of interest. Consequently, they are regarded as the preferred choice for various analytical procedures. These samples were prepared by purging them with compressed air. In contrast, powder samples were obtained through scraping the surface of the objects, which may be subject to contamination from surface rust; thus, they serve solely as qualitative supplementary references.

Investigation of the casting technology

Ancient bronzes were predominantly produced through casting, and regardless of the method—piece-mold or lost-wax—a well-designed gating system was essential for achieving the intended shapes, patterns, and hollow structures28,29,30. By examining the morphological characteristics and technical traces (such as parting lines, core supports, and repair blocks) of the object, it is possible to partially reconstruct its technical details30,31,32,33. In addition to visual inspection, we also attempted to perform X-ray analysis on the bronze horses using an X-ray tube (GILARDONI ART-GIL 350/6) with voltage ranging from 100 to 130 kV, a current of 4.5 mA, and an exposure time of 180 s.

Analysis with optical microscopes (OM)

We conducted petrographic observations on the casting clay cores, filling soil, and hardened substance to visually compare the grains’ sizes, sphericity, color, and distribution among these different samples. Due to their diminutive size, the samples were unsuitable for petrographic thin section preparation, the block-shaped ones were embedded in epoxy resin, followed by meticulous polishing, and subsequently subjected to direct observation under an optical microscope. The utilized equipment was the HIROX RX-100 three-dimensional digital video microscope system, equipped with the AC-2016VD lens capable of magnification ranging from 20 to 160 times.

Furthermore, the metal body was also embedded in epoxy resin, meticulously polished, and subsequently subjected to etching using an ethanol solution containing ferric chloride and hydrochloric acid34. The resulting microstructure was then examined under a metallographic microscope. The utilized equipment was the XD30M series metallographic microscope from Sunny Optical Technology Co., Ltd., equipped with a 10x eyepiece lens as well as 5x, 10x, 20x, and 50x objective lenses.

Analysis with a scanning electron microscope-energy dispersive spectrometer (SEM-EDS)

Embedded and polished samples were carbon-coated and then observed utilizing a scanning electron microscope (TESCAN VEGA-3XMU). The elemental composition of different regions was measured utilizing an energy dispersive spectrometer (OXFORD INCA x-act). The scanning electron microscope was equipped with a tungsten lamp electron gun, operating at an excitation voltage of 20 kV. Elemental analysis was conducted in backscattering mode, with a working distance of 15 mm. Each region was measured five times in parallel, and the mean value was calculated. Subsequently, the results were normalized and presented in terms of weight percentage (wt%).

In order to assess the accuracy and precision of the EDS results, we conducted sample preparation and analysis on two soil reference materials and one tin bronze reference material, employing the methodology previously described. The soil reference materials were developed by the Institute of Geophysical and Geochemical Exploration, Chinese Academy of Geological Sciences, classified as national first-grade standards in China, while the tin bronze reference material was developed by Shenyang Nonferrous Metal Processing Factory and recognized as a general industry standard material. The average measurement values, error values, and deviation values are presented in Tables 2 and 3.

Furthermore, the relative volume of grains( ≥ 10μm), clay matrix( < 10μm), and pores in the casting cores, filling soils, and hardened substances were quantified using a point counting method35 applied to SEM images. The equivalent projected area diameter of each counted grain was calculated, with the formula as follows:

In this formula, “d” represents the equivalent projected area diameter, “S” represents the projected area of the grain, and the proportionality constant “\({\rm{\pi }}\)” is taken as 3.14. The counting interval was set to be greater than or equal to the maximum grain diameter in the sample to avoid duplicate counts, and it was ensured that each sample has a minimum of 200 counting points. Point counting and grain size calculation were conducted separately using Fiji (ImageJ)36 and AutoCAD software.

Analysis with an X-ray diffractometer (XRD)

We conducted X-ray diffraction analysis on the casting clay cores, hardened substances, and various soil samples to qualitatively determine their mineral composition. Piece-shaped samples were prioritized for selection, finely ground in an agate mortar and then sieved through a 200-mesh sieve before undergoing instrumental testing. The X-ray diffractometer was the Rigaku Ultima IV from Japan, operating with CuKα radiation at 40 kV and 40 mA. The scanning parameters included a speed of 1°/min and a range of 5–70°. The obtained XRD patterns were cross-referenced with the ICDD (International Centre for Diffraction Data)37database using Jade 6 software to ascertain the mineral composition.

Analysis of thermogravimetry-differential scanning calorimetry (TG-DSC)

Thermal analysis can partially reveal the heating history of clay materials, and provide qualitative and semi-quantitative assessments of specific inclusions, such as calcite38, thereby aiding in the determination of the cores’ heating temperature and the attribution of the filling soils and hardened substances. The analytical instrument utilized was a NETZSCH STA 449 F5 synchronous thermal analyzer manufactured in Germany. For each test, the sample was weighed to 8 ± 0.05 mg and then placed in an aluminum crucible. Subsequently, it was heated from 30 °C to 1000 °C at a rate of 10 K/min in a nitrogen atmosphere, resulting in a thermal flow/mass loss synchronous curve.

Results

Casting technology of the bronze horses

The two bronze horses underwent post-production surface refinement, during which some technical traces were removed. Nevertheless, the remaining parting lines still indicate that the piece-mold method was used for casting. Taking either one of them as an example, the body mold section was divided into two halves along the mane and backbone, with each half featuring an ear-shaped cavity on its inner surface. The rear section of the mane is integrated with the “saddle” structure, while being separated from the front section, resulting in discontinuous hair patterns between the two sections (Figs. 3a, 4a, c). Additionally, there is a gap between the “saddle” and the horse’s body, suggesting that the “saddle” was individually cast before being combined with the body. A bottom mold section should be positioned between the four legs, and between this mold section and body mold sections, parting lines were formed at the junction of the body side and belly, chest and belly, as well as each leg’s front and rear edges (Fig. 3b). The continuous parting lines extending from the hind legs’ rear edge to the tail’s sides (Fig. 3c) suggests the presence of a tail mold section, which was linked to both the body and bottom mold sections. The tail root is thickened on the inner side into a wedge shape, which is believed to have been intentionally created by carving a groove into the bottom mold section inner surface to reinforce the strength of the tail root and prevent breakage or detachment (Fig. 3d). The facial features were also captured in a mold section, including the eyes (Fig. 3f, g). The section from the chest to the lower jaw may be molded separately or as part of the body molding, and the residual parting line at the lower jaw suggests that the mold section here was also divided into two halves (Fig. 3h). The hollow nature of the body and hooves suggests the presence of clay cores during the manufacturing process, while the solid metal legs indicate that the two kinds of clay cores were not interconnected. There should be clay supports attached to the body core, which were the same thickness as the casting cavity, thus forming a hollowed-out structure for the nose and mouth (Fig. 3i).

The parting lines are marked with yellow arrows. a The mane of the GQ744-1 bronze horse. b The junction of the GQ744-1 bronze horse’s chest and belly. c The tail of the GQ744-2 bronze horse. d The inner side of the GQ744-2 bronze horse’s tail root. e The outer side of the GQ744-1 bronze horse’s tail root. f The left side of the GQ744-1 bronze horse’s face. g The left eye of the GQ744-2 bronze horse. h The lower jaw of the GQ744-1 bronze horse. i The nose and mouth of the GQ744-2 bronze horse; the deviation of the nasal structure is attributed to the displacement of the core support during casting.

The arrows indicate the presence of concealed fissures, while the circles signify the suspected spacer traces. a GQ744-1 bronze horse, lateral imaging perspective. b GQ744-1 bronze horse, top-down imaging perspective. c GQ744-2 bronze horse, lateral imaging perspective. d GQ744-2 bronze horse, top-down imaging perspective.

Furthermore, it is essential to incorporate metal spacers between the body core and the body mold section as well as the bottom mold section to ensure the stability of the casting cavity structure. Nevertheless, due to extensive corrosion, no discernible traces of these spacers were evident on the horses’ surface. The X-ray images reveal multiple suspicious spacers at the facial region (Fig. 4), necessitating further validation through more advanced CT (computed tomography) technology.

The metallographic structure and elemental composition of the metal sample

The metallographic analysis results of the bronze horse exhibit a characteristic casting microstructure. In Fig. 5, the dendritic segregation of α solid solution is evident, with refined dendrite growth indicating favorable cooling conditions during casting34. A substantial quantity of (α + δ) eutectoid structure occupies the interdendritic spaces, while lead is distributed within the matrix in the form of spherical shapes and fine particles. In addition, the microstructure contains numerous spherical free copper phases and cuprous oxide phases. These phases result from the deposition of copper in various valence states during the corrosion and mineralization processes within the pores formed by casting shrinkage or lead loss39.

Figure 6 depicts the backscattered electron images at different magnifications and the EDS test regions of the sample, with corresponding test data presented in Tables 4 and 5. The analysis indicates that the bronze horse is a Cu-Sn-Pb ternary alloy, with tin and lead content ranges of 13.08–16.05% and 4.57–9.50%, respectively, and average contents of 15.10% for tin and 6.41% for lead. Considering the minor mineralization present in the sample, which has resulted in the partial loss of copper and lead elements, the actual tin content in the alloy is likely somewhat lower than the analytical value40, estimated to be approximately 10% to 15%. The presence of this kind of composition is more prevalent in the bronze ritual vessels excavated from the tombs of high-ranking nobles at Anyang during the Yin Ruins Phase II41,42, and can also be identified in certain Yin Ruins style bronze vessels unearthed in the Loess Plateau area43. However, it exhibits distinct differences from the overall characteristics of lead-rich, arsenic-rich, and low-tin content found in other Yanjiagou tomb’s bronze vessels19,21. Moreover, the presence of impurity elements such as As, Fe, Sb, Ni, Ag, and Zn in the sample is at remarkably low levels, suggesting a high degree of refinement in the raw materials utilized for casting the bronze horse.

The micro-region composition analysis further confirms the results of the metallographic observation. In Fig. 6b, SEM images revealed grayscale disparities between the inner and outer regions of the α solid solution dendrites, indicating the presence of intragranular segregation, with the dendrite centers predominantly composed of pure Cu and Sn elements and minimal mineralization. Conversely, the (α + δ) eutectoid structure exhibits higher oxygen content, suggesting preferential corrosion of the tin-rich phase. Additionally, lead particles contain a certain amount of sulfur, potentially originating from ore or sulfur-containing substances in the burial environment.

The petrographic characteristics of casting clay cores and soil samples

The optical micrographs in Fig. 7 depict the casting cores, filling soils, and hardened substances. Among these, the morphological characteristics of the three filling soil samples from the bronze horses exhibit a fundamental similarity, with a matrix displaying a grayish-brown hue and only sporadic well-sorted fine grains (Fig. 7g–i). The morphological characteristics of the hardened substance from the GQ744-2 bronze horse’s mouth (Fig. 7j, k) are similar to those observed in the casting core from its left hind hoof (Fig. 7c). Their matrix exhibits a reddish-brown hue, interspersed with a sparse distribution of large grains, predominantly manifesting angular and subangular shapes. The casting core matrix of the GQ744-1 bronze horse exhibits a slightly darker hue compared to that of the GQ744-2 bronze horse. While the size of the large grains is similar in both, there is a slightly higher roundness observed in the grains of the GQ744-1 bronze horse. Additionally, differences are also noted in the C001 and C002 cores for the GQ744-1 bronze horse’s hooves, with the latter being looser in texture and containing fewer large grains. The casting cores of the three Ding exhibit distinct variations in matrix hue, grain size, and grain morphology (Fig. 7d–f), all differing from those of the bronze horses’ casting cores. Notably, the GQ743-3 Ding’s casting cores are predominantly composed of clay matrix, with few large grains. Some pores display a banded structure, likely resulting from the combustion of plant fibers.

a Casting core of the GQ744-1 bronze horse’s right hind hoof (C001, 160x). b Casting core of the GQ744-1 bronze horse’s left hind hoof (C002, 160x). c Casting core of the GQ744-2 bronze horse’s left hind hoof (C004, 160x). d Casting core of the GQ743-1 Ding (C005,160x). e Casting core of the GQ743-3 Ding (C006; 160x). f Casting core of the GQ743-4 Ding (C009, 160x). g Filling soil inside the GQ744-1 bronze horse’s mouse (S001, 160x). h Filling soil inside the GQ744-2 bronze horse’s mouse (S003, 160x); i) Filling soil inside the GQ744-2 bronze horse’s abdomen (S004, 160x). j Hardened substance on the inner bottom surface of the GQ744-2 bronze horse’s mouth (I001, 130x). k Hardened substance on the inner bottom surface of the GQ744-2 bronze horse’s mouth (I001, 160x). l Hardened substance on the inner surface of the GQ744-2 bronze horse’s broken right front leg (I002, 160x).

Additionally, a particularly unique sample is the hardened substance on the inner surface of the GQ744-2 bronze horse’s broken right front leg (Fig. 7l). Its matrix consists of dark-red and yellowish-brown layers, and the grain size is slightly larger than that of the filling soils. The dark-red layer exhibits greater density, while the yellowish-brown layer contains more pores, with local inclusions of green corrosion products. An orange band is present at the interface between the two kinds of matrix, potentially indicating differing chemical compositions.

We then conducted point counting analysis on the high-quality SEM images of the casting cores and soil samples and subsequently generated a stacked bar chart illustrating the percentage bulk composition (Fig. 8) as well as a boxplot depicting grain size distribution (Fig. 9) for each sample. Upon examination of the figures, it is evident that the bulk composition of the casting cores C002 and C004, as well as the hardened substance I001, exhibit similarities, while casting core C001 has a notably a higher grain content. Furthermore, there is a relatively lower presence of large grains in the casting core C002 compared to consistent distribution patterns of grain sizes among C001, C004, and I001, aligning with microscopic observations.

About the bronze Ding, the bulk composition of the casting cores for the same vessel exhibits a high degree of similarity, while there are significant distinctions between different vessels. However, in terms of grain size, there is a substantial disparity between C007 and C008, which are from the same vessel, potentially attributable to the stochastic errors arising from the limited number of grain statistics.

The filling soil S003 exhibits higher porosity and lower grain content compared to the aforementioned samples and is devoid of grains larger than 50μm in diameter. Considering its loose and fragile characteristics, it is likely that the sample represents soil that infiltrated the bronze horse during burial, rather than being part of the casting core.

According to relevant studies, the casting molds, cores, and models unearthed at Yin Ruins have a low content of clay matrix and a high content of silt, achieved through the process of washing loess raw materials24,44,45,46. In comparison, the proportion of clay matrix of Yanjiagou bronze artifacts appears to be marginally higher. Additionally, in Yin Ruins, the coarse sand content in the outer layer of the double-layer mold and the core is significantly higher compared to that in the inner layer and the model, suggesting a potential sand-adding process during the former’s production24,45,46. The situation with the Yanjiagou bronze artifacts’ casting cores is analogous. Apart from C005, the grain sizes of the other clay cores do not conform to a normal distribution. Their primary grain sizes are concentrated within the silt range (10–60 μm), with coarse sand ( > 60μm) present in lower amounts. Despite its scarcity, the coarse sand exhibits good sorting, suggesting a potential anthropogenic addition.

The major elements of casting clay cores and soil samples

We have chosen ten soil elements (Na, Mg, Al, Si, P, K, Ca, Ti, Mn, Fe) and three alloy elements (Cu, Sn, Pb) as the subjects of analysis. The results show that the dark-red matrix of hardened substance I002 is predominantly composed of Cu element, with a minor presence of Pb, accounting for mass ratios of 84.27% and 11.95%, respectively, suggesting that the primary component is likely cuprous oxide. In contrast, the yellowish-brown matrix is largely constituted by Pb, exhibiting a mass ratio as high as 98.70%, which may represent a mixture of lead salts and lead oxides. Additionally, the orange band at the interface between these two matrices also exhibits significantly high lead content (Fig. 10), indicating the main presence of lead oxides. Consequently, it can be preliminarily inferred that I002 does not originate from the residual casting core but rather represents a corrosion layer formed through outward migration and deposition of alloy elements during burial. As for other samples, since the elements of Cu, Sn, and Pb are very minimal, we only present the soil elements in the form of oxides and list the normalized average element content in Table 6.

The data in the table reveals that SiO2 and Al2O3 are the predominant constituents of the samples, with content ranges spanning from 55.70% to 71.98% and 10.21% to 22.74%, respectively, indicating substantial variability among the samples. The primary source of SiO2 is attributed to quartz grains within the samples, and its relative content may be influenced by processes such as the washing of loess and the addition of sand during manufacturing. The presence of higher levels of P2O5 in samples C001, C002, and C004 suggests the possible addition of plant ash to the raw materials. Additionally, it is important to note the presence of CaO, which has been identified as a significant indicator element in previous research on the potential locations of bronze casting. Owing to variations in leaching processes, the concentrations of Ca and Mg in the loess deposits within the Yellow River basin are notably higher than those found in the red soil deposits of the southern region, with a 4% disparity serving as an approximate threshold for differentiation22,23. The molds, cores, and models utilized in the casting of ancient bronzes were often crafted from locally sourced materials, and the firing process has minimal impact on the concentrations of most major and trace elements47,48, thereby allowing for the preservation of the compositional characteristics of the indigenous raw materials to a significant extent within the finished product. Comparing the data in Table 6, the Ca content in the clay cores (C001, C004) and filling soils (S001, S004) of the two bronze horses is notably higher, with some reaching levels exceeding 15%; the Ca content in the clay cores (C009, C010, and C011) of GQ743-4 Ding is marginally lower, at approximately 6%; while the Ca content in the clay cores (C005, C006, C007, and C008) of GQ743-1 and GQ743-3 Ding is exceedingly low, not surpassing 2%. These findings suggest that the unearthed bronze artifacts from the Yanjiagou tomb may have been sourced from diverse casting workplaces, with indications that the bronze horses were likely cast in northern regions and certain bronze Ding could potentially be linked to casting workshops in southern regions. Particularly noteworthy is GQ743-3 Ding, as its clay cores (C006, C007, and C008) exhibit lower levels of Na and Mg but higher levels of Al, Ti, and Fe—indicative of soil composition characteristics specific to southern regions49.

To further trace the potential source of the clay cores used in casting the bronze horses, we gathered chemical composition data for some soils, molds, and cores from the Loess Plateau and its surrounding areas for comparative analysis (See supplementary materials). These analyzed samples predominantly originate from local natural environments, including sites such as Heimugou and Peijiamao, as well as bronze casting sites from the Shang and Zhou dynasties, such as Yin Ruins, Lijia, Guanzhuang, and Houma; their geographical positions are illustrated in Fig. 1. It should be noted that some of the bronze casting sites where molds and cores have been unearthed have a different dating from the Yanjiagou tomb, but the geochemical changes over such a time scale can be virtually ignored. The considerations of local craftsmen in selecting raw materials should be similar at different periods, thus these samples retain their comparative significance. We utilized the SPSS (Statistical Product and Service Solutions) software to perform factor analysis on the seven elements Na, Mg, Al, K, Ca, Ti, and Fe. The Kaiser-Meyer-Olkin (KMO) test statistic yielded a value of 0.623 ( > 0.5). Additionally, Bartlett’s sphericity test produced a probability value of P = 0 ( < 0.05), leading to the rejection of the null hypothesis. The first two factors extracted through principal component analysis account for a cumulative variance contribution rate of 65.18%. The factor scatter plot (Fig. 11) reveals that Al2O3, K2O, and TiO2 exhibit higher loadings on factor 1, whereas CaO demonstrates elevated loadings on factor 2. Although most of the reference samples come from loess deposit areas in northern China, the clay cores of the bronze horses from Yanjiagou tomb exhibit a distinct difference in distribution range when compared to samples from casting workshops at Yin Ruins, Lijia, Guanzhuang, etc. It demonstrates a certain range overlap with samples from Houma, while sharing a similar distribution center with soil samples from Yanjiagou, Heimugou, and Peijiamao. These findings suggest a potential likelihood that the bronze horses were locally cast on the Loess Plateau; however, further evidence is required to substantiate this claim. The clay cores of the GQ743-1 and GQ743-3 Ding are situated at a significant distance from the aforementioned northern sample group, suggesting that these two artifacts may have been cast in a specific southern region before being transported to the Loess Plateau.

Al2O3, K2O, and TiO2 exhibit higher loadings on factor 1, whereas CaO exhibit higher loadings on factor 2. The chemical composition of the bronze horse cores reflect characteristics of raw materials sourced from northern regions, but there is no significant overlap in the compositional ranges between these samples and those from Yin Ruins.

The mineral composition of casting clay cores and soil samples

The XRD patterns and mineral identification results for the casting cores, soil samples, and hardened substances are presented in Fig. 12. Notably, the mineral composition of the three filling soil samples (S001, S003, and S004) within the bronze horses are entirely consistent, primarily comprising quartz, albite, adularia, microcline, dolomite, calcite, muscovite, hornblende, and chlorite. The common mineral types and proportions of the buried soils (S002 and S005) closely resemble those of the filling soils, but they also contain additional minerals such as cerussite, hydrocerussite, and malachite, which are rich in lead and copper. The presence of these minerals is likely attributable to contamination of corrosion products on the surface of the objects.

The mineral composition of the hardened substance on the inner bottom surface of the horse’s mouth (I001) is in accordance with that of the casting cores from its hooves. Combining the results of XRD, OM, and SEM-EDS, it can be inferred that this sample is also indicative of a residual casting clay core. In comparison to the filling and buried soils, chlorite was not detected in the bronze horses’ casting cores, possibly due to the washing process of raw materials leading to a reduction in clay mineral content. Furthermore, it is noteworthy that the absence of calcite in C002 differs from other casting cores of the horses and directly contributes to the lower Ca content in this sample. Some researchers have observed that the clay cores utilized in the casting of large bronze artifacts may exhibit notable variations contingent upon their locations, with differences in raw materials utilized during segmented casting being identified as a contributing factor to this diversity50. Although the main body of the Yanjiagou bronze horses was cast in a single operation, variations in the raw materials utilized for different sections of the molds and cores may have occurred during this process.

Owing to the limited sample size, only the yellowish-brown layer’s mineral composition was analyzed in I002. The results indicate that the high lead content is primarily attributed to cerussite and phosgenite, with minor amounts of quartz, microcline, albite, and muscovite. Combining observations from OM and EDS analysis results leads to the conclusion that this sample is not a residual casting core but rather a combination of surface corrosion products and soil mineral grains. Additionally, the mineral composition of the casting cores for the three bronze Ding differs significantly from that of the two bronze horses, aligning with the findings of petrographic and chemical composition analyses. Firstly, the clay cores of the three bronze Ding are devoid of dolomite; furthermore, the clay cores of GQ743-1 and GQ743-3 Ding lack calcite. The substantial disparities in mineral composition further underscore the distinctions in the casting provenance of the bronze horses and the Ding.

The thermal response of casting clay cores and soil samples

The TG-DSC curve provides a comprehensive depiction of the thermal and mass changes in the target sample across varying temperatures, thereby elucidating the reaction type and chemical composition. Research indicates that ceramic products derived from clay undergo different physical and chemical transformations at varying temperatures during the firing process, with the irreversible changes serving as reliable indicators of the maximum effective heating temperature of the sample38,51,52,53. Taking calcareous clay as an example, the interlayer water and adsorbed water are first removed at approximately 200 °C. This process is endothermic, reversible, and constitutes a physical alteration. The dehydroxylation of layered silicate minerals (such as clay minerals and micas) occurs within the temperature range of approximately 450 °C to 900 °C, leading to the removal of structural water. This process is characterized by its endothermic nature and irreversibility. Certain clay minerals may undergo dehydroxylation at lower temperatures, contingent upon the specific mineralogical composition and crystalline lattice structure52. Within the temperature range of 600 °C–900 °C, calcite undergoes endothermic decomposition, yielding CaO and liberating CO2 gas. At temperatures exceeding 950 °C, the primary layered silicate minerals are completely decomposed and react with CaO to generate novel secondary minerals.

Figure 13 depicts the TG-DSC curves for selected samples. Following baseline correction with blank tests, all the samples exhibit an upward curvature, attributed to changes in specific heat during the heating process54. Despite this, combined with the results of XRD, certain endothermic peaks remain discernible. The endothermic peaks observed in the bronze horses’ casting core and filling soil samples at temperatures around 600–700 °C are accompanied by a significant decrease in mass, indicative of the decomposition of calcite and dolomite55,56. Furthermore, the endothermic peak and conspicuous weight-loss step exhibited by the hardened substance I002 at 300–400 °C correspond to the decomposition of cerussite57. Additionally, the minor endothermic peak at 573 °C corresponds to the phase transition from α-quartz to β-quartz58. Notably, the endothermic peaks associated with dehydration and dehydroxylation processes are relatively inconspicuous and can only be inferred from TG curve analysis.

The endothermic direction in the DSC curve is consistent with the decreased direction of the ordinate value. a Casting core of the GQ744-1 bronze horse’s right hind hoof (C001). b Casting core of the GQ744-1 bronze horse’s left hind hoof (C002). c Casting core of the GQ744-2 bronze horse’s left hind hoof (C004). d Casting core of the GQ743-1 Ding (C005). e Casting core of the GQ743-3 Ding (C007). f Casting core of the GQ743-4 Ding (C009). g Filling soil inside the GQ744-2 bronze horse’s mouth (S003). h Hardened substance on the inner bottom surface of the GQ744-2 bronze horse’s mouth (I001). i Hardened substance on the inner surface of the GQ744-2 bronze horse’s broken right front leg (I002, the yellowish-brown layer).

Comparatively, the TG curves of the casting cores and filling soils for the bronze horses both exhibit significant dehydroxylation weight-loss steps below 300 °C, with a more pronounced weight loss; however, the dehydroxylation weight-loss step for the casting cores of the bronze Ding is less apparent, with a smaller weight loss. This implies that the casting cores’ firing temperature of the bronze horses may be lower than that of the three bronze Ding. Given that these artifacts have been buried for several thousand years, rehydroxylation has occurred in the clay cores due to environmental conditions59. Additionally, the molten metal during casting may induce a thermal effect on the clay cores assembly. Therefore, a conservative estimate suggests that the maximum effective temperature for preheating the bronze horses’ casting cores is slightly lower than the onset temperature of calcite decomposition, at approximately 500 °C. With relatively lower firing temperatures, the cores exhibit limited hardening, ensuring their collapsibility and facilitating easy removal to achieve the hollow structure of the casting objects. Additionally, it retains a degree of deformability in the cores, thereby reducing the risk of objects’ cracking during casting.

Discussion

Upon analysis of the aforementioned results, it is evident that the bronze horses discovered in the Yanjiagou tomb exemplify the fundamental characteristics of piece-mold casting technology prevalent during the Shang and Zhou dynasties. The initial stage of the bronze production process involves creating a model capable of producing various components of the mold or core box46,60. The striking resemblance between the two bronze horses strongly implies their potential origin from a shared model. Yue conducted a comparative analysis of the bronze vessels unearthed at Yin Ruins, positing that vessels with identical shapes were cast from the same model, while the differences in local patterns resulted from unclear mold imprints necessitating subsequent refinement. The craftsmen in the late Shang Dynasty had already acquired the expertise to replicate multiple items using either a clay model or an existing bronze vessel61. Nevertheless, certain scholars have a more stringent criterion for “casting with the same model”, contending that definitive evidence of one model producing multiple vessels did not emerge until around 500 BCE62.

In this research, the absence of intricate patterns on the surfaces of the two bronze horses poses challenges in determining whether they were cast from a common model. Consequently, we conducted an alignment of the two restored bronze horses’ 3D models. As illustrated in Fig. 14, the trunk parts of both bronze horses exhibit a satisfactory fit; however, notable misalignments are present in the left ear, both front hooves, and the right hind hoof which were added during restoration. Furthermore, the original contours of the face, the tail and the rear section of the mane also demonstrate significant misalignments. According to the results from our investigation into casting technology, each of these parts possesses a distinct mold section that is independent of the body mold sections, leading to possibly increased randomness and potential deviations during their individual processing and subsequent assembly62.

To achieve a quantitative assessment of the shape similarity between the two bronze horses, we performed a deviation analysis based on the optimal alignment of the 3D models and generated a deviation chromatogram using the GQ744-1 bronze horse model as a basic reference (Fig. 15). The analysis reveals that the maximum deviation between the two bronze horses is within ±5 mm, with a significant portion of the body exhibiting deviations within ±1 mm (indicated by the green area), which constitutes 75.45% of the total measurements. Notably, the most pronounced deviations are observed on the face, tail, legs, and the elliptical structure on the back, corroborating initial impressions derived from comparative analysis.

Beyond the shape aspects, it is essential to compare the limited pattern details (Fig. 16). These patterns depict the hair on the mane and tail, exhibiting a raised texture that suggests the patterns were recessed on the corresponding mold section’s inner surface. The mold patterns may have been imprinted from a model or could have been directly engraved. However, the creation of such simple patterns typically does not necessitate the application of clay strips onto the model; thus, it is more plausible that these designs were engraved directly onto the mold section’s inner surface. This technique represents a traditional decorative practice that had existed in the Central Plains of China since the middle Shang Dynasty63. The pattern details on the two bronze horses exhibit significant differences, indicating that their patterns were not from the same model. Conversely, their body shapes demonstrate a high degree of similarity, suggesting that the trunks may have originated from a same model without any decorations. Based on this, through the utilization of partial molding and direct engraving of patterns onto the mold section’s inner surface, distinctive details of the facial features as well as the mane and tail hair can be achieved.

Additionally, craftsmen employed “separate casting” technology to fabricate the two bronze horses, to seamlessly integrate the tails with their bodies. Upon observation, it has been noted that the parting lines on both sides of the tail are superimposed onto the tail’s pre-existing surface but lack a distinct boundary with the body (Fig. 3c). This implies that the tail was first cast and subsequently placed within the overall mold, with the body part being cast later and naturally integrated with the tail. The wedge-shaped protrusion located at the tail root’s inner side is also part of the body’s casting. Existing evidence suggests that the “separate casting” technology may have originated during the transition from the early Shang Dynasty to the middle Shang Dynasty. The earliest method involved a “casting-on” approach, where the object’s body was cast first, followed by casting the attachments onto it. This is exemplified by the discovery of bronze Jia and Gui from the Panlongcheng site in Huangpi, Hubei Province64. Furthermore, the “wrapping-type precasting method” used in Yanjiagou’s bronze horses appeared in the late stage of the middle Shang Dynasty65. During the Yin Ruins Phase II, a variety of separate casting techniques were undergoing refinement and widespread adoption60,65. Concurrently, bronze artifacts with a Central Plains style, which were produced using these techniques, also emerged in the Loess Plateau region31. The casting techniques demonstrated in the bronze horses are akin to those prevalent in Anyang during the same period, suggesting a probable influence from the Central Plains regime.

In terms of quality, the two bronze horses are meticulously crafted and exhibit no apparent casting defects or signs of repair casting, setting them apart from the vessels such as Ding and Gui unearthed together. The clay core material is characterized by a low clay matrix and high silt content, combined with a lower firing temperature to ensure minimal shrinkage, excellent thermal shock resistance, and effective collapsibility. The technology of creating clay casting materials has its origins in pottery making, but their respective applications have led to distinct technical characteristics25. The craftsman responsible for crafting the bronze horses possessed a profound understanding of this and applied it to product quality control.

As for the alloy composition, the bronze horse contains approximately 10% to 15% tin, falling within the normal range for tin usage in bronzes but significantly higher than that of all the weapons found together. The ritual vessels from the Yanjiagou tomb are primarily composed of red copper, lead-arsenic bronze, and arsenic bronze, with lower alloy element content and no tin19,21. Conversely, the alloy composition of the bronze horse demonstrates significant conformity with the bronze ritual vessels unearthed from high-ranking noble tombs at Anyang during Yin Ruins Phase II, as well as certain imported Anyang bronze ritual vessels unearthed on the Loess Plateau41,42,43. The scarcity of tin resources has led to a stratification in the tin content of bronze artifacts, reflecting social hierarchies. The elite nobility have had greater access to these resources, even resulting in instances of excessive tin usage, notably during the Yin Ruins Phase II at Anyang41,42. In contrast, the population in the Loess Plateau during the same period faced a scarcity of metal resources, resulting in low alloy element content as a characteristic of most artifacts43. The significance of the bronze horse, with its technological quality approaching that of Anyang, to the inhabitants of the Loess Plateau cannot be overstated. It may serve as a localized manifestation of Anyang’s technological dissemination, a point which will be further explored in subsequent sections.

The author of the Yanjiagou tomb’s archaeological report conducted a preliminary investigation into the shape characteristics of the bronze horse, and his conclusions were generally acknowledged by fellow researchers14. Nevertheless, there is a need for further discussion on two aspects: (1) Whether the bronze horse is solid or hollow? (2) Whether the elliptical structure on the back of the bronze horse represents a “saddle”?

The first question involves the judgment of the filling material’s nature within the bronze horse. In ancient bronze castings, the utilization of clay cores not only saved metal raw materials but also mitigated defects arising from entrapped gases during the pouring process66,67. The clay cores were typically removed after casting while the blind cores completely encased in casting liquid remain within the final object. Analysis results indicate that the filling soil inside the bronze horse exhibits similarities in petrographical structure, elemental composition, and mineral component to the buried soil enveloping the object’s surface. however, it differs notably from the residual cores in the hooves, suggesting its nature is soil that has been deposited during the burial process. The original clay core within the horse’s body had been removed, although some residue remained on the inner surface which is difficult to clean. Nevertheless, the exposed hoof clay core, which was easier to clean, was preserved completely, suggesting a deliberate removal process aimed at achieving a functional hollow structure within the horse’s body. In essence, both bronze horses function as containers.

For the second question, we contend that the elliptical structure on the back of the bronze horse does not correspond to a saddle depiction. This assertion is predicated on the positioning of the mane above the elliptical structure, which still exhibits hair patterns, indicating that it traverses through the “saddle”, thereby deviating from the overall realistic logic embodied by the bronze horse. Furthermore, the elliptical structure is separate from the horse’s body, with a gap connecting to the horse’s abdominal cavity. Consequently, it is plausible that this structure serves as a potential vessel lid, while the mane of the horse adeptly functions as a lid handle.

Archaeological materials indicate that bronze vessels depicting realistic animal images first emerged during the late Shang Dynasty and gained popularity in the periods of Western and Eastern Zhou. Primarily utilized as wine containers, these bronze vessels collectively known as “Niaoshouzun” (bird and beast-shaped Zun)68 encompass three distinct types: Zun, Gong, and You. The imitated animals include owl, duck, buffalo69, rhino70, goat, elephant71, pig72, horse73, tiger, rabbit, fish, etc. Niaoshouzun was typically possessed by elite nobles and played a significant role in rituals and commemorations74,75. The Yanjiagou bronze horse’s symmetrical upright shape and the back lid designed to match the body are reminiscent of features found in other quadruped animal vessels, suggesting they should be classified within the Niaoshouzun system of the Shang and Zhou dynasties and named “horse Zun”. Previously, the discovery of “horse Zun” was limited to a single example from the middle Western Zhou period, namely the “Liju” Zun also from Shaanxi province. This artifact shares a similar style with the Yanjiagou horse Zun and may indicate a specific relationship of transmission and influence between them76. During the late Shang Dynasty, the distribution of Niaoshouzun was concentrated in Anyang and the Xiangjiang River basin. Some scholars suggest that the abundance of distinctive bronze artifacts found in the latter area indicates a developed bronze civilization and independent bronze handicraft industry, which had close technological exchanges with the Central Plains. The realistic animal-shaped bronze vessels discovered in Anyang are thought to reflect southern traditions77,78. Additionally, it has been proposed that the bronzes discovered in the Xiangjiang River basin are linked to the southward migration of Shang’s remnant people and local powers in the Jianghan Plain during the transition from the Shang to the Zhou Dynasty, and the probability of locally casting animal-shaped vessels in the Xiangjiang River basin is minimal79. The earliest origins of Niaoshouzun remain uncertain, but it is evident that such vessels were not prevalent in the Loess Plateau region. The pair of horse-shaped Zun, part of a drinking vessel set, likely emerged under the influence of neighboring cultural circles, possibly reflecting the acceptance and observance of “Shang rites” by the inhabitants of the Loess Plateau80.

In recent decades, a large number of late Shang Dynasty bronze artifacts have been accidentally discovered in the Loess Plateau during production and construction activities. Through the progression of proactive archaeological excavations, these bronze artifacts have been gradually ascribed to the Lijiaya culture, a local state culture. In terms of morphological and decorative styles, the bronze group from the Loess Plateau demonstrates a diverse source, drawing influences from the Central Plains, northern grasslands, and Guanzhong region, among others. Researchers have categorized them into three distinct styles: local style, Shang style, and mixed style. It was postulated that the local-style and mixed-style artifacts were locally produced in the Loess Plateau81. Previously, the Yanjiagou bronze horses were considered typical local-style artifacts17,21. These artifacts are deeply influenced by the northern grassland bronze culture, with a tradition of depicting round-sculpted animals. However, they were primarily utilized for partical decorations, and independent round-sculpted artifacts were very rare. Following the preceding discussion, the bronze horses are believed to exhibit influences of Shang culture in terms of their shapes and technological details, yet their completely realistic and unadorned features distinguish them from typical Shang-style artifacts. Consequently, they should be hybrid artifacts that combine styles of the Central Plains and the local area. Cao highlighted the sporadic discovery of the mixed-style artifacts across the Loess Plateau, suggesting that they were unlikely to be bespoke items from Anyang, but rather products made by craftsmen who had mastered Anyang’s techniques within their indigenous workshops on the Loess Plateau17. In recent years, the largest architectural remains of the late Shang period outside of Yin Ruins were found in Qingjian County, the core area of Lijiaya culture. Within these remains, three houses yielded Lijiaya culture’s ceramic molds, models, and clay cores for the first time, which were used to cast a variety of items such as containers, weapons, and chariot equipment82. This discovery suggests that the population on the Loess Plateau had developed a certain scale and level of metallurgical production, so there were technical capabilities for the bronze horses’ local casting. Furthermore, the analysis of the casting cores from the Yanjiagou tomb indicates that the bronze artifacts unearthed were sourced from diverse casting workshops, and there is a likelihood that the two bronze horses were locally cast in the Loess Plateau region, aligning with discussions on styles. Regrettably, the current archaeological investigations and excavations in this region remain quite limited, hindering our ability to conduct more precise comparative studies at this time. It is still unclear where the bronze horses’ casting workshop was located, and the allocation of metal resources within the Lijiaya culture has yet to be clarified.

From a geological perspective, the lack of metal mineral resources in the Loess Plateau necessitates the reliance on raw material input from other regions for local bronze casting. Based on previous research on lead isotopes and trace elements, it is evident that during the late Shang period, the Loess Plateau region shared similar ore sources of bronzes with the Central Plains21,43. The high radioactive origin lead was found in the raw materials used for casting the two bronze horses21, prevalent during Yin Ruins Phase I to Phase II. While this type of lead material was also widely utilized in contemporaneous regional bronze civilizations around the Central Plains and its precise source remains unclear83,84,85, it provides evidence that the Loess Plateau region played a role in the late Shang dynasty’s metal resource distribution network. Local powers probably acquired the necessary raw materials, technology, and even skilled craftsmen for casting the bronze horses from direct or indirect interactions with the Shang dynasty through means such as warfare, rewards, economic exchanges, and population migration.

The final topic for discussion pertains to the sources of the bronze horses’ imagery. Presently, the prevailing perspective posits that equine domestication initially occurred in the middle and western Eurasian steppe around the 4th to 3rd millennium BCE before disseminating globally86,87,88. While sporadic evidence of human-horse interactions exists in northern China during the Late Paleolithic era89, a definitive timeline for equine origins within China remains elusive. It was not until the late Shang period that horse bones, chariots, as well as associated horse artistic depictions and written records began to proliferate across archaeological sites throughout the expansive Central Plains region typified by Yin Ruins13,90. Nonetheless, the representation of horses in the flourishing bronze art of this period remained relatively scarce, with all known instances being concentrated in the northern region. The Yanjiagou bronze horses stand as the sole tridimensional depiction of its kind. Furthermore, the regions flanking the Longshan Mountain, western Guanzhong Plain, and the Loess Plateau exhibit the most abundant evidence of horse utilization beyond the direct governance of the Shang Dynasty (Fig. 1). Geographically contiguous and positioned within the “crescent-shaped” cultural diffusion region91, they function as conduits for interaction between the Central Plains and regions to the west and north92. It is plausible that these areas served as continuous suppliers of horse resources to the dynasties in the Central Plains. Recently, proactive archaeological excavations in the Loess Plateau region have yielded significant findings, including the discovery of the late Shang period burials of high-ranking nobles accompanied by chariots and horses, with bronze chariot equipment exhibiting typical Central Plains styles93,94,95. Analysis of the horse bones indicates that during the late Shang period, inhabitants of the Loess Plateau had access to high-quality horse resources96, which played a crucial role in interest exchange with the Central Plains. Furthermore, their innovative incorporation of horse imagery into ritual objects reflects a deep reverence for this animal, potentially elevating horses to a spiritual totem akin to the owl depicted on the Niaoshouzun of the Shang people.

Through a comprehensive technical examination and archaeological contextual analysis of the two bronze horses unearthed at Yanjiagou tomb, we can derive the following key conclusions:

-

(1)

The two bronze horses are not solid sculptures as previously believed, and the depiction of a “saddle” on their backs is inaccurate. They function as a pair of drinking vessels, specifically known as “Niaoshouzun” (bird and beast-shaped Zun), which were prevalent during the Shang and Zhou dynasties. They possibly reflect the Lijiaya culture’s acceptance and observance of “Shang rites”.

-

(2)

The production of the bronze horses represents a sophisticated amalgamation of various techniques, including mold engraving decoration, separate casting methodology, alloy formulation, and core-making processes; it is plausible that same-model casting techniques were also utilized. These methods reflect the technical characteristics and standards of the Shang Dynasty. It is likely that the two bronze horses were created by craftsmen from Anyang or local craftsmen who had assimilated Anyang’s technological expertise.

-

(3)

The bronze horses may have been cast in the local area, although the exact casting location remains a subject of ongoing research and debate. The possibility of casting in the Central Plains and subsequent import to the Loess Plateau cannot be entirely ruled out at this stage.

The bronze horses serve as a reflection of the intimate connection between Lijiaya culture and the Shang Dynasty, offering a glimpse into the interactions between the Central Plains regime and its neighboring states. Currently, Scholarly research is actively engaged in exploring the late Shang state culture in the Loess Plateau region. This study represents the first comprehensive technical examination of typical bronze artifacts in this area, to provide a scholarly reference and insight for fully elucidating the local population’s bronze handicraft industry in future studies. As new research materials continue to accumulate, several unresolved issues, including the precise identification of the casting workshops and the processes related to recycling and remelting metal, are also expected to be addressed.

Data availability

All data generated or analyzed during this study are included in this published article and its supplementary information files.

References

Damgaard, P. B. et al. The first horse herders and the impact of early Bronze Age steppe expansions into Asia. Science 360, 7711 (2018).

Kanne, K. Riding, Ruling, and Resistance: Equestrianism and Political Authority in the Hungarian Bronze Age. Curr. Anthropol. 63, 289–329 (2022).

Taylor, W. T. T. et al. A Bayesian chronology for early domestic horse use in the Eastern Steppe. J. Archaeological Sci. 81, 49–58 (2017).

Eres, M. P. I. et al. Mass animal sacrifice at casas del Turuñuelo (Guareña, Spain): A unique Tartessian (Iron Age) site in the southwest of the Iberian Peninsula. PLOS One. 18, e0293654 (2023).

Lepetz, S. Horse sacrifice in a Pazyryk culture kurgan: the princely tomb of Berel’ (Kazakhstan). Selection criteria and slaughter procedures. Anthropozoologica 48, 309–321 (2013).

Conard, N. J. Palaeolithic ivory sculptures from southwestern Germany and the origins of figurative art. Nature 426, 830–832 (2003).

Conti, C. et al. Scientific investigation to look into the conservation history of a Tang Dynasty terracotta Dancing Horse. Herit. Sci. 10, 1–11 (2022).

Xu, B. Y., Yang, G. X., Jiao, B. W. & Zhu, H. Analysis of ancient and modern horse genomes reveals the critical impact of lncRNA-mediated epigenetic regulation on horse domestication. Front Genet. 13, 944933 (2022).

Taylor, W. T. T. et al. Understanding early horse transport in eastern Eurasia through analysis of equine dentition. Antiquity 95, 1478–1494 (2021).

Gaunitz, C. et al. Ancient genomes revisit the ancestry of domestic and Przewalski’s horses. Science 360, 111–114 (2018).

Chechushkov, I. V., Epimakhov, A. V. & Bersenev, A. G. Early horse bridle with cheekpieces as a marker of social change: An experimental and statistical study. J. Archaeological Sci. 97, 125–136 (2018).

Wei, G. F., Zhang, R. X., Shi, H. Y., Wang, N. & Yang, T. The Provenance of Copper Materials for bronze chariot-horses Unearthed from Yang’ an Han Tomb in Qionglai, Sichuan Province revealed by the lead isotope analysis and trace elements analysis. Archaeol. Anthropol. Sci. 16, 1–12 (2024).

Kikuchi, H. & Liu, Y. Y. Rethinking domestic horses in ancient China. Cultural Relics South. China 1, 136–150 (2019). (in Chinese).

Wang, Y. G., Cui, F. G. & Li, Y. L. Bronze vessels of the late Shang Dynasty unearthed in Ganquan County. Shaanxi Prov. Archaeol. Cultural Relics 3, 11–22 (2007). (in Chinese).

Shaanxi Academy of Archaeology. Lijiaya. (Cultural Relics Press, Beijing, 2013). (in Chinese)

Center for the Chinese Bronze Research at Shaanxi Normal University. New understanding on the food-favoured culture in the western Zhou. Archaeol. Cultural Relics 1, 32–38 (2009). (in Chinese).

Cao, D. Z. The Loess Highland in a Trading Network (1300-1050 BC). (Princeton University, Princeton, 2014).

Wang, T. Y. The issues about the Bronze Ding-tripods with simplified animal mask design of the late Shang Dynasty seen from the Yanjiagou Shang tomb. Archaeology 11, 77–88 (2017). (in Chinese).

Liu, C. et al. Scientific analysis and research on late Shang bronze wares from Yanjiagou cemetery in Ganquan County, Shaanxi Province. Sci. Conserv. Archaeol. 33, 31–38 (2021). (in Chinese).

Bray, P. et al. Form and flow: the “karmic cycle” of copper. J. Archaeol.Sci. 56, 202–209 (2015).

Liu, Y. X. H. Scientific analysis and discussion on bronzes of the late Shang Dynasty unearthed from the Yanjiagou cemetery in Ganquan, Shaanxi. (Northwest University, Xi’an, 2022). (in Chinese)

Ma, D. et al. Study on the casting cores to identify the manufacturing place of Chinese bronze vessels excavated in the Qiaojiayuan tombs from Spring and Autumn period. Archaeol. Anthropol. Sci. 12, 203 (2020).

Luo, W. G., Song, G. D., Cui, B. X., Wang, W. & Chen, D. Based on chemical and mineralogical examination of casting cores to determine the foundry area of bronze vessels from the Xiaxiangpu site in Nanyang city, Henan Province, China. Microchem. J. 150, 104133 (2019).

Stoltman, J. B. et al. New insights into the composition and microstructure of ceramic artifacts associated with the production of Chinese bronzes at Yinxu, the last capital of the Shang dynasty. Archaeol. Res. Asia. 15, 88–100 (2018).

Liu, S. R., Wang, K., Cai, Q. F. & Chen, J. L. Microscopic study of Chinese bronze casting molds from the Eastern Zhou period. J. Archaeol. Sci. 40, 2402–2414 (2013).

Liu, N. D. et al. Comparative study of Bronze Age ceramic moulds reveals diachronic and spatial change in mould material processing in the Central Plain of China, c. 13th-3rd century BCE. J. Archaeol. Sci. 174, 106145 (2025).

Lombardi, G. The casting core composition and provenance of the Goljamata Kosmatka (Bulgaria) bronze head. J. Archaeol. Sci. 36, 520–527 (2009).

Peng, P. Between piece molds and lost wax: the casting of a diatrete ornamentation in early China rethought. Humanit Soc. Sci. Commun. 10, 1–12 (2023).

Rose, T., Fabian, P. & Goren, Y. The (in)visibility of lost wax casting moulds in the archaeological record: observations from an archaeological experiment. Archaeol. Anthropol. Sci. 15, 1–20 (2023).

Lapérouse, J. F., Eppihimer, M., Flisch, A. & Zboray, R. Revealing ancient technology: a high-energy X-ray computed tomography examination of a Mesopotamian copper alloy head. Herit. Sci. 12, 1–14 (2024).

Liu, J. Y. et al. Observation and analysis on the casting process of bronze vessels in the Shang Dynasty unearthed in Zizhou. Shaanxi Prov. Cultural Relics South. China 1, 58–66 (2015). (in Chinese).

Maher, M. A. X-RAY computed tomography of a late period falcon bronze coffin. Radiat. Phys. Chem. 166, 108475 (2020).

Gettens, R. J. The Freer Chinese Bronzes: Volume II, Technical Studies. (Smithsonian Institution, Washington DC, 1969).

Scott, D. A. Metallography and microstructure of ancient and historic metals. (Getty Conservation Institute, Los Angeles, 1991).

Stoltman, J. B. A quantitative approach to the petrographic analysis of ceramic thin sections. Am. Antiquity. 54, 147–160 (1989).

Schindelin, J. et al. Fiji: an open-source platform for biological-image analysis. Nat. Methods 9, 676–682 (2012).

Gates-Rector, S. & Blanton, T. The Powder Diffraction File: a quality materials characterization database. Powder Diffr. 34, 352–360 (2019).

Drebushchak, V. A., Mylnikova, L. N. & Drebushchak, T. N. Thermoanalytical investigations of ancient ceramics: Review on theory and practice. J. Therm. Anal. Calorim. 133, 135–176 (2018).

Quaranta, M., Catelli, E., Prati, S., Giorgia, S. & Rocco, M. Chinese archaeological artefacts: Microstructure and corrosion behaviour of high-leaded bronzes. J. Cultural Herit. 15, 283–291 (2014).

Liang, Z. P., Jiang, K. X. & Zhang, T. A. Corrosion behaviour of lead bronze from the Western Zhou Dynasty in an archaeological-soil medium. Corros. Sci. 191, 109721 (2021).

Liu, R. L. et al. Social hierarchy and the choice of metal recycling at Anyang, the last capital of Bronze Age Shang China. Sci. Rep. 10, 18794 (2020).

Pollard, A. M., Zhang, Y. & Liu, R. L. Bronze alloying recipes at Anyang during the Shang Dynasty. Archaeol. Anthropol. Sci. 15, 1–12 (2023).

Liu, J. Y. Scientific study on the Shang and Zhou periods bronzes unearthed from Northern Shaanxi_ cultural connections between loess highland and Anyang in the late Shang dynasty. (University of Science and Technology Beijing, Beijing, 2015). (in Chinese)

Stoltman, J. B., Jing, Z. C., Tang, J. G. & Rapp, G. Ceramic production in Shang societies of Anyang. Asian Perspect. 48, 182–203 (2009).

Yue, Z. W. et al. Material source and processing of pottery mold, ceramic mold and clay core in zhe Yin Ruins. Cultural Relics South. China 4, 152–159 (2015). (in Chinese).

Cheng, W. Y. & Shen, C. Bronze casting clay moulds and production sequences: understanding knowledge and Organization of the Artisans in Late Shang (14th - 11th century BC), China. Asian Archaeol. 6, 137–151 (2022).

Menzies, M., Seyfried, W. & Blanchard, D. Experimental evidence of rare earth element immobility in greenstones. Nature 282, 398–399 (1979).

Cogswell, J., Neff, H. & Glascock, M. The Effect of Firing Temperature on the Elemental Characterization of Pottery. J. Archaeological Sci. 23, 283–287 (1996).

China National Environmental Monitoring Centre. Background values of soil elements in China. (China Environmental Science Press, Beijing, 1990). (in Chinese)

Mugnaini, S., Giamello, M., Pisani, A. & Siano, S. Casting cores used to craft large bronze masterpieces of the Florentine Renaissance and Mannerism. J. Archaeol. Sci. 47, 85–98 (2014).

Kazakou, T., Zorba, T., Vourlias, G., Pavlidou, E. & Chrissafis, K. Combined studies for the determination of the composition and the firing temperature of ancient and contemporary ceramic artefacts. Thermochim. Acta 682, 178412 (2019).

Ravisankar, R., Naseerutheen, A., Rajalakshmi, A., Annamalai, G. R. & Chandrasekaran, A. Application of thermogravimetry-differential thermal analysis (TG-DTA) technique to study the ancient potteries from Vellore dist, Tamilnadu, India. Spectrochimica Acta Part A: Mol. Biomol. Spectrosc. 129, 201–208 (2014).

Cornelius, T., Theodoros, N. & Irmgard, H. Thermally triggered two-stage reaction of carbonates and clay during ceramic firing — A case study on Bronze Age Cypriot ceramics. Appl. Clay Sci. 43, 69–78 (2009).

Hemminger, W. F. & Sarge, S. M. The baseline construction and its influence on the measurement of heat with differential scanning calorimeters. J. Therm. Anal. 37, 1455–1477 (1991).

Xie, J. J. et al. The thermochemical activity of dolomite occurred in dolomite - palygorskite. Appl. Clay Sci. 119, 42–48 (2016).

Resio, L. C. Dolomite thermal behaviour: A short review. Phys. Chem. Miner. 51, 19 (2024).

Hendriks, L. et al. The Ins and Outs of 14 C Dating Lead White Paint for Artworks Application. Anal. Chem. 92, 7674–7682 (2020).

Karunadasa, K. S. P., Manoratne, C. H., Pitawala, H. M. T. G. A. & Rajapakse, R. M. G. The composition, unit cell parameters and microstructure of quartz during phase transformation from α to β as examined by in-situ high-temperature X-ray powder diffraction. J. Phys. Chem. Solids 117, 131–138 (2018).

Drebushchak, V. A., Mylnikova, L. N., Drebushchak, T. N. & Boldyrev, V. V. The investigation of ancient pottery: Application of thermal analysis. J. Therm. Anal. Calorim. 82, 617–626 (2005).

Barnard, N. Bronze Casting and Bronze Alloys in Ancient China. (Australian National University and Monumenta Serica, Canberra, 1961).

Yue, H. B. & Yue, Z. W. Preliminary analysis of the “one model for multiple items” phenomenon in Yin Ruins’ bronze casting. Cultural Relics South. China 3, 92–99 (2014). (in Chinese).

Li, K. S. et al. Decorated models, replication, and assembly lines for bronze industrial production in 500 B.C.E. China. Early China 44, 109–142 (2021).

Bagley, R. Anyang Mold-Making and the Decorated Model. Artibus Asiae. 69, 39–90 (2009).

Hubei Provincial Museum. Bronzes from the Erligang period of the Shang Dynasty discovered at Panlongcheng. Cultural Relics 2, 26–41 (1976). (in Chinese).

Liu, Y. A preliminary study of the separate casting technique at Yinxu. Cultural Relics Cent. China 5, 82–89 (2018). (in Chinese).

Salem, Y. Casting, gilding and corrosion mechanisms in two gilded hollow bronze statues from ancient Egypt. J. Archaeol. Sci.: Rep. 43, 103446 (2022).

Yang, H. et al. New solidification simulation reveals the secret of the hidden metal cores in ancient Chinese bronzes. Herit. Sci. 11, 1–12 (2023).

Rong, G. A comprehensive examination of ritual vessels from the Shang and Zhou Dynasties. (Shanghai People’s Publishing House, Shanghai, 2008). (in Chinese)

Henan Provincial Administration of Cultural Heritage. The Yin Ruins in Cultural Relics: The Ox-shaped Vessel of “Ya Zhang”. https://wwj.henan.gov.cn/2023/03-09/2704334.html (2024).

Asian Art Museum. Ritual vessel in the shape of a rhinoceros. https://searchcollection.asianart.org/objects/5145/ritual-vessel-in-the-shape-of-a-rhinoceros?ctx=ee65a1e67d59e44e94db1cf724c64131ee027f62&idx=0 (2024).

Smithsonian: National Museum of Asian Art. Spouted vessel (he) in the form of an elephant with masks (taotie), dragons, and snakes. https://asia.si.edu/explore-art-culture/collections/search/edanmdm:fsg_F1936.6a-b/ (2024).

Hunan Museum. Bronze Pig Zun. https://de.hnmuseum.com/collection/collectionDetails.html?id=1002229330299846656&type=index# (2024).

National Museum of China. Bronze Colt-shaped Zun of Lord “Li”. https://www.chnmuseum.cn/zp/zpml/kgfjp/202108/t20210802_250941.shtml (2024).

Du, N. S. Discussion on bronze Niaoshouzun. Palace Mus. J. S1, 174–186 (1995). (in Chinese).

Rawson, J. Western Zhou Ritual Bronzes: from the Arthur M. Sackler Collections. (Harvard University Press, Boston, 1990).

National Museum of China. Research series on collections of the National Museum of China: bronzes of the Shang Dynasty. (Shanghai Ancient Book Publishing House, Shanghai, 2020). (in Chinese)

Kane, V. C. The Independent Bronze Industries in the South of China Contemporary with the Shang and Western Chou Dynasties. Arch. Asian Art. 28, 77–107 (1974).

Bagley, R. W. Shang Ritual Bronze in the Arthur M. Sackler Collections. (Harvard University Press; Boston, 1987).

Xiang, T. C. The discovery of Tanheli city site and the restudy of the Ningxiang bronze group. Cultural Relics 8, 35–44 (2006). (in Chinese).

Zou, H. Archaeological treatises of Xia, Shang and Zhou Dynasties. (Cultural Relics Publishing House, Beijing, 1980). (in Chinese)

Lv, Z. R. A preliminary study on “Guifang” culture and related issues. Relics Museolgy. 1, 32–37 (1990). (in Chinese).

Chong, J. R. The Shang Dynasty site in Xinzhuang, Qingjian County. In Year book of archaeology in China (2016) (ed. Wang, W.) 405-406 (China Social Science Press, Beijing, 2017). (in Chinese)

Sun, W. D. et al. Origin of the mysterious Yin-Shang bronzes in China indicated by lead isotopes. Sci. Rep. 6, 23304 (2016).

Jin, Z. Y., Liu, R. L., Rawson, J. & Pollard, A. M. Revisiting lead isotope data in Shang and Western Zhou bronzes. Antiquity 91, 1574–1587 (2017).

Liu, R. L., Rawson, J. & Pollard, A. M. Beyond ritual bronzes: identifying multiple sources of highly radiogenic lead across Chinese history. Sci. Rep. 8, 11770 (2018).

Librado, P. et al. Widespread horse-based mobility arose around 2200 BCE in Eurasia. Nature 631, 819–825 (2024).

Librado, P. et al. The origins and spread of domestic horses from the Western Eurasian steppes. Nature 598, 634–640 (2021).

Klecel, W. & Martyniuk, E. From the Eurasian Steppes to the Roman Circuses: A Review of Early Development of Horse Breeding and Management. Animals 11, 1859 (2021).

Liu, Y. Y. Research on domestic horses of pre-Qin period. (Graduate School of Chinese Academy of Social Sciences, Beijing, 2013). (in Chinese)

Lu, C. et al. Temporal and spatial patterns of domestic horse utilisation in northern China during the pre-Qin period. J. Archaeological Sci. 170, 106042 (2024).

Hein, A. The “Crescent-Shaped Cultural-Communication Belt”: Tong Enzheng’s Model in Retrospect. (British Archaeological Reports, Oxford, 2014).

Rawson, J. China and the steppe: reception and resistance. Antiquity 91, 375–388 (2017).

Sun, Z. W. & Yu, Y. G. Excavation report of the Houliujiata Shang Dynasty’s cemetery at Zhaigou site, Qingjian County, Shaanxi Province. Archaeol. Cultural Relics 2, 44–69 (2024). (in Chinese).

China Global Television Network. Remarkable Shang Dynasty discoveries in north China. https://news.cgtn.com/news/2023-05-31/Remarkable-Shang-Dynasty-discoveries-in-north-China-1kfJPU166bu/index.html (2023).

National Cultural Heritage Administration. Zhaigou site in Qingjian, Shaanxi. http://www.ncha.gov.cn/art/2024/3/27/art_2759_187888.html (2024).

Li, N. et al. Archaeological scientific identification and analysis of the Houliujiata Shang Dynasty’s cemetery at Zhaigou site, Qingjian County, Shaanxi Province. Archaeol. Cultural Relics 2, 140–152 (2024). (in Chinese).

Acknowledgements