Abstract

This study aims to investigate the production techniques and kiln origins of the unearthed Jun-glazed wares. It examines the microstructure and chemical composition of the wares, as well as their physical properties. The investigation employs a combination of ultra-depth field microscope, SEM-EDS, EDXRF, ICP-MS, TIMS, and thermal dilatometer. The analysis revealed that the content of Al2O3 in the body of Jun glaze ware unearthed from the Yanjialiang site is high, with YJ9 reaching 39.72%. It exhibits distinct formula characteristics in its body material and relatively coarse production quality, markedly differing from the Jun-glazed wares of the Song, Jin, and Yuan Dynasties excavated in Henan, China, in terms of composition, microstructure, and other aspects. This is the first time that this unique Jun-glazed wares composition has been discovered. Some Jun-glazed wares were produced from the Ding kiln, Hebei Province, others are likely produced from Jun Kilns in central and western Henan, as suggested by their compositional data.

Similar content being viewed by others

Introduction

The most famous place for the production of Jun-glazed wares during the Yuan Dynasty was Henan, China. The study of ancient Jun-glazed wares plays a pivotal role in contemporary archeological research on ceramic technology and remains a subject of intense interest. Recently, scholars have conducted extensive research on Jun-glazed wares, focusing on aspects such as the coloration mechanism, firing process, and origin analysis. For example, the varying chemical compositions of porcelain glaze can be examined by analyzing the chemical components and concentration1,2. Senior scholars have tested ancient Jun-glazed ware samples to investigate their coloration mechanism and firing process3. Besides, some scholars have mainly focused on the composition and formation of the middle layer of Jun-glazed wares and the corrosion of ancient Chinese Jun-glazed wares4,5. The academic community has also made a lot of achievements in the microstructural evolution of porcelain bodies at different temperatures6,7. In addition, several scholars employed portable X-ray fluorescence (XRF) analysis, trace element analysis, and micro-Raman spectroscopy to differentiate the classifications and origins of the body and glaze materials8,9,10. These studies primarily concentrated on Jun-glazed wares from Henan, Shandong, and other central plains in China and overseas, with limited research in the northern grassland areas. Therefore, the in-depth exploration of the porcelain trade between the northern grassland areas and the central plains of China, has been significantly constrained. However, the discovery of the Yanjialiang Site offers a promising opportunity to address this gap.

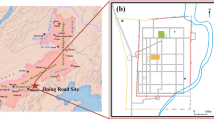

The Yanjialiang Site is a town ruin of the Yuan Dynasty, which is situated in Machi Town, Jiuyuan District, Baotou City, Inner Mongolia Autonomous Region, China (Fig. 1). It served as the sole route to the crucial military post “Naliandao” during the Yuan Dynasty. Combined with the railroad line project of the Inner Mongolia Huadian Baotou Power Generation Co., Ltd., the Inner Mongolia Institute of Cultural Relics and Archeology and the Baotou Cultural Relics Management Office jointly conducted a rescue archeological excavation in the railway construction zone from May to November 2006. Spanning over 20,000 square meters, the excavation revealed ash pits, ash ditches, house sites, cellars, and kiln sites. The unearthed relics, predominantly porcelain, represented multiple categories and originated from various kiln systems, including the Jingdezhen, Cizhou, Longquan, Ding, and Jun kiln systems. These porcelain wares are invaluable for studying the porcelain trade in the northern grassland areas during the Yuan Dynasty and hold significant academic value for in-depth research into trade and commerce between the northern region, the central plains, and even the southern region. The Jun-glazed wares are “essentially identical to the artifacts unearthed in Jun kilns”11. However, scholars have not definitively determined the origin of these wares.

(Baotou in the map is the location of the Yanjialiang site, Base map adapted from SY, CC BY-SA 4.0 <https://creativecommons.org/licenses/by-sa/4.0>, via Wikimedia Commons).

Therefore, 20 fragments of Yuan Dynasty Jun-glazed wares excavated from the dwellings and commercial district of the Yanjialiang Site were selected for this study. Various scientific testing methods are employed, including ultra-depth of field microscopic observation, scanning electron microscopy-energy dispersive spectrometry (SEM-EDS), polarization microscopy, energy-dispersive X-ray fluorescence (EDXRF) spectrometry, plasma mass spectrometric analysis, thermal surface ionization mass spectrometer, and thermal dilatometer. These techniques aim to gather data specimens of Jun-glazed wares from the Yanjialiang Site, examining the microstructure of the glaze and body, analyzing the chemical compositions of the body and glaze, determining the content of trace elements and physical properties in the body, and determining their production levels. In addition, to further clarify the origins of the Jun-glazed wares unearthed at the Yanjialiang Site, the research data of Jun-glazed wares from the Song, Jin, and Yuan Dynasties are compared.

Methods

Materials

The 20 selected Jun-glazed ware samples were provided by the Baotou Museum in China. All samples were bowls labeled YJ1-YJ20. These samples were excavated from various archeological squares, to represent the diversity in the production quality of Jun-glazed wares found at different site locations. The body colors changed from yellow and brick red to gray, with most bodies exhibiting a rough and loose texture. The glaze hues varied, including sky green, sky blue, and moon white. Predominantly, the wares’ exteriors were semi-glazed, with a minority displaying conspicuous brown holes or glaze flows. Figure 2 presents these detailed features.

Cross-sectional observational analysis

Cross-sectional observations of the samples, along with micrograph capture and storage, were performed using an ultra-depth field microscope (VHX-6000, KEYENCE, Japan) under 50–200 times magnification lenses. In this regard, the sample was cut into a cube with a size of 2 cm, a section was selected for polishing, and then an ultrasonic cleaning machine was utilized to clean it three times, each time for 3 min. Finally, samples were put into a blast drying oven at 100 °C.

SEM-EDS

The microstructures and elemental composition of the glaze were examined using a scanning electron microscope (SEM, SU8000 series, Hitachi, Japan) and an EDS. This process involved observing the microstructures of both glaze and body, analyzing images and crystal morphology, and conducting a semi-quantitative elemental analysis in the body, middle, and glaze layers. The SEM-EDS was operated at a voltage of 15 kV. The sample treatment process was as follows: the sample was cut into a cube with a size of 1 cm, and the sample block was cleaned by an ultrasonic cleaner. The sample was dried at 100 °C for 12 h in a drying oven, and then the sample was fixed in epoxy resin. Once the epoxy resin solidified, the sample was polished and then etched with 5% HF acid for 15 s. Then, the sample was cleaned by an ultrasonic wave and dried. Finally, a layer of gold was sprayed on the surface of the sample.

Polarization microscopy analysis

The glaze layer’s microstructures were studied under 5×, 10×, 20×, and 50× magnifications using a polarization microscope (LEICA DFC 7000 T), with simultaneous photography and documentation. The sample was cut into a cube with 2 cm in size. A cross-section was selected for polishing, then cleaned using an ultrasonic cleaner, and finally dried.

EDXRF analysis

The elemental composition of both the bodies and glazes of these porcelain samples was analyzed using an EDXRF spectrometer (EAGLE III XXL, EDAX, USA). The testing parameters were as follows: for primary elements, a 25 kV voltage, 600 μA current, a 0.3 mm beam spot, a 200 s measurement time, and results were deduced post-standard sample calibration for approximate quantitative analysis. In order to improve the representation and precision, three spots were measured for each sample, and an average was calculated after the consistency t-test. The sample was cut into a sample block with a size of 1 cm, one of the cross-sections was selected to be polished to a flat surface, and ultrasonic cleaning and drying were used. The detection positions were located on the polished section.

Trace elements analysis

The bodies’ trace elements were analyzed using a high-resolution inductively coupled plasma mass spectrometer (ELEMENT XR, Thermo Fisher Scientific, USA). The conditions set included a 1400 W power, cooling gas at 15 L/min, auxiliary gas at 0.982 L/min, and an integral time for a single element of 0.01 s. The porcelain sample was ground into powder after removing the glaze layer, and the specification of the powder was 200 mesh.

Strontium isotope analysis

The strontium isotope data of the sample matrix were obtained by using the Phoenix thermal surface ionization mass spectrometer of Isotopx company in the United Kingdom. The preparation of the sample was mainly to grind the body into powder after the glaze layer was removed, and the specification was 200 mesh.

Firing temperature analysis

Germany NETZCH DIL402C thermal dilatometer was utilized to test the firing temperature of samples. The temperature range was taken as RT-1550 °C, the heating rate was taken as 0.001−50 K/min and the temperature accuracy was taken as 0.1 K. The preparation of the sample aimed to remove the glaze layer of the porcelain sample cut and grind the remaining matrix into a 0.5 cm × 0.5 cm × 4.5 cm cuboid.

Results and discussion

Chemical composition analysis

The bodies of these 20 samples underwent XRF quantitative analysis, the results of which are summarized in Table 1. Cluster analysis on these results revealed two distinct groups when applying a threshold λ of 8, as shown in Fig. 3. The first group, YJL-1, comprised 16 samples (YJ2, YJ17, YJ18, YJ6, YJ16, YJ20, YJ8, YJ9, YJ13, YJ14, YJ3, YJ15, YJ5, YJ7, YJ10, and YJ11), characterized by high Al2O3 content (33.16–39.72%) and low SiO2 content (51.95–59.83%). The second group, YJL-2, included four samples (YJ1, YJ12, YJ19, and YJ4), with lower Al2O3 content (26.00–29.40%), but higher SiO2 content (61.87–65.71%) compared to YJL-1. The cluster analysis diagram showed a rapid convergence among YJL-2 samples, indicating a close relationship and similar origin.

Hence, based on the chemical composition and categorization, it is tentatively concluded that the raw materials for the bodies of YJL-1 and YJL-2 originated from different regions.

The Jun Kilns, operational since the Tang Dynasty and reaching their zenith during the Song Dynasty, were reactivated in the Jin and Yuan Dynasties. Jun-glazed wares, primarily produced in today’s Yuzhou City, Henan Province, China, were part of an extensive kiln system in the surrounding areas. Regarding the origin of Jun-glazed wares excavated at the Yanjialiang Site, archeologists hypothesize they were likely crafted in Henan, China. Consequently, this study focused on Jun-glazed wares from the Song, Jin, and Yuan Dynasties unearthed in Henan for comparative analysis. Specifically, this included Jun-glazed wares from the Song Dynasty unearthed at Linru Kilns (LR)2, Yuan Dynasty wares from Liujiagou and Zhaojiawa in Henan (Z)12, Song Dynasty wares from Juntai Kilns (G)13, and Jin Dynasty wares from Lushan Duandian Kilns (LS)14. The data selected above were calibrated for comparability.

The primary composition analysis (PCA) figure (Fig. 4) demonstrated that the cumulative contribution rate of the three principal components was 83.58%, elucidating most of the data characteristics, the load matrix, eigenvalue, and contribution rate of principal components are shown in Table 2. Significant disparities in body composition between YJL-1 samples and Henan Jun-glazed wares were observed, along with marked distinctions between the two groups. This indicated substantial differences between YJL-1 samples and Henan Jun-glazed wares. In contrast, the compositional disparity between YJL-2 samples and Henan Jun-glazed wares was comparatively minor. Crucially, LR and Z exhibited overlaps in the central distribution area, suggesting that the body composition of YJL-2 samples resembled that of the Jun-glazed wares from central and western Henan, China. This implied that the YJL-2 samples might originate from Jun Kilns in these regions of Henan, China.

In order to further explore the relationship between the YJL-1 samples and Henan Jun-glazed wares, a plasma mass spectrometer (ELEMENT XR) was employed to analyze trace elements in some sample bodies. The test results are presented in Table 3.

A comparison and analysis of trace elements in YJL-1 samples and Henan Jun-glazed wares from the Song and Yuan Dynasties were conducted15, and used MetaboAnalyst 6.0 software (confidence factor: 95%), a primary composition analysis diagram was plotted (Fig. 5). The cumulative contribution rate of the two primary components was 87.23%, explaining the majority of the data characteristics, the load matrix, eigenvalue and contribution rate of principal components are shown in Table 4. The figure revealed distinct differences in the trace elements of YJL-1 samples’ bodies compared to those of Jun-glazed wares unearthed in Henan, China, suggesting that the body materials of YJL-1 samples differed from those used in Juntai Kiln Jun-glazed wares in Henan, China.

In the body composition of YJL-1, there is an obvious characteristic where the content of Al2O3 in the body is high. Scholars have detected the porcelain of the Ding kiln in the Northern Song Dynasty and Jin Dynasty, where the content of Al2O3 in the body shows similar characteristics to those of YJL-116. Other studies have also shown that the content of Al2O3 in the body of Ding kiln porcelain is high, at 31–35%17. The content of Al2O3 and SiO2 in this kind of porcelain body is consistent with the content of the YJL-1 samples tested in this study.

The Cultural Relics Task Force of the Hebei Provincial Bureau of Culture of China once investigated the ancient porcelain kiln site of Ding Kiln in Hebei Province of China and found fragments of Jun glaze ware from the Yuan Dynasty. Its appearance is very similar to that of Jun glaze ware in this study. The survey report pointed out: ‘ After the Northern Song Dynasty, the region also maintained a part of the production, but its products have been negligible, and the quality of firing is increasingly crude’18. It shows that the kiln sites in this area were still producing some low-quality porcelain in the Yuan Dynasty.

To sum up, from the chemical composition analysis and investigation report, YJL-1 samples may be related to the porcelain of the Ding kiln in the Yuan Dynasty. Under this instruction, the author went to the Ding kiln site and took 19 porcelain samples from the Yuan Dynasty Ding kiln. YJL-1 samples and the Yuan Dynasty porcelain pieces unearthed from the Ding kiln were sent to the Beijing Institute of Nuclear Industry Geology for the determination of trace elements in the matrix. The instrument used was an ELEMENT XR inductively coupled plasma mass spectrometer, and the trace element data of the sample matrix were obtained. The scatter diagram of trace elements in the matrix was drawn using Origin. As shown in Fig. 6, the content of trace elements in the matrix of the two samples was within the same fluctuation range. The results of trace data detection show that the trace element content of the YJL-1 samples is similar to that of the porcelain body of the Yuan Dynasty unearthed from Ding kiln, Hebei Province, and it is speculated that it is more likely to be homologous.

Previous studies have pointed out that the strontium isotope ratio method plays an essential role in investigating the origin of ancient porcelain. In order to further explore whether the two porcelains are the same source, the YJL-1 samples and the Yuan Dynasty porcelains unearthed from Ding kiln were sent to the Beijing Institute of Nuclear Industry Geology for the determination of the strontium isotope composition of the matrix. The instrument used was a Phoenix thermal surface ionization mass spectrometer, and the strontium isotope data of the sample matrix were obtained.

According to the test data, the scatter plot of the strontium isotope was drawn by Origin, as shown in Fig. 7. The fluctuation range of strontium isotope content in the YJL-1 matrix was within the fluctuation range of strontium isotope in the Ding kiln porcelain matrix of the Yuan Dynasty.

In summary, this study analyzes and discusses the characteristics of high aluminum content in the matrix, the investigation work of archeologists, the characteristics of trace elements in the matrix and the characteristics of strontium isotopes in the matrix. The above research results show that YJL-1 samples come from the Ding kiln in Hebei Province, China.

EDXRF spectrometry was utilized to examine the glaze composition data of Jun-glazed wares from the Yanjialiang Site, with findings displayed in Table 5. The glaze layer compositions of YJL-1 and YJL-2 samples were compared with those of Jun-glazed wares from the Song and Yuan Dynasties in Henan, China2,14,19, and used MetaboAnalyst 6.0 software (confidence factor:95%), and a PCA plot was created (Fig. 8). The cumulative contribution rate of the two primary components was 80.6%, accounting for most of the data characteristics, the load matrix, eigenvalue and contribution rate of principal components are shown in Table 6. The glaze layer compositions of YJL-1 samples differed significantly from those of Jun-glazed wares from folk Jun Kilns in the Yuan Dynasty (LJG), official Jun Kilns in the Song Dynasty (JG), and folk Jun Kilns in the Song Dynasty (JM), indicating distinct differences in glaze material formulas. Conversely, YJL-2 samples displayed similar compositions to Henan Jun-glazed wares, with overlapping central distribution parts, suggesting comparable glaze material formulas.

The content of SiO2, Al2O3, CaO, K2O, Fe2O3, and TiO2 in the glaze layers of YJL-1 and YJL-2 samples and Henan Jun-glazed ware samples was analyzed and compared. A box plot was created, as shown in Fig. 9. According to the figure, the chemical composition of YJL-1 samples exhibited distinct characteristics; notably, each component’s fluctuation range was small. The SiO2 content was relatively high, significantly surpassing that of the Henan Jun-glazed wares. Al2O3 content was concentrated and lower compared to samples from Henan Liujiagou Kiln and official Kilns. The CaO content was lower than that in Henan Jun-glazed wares. K2O content was concentrated and notably lower than in Henan Jun-glazed wares. The Fe2O3 content was lower than in samples from official Jung Kilns in Henan. TiO2 content was concentrated and lower than in Henan Jun-glazed wares. Overall, the disparity in SiO2 and Al2O3 content in YJL-1 samples was substantial, as characterized by high SiO2 content and low Al2O3 content. The Al2O3/SiO2 molar ratio ranged between 0.18 and 0.25, and the glaze’s gloss was low. The YJL-2 samples demonstrate notable compositional parallels in terms of Al2O3, K2O, and Fe2O3 concentrations with Henan Jun porcelain. Although discernible discrepancies exist in SiO2, CaO, and TiO2 levels between the two. The fluctuation range of compositional content in YJL-2 samples is closer to that in Henan Jun porcelain than that of YJL-1 glaze.

The aforementioned analysis revealed distinct differences between the YJL-1 samples and the Henan Jun-glazed wares in both the body and glaze layers, while the YJL-2 samples displayed notable similarities. It shows that there was a close trade between Inner Mongolia and Henan Province in the Yuan Dynasty, and the porcelain in the ware was one of the trade commodities.

Physical properties of the body

Physical properties such as water absorption and firing temperature are essential for discussing the process and principle of porcelain.

The water absorption rate of the porcelain body was measured using the boiling method and the liquid static weighing method. The test results are shown in Table 7. The data show that most of the YJL-1 samples are stoneware, and the YJL-2 samples are porcelain.

The results of the German NETZCH DIL402C thermal expansion instrument were utilized to test the firing temperature of the sample of Jun glaze, as shown in Table 8. The firing temperature of the YJL-1 sample is between 1201 °C and 1278 °C. The firing temperature of the YJL-2 sample is between 1279 °C and 1291 °C. It can be seen that the YJL-1 sample firing temperature is slightly low.

Microscopic observation analysis

The microstructures of the glaze layer and body of the YJL-1 samples were examined using an ultra-depth-of-field microscope, a scanning electron microscope, and a polarizing microscope. This study aimed to explore the relationship between the YJL-1 samples and the Henan Jun-glazed wares.

Firstly, the microscopic observation of the glaze layer is carried out. The bubbles in the glaze layer of the YJL-1 samples were observed by SEM. The bubbles larger than 200 μm are mainly distributed in the middle layer of the glaze layer, while the bubbles smaller than 200 μm are distributed in the surface layer (Fig. 10a). This feature is similar to the bubble distribution in the glaze layer of Jun glaze ware unearthed in the Jin Dynasty and Yuan Dynasty in Hebei Province20.

The previous data indicated that the firing temperature of YJL-1 samples is low, and the flux agent content in the YJL-1 samples’ glaze layer was minimal, resulting in high glaze viscosity during the porcelain firing process and thus impeding gas discharge. Table 9 illustrates the thickness of the glaze layer for these samples, with the thickest sample (YJ10) measuring 1.38 mm.

The glaze layers of Jun-glazed wares from the Yuan Dynasty, unearthed from folk kilns in Liujiagou and Zhaojiawa, varied from 0.5 mm to 2 mm12. Those excavated from the Yanjialiang Site were thinner than those from the Yuan Dynasty folk kilns. These layers exhibited a dispersed blue milky light and opalescence, characterized by numerous flow-like textures of interwoven blue and white stripes (Fig. 10b).

The glaze layer of the YJL-2 samples was observed by SEM and ultra-depth field microscope (Fig. 10c, d). The YJL-2 specimen exhibits a substantial glaze thickness with multi-layer glaze, characterized by high-density bubbles distributed throughout the matrix. The glaze characteristics of the YJL-2 sample are similar to the glaze characteristics of Jun porcelain from Juntai kiln at Yuzhou, Henan21.

Furthermore, the SEM was employed to examine the glaze layer of the samples at 1000–20,000× magnification, revealing that the glaze layer was not homogenous. It comprised various microstructures, including bubbles, numerous unreacted quartz grains, horse-tooth square quartz adjacent to the unreacted quartz grains (Fig.11a, b), and anorthite (Fig.11c, d).

The glaze layer of the YJL-1 samples underwent SEM analysis at 20,000–30,000× magnification. This revealed phase separation droplets, spherical and ellipsoidal in shape, as depicted in Fig. 12a, b. These droplets varied in size, with maximum diameters of 150 nm and a minimum diameter of 50 nm. The majority of droplets were smaller than 100 nm. These droplets fell within the Rayleigh scattering range, reflecting blue light. The samples unearthed from the Dong Xia sites in Russia’s Primorye region, exhibited a semi-interconnected phase separation structure, likely due to higher glaze calcium content22. The CaO content of YJL-1 samples was lower than that in Jun-glazed wares found in Dong Xia sites. Consequently, unlike the connected droplets in the samples of Dong Xia sites, the samples displayed discrete droplets. The phase separation structure is closely related to the SiO2/Al2O3, and the SiO2 content of YJL-1 samples was higher than that of the Jun-glazed wares found in Dong Xia sites. Previous studies have shown that the larger the SiO2/Al2O3, the smaller the size of the phase-separated droplets (less than 100 nm), making it closely packed, which is consistent with the phase-separated structure in the glaze layer of the YJL-1 samples, but different from the Dong Xia sites. The Jun glaze wares unearthed from the site of the Dong Xia sites were derived from the Jun kiln of Henan in the Jin Dynasty, which indicates that there is a significant difference in the morphology of the phase-separated droplets in the glaze layer between the YJL-1 samples and the Jun glaze wares of the Jin Dynasty in Henan.

Moreover, the glaze layer of the YJL-1 samples was examined using the polarizing microscope, ultra-depth field microscope, and SEM, as depicted in Fig. 13a–c. A large number of crystals were precipitated around the bubbles, and there is melting erosion around the crystals. The composition of the crystal was detected by EDS (Fig. 13d), and the content of Si element in the crystals was high, which could be confirmed as quartz. A multitude of unreacted quartz grains were present in the glaze layer of YJL-1 samples, whereas the glaze layer of the Henan Jun-glazed wares from the Song Dynasty featured anorthite crystallization. The glaze layers of these two sample types exhibited distinct microstructures. A previous study noted that prolonged firing times or slow cooling rates can lead to extensive and thick anorthite crystallization23. The disparity in glaze layer microstructures suggests that the firing systems for the YJL-1 samples differed from those used for Henan Jun-glazed wares of the Song Dynasty.

Secondly, the microscopic observation of the body-glaze reaction crystallization layer is carried out. A prominent body-glaze reaction crystallization layer (Fig. 14a) was observed under SEM at a magnification of 1000×. Through EDS analysis, it was found that Al, Si, O, and Ca elements were present in high concentrations in the crystals (Fig. 14b). Therefore, these crystals can be confirmed as anorthite crystallization. Anorthite crystallization and liquid droplets were noted near the glaze layer. The body-glaze reaction layer of Henan Jun-glazed wares from the Song Dynasty shows needle-like precipitated crystals, with no obvious upper and lower layers of precipitated crystals24. Comparisons between Yanjialiang Jun-glazed wares and Henan Jun-glazed wares, reveal variations in the microstructure of the body-glaze reaction layers among these sample types.

Finally, the microscopic observation of the body is carried out. The bodies of YJL-1 samples were examined using an ultra-depth-of-field microscope. The bodies of YJ2, YJ8, YJ9, and YJ18 were found to be yellowish, those of YJ10, YJ11, and YJ15 were brick red, and the bodies of YJ3, YJ5, YJ6, YJ7, YJ13, YJ14, YJ16, YJ17, and YJ20 were gray. Noticeable impurity grains were visible in the sample bodies (Fig. 15).

SEM analysis was employed to inspect the mullite in these bodies. There are a large number of squamaceous crystals in the porcelain matrix (Fig. 16a). Through EDS analysis, it was found that Al, Si, and O elements were present in high concentrations in the crystals (Fig. 16b), therefore, these crystals can be confirmed as mullite. Except for the body of YJ8, which displayed secondary needle mullite, the other samples predominantly contained primary scaly mullite. The primary mullite forms the foundation for secondary mullite development25. In most samples, the mullite was underdeveloped, indicating that its mechanical strength had not achieved the optimal level. A significant development of mullite needle crystals, transforming clay agglomerates into numerous herringbone-shaped mullites, was observed in the microstructures of porcelain bodies of ancient Jun-glazed wares (including those from the Song and Yuan Dynasties) in Yuxian, Henan, China24. The study highlighted that the microstructures of ancient Jun-glazed ware bodies from Henan predominantly comprised thick secondary mullite needle crystals, fully developed primary mullite, and triple-crossed mat-like structures created by both mullite types26. This contrasted starkly with the microstructure of mullite in the bodies of the samples tested in this study.

In the sample porcelain bodies, numerous unreacted quartz grains were detected under the microscope, measuring approximately 0.21 mm in length (Fig. 17a). This indicated that the body mud material was coarse. Coarse mud materials reduce the contact surface between the particles, causing the various components not to be fully mixed, resulting in a low uniformity of the mud, which is detrimental to the firing process and heightens the likelihood of underfiring. Moreover, the abundance of unreacted quartz grains suggests that the sample firing temperatures were relatively low, placing the samples underfired. This is consistent with the test results of the firing temperature above.

Numerous pores were observed in the sample bodies, as illustrated by the black areas in the SEM images (Fig.17b). These pores were abundant, irregular in shape, and unevenly distributed throughout the body. The network of pores contributed to the overall rough texture of the sample bodies.

Texture features analysis of the glaze revealed numerous bubbles and unreacted quartz grains in the YJL-1 samples. The matrix microstructure consisted mainly of scaly primary mullite, indicating a relatively low firing temperature and incomplete decomposition of clay grains during raw material preparation, which hindered the development of secondary needle mullite27. In addition, a significant presence of residual quartz and pores in the body led to suboptimal mechanical properties of the sample bodies. These observations suggested a low-grade raw material, a coarse washing process, and a lower level of production proficiency. In general, the microstructures of the glaze layer and body of YJL-1 samples showed marked differences from those of ancient Jun-glazed wares from Henan, China.

The 20 pieces of Jun-glazed ware unearthed at the Yanjialiang Site could be categorized into two groups based on the composition of their bodies, specifically YJL-1 and YJL-2.

A large number of primary mullite, irregularly distributed pores and un-reacted quartz grains were generated in the matrix of both types of samples. This is a common feature of the Jun-glazed stoneware in the Yuan Dynasty, that is, the rough production process.

The body composition of the YJL-1 samples shows a very high Al2O3 content, which is between 33.16% and 39.72%, while the SiO2 content is low. The Al2O3 content in the matrix of the YJL-2 samples is lower than that of the first type, between 26.00% and 29.40%, and the SiO2 content is higher than that of the first type.

The YJL-1 samples exhibited a low glaze gloss, numerous bubbles, and a high quantity of unreacted quartz grains. Anorthite crystals are formed in the glaze layer of YJL-2.

Compared to YJL-2 samples, the fluctuation range of the content of each component in the glaze layer of the YJL-1 samples is small, with a higher content of SiO2, a concentration of Al2O3, and a lower content of CaO, Fe2O3, and TiO2. In general, there is a big gap between the silicon and aluminum content in the glaze of the YJL-1 samples, which is characterized by high silicon and low aluminum. The fluctuation range of the individual chemical compositions in the glaze of the YJL-2 samples is large, showing the characteristics of each composition as being higher than that of the YJL-1 samples, and the content is similar to that of Henan Jun glazed wares.

The chemical compositions and microstructures of the glaze layer and the body of the YJL-1 samples significantly differ from those of Jun-glazed wares from the Song, Jin, and Yuan Dynasties excavated in the central and western regions of Henan Province, China. This is the first time that this type of special composition of Jun-glazed wares has been discovered, and this study recognizes a new, distinctive Jun ware technological variant. Senior scholars believe that Ding Kiln in Hebei Province, China, does not produce Jun-glazed wares. Through the detection of trace elements and strontium isotopes, it can be determined that YJL-1 comes from Ding kiln, Hebei Province, China.

In contrast, the YJL-2 samples are highly consistent with Jun-glazed wares from the Song and Yuan Dynasties discovered in Henan, China, in terms of composition. Previous research indicated that Jun-glazed ware fragments unearthed from various kiln sites and during different periods in Henan Province, China, vary in the chemical compositions of the body and glaze. However, they maintain a high degree of consistency. Consequently, it is hypothesized that the YJL-2 samples may originate from Jun Kilns in the central and western regions of Henan, China.

For the first time, this study employed scientific and technological methods to detect and analyze the Jun-glazed wares of the Yuan Dynasty civilians unearthed in Inner Mongolia. The data obtained included chemical compositions and microstructures of the body and glaze. These findings reveal the processing level of Jun-glazed wares from the Yuan Dynasty at typical sites in Inner Mongolia, China, and lay the groundwork for subsequent research.

Data availability

No datasets were generated or analyzed during the current study.

References

Chen, X. et al. On the inter layer, opalescence and coloration of Jun ware in the Song and Yuan Dynasties. J. Chin. Ceram. Soc. 11, 129–140 (1983).

Guo, J., Cheng, H. & Chen, X. Discrimination between Song Ru ware and Song Jun ware. J. Ceram. 03, 153–157 (1999).

Luo, Y., Pan, W. & Li, S. Discussion of coloring mechanism and sintering process for Jun kiln. Ceramics 06, 23–26 (2000).

Cheng, L. et al. Analysis of elemental maps from glaze to body of ancient Chinese Jun and Ru porcelain by micro-X-ray fluorescence. Nucl. Instrum. Methods Phys. Res. B. 267, 117–120 (2009).

Li Z. Studies on corrosion of ancient Jun ware glazes in China. PhD thesis (Beijing University of Science and Technology, 2022); https://wwwv3.cqvip.com/doc/degree/1872490543.

Iqbal, Y. & Lee, W. E. Microstructural evolution in triaxial porcelain. J. Am. Ceram. Soc. 83, 3121–3127 (2000).

Sanz A., Bastida J., Kojdecki M. A. & Caballero A., Serrano F. J. Evolution of size and shape of mullite crystallites in triaxial porcelains 435–440 (Oldenbourg Wissenschaftsverlag, München, 2009); https://wwwv3.cqvip.com/doc/journal/2743449753.

Niziolek, L. C. Portable X-ray fluorescence analysis of ceramic covered boxes from the 12th/13th-century Java Sea Shipwreck: a preliminary investigation. J. Archaeol. Sci. Rep. 21, 679–701 (2018).

Niziolek, L. C. Earthenware production and distribution in the prehispanic Philippine polity of Tanjay: results from laser ablation-inductively coupled plasma-mass spectrometry (LA-ICP-MS). J. Archaeol. Sci. 40, 2824–2839 (2013).

Colomban, P. & Treppoz, F. Identification and differentiation of ancient and modern European porcelains by Raman macro- and micro-spectroscopy. J. Raman Spectrosc. 32, 93–102 (2001).

Ta L., Zhang H. & Zhang H. Excavation briefing of the Yanjia Liang Site in Baotou, p 646 (Science Press, Beijing, 2010).

Guo, Y. & Li, G. Scientific analysis of ancient Jun Wares. China Ceramics04, 52–57 (1992).

Li, G. et al. Proton-induced X-ray emission analysis of the clay sources for Ru official ware and Jun official ware ceramics. Sci. Sin.36, 239–247 (2006).

Jin, X. Study on the technology of duandian Kiln in Lushan, Henan Province. Master’s thesis (Zhejiang University, 2019); https://wwwv3.cqvip.com/doc/degree/1871217785.

Zhao, W. et al. The fingerprint elements analysis on the provenance relation between ancient Chinese Ru porcelain and Jun porcelain. Nucl. Tech. 25, 461–466 (2002).

Cui, J. F. et al. Chemical analysis of white porcelains from the Ding kiln site, Hebei Province, China. J. Archaeol. Sci. 39, 818–827 (2012).

Li, G. Z. & Guo, Y. Y. Study on the white porcelain of Ding Kiln in Past Dynasties. J. Chin. Ceram. Soc. 03, 306–313 (1983).

Lin, H. Investigation and trial excavation of Dingyao Site in Jianci Village, Quyang County, Hebei Province. Archaeological 08, 396–412 (1965).

Li, R. et al. Pixe study on the source of raw materials of Ru and Jun Guan porcelain with three pepresentative glaze colors. J. Beijing Norm. Univ. 42, 144–149 (2006).

Wang, Y. et al. Application of micro-CT technique to the microstructure characterization of Jun glaze porcelain. J. Ceram. 45, 281–289, https://doi.org/10.13957/j.cnki.tcxb.2024.02.005 (2024).

Yan, X., Dong, J., Li, Q. I., Guo, M. & Hu, Y. Preliminary research in section structure characteristics of ancient glaze based on OCT technology. Chin. J. Lasers 41, 201–206 (2014).

Li, W. et al. Provenance identification of the high-fired glazed wares excavated from the Late Jin Dynasty (Dong Xia State) sites in Russia’s primorye region. J. Archaeol. Sci. Rep. 21, 512–527 (2018).

Chandra L. R. Petrographic and image analysis of thin sections of classic wares of Song Dynasty. In Proc. International Symposium on Science and Technology of Five Great Wares of the Song Dynasty, Beijing, China (eds. Ningchang, S. & Jianmin, M.) 385 (Science Press, Beijing, 2015); https://book.douban.com/subject/26931628/

Chen, X., Huang, R., Chen, S., Zhou, X. & Ruan, M. The structural characteristics of Henan antique Jun ware sherds and the evidences of their two kinds of phase separation. J. Chin. Ceram. Soc. 9, 245–252 (1981).

Iqbal, Y. & Lee, W. E. Fired porcelain microstructures revisited. J. Am. Ceram. Soc. 82, 3584–3590 (1999).

Li, J. History of Chinese Science and Technology: Ceramics Volume 1st edn., 427 (Science Press, Beijing, 1998).

Tite, M. S., Freestone, I. C. & Wood, N. An investigation into the relationship between the raw materials used in the production of chinese porcelain and stoneware bodies and the resulting microstructures. Archaeometry 54, 37–55 (2012).

Acknowledgements

Thank Fellow Haibin Zhang, for providing samples. This research was funded by Inner Mongolia Autonomous Region Science and Technology Plan Project, grant number 2023YFSW0019, and Basic Scientific Research Projects of Universities Directly under the Inner Mongolia Autonomous Region, grant number JY20250063.

Author information

Authors and Affiliations

Contributions

Ke Shi undertook experimental work and wrote the draft manuscript, as well as the final manuscript. Mei Yong designed the study and drafted the manuscript. Lijun Dong worked on designing the experiments and on the draft.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Shi, K., Yong, M. & Dong, L. Composition and microstructure of Yuan Dynasty Jun glazed stoneware from Yanjialiang site, Inner Mongolia, China. npj Herit. Sci. 13, 157 (2025). https://doi.org/10.1038/s40494-025-01711-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s40494-025-01711-0

This article is cited by

-

Provenance study of Tang-dynasty black-glazed porcelains unearthed at the Yingou site

npj Heritage Science (2026)