Abstract

During the Neolithic period, ground stone tools were essential for both social production and daily life, serving as one of the most significant indicators of prehistoric human activities. Among these tools, grinding stones are particularly noteworthy, facilitating the production of other ground stone artifacts. Based on the ground stone tools unearthed from a Liangzhu culture site at Xicaodun, this study employs a combination of hierarchical dynamic typology, design theory, use-wear analysis, and microeconomic concept to provide a comprehensive understanding of the ground stone artifacts. The study further explores the design and use strategies of grinding stones to reveal the underlying economic practice. The findings suggest that the Xicaodun site may have functioned as a specialized workshop for the production of ground stone tools. Moreover, the design and use patterns of the grinding stones reflect a strategic effort to optimize material use for the continued operation of the workshop.

Similar content being viewed by others

Introduction

During the Neolithic period, ground stone tools were fundamental to production activities, and the methods by which they were made and utilized offer valuable insights into the societal organization and lifestyle of the time. The term “ground” actually refers to two different processes, namely manufacture-ground and use-ground1. Manufacture-ground is a technological perspective, which means that stone tools are primarily manufactured through abrasion, polish, or necessary impaction, like an axe. Use-ground is a functional perspective used to describe tools that are used to grind, abrade, polish, pound or impact, such as metates and mortars2,3. Grinding stones, as a category, are typically considered “use-ground” tools, primarily used for various grinding activities.

Grinding stones have been utilized by humans since at least the African Middle Stone Age, primarily for processing cereals, pulses, and other foodstuffs for consumption, as well as for grinding pigments4,5,6. As tools with a global presence, grinding stones have been extensively studied worldwide7,8,9,10,11,12,13,14,15,16,17,18,19,20,21. Archaeological research on grinding stones in China began in the 1930s, when Liang first discovered and reported the earliest examples in northern China22. A subsequent report confirmed that these grinding stones were used for grain processing, a finding that has been widely accepted in the field23. From the 1970s to the 1990s, as archaeological materials became more abundant, systematic functional studies of grinding stones were conducted. Since the early 21st century, the integration of advanced scientific methods and techniques has provided new insights into the functions of grinding stones24,25,26,27,28,29. While the majority of research has focused on the relationship between grinding stones and plant-based foods, one of their key functions is the production of tools, particularly ground stone tools.

Based on the ground stone artifacts unearthed from a Liangzhu culture site at Xicaodun, this paper clarifies the overall picture of ground stone artifacts by means of hierarchical dynamic typology. The focus is primarily on grinding stones, with an exploration of their design and usage strategies, analyzed through design theory and use-wear analysis. Additionally, the fundamental microeconomic principle of ‘opportunity cost’ is introduced to explore the economic thinking and behavioral patterns of the prehistoric inhabitants in relation to the production and use of stone tools.

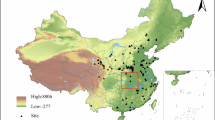

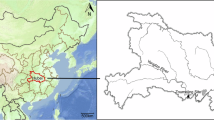

The Xicaodun site (30°38′21″N, 120°47′32″E) is located in the southeast of Nanhu District, Jiaxing City, Zhejiang Province, China (Fig. 1). In June 2020, it was investigated and recognized as a site of Liangzhu culture (3300BC-2300BC) by the Cultural Heritage Department. From 2020 to 2021, rescue excavations were conducted at the site under the auspices of the Zhejiang Provincial Institute of Cultural Relics and Archaeology. Many different features were uncovered, including mounds, ash pits, ash ditches, shaft kiln as well as remnants of pottery, stone tools and jade objects30. Among them, the number of ground stone tools accounted for about 81.1 percent of the total amount, which shows that the typical artifacts of the Xicaodun site are ground stone tools. At present, the site has not been subjected to absolute dating techniques. Pottery styles suggest that this site dates back approximately to middle-late period of Liangzhu culture (3300BC-2300BC). Mainly distributed in the valley of the Lower Yangtze River, near Lake Tai (one of China’s largest lakes), the Liangzhu culture was considered to be an early civilized state with a unified belief system in Late Neolithic China, with about 1000 archaeological sites found31,32,33.

The Jiaxing City region is characterized by a low and flat topography, with an average elevation of only 3.7 meters above sea level. The landscape is predominantly composed of low hills, primarily concentrated in the southeastern part of the Qiantang River, on the northern shore of Hangzhou Bay, to the south of the Xicaodun site. These hills have elevations generally below 200 meters, with the highest peak being Gaoyang Mountain at 251.6 meters. From an engineering perspective, the stone resources in these nearby mountains are insufficient to support the establishment of a stone quarry. Lithologically, the dominant rock types in this area include dolomite, dacitic breccia-bearing tuff, lava, and ignimbrite. In contrast, the residents of the Xicaodun site predominantly selected raw materials such as siltstone, fine sandstone, mudstone, siliceous rock, and spotted hornfels for tool production. This suggests that the stone materials used at the Xicaodun site were not sourced from the nearby mountains but rather from more distant mountain ranges.

The Tianmu Mountains, situated on the Hangjiahu Plain, are characterized by a greater abundance of stone resources and rock types. It is located in the south-west of the Xicaodun site, approximately 100 kilometers from the latter. The Tianmu Mountains are predominantly composed of medium- and fine-grained quartz sandstone and siltstone, which are also commonly found at the Xicaodun site. Given the scarcity of local stone resources in the immediate vicinity, it is likely that the majority of raw materials used at the site were sourced from external locations, with the Tianmu Mountains representing the most probable source, or potentially other more distant areas.

Methods

A total of 671 stone artifacts have been excavated from the Xicaodun site, with the primary tool types including grinding stones, stone knives, stone arrowheads, stone adzes, stone chisels, stone sickles, and stone axes, collectively representing a diverse and comprehensive range of tools (Fig. 2). Among these, grinding stones are the most abundant, with a total of 221 specimens. These grinding stones exhibit a variety of shapes and sizes, ranging from relatively large specimens with clear evidence of modification to smaller pieces that retain the original form of the raw material.

The lithic materials used at the Xicaodun site are closely associated with specific types of ground stone tools. Stone arrowheads, which exhibit complex shapes and are prone to wear, are primarily made from softer and more easily worked mudstone. Stone knives, designed for cutting, are generally crafted from compact and durable spotted hornfels. Stone adzes, used predominantly for woodworking34, are typically made from siliceous rock, chosen for its harder texture. To optimize their effectiveness, the rock layers of the adzes are often oriented perpendicular to the edge, preventing the force of impact from aligning parallel to the rock’s natural planes of weakness. Grinding stones, which are the most numerous tool type at the site, are made from a wider variety of rocks, including sandstone, fine sandstone, siltstone, spotted hornfels, andesite, mudstone, and tuff. Among these, fine sandstone grinding stones are the most abundant, with a total of 148 pieces. Fine sandstone is characterized by uniform grain structure, fine texture, and loose composition, with properties such as high-water absorption, sound insulation, and resistance to breakage and weathering. These qualities make fine sandstone an ideal material for crafting grinding stones, potentially extending their service life and enhancing their functional efficiency.

Given that the raw materials likely originated from the relatively distant Tianmu Mountains, or potentially even more distant regions, it is highly probable that stone tool makers were selective in their choice of lithic materials.

Hierarchical dynamic typology

To provide a comprehensive understanding of ground stone tools, a typological analysis is essential. Hierarchical Dynamic Typology is a method used to classify chipped stone tools within the framework of the ‘Chaîne Opératoire’ concept. This approach involves a preliminary analysis of the technology, form, and function of the tools, followed by an examination of their development from preparation to discard. Based on this progression, tools are categorized into four main groups: prepared type, manufactured type, utilized type, and discarded type, with additional sub-groups for further differentiation35.

The concept of the ‘Chaîne Opératoire’ originated in the 1960s within the field of Paleolithic archaeology in France. Initially, it was used in a more specific context to describe the operational procedures involved in the production of stone tools, emphasizing the distinct phases of the stone tool production process36,37. By the 1980s, the definition of ‘Chaîne Opératoire’ was expanded to encompass not only the production process but also the procurement of raw materials, the manufacture and processing of tools, and their subsequent use and disposal as part of a dynamic, continuous sequence38. The purpose of examining the life history of stone tools should not stop at the stage of analysing the process of stone tool production, but extend further to an eco-economic consideration of human technological behavior39.

Guided by the ‘Chaîne Opératoire’ framework, this paper views the production to the disposal of ground stone artifacts at the Xicaodun site as a dynamic process. Through the application of hierarchical dynamic typology, the study provides a comprehensive summary of the ground stone tool assemblage, establishing a foundation for further research into the grinding stones at the site.

Design theory

Design refers to the entire process of transforming an idea into a tangible object. It begins with the initial conception of an idea, which is then shaped through imagination and ultimately brought to fruition through skilled techniques. This process is characterized by a clear progression from idea to action. In the context of Paleolithic lithic technology, a distinction already existed between curated and expedient tools40,41. Curated stone tools were refined, standardized in form, and designed to serve a variety of functions. In contrast, expedient tools were typically rough, simple, and variable in shape. The former reflects a deliberate design process, suggesting that toolmakers had a pre-conceived notion of the tool’s form and function, which was then realized through curation techniques. Expedient tools, however, demonstrate the toolmaker may have had a general idea but created a tool with minimal modification, driven by practical necessity.

Adams applied design theory to the study of ground stone artifacts, proposing two behavioral constructs of design: expedient and strategic. If the natural shape of the rock was altered only through use or only enough to make it functional, the item is considered to have an expedient design. Modifications that make the item easier to hold, to improve efficiency, or to achieve a specific shape that does not relate to function indicate a strategic design3. These two design behaviors not only reflect different technological considerations but also suggest varying levels of preference and intensity in tool use. Building on Adams’ criteria for classifying ground stone tools, this study examines the design strategies employed in the grinding stones at the Xicaodun site.

Use-wear analysis

The term ‘use-wear’ is used to describe the study of wear traces on the edges and/or surfaces of objects caused by use2,42,43. In practice, a variety of behaviors can contribute to or influence the formation of traces on objects. Beyond functional studies44,45,46,47, the scope of use-wear analysis has increasingly expanded to include not only the formation of use-wear but also post-depositional processes48,49,50,51. By examining the surface traces on stone artifacts through use-wear analysis—such as microtraces including flake scars, polish, rounding, and striations—and comparing archaeological specimens with experimental replicas in simulation experiments, it is possible to gain insights into the manufacturing techniques, usage, and processing of stone artifacts, as well as other relevant information.

For the study, we selected typical archaeological grinding stones and experimental grinding stones to collect data of wear traces. These specimens were observed under a 3D digital Keyence VHX-5000 microscope with magnifications between 20 × and 200 ×. The data we applied in this study for use-wear analysis are collected by the Laboratory of Art and Archaeology Image, Zhejiang University, China.

Microeconomics analysis

The products of the ‘economy’ encompass both material and spiritual goods, as well as economic behaviors and activities. Among these, material products or commodities are of primary importance and represent the central focus of archaeological research. The relics of stone tools, pottery, jade objects/tools, as well as the remains of workshops, buildings, and settlements uncovered by archaeologists, are closely linked to the production and daily life of ancient societies. These artifacts serve as tangible evidence of the economic behaviors and activities of past populations.

Microeconomics is a branch of economics that examines the behavior of individuals and firms in making decisions about the allocation of scarce resources, as well as the interactions between these agents52. The efficient allocation and utilization of limited resources require individuals to carefully assess the trade-offs between resource use and associated costs. The concept of opportunity cost provides a framework for such evaluations. According to the New Oxford American Dictionary, opportunity cost is defined as “the loss of potential gain from other alternatives when one alternative is chosen.” Given the finite nature of resources, allocating them to one purpose often results in the forgoing of potential benefits from alternative uses, thus incurring a cost. Opportunity costs encompass both explicit and implicit costs: explicit costs refer to the direct financial outlay associated with a particular decision, while implicit costs represent the value of benefits lost by not choosing the next best alternative53.

The principle of opportunity cost encourages the efficient use of scarce resources by maximizing the benefits derived from their allocation to a particular purpose, rather than to alternative uses. During the Neolithic period, as prehistoric people engaged in the production and use of stone tools, pottery, and other materials, they faced considerations and trade-offs in the selection of raw materials, design choices, and functional requirements. By incorporating the concept of opportunity cost into the analysis, the production and use of ground stone artifacts can be examined from an economic perspective, offering insights into the social organization and production strategies of prehistoric societies.

Results

Results of hierarchical dynamic typology

The first category of stone products is prepared type. That is to say, stone products at the stage of quarrying or production processing include both the raw materials and the stone tools required for production.

At the Xicaodun site, a total of 263 artifacts belong to this category, comprising 42 raw material specimens and 221 grinding stones. The latter account for 32.9% of the total stone assemblage. The raw materials are primarily composed of crystalline tuff, with smaller quantities of mudstone and spotted hornfels.

The second category, manufactured type, refers to stone products produced during the manufacturing process that were not utilized, including stone flakes, by-products, blanks, and preforms. At the Xicaodun site, a total of 237 artifacts fall into this category, representing 35.3% of the entire lithic assemblage.

Stone flakes (92 pieces) are primarily formed during the production and trimming of ground stone tools. These are divided into two types: normal flakes (without traces of ground) and special flakes (with visible ground traces, but the cause is unknown). Of the total, 81 are normal flakes, predominantly made from mudstone and spotted hornfels. The remaining 11 special flakes are also made from spotted hornfels and mudstone.

Blanks (24 pieces) are stone artifacts that have been partially flaked and shaped, and they are associated with tools such as knives, arrowheads, chisels, ploughs, and soil-working tools.

Preforms (45 pieces) refer to stone artifacts that have been largely shaped through knapping but have not yet been polished.

By-products are non-purposeful products generated during the manufacturing process, including chips and chunks, which are more difficult to characterize in terms of their intended use. The 19 chips identified are small, broken flakes less than 1 cm in size, while the 57 chunks represent larger blocks produced during the manufacturing phase. Some of these chunks display visible traces of ground, and are mainly composed of spotted hornfels and mudstone.

Turning to the third category, utilized type includes stone artifacts that have been used, as well as those that have been subsequently modified for secondary purposes. These primarily include various types of shaped tools, reshaped tools, and some unidentified implements.

At the Xicaodun site, 91 shaped tools are identified, accounting for approximately 13.6% of the total lithic assemblage. These tools mainly consist of knives, arrowheads, adzes, chisels, axes, soil-working tools, net sinkers, as well as some unidentified items. Among the stone knives (21 pieces), two types are distinguished: handled and handleless knives. The 38 stone arrowheads include both willow leaf-shaped and sword-shaped varieties. The 16 stone adzes and 10 stone chisels are categorized into large and small subgroups. The smaller adzes and chisels are well-polished, with visible breakage at the edges, while the larger specimens exhibit more significant edge damage. In addition, there is one axe, one soil-working tool, one net sinker, and one unidentified tool.

Two modified tools are also present at the site. One of these is identified as a stone axe; however, its poor symmetry and the wide, short shape suggest it may be a modified artifact rather than a typical stone axe. The second modified tool is of an unusual form, with an almost trapezoidal plane and a pecked hole, leading to the hypothesis that it may be a uniquely shaped stone plough. However, due to significant breakage, the exact function and nature of this ground stone tool remain uncertain.

Discarded type is the final category. It refers to stone artifacts that were intentionally discarded due to technological failures during production or a loss of effectiveness through use.

At the Xicaodun site, a total of 80 broken stone artifacts have been identified, including knives, arrowheads, adzes, chisels, sickles, ploughs, soil-working tools, and some unidentified implements. These broken artifacts represent 11.9% of the total lithic assemblage from the site.

The results of hierarchical dynamic typology reveal that the prepared type of stone artifacts accounts for the largest proportion (39.2%), with 42 pieces of raw materials and 221 pieces of grinding stones (see Table 1). The manufactured type makes up a smaller proportion (35.3%), while the utilized type represents an even lower share (13.6%). Within the shaped tools category, stone knives and stone arrowheads are particularly prevalent, appearing in various stages of production, such as blanks and preforms. This suggests that stone knives and arrowheads were likely the primary products at the Xicaodun site, and that a relatively complete production process was followed. The decreasing proportions of the prepared, manufactured, utilized, and discarded types imply that the Xicaodun site was predominantly focused on the production of ground stone tools, utilizing advanced manufacturing technologies. This is supported by the high utilization rate of raw materials and the low incidence of waste. It is therefore hypothesized that the site functioned as a specialized workshop for ground stone tool production, with stone knives and stone arrowheads serving as the main products. Given the crucial role of grinding stones in the production of these tools, understanding their design and use is of particular significance.

Design strategy of grinding stones

The grinding stones at the Xicaodun site exhibit clear evidence of deliberate modification and strategic design. These stones come in various shapes, including pillow-shaped and polygonal pyramid forms. Typically, they feature multiple working surfaces, each carefully processed to achieve a flatness suitable for use. The working surfaces show signs of high-intensity use, evidenced by internal concavities, which likely formed through repeated use over an extended period. A total of 143 strategically designed grinding stones were identified at the site, with medium to large specimens predominating, and some extra-large examples also present. Of these, 27 stones have a single working surface, 29 have double working surfaces, and 87 exhibit multiple working surfaces. In terms of lithology, nearly all the grinding stones are made of sandstone and fine sandstone, with only two examples composed of mudstone and tuff.

Pillow-shaped grinding stones at the site exhibit varied characteristics in their working surfaces. For example, T4G1②:9, made of mica-bearing fine sandstone, has four distinct working surfaces. Working surface 1 is polygonal and concave, with faintly visible striations. Working surface 2 is polygonal and flat, also exhibiting visible striations. Working surface 3 is polygonal, wavy, and undulating, with pronounced subsidence and visible striations. Working surface 4 is polygonal, characterized by interwoven natural and working areas, and displays a significant degree of concavity. The edges of all the working surfaces are angularly smoothed (Fig. 3:1). Similarly, H7①:5, made of mica-bearing feldspathic fine sandstone and exhibiting four working surfaces, shows distinctive wear patterns. Working surface 1 is quadrilateral and concave, with moderate use wear, displaying messy and deeper striations along with a few pecked traces. Working surface 2 is sub-rectangular and more deeply concave, with striations parallel to the long axis. Working surface 3 is quadrilateral, featuring two concave depressions with inconspicuous striations. Finally, working surface 4 is irregularly polygonal and slightly concave, with visible transverse and oblique striations (Fig. 3:2).

Large polygonal pyramid-shaped grinding stones exhibit significant wear on their working surfaces. An example of such a stone is T4G1①:8, made of mica-bearing feldspathic fine sandstone. This specimen has a quadrangular pyramid shape, wide at the base and narrowing towards the top, with a nearly flat bottom. The working surfaces are all quadrilateral, smooth, and concave, displaying faint striations. Among these surfaces, the concavity of working surface 2 is particularly pronounced (Fig. 4).

A total of 78 grinding stones with expedient design have been identified at the Xicaodun site. These artifacts show no clear signs of intentional modification or design, retaining the natural shapes of the raw materials. Generally, the natural surfaces are exposed, with significant soil coverage and a lack of striations. The working surfaces are only roughly processed and were used without further smoothing. Of these, 49 pieces feature a single working surface, 16 have double working surfaces, and 13 exhibit multiple working surfaces.

The category with a single working surface is predominantly composed of small to medium-sized stones, with only one working surface. Notably, post-depositional traces are relatively pronounced. For example, T1①:4, made of fine sandstone, has an irregularly polygonal and slightly concave working surface, with three grooves visible. The left groove is wider, while the right two are narrower (Fig. 5:1). Another example, T3②:41, made of andesite, has a nearly triangular working surface, with visible striations along the thicker side and reddish-orange attachment on the surface (Fig. 5:2).

The grinding stones with double working surfaces are generally more smoothly ground. For instance, T1G1②:33, made of greenish-grey feldspar fine sandstone, features two working surfaces. Working surface 1 is triangular, predominantly retaining its natural surface, though it appears to have been pecked, showing numerous pits. Working surface 2 is rectangular, relatively flat, and exhibits small striations (Fig. 6:1). Another example, T1G1③:19, made of mica-bearing fine sandstone, has two working surfaces. Working surface 1 is approximately triangular, with the left half flat and featuring two deep U-shaped grooves, accompanied by distinct striations within the grooves, while the right half retains its natural surface. Working surface 2 is natural and shows no obvious signs of use (Fig. 6:2).

As an example of the type with multiple working surfaces, H7①:6 is a large grinding stone made of mica-bearing feldspar fine sandstone. All of its surfaces are heavily abraded. Working surface 1 is trapezoidal and flat, displaying cluttered striations that may correspond to the natural texture of the stone. Working surface 2 is also trapezoidal and flat, with subtle striations. Working surface 3 is relatively flat but rough, clearly retaining a natural surface with no evidence of ground or grinding. Similarly, working surface 4 shares the same characteristics as surface 3, although it has a regular shape (Fig. 7).

Expedient grinding stones exhibit a certain degree of randomness in their design, characterized by irregular shapes, uneven working surfaces, and the direct use of natural surfaces. These stones, however, display variable patterns of use; some may remain in use for extended periods, while others are discarded after only brief use. In terms of material composition, expedient grinding stones are predominantly made of sandstone, with a smaller proportion (11 pieces) crafted from spotted hornfels, siliceous rock, and tuff. While the number of grinding stones made from non-sandstone materials is relatively small, it significantly exceeds their representation among strategic grinding stones. This suggests that the inhabitants of the Xicaodun site demonstrated flexibility in the production of expedient grinding stones, indicating a rational approach to the allocation and use of lithic resources. Specifically, when high-quality raw materials for grinding stones were scarce, they likely opted for readily available or discarded materials for short-term use.

At the Xicaodun site, there are also grinding stones that exhibit both strategic and expedient design features. Observations suggest that these stones generally prioritize strategic design, with expedient design features added later. The use of these grinding stones varied according to the specific requirements of the task in the actual activity, often resulting in the co-existence of both design types. This dual design approach appears to be relatively common at the site. For example, T4G1①:4 (Fig. 8), made of fine sandstone, has four working surfaces. Working surfaces 1 and 2 are quadrilateral, flattened by ground, and slightly concave, showing signs of moderate wear, indicating their strategic design. Working surface 3 is rectangular, while working surface 4 is nearly trapezoidal; both retain the natural texture of the raw material over most of their area, although they are marked by numerous crosswise grooves. Based on these characteristics, it is suggested that working surfaces 1 and 2 were designed strategically, while surfaces 3 and 4 likely represent expedient design.

Based on the raw material choices and design characteristics of the grinding stones, several conclusions can be drawn. Decisions made at the design stage generally begin with choosing lithic material for appropriate size and texture14,16,54. At the Xicaodun site, the prehistoric people predominantly favored three types of rocks—sandstone, siltstone, and fine sandstone—which were well-suited for the manufacture of grinding stones. The varying grain sizes of these materials allowed the production of grinding stones capable of performing a range of tasks. Consequently, grinding stones made from these materials tend to feature strategic design, typically incorporating multiple working surfaces to enhance functionality. In contrast, expedient grinding stones are characterized by fewer working surfaces than their strategic counterparts (Table 2). The purpose of strategic design is to extend the lifespan of the grinding stones and improve their usability. As such, the number and arrangement of working surfaces are deliberately planned during the manufacturing process. Expedient design, on the other hand, prioritizes flexibility, allowing for modifications as needed. These grinding stones often retain more of the natural surface of the raw material and lack fixed shapes. This adaptability reflects a more immediate or short-term use pattern. In general, the preference for strategic design may stem from a natural inclination to maximize the service life of the grinding stones. Furthermore, the prevalence of strategic grinding stones at the site could also reflect the scarcity of lithic resources, underscoring the importance of rational resource allocation and utilization in the production process.

Use strategy of grinding stones

Both expedient and strategic grinding stones were used intensively at the site, and most of these stones exhibit visible traces of use on their working surfaces, reflecting a typical pattern of maximizing the utility of stone tools. Grooves are commonly observed on the working surfaces of expedient grinding stones, and it is hypothesized that these grooves may have resulted from grinding tools. For instance, T3G1④:3 (Fig. 9) features a particularly deep, V-shaped groove. This specimen is small enough to be handheld, and under 50× magnification, the groove is observed to be long, narrow, and asymmetrical, with a shallow left side and a deeper right side. The depth and intrusion distance of the groove suggest that the stone was subjected to intensive use.

Strategic grinding stones are generally in good condition, with some working surfaces exhibiting reflective areas that may be indicative of patchy polish resulting from either manufacture or use. For example, on working surface 1 of specimen T4G1①:4, the visible polish appears brighter and is distributed in clusters, with a smooth texture. Under 200× magnification, diagonal striations can be observed within the polish (Fig. 10:1, 2). Comparative analysis with the results of a simulation experiment reveals that, at the same magnification, the polish on the archaeological specimen closely resembles that of the experimental specimen, albeit more developed. In the simulation experiment, a replication with similar lithology to the archaeological piece was used to grind hornfels for 5 min, resulting in polish created through contact between the stones (Fig. 10:3, 4). Based on this comparison, it is inferred that the polish on specimen T4G1①:4 likely formed during the processing of other stone tools. The brightness and development of the polish suggest that this grinding stone was used with considerable intensity.

The use strategy of grinding stones at the Xicaodun site is reflected not only in the intensity of their use but also in the sequence in which the working surfaces were utilized. Through both macro- and micro-level observations, we have identified 22 grinding stones that exhibit clear trace-breaking patterns between working surfaces, indicating that these surfaces were used sequentially (Table 3). This suggests that prehistoric people selectively employed different working surfaces according to their specific needs during production and processing activities. Notably, this phenomenon is observed exclusively in strategic grinding stones, further supporting the notion that such stones were used more frequently and intensively. This evidence underscores the effectiveness of strategic design in extending the functional lifespan of grinding stones, despite the greater initial time and labor investment required. The process of strategically designing a grinding stone typically involves considerable pre-conceptualization and additional effort during manufacture, resulting in higher initial costs. However, these stones ultimately provide greater long-term utility compared to their expedient counterparts.

Regarding the utilization sequence, it is evident that strategic grinding stones were used multiple times across different surfaces. As noted earlier, these grinding stones are predominantly of medium to large size, with some reaching extra-large dimensions. Such sizes require high-quality stone and more lithic resources, meaning that the initial selection of a larger stone for strategic design reduces the overall quantity of grinding stones produced. This necessitated careful planning by prehistoric people to maximize the utility of available resources. In this context, the reuse of strategic grinding stones allowed for more efficient utilization of both the stones and the available lithic resources, contributing to a more economical approach to tool production.

Cost-effectiveness of grinding stones

The selection, acquisition, transport and management of lithic raw materials can provide significant insight into people’s economic activities55. These issues has been the subject of ongoing research by scholars56,57,58. While it is not always stated explicitly, a widespread assumption is that people will try and optimize their use of raw materials, obtaining the greatest utility with the least effort59, especially when resources are scarce. Ultimately, these behaviors may reflect the economic decision-making processes of prehistoric people, whether made consciously or unconsciously, in response to the challenges posed by limited resources. These practices also indicate their task-oriented cognitive abilities, which were focused on setting specific goals for engaging in productive activities.

The concept of opportunity cost, borrowed from microeconomics, helps to better understand the economic decision-making processes from a cost/benefit perspective, as it refers to the trade-offs inherent in the choices individuals make when resources are scarce. In this context, the various labor costs directly or indirectly involved in the production, use, or repair of grinding stones can be considered explicit costs. Direct and indirect modes of lithic material acquisition have been identified, including incidental, logistically mobile, exchange, trade, etc60,61. Each mode requires varying amounts of time and labor. Notably, no lithic resources have been identified in the immediate vicinity of the Xicaodun site, and the Tianmu Mountains, a likely source, are located approximately 100 kilometers away. This suggests that the mode was likely logistically mobile or indirectly acquired, meaning that raw materials were either collected by specialized individuals or obtained through trade or exchange. This process would have made access to raw materials costly and limited. Therefore, optimizing the use of lithic resources became essential. The first step in this optimization was the selection of different rock types for various ground stone tools. For grinding stones, the strategic design utilized higher-quality raw materials, with 98.6 percent of these stones being composed of sandstone and fine sandstone. In contrast, expedient grinding stones were made from materials of varying quality, as detailed in Table 2. The final step involved enhancing the efficiency of grinding stone use and extending their service life through design and use strategies, thus improving the overall utilization of lithic resources.

Furthermore, it is crucial to account for implicit costs, which refer to the foregone benefits associated with alternative options when making a choice. In this context, opting for an expedient design would reduce production time and, consequently, production costs, allowing grinding stones to be put to use more quickly. However, the prevalence of strategic grinding stones suggests that this may not necessarily be the most optimal solution. As surmised earlier, the site might function as a specialized workshop for ground stone tool production and tasks are defined primarily in terms of their objectives62. The strategic grinding stones are capable of enduring more intensive use, thereby decreasing the frequency of replacement. This durability enables them to serve as the primary tools in ground stone tool production, even during periods of raw material scarcity, thus ensuring the continuous operation of the workshop. As such, these strategies, encompassing the design and use strategies, transcend mere subsistence strategies to become social strategies. This implies that these grinding stones may be imbued with social and cultural values beyond their functional roles63,64, and the prehistoric people may gain from being seen to conform to socially sanctioned values65, as the ‘workshop’ itself functions as a social institution. Such economic decisions are not only driven by material constraints but are also shaped by power dynamics, social roles, and collective identities66.

However, in applying the concept of opportunity cost, the site is considered as an individual entity, or a system. Actually, the society is a plurality of individuals, which including diverse genders, identities, classes, etc. Finding the proper balance between the individual and the system, has been a persistent problem for archaeology67, especially with the lack of relevant research. Although the concept of opportunity cost faces certain limitations in specific contexts—such as the difficulty of fully capturing the complexity of social roles and interactions—its application to the Xicaodun site provides valuable insight into the economic decisions of its inhabitants, thereby enriches our understanding of prehistoric economic practices, even within the constraints of the available evidence.

Discussion

In this study, we first employ a hierarchical dynamic typology to demonstrate that the Xicaodun site likely functioned as a workshop for ground stone tool production, with stone knives and stone arrowheads as its primary outputs. Attention is given to the characteristic artifacts, particularly the grinding stones, which were key tools in the workshop. Through an analysis of their design and use strategies, aided by design theory and use-wear analysis, we find that strategic grinding stones were the predominant tools at the site, while expedient grinding stones were used less frequently. Strategic grinding stones are generally larger, with specific shapes and multiple working surfaces, whereas expedient grinding stones are typically smaller, irregularly shaped, and feature only one working surface. Despite these differences, both types exhibit high use intensity, characterized by deeply ingrained grooves, with strategic grinding stones showing extensive polish and a well-developed utilization sequence across their working surfaces. Furthermore, the concept of opportunity cost is introduced to explore the economic aspects behind the grinding stones. This analysis focuses on reducing the costs associated with the quarrying of lithic resources and making trade-offs between raw materials, design, and use strategies in order to achieve the optimal allocation of resources for sustaining workshop operations.

In comparison to other ground stone tools, grinding stones involve relatively simple production technology, with their primary function being grinding, albeit with variation in the types of materials processed. Nevertheless, grinding stones serve not only as tools in productive activities but also as instruments for producing other productive tools. The various layers of information embedded in their design and use merit further investigation. This paper aims to uncover the economic information behind grinding stones from a design and use-strategy perspective. In doing so, it seeks to offer insights into the production and economic behaviors of prehistoric people during the Neolithic period.

Data availability

The data used and analyzed during the current study are available from the corresponding author on reasonable request.

References

Chen, H. et al. A functional study of ground stone tools from the Bronze Age site of Dingjiacun in South China: Based on use-wear evidence. J. Archaeological Sci.: Rep. 40, 103215 (2021).

Odell, G. H. Lithic Analysis. Boston, MA: Springer US; 2004. https://doi.org/10.1007/978-1-4419-9009-9.

Adams, J. L. Ground Stone Analysis: A Technological Approach. 2nd ed. Salt Lake City: The University of Utah Press; 2013.

Mcbrearty, S. & Brooks, A. S. The revolution that wasn’t: a new interpretation of the origin of modern human behavior. J. Hum. Evolution 39, 453–563 (2000).

Eoin, L. N. Geophytes, Grasses and Grindstones: Replanting Ideas of Gathering in Southern Africa’s Middle and Later Stone Ages. South Afr. Archaeological Bull. 71, 36–45 (2016).

Mercader, J. Mozambican Grass Seed Consumption during the Middle Stone Age. Science 326, 1680–1683 (2009).

Arthur, J. W. Culinary crafts and foods in Southwestern Ethiopia: an ethnoarchaeological study of gamo groundstones and pottery. Afr. Archaeological Rev. 31, 131–168 (2014).

Robitaille, J. The ground stone industry of the Mursi of Maki, Ethiopia: Ethnoarchaeological research on milling and crushing equipment (technique and function). J. Lithic Stud. 3, 429–456 (2016).

Fullagar, R., Field, J., Denham, T. & Lentfer, C. Early and mid Holocene tool-use and processing of taro (Colocasia esculenta), yam (Dioscorea sp.) and other plants at Kuk Swamp in the highlands of Papua New Guinea. J. Archaeological Sci. 33, 595–614 (2006).

Hayes, E., Pardoe, C. & Fullagar, R. Sandstone grinding/pounding tools: Use-trace reference libraries and Australian archaeological applications. J. Archaeological Sci.: Rep. 20, 97–114 (2018).

Hamon, C. Functional analysis of stone grinding and polishing tools from the earliest Neolithic of north-western Europe. J. Archaeological Sci. 35, 1502–1520 (2008).

Hamon, C., Cagnato, C., Emery-Barbier, A. & Salavert, A. Food practices of the first farmers of Europe: Combined use-wear and microbotanical studies of Early Neolithic grinding tools from the Paris Basin. J. Archaeological Sci.: Rep. 36, 102764 (2021).

Longo, L. Gestures from the past: Grinding stones and starchy food processing at the dawn of modern humans. 2016 22nd International Conference on Virtual System & Multimedia (VSMM), Kuala Lumpur, Malaysia: IEEE; 2016. p. 1-7.

Adams, J. et al. Functional analysis of macro-lithic artifacts: a focus on working surfaces. In: Sternke F., Eigeland L., Costa L. J., editors. Non-Flint Raw Material Use in Prehistory: Old prejudices and new directions. Oxford: Archaeopress; 2009. p. 43-66.

Schneider, J. S. Quarrying and Production of Milling Implements at Antelope Hill, Arizona. J. Field Archaeol. 23, 299 (1996).

Horsfall, G. A. Design Theory and Grinding Stones. In: Hayden B., editors. Lithic Studies Among the Contemporary Highland Maya. Tucson: University of Arizona Press; 1987. p. 332–337.

Hamon, C. et al. Present use and production of metates and molcajetes in Turícuaro (Michoacán, Mexico): deciphering the evolution of food preparation practices. Ethnoarchaeology 15, 208–232 (2023).

Dubreuil, L. Long-term trends in Natufian subsistence: a use-wear analysis of ground stone tools. J. Archaeological Sci. 31, 1613–1629 (2004).

Dubreuil, L. et al. Current Analytical Frameworks for Studies of Use–Wear on Ground Stone Tools. In: Marreiros J. M., Gibaja Bao J. F., Ferreira Bicho N., editors. Use-Wear and Residue Analysis in Archaeology, Cham: Springer International Publishing; 2015, p. 105–158.

Saghessi, D. Artefactos picados, abradidos y/o modificados por uso en Norpatagonia. El caso del sitio Loma de los Muertos (pcia. de Rio Negro). Rev. Mus. Antrop. 13, 89–94 (2020). (in Spanish).

Ciampagna, L., Cardillo, M. & Alberti, J. Estudio arqueobotánico de artefactos de molienda provenientes de la localidad arqueológica Punta Odriozola (golfo San Matías, Río Negro). Rev. Mus. Antrop. 13, 37–44 (2020). (in Spanish).

Liang S. Neolithic stone tools and pottery sherds collected in Zhabuganmiao, Linxi, Shuangjing and Chifeng region of Rehe Province. In: Field Archaeological Reports, vol. 1. Shanghai: The Commercial Press; 1936. p. 1-67. (in Chinese)

Society for East Asian Archaeology. Chifeng Hongshanhou: Prehistoric Remains of the Hongshanhou Site in Chifeng, Rehe. Translated from the Japanese by Dai Y and Kang Y. Huhehaote: Inner Mongolia University Press; 2015. (in Chinese)

Liu, L. et al. A functional analysis of grinding stones from an early holocene site at Donghulin, North China. J. Archaeological Sci. 37, 2630–2639 (2010).

Liu, L. et al. Plant exploitation of the last foragers at Shizitan in the Middle Yellow River Valley China: evidence from grinding stones. J. Archaeological Sci. 38, 3524–3532 (2011).

Liu, L., Duncan, N. A., Chen, X. & Ji, P. Plant-based subsistence strategies and development of complex societies in Neolithic Northeast China: Evidence from grinding stones. J. Archaeological Sci.: Rep. 7, 247–261 (2016).

Liu, L., Duncan, N. A., Chen, X., Zhao, H. & Ji, P. Changing patterns of plant-based food production during the Neolithic and early Bronze Age in central-south Inner Mongolia, China: An interdisciplinary approach. Quat. Int. 419, 36–53 (2016).

Chen, T. Study on the Function of Grinding Stone Tools in Prehistoric China from the Perspective of Archaeological Evidence. Agric. Archaeol. 6, 124–130 (2019). (in Chinese).

Chen, H. Progress, problem and prospect: An overview of lithic use-wear study in China. Quat. Int. 535, 58–68 (2020).

Shi, X. et al. Excavation Brief of the Xicaodun Site, Nanhu District, Jiaxing, Zhejiang, China. Southeast Cult. 1, 38–52 (2024). (in Chinese).

Liu, B. Liangzhu and centennial archaeology: the underestimated neolithic age in China. Front. Hist. China 17, 247–266 (2022).

Renfrew, C. & Liu, B. The emergence of complex society in China: the case of Liangzhu. Antiquity 92, 975–990 (2018).

Qiu, Z., Ding, J., Wang, X. & Jiang, H. Vegetation landscape and paleoenvironment evolution recorded at the late Neolithic Zhumucun site, East China. Quat. Int. 640, 12–22 (2022).

Cui, Q., Zhang, J., Yang, Y. & Sun, Y. Use-wear analysis of the stone tools from the Jiahu site in Wuyang county, Henan province. Acta Anthropologica Sin. 36, 478–498 (2017). (in Chinese).

Chen, H., Sun, M. & Tang, J. The ‘Chaîne Opératoire’and ‘life history’ of ground stone tools from the Wufengbei site, Suzhou, China. Archaeology 11, 72–82 (2020). (in Chinese).

Leroi-Gourhan A. et al. Technique et langage. Paris: Albin Michel; 1964. p. 158-159. (in French)

Leroi-Gourhan A. Gesture and Speech. Translated from the French by Anna Bostock Berge. Massachusetts: The MIT Press; 1993. p. 230-234.

Tixier, J., Inizan, M.-L. & Roche, H. Préhistoire de la pierre taillée. 1: Terminologie et technologie. Antibes: C.R.E.P; 1980. (in French)

Peng, F. Rethinking Chaîne Opératoire. Acta Anthropologica Sin. 34, 55–67 (2015). (in Chinese).

Binford, L. R. Inter-assemblage variability: The Mousterian and the functional argument. In: Renfrew C., editors. The Explanation of Culture Change. London: Duckworth; 1973. p. 227-254.

Hayden, B. Resource models of inter-assemblage variability. Lithic Technol. 15, 82–89 (1986).

Marreiros, J., Mazzucco, N., Gibaja, J. F. & Bicho, N. Macro and Micro Evidences from the Past: The State of the Art of Archeological Use-Wear Studies. In: Marreiros J. M., Gibaja Bao J. F., Ferreira Bicho N., editors. Use-Wear and Residue Analysis in Archaeology, Cham: Springer International Publishing; 2015. p. 5–26.

Fullagar, R. & Matheson, M. Traceology: a summary. In: Smith C., editors. Encyclopedia of Global Archaeology. New York: Springer; 2013. p. 73–85.

Liu, L., Wang, J. & Levin, M. J. Usewear and residue analyses of experimental harvesting stone tools for archaeological research. J. Archaeological Sci.: Rep. 14, 439–453 (2017).

Fullagar, R., Hayes, E., Chen, X., Ma, X. & Liu, L. A functional study of denticulate sickles and knives, ground stone tools from the early Neolithic Peiligang culture, China. Archaeological Res. Asia 26, 100265 (2021).

Xue, L., Chen, H. & Chen, M. An experimental investigation of the ground stone knives and sickles in the Lower Yangtze River Region during the Late Neolithic and Bronze Age. J. Archaeological Sci.: Rep. 51, 104208 (2023).

Xue, L. et al. A functional study of ground stone knives and sickles in the Lower Yangtze River Region during the Late Neolithic and Bronze Age. J. Archaeological Sci.: Rep. 61, 104892 (2025).

Wilkins, J., Schoville, B. J., Brown, K. S. & Chazan, M. Evidence for Early Hafted Hunting Technology. Science 338, 942–946 (2012).

Schoville, B. J. Testing a taphonomic predictive model of edge damage formation with Middle Stone Age points from Pinnacle Point Cave 13B and Die Kelders Cave 1, South Africa. J. Archaeological Sci. 48, 84–95 (2014).

Lerner, H. J. Intra-raw material variability and use-wear formation: an experimental examination of a Fossiliferous chert (SJF) and a Silicified Wood (YSW) from NW New Mexico using the Clemex Vision processing frame. J. Archaeological Sci. 48, 34–45 (2014).

Chu, W., Thompson, C. & Hosfield, R. Micro-abrasion of flint artifacts by mobile sediments: a taphonomic approach. Archaeol. Anthropol. Sci. 7, 3–11 (2015).

Buchanan, J. M. Opportunity Cost. In: Eatwell J., Milgate M., Newman P., editors. The World of Economics, London: Palgrave Macmillan UK; 1991. p. 520–525.

Hutchison, E. Principles of Microeconomics. University of Victoria; 2017.

Delgado-Raack, S., Gómez-Gras, D. & Risch, R. The mechanical properties of macrolithic artifacts: a methodological background for functional analysis. J. Archaeological Sci. 36, 1823–1831 (2009).

Yue, J., Li, Y., Zhang, Y. & Yang, S. Lithic raw material economy at the Huayang site in Northeast China: localization and diversification as adaptive strategies in the Late Glacial. Archaeol. Anthropol. Sci. 12, 107 (2020).

Rebecca C. M. Lithic resource management during the Belgian Early Upper Paleolithic: Effects of variable raw material context on lithic economy. United States - New Mexico: The University of New Mexico; 2000.

Li, F., Kuhn, S. L., Chen, F. & Gao, X. Raw material economies and mobility patterns in the Late Paleolithic at Shuidonggou locality 2, north China. J. Anthropological Archaeol. 43, 83–93 (2016).

Jochim, M. A Strategic Approach to Stone Tool Economy: An Example from Southwest Germany. Lithic Technology. 2024:1–8.

Kuhn, S. L. The Evolution of Paleolithic Technologies. 1st ed. Abingdon, Oxon; New York, NY: Routledge, 2020. https://doi.org/10.4324/9781315642024.

Binford, L. R. Willow Smoke and Dogs’ Tails: Hunter-Gatherer Settlement Systems and Archaeological Site Formation. Am. Antiq. 45, 4–20 (1980).

Blades, B. S. Aurignacian lithic economy and early modern human mobility: new perspectives from classic sites in the Vézère valley of France. J. Hum. Evolution 37, 91–120 (1999).

Ingold, T. The Perception of the Environment: Essays on Livelihood, Dwelling and Skill. 1st ed. London: Routledge; 2021. https://doi.org/10.4324/9781003196662.

Pfaffenberger, B. Fetishised objects and humanised nature: towards an anthropology of technology. Man 23, 236 (1988).

Pfaffenberger, B. Social anthropology of technology. Annu. Rev. Anthropol. 21, 491–516 (1992).

Hodder, I. & Hutson, S. Reading the Past: Current Approaches to Interpretation in Archaeology. 3rd ed. Cambridge University Press; 2003. https://doi.org/10.1017/CBO9780511814211.

Dobres, M. A. & Robb, J. Agency in archaeology. Paradigm or platitude? In: Dobres MA, Robb J, editors. Agency in Archaeology. 1 ed. London: Routledge; 2014. p. 3–17.

Brumfiel, E. M. Distinguished lecture in archeology: breaking and entering the ecosystem—gender, class, and faction steal the show. Am. Anthropologist 94, 551–567 (1992).

Acknowledgements

The authors would like to thank Zhejiang Provincial Institute of Cultural Relics and Archaeology, Jiaxing Institute of Cultural Relics Protection and Archaeology and Jiaxing Museum for their excavation work and support for the study. Additionally, we would like to thank Ph.D. student Liping Xue from the School of Art and Archaeology, Zhejiang University, for conducting the grinding experiment and reviewing the manuscript. This work was supported by the National Social Science Foundation of China (Grant No. 23BKG030, granted to Dr. Hong Chen).

Author information

Authors and Affiliations

Contributions

Hong Chen designed the study, analyzed the data, and wrote the manuscript. Yongming Lu participated in data processing and analysis, visualization work, and the revision of manuscript. Yixue Tang collected basic data and participated in the data analysis. Yao Jin participated in basic data collection. Ye Zhao, Xiqi Shi and Yang Geng conducted the excavation and provided the archaeological specimens and relevant data. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Chen, H., Lu, Y., Tang, Y. et al. Exploring the role of grinding stones in Neolithic economic practices: insights from the Xicaodun site in Southeastern China. npj Herit. Sci. 13, 285 (2025). https://doi.org/10.1038/s40494-025-01824-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s40494-025-01824-6