Abstract

This work aimed to explore the influences of different salts and temperatures on the salt weathering of sandstone in the Nankan Grotto. Capillary salt weathering tests were designed under different conditions. The geochemical, physical, and mechanical properties of sandstone were also analysed. After the tests, the electrical conductances (EC), anion concentrations, masses, P-wave velocities, and porosities of specimens increased as the test temperature was changed from 15 °C to 35 °C within individual experimental settings. Under 6% Na2SO4 + 3% NaNO3 condition, only Na2SO4 exerted crystallization pressure, which exceeded the tensile strength of Nankan sandstone (2.20 MPa). Under 3% Na2SO4 + 6% NaNO3 condition, NaNO3 crystallized at 25 °C and 35 °C, and Na2SO4 crystallized at 35 °C. Their crystallization pressures exceeded the tensile strength of Nankan sandstone. Temperature influences the physical properties of a salt solution, which determines the salt weathering intensity. Our research suggests that salt weathering issues in grottoes should be evaluated in different seasons.

Similar content being viewed by others

Introduction

Sandstone is a universal construction material for monuments and buildings around the world. Notably, sandstone grottoes account for more than 80% of the total grottoes in China1,2. Typical relics carved in sandstone around the world include the Matera Sassi in Italy3, the Parthenon Temple in Greece4, the Roman Theater in Jordan5, the Luxor Temple in Egypt6, the Angkor Temple in Cambodia7, the Yungang Grottoes and Dazu Rock Carvings in China8,9,10. These heritages represent the greatest craftsmanship level of human society at that time.

Sandstone grottoes are generally invulnerable due to the high degree of cementation of the material11,12. However, some of them have undergone severe damage over the long geological timescales13,14,15,16,17. Notably, salt weathering is a ubiquitous damage, causing severe decay in sandstone, which has been repeatedly investigated by numerous laboratory or field studies18,19,20. Salt damage often led to the discoloration, deformation, and even detachment of the stone material, which has greatly destroyed the artistic, historical, and scientific values of the sandstone heritages.

It is widely accepted that the degree of salt weathering in sandstone is controlled by the salt properties and amounts, the petrographic characteristics, and the external environments10. The physical properties of a salt solution, such as its viscosity, density, surface tension, and contact angle, control the dynamics of solution flow within the porous network of the sandstone21. In addition, the petrographic characteristics of the sandstone determine the concentration and mixture of ions in the solution, which further determine the type of salt and its amount22,23. The micro-structures of sandstone, such as pore volume, size distribution, shape, and degree of interconnection, control the mode and rate of solution transport and retention24,25,26,27. At the same time, the environmental conditions (such as temperature and relative humidity) control the drying kinetics of the solution12,28,29. These factors determine the type, amount, and location of salt crystallization, and further the deterioration patterns of the porous substrate23. Therefore, it is indispensable to study their influence on the salt weathering of sandstone.

The Nankan Grotto was included in the third group of major historical and cultural sites protected at the national level by the State Council in 1988. The Nankan Grotto is an exquisite sandstone monument representing Buddhist and Taoist grotto art from the Sui and Tang dynasties, and it has undergone severe weathering over more than 1300 years. In the Nankan Grotto, Na2SO4 and NaNO3 were detected in the compositions of subflorescence and efflorescence30. It is still unclear which salt dominated the formation of subflorescence. Here, we designed salt weathering tests of sandstone under different salt types, concentrations, and temperatures. The sandstone samples before and after-test were collected to analyze the mineralogy, major elements, petrophysical properties, and microstructure. The main objectives of this study were (i) to analyze the salt weathering characteristics of sandstone in the Nankan Grotto, (ii) to investigate the influences of salt types, concentrations, and environments for the salt weathering test of sandstone, and (iii) to explore the microscopic salt weathering mechanism of sandstone in the Nankan Grotto. The results of this study provide new insights that improve our knowledge of the salt weathering of sandstone under different salt properties and environments.

Methods

Study site and sampling

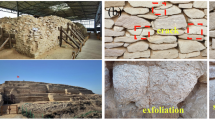

The Nankan Grotto is located in Bazhong City, Sichuan Province (Fig. 1a), which is located in the northeast corner of the Sichuan Basin. The exquisite Buddha statues are concentrated in the Giant Buddha Cave Area (Fig. 1d). Bazhong City is characterized by a subtropical humid mountain climate and is frequently subjected to the Asian monsoon31. The average annual temperature is approximately 16 °C. The lowest average daily temperature is in January (6.1 °C), and the highest temperature occurs in July (27.1 °C). There are approximately 12–15 high temperature days per year (>35 °C). The temperature rarely drops below 0 °C in winter, except for an average of 2 or 3 days per year. The mean annual precipitation is approximately 1117.2 mm in the study area. Rainfall is mainly concentrated from May to October, accounting for approximately 75%–83% of the total annual rainfall. The annual relative humidity varies from 64% to 84%.

The experimental samples for geochemical, mechanical, and physical analyses were fresh sandstone samples (named NS) extracted from the uncarved area of the Nankan Grotto (Fig. 1b, c). The sandstone belongs to the Lower Cretaceous Bailong Formation. Bailong Formation is dominated by grayish white or bluish gray sandstone. The composition of the sandstone is mainly quartz, feldspar, calcite, and clay minerals, containing a small amount of muscovite, biotite, hematite, zircon, and rutile. The content of detritus is 80~90%. The cements are mainly siliceous and calcareous materials, the second is clay minerals, and most of them are porous cementation. The sandstone is mainly medium-fine-grained with a particle size of 0.1~0.3 mm. The grain morphology is sub-angular to sub-circular, with poor sorting and low maturity30.

Some sandstone blocks were randomly collected from the same height, as shown in Fig. 1b. The surfaces of the sandstone were polished before processing. Then, they were processed into standard cylindrical samples of Φ50 mm × 100 mm. The drilling direction was perpendicular to the bedding plane, that is, the height direction of the sample was perpendicular to the bedding plane. The non-parallelism error of the two end faces of the cylinder was less than 0.05 mm, and the unevenness error was less than 0.02 mm. The diameter error of the two end faces along the height direction was less than 0.3 mm. The end faces of the sample were perpendicular to the axis, and the maximum vertical deviation was less than 0.25°. The appearances of the rock samples were intact without apparent cracks. A total of 44 specimens were collected from the rock blocks. 27 specimens were used in this study.

Mineralogical analysis

The mineralogy of the sandstone was analyzed via X-ray diffraction (XRD), which was equipped with Cu-Kα radiation (λ = 1.54059 Å). The XRD (Bruker D8 DISCOVER, Germany) was operated at 40 kV and 40 mA. The detailed analysis procedures can be referred to in the previous studies30,32. The XRD patterns of whole rock samples were recorded at a step size of 0.02°/s, and the 2θ angle was from 5° to 45°. The clay fractions (<2 μm) were preprocessed as described by Ling et al.33. Then, the clay fractions were further treated via (i) air drying, (ii) the addition of ethylene glycol, and (iii) thermal-processing at 450 °C. The XRD patterns of clay samples were recorded at a step size of 0.02°/s, and the 2θ angle was from 2.5° to 15°. The mineral concentrations were quantified using whole pattern fitting and Rietveld refinement. Measurements were carried out on standard and parallel samples. The relative standard deviation (RSD) of the XRD measurements was less than 10%, and the lowest detection limit was 0.1 wt.%.

Major element analysis

The major element compositions were determined via X-ray fluorescence spectroscopy (XRF; PANalytical PW2424, Netherlands). Before the XRF measurement, two powdered samples were prepared. One sample was fused with LiBO2-Li2B4O7 flux and an oxidizing agent (LiNO3). The detailed procedures referred to Ling et al.34. Then, the melted sample was poured into a platinum mold for XRF analysis. Another sample was calcined in a muffle furnace with oxygen at 1000 °C to calculate the loss on ignition (LOI). Measurements were carried out on standard and parallel samples. The relative deviation (RD) and relative error (RE) of the XRF measurements were less than 5%. The lowest detection limit was 0.01%.

Scanning electron microscopy

The microscopic structure of the samples and the morphology of salt crystals were observed via a tungsten filament scanning electron microscope (SEM, JSM-IT500, Japan), which was equipped with an Oxford ULTIM Max 40 EDS system. The samples were coated with platinum (Emitech SC7620 sputter coater) prior to observation, and then operated at an accelerating voltage of 10 kV.

Physical and mechanical properties measurements

Density/dry density was measured as the ratio between natural/dry mass and bulk volume of the sample (Φ50 ×100 mm) in accordance with the GB/T 50266 standard35. Before the measurement of dry mass, the samples were completely dried in a drying oven at 105 °C until a constant mass was reached. For the oven-dried samples, the dry mass was weighed. The apparent volume was measured on the basis of its dimensions.

Natural water content was the ratio of the difference between natural mass and dry mass to dry mass35. Saturated water absorption was carried out on the samples (Φ50 ×50 mm) in accordance with the GB/T 50266 standard35. Firstly, the sample was completely dried in a drying oven at 105 °C for 24 h to eliminate the existing moisture. Then, the sample was immersed completely in distilled water for 48 h under vacuum conditions. Saturated water absorption was expressed as the mass ratio of absorbed water and oven-dried sample in the form of a percentage35.

The porosity and pore size distribution were determined by mercury intrusion porosimetry (MIP, Micromeretics AutoPore IV 9505, America). First, the salts in the samples were washed away. Then, the samples were completely dried in a drying oven at 105 °C for 24 h under high vacuum conditions. Mercury was introduced into the pore volume at discrete pressure steps. When the maximum pressure of 200 MPa was reached, the intrusion process stopped, and then the extrusion process started. The pore volume was measured based on the intrusion volume of mercury.

P-wave velocity was measured using an ultrasonic tester (Proceq, Pundit Lab, Switzerland), which was equipped with a transmitter and a receiver35. Firstly, the sample was placed in an oven at 105 °C for 24 h. Before the measurement, the coupling agent (vaseline) was applied to the P-wave transmitter and receiver and the two end faces of the cylinder. The transmitter and receiver were placed at both ends of the sample to test the P-wave velocity.

The tensile strength was determined via the Brazilian splitting test, which was carried out on the HTBW-1 elastic modulus test machine35. The experimental sample size was Φ50 mm × 25 mm. Before loading, the sample was placed in the center of the mold, and then an iron block was placed on the top of the mold. This was to ensure that no gap was present along the line of contact between the specimen and the loading jaws. Then, loading was applied on the iron block with a loading speed of 0.3 MPa/s. When the sandstone sample was completely destroyed, the applied load value was recorded for calculating the tensile strength.

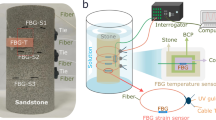

Capillary salt weathering test

In order to study the influences of different salt characteristics and environments on salt migration in the sandstone, a series of capillary salt weathering tests were designed. Before the tests, a P-wave velocity test was carried out on the specimens (Φ50 × 100 mm) to screen out specimens with similar P-wave velocities for the next step. Then, these specimens were dried at 105 °C for 24 h and taken as experimental samples for the capillary salt weathering test.

The cylindrical samples were placed vertically on permeable-stone slices (Φ65 ×10 mm). The bedding plane of the samples was horizontal; that is, the direction of salt solution uptake was perpendicular to the bedding plane. Then, they were placed in a container where the solution touched the top surface of the permeable stone. In the Nankan Grotto, Na2SO4 and NaNO3 were detected in the compositions of subflorescence30. Therefore, two salt solutions were used: 3% Na2SO4 + 6% NaNO3 solution and 6% Na2SO4 + 3% NaNO3 solution. For each salt type, three ambient temperatures were adopted: 15 °C, 25 °C, and 35 °C. All of the settings were placed in a climate chamber with constant relative humidity (75 ± 3%). The settings using 3% Na2SO4 + 6% NaNO3 solution under 15 °C, 25 °C, and 35 °C conditions were named as N-15, N-25, and N-35, respectively. The settings using 6% Na2SO4 + 3% NaNO3 solution under 15 °C, 25 °C, and 35 °C conditions were named as S-15, S-25, and S-35, respectively.

After the test, the weight, P-wave velocity, microstructure, and porosity of the samples were measured. Subsequently, each sample was divided into 5 equal parts along the height direction. Each part was a cylinder with a diameter of 50 mm and a height of 19.8 ± 0.1 mm. Then, they were ground into powder and mixed with deionized water (solid-liquid ratio was 1:10) in accordance with GB/T 50123 standard36. The uppermost suspension of mixture was filtered through 0.22 μm nylon filters for electrical conductance and anion concentration analyses. The electrical conductance (EC) was detected using a portable multimeter device (HANNA HI98129, Italy). The anions (SO42−, NO3−) were measured using ion chromatography (IC, Dionex ICS-1100, Thermo Fisher Scientific Inc., USA).

Results

Mineralogy of the sandstone

The XRD analysis result of NS is shown in Table 1. The quartz concentration was the highest (69.2 wt.%), followed by the feldspar (21.4 wt.%), calcite (4.9 wt.%), and clay mineral (4.5 wt.%). The clay minerals were mainly illite-smectite mixed layer (2.6 wt.%), with minor illite (1.3 wt.%) and chlorite (0.6 wt.%). Compared with the sandstone GS* in the previous study in the Nankan Grotto, NS showed higher quartz and feldspar concentrations and lower calcite concentration than GS*.

Major element compositions

The major element compositions are summarized in Table 2. For NS, SiO2 concentration (76.06%) was the highest, followed by the Al2O3 (7.57%), CaO (4.62%), Fe2O3 (1.63%), K2O (1.55%), and Na2O (1.39%) concentrations. The concentrations of the other oxides, such as MgO (0.72%), P2O5 (0.07%), SO3 (0.08%), and TiO2 (0.46%), were less than 1.0%. Compared with GS*, NS showed similar major element compositions with GS*.

Physical and mechanical properties

The results of density, dry density, porosity, natural water content, saturated water absorption, P-wave velocity, and tensile strength of NS are shown in Table 3. The density and dry density of NS were 2.42 g/cm3 and 2.38 g/cm3, which were denser than GS*. The porosity of NS was 7.17%, which was similar to GS*. The natural water content and saturated water absorption of NS were 1.60 wt.% and 4.96 wt.%. The P-wave velocity of NS was 2062 m/s. The tensile strength of NS was 2.20 MPa.

EC variations

The EC variations after salt weathering test are shown in Fig. 2. Under the condition of 3% Na2SO4 + 6% NaNO3 solution, the EC values showed increasing trends as height increased at the three temperatures (Fig. 2a). The EC values of N-15, N-25, and N-35 increased slowly from 1 cm to 7 cm and increased rapidly from 7 cm to 9 cm. The maximum EC values appeared at 9 cm in the samples. At the same height, the EC values showed an increasing trend as the temperature increased from 15 °C to 35 °C. The maximum EC value of N-15, N-25, and N-35 was 362 μs/cm, 1051 μs/cm, and 2035 μs/cm, respectively.

a EC variations under the condition of 3% Na2SO4 + 6% NaNO3 solution. b EC variations under the condition of 6% Na2SO4 + 3% NaNO3 solution. N-35: 3% Na2SO4 + 6% NaNO3 solution & 35 °C condition; N-25: 3% Na2SO4 + 6% NaNO3 solution & 25 °C condition; N-15: 3% Na2SO4 + 6% NaNO3 solution & 15 °C condition; S-35: 6% Na2SO4 + 3% NaNO3 solution & 35 °C condition; S-25: 6% Na2SO4 + 3% NaNO3 solution & 25 °C condition; S-15: 6% Na2SO4 + 3% NaNO3 solution & 15 °C condition.

Under the condition of 6% Na2SO4 + 3% NaNO3 solution, the EC values also showed increasing trends as height increased at the three temperatures and showed the maximum at the 9 cm of the samples (Fig. 2b). At the same height, the EC value of S-35 was the highest, followed by S-25, and the EC value of S-15 was the lowest. The maximum EC value of S-15, S-25, and S-35 was 481, 1335, and 1700 μs/cm, respectively. The EC values of N-35 were always higher than those of S-35. In contrast, the EC values of N-15 were always lower than those of S-15. The EC values of N-25 were higher than those of S-25 at 1, 3, and 5 cm, and lower than those of S-25 at 7 and 9 cm.

Anions concentrations

The SO42− and NO3− concentrations along height direction after the salt weathering test are shown in Fig. 3. Under the condition of 3% Na2SO4 + 6% NaNO3 solution, the SO42− concentrations of N-15 showed little variation along height direction. The SO42− concentrations of N-25 showed an increasing trend from 1 cm to 7 cm and decreased from 7 cm to 9 cm. The SO42− concentrations of N-35 showed an increasing trend as height increased (Fig. 3a). The NO3− concentrations of N-15, N-25, and N-35 showed increasing trends as height increased, especially, they increased sharply from 5 cm to 9 cm (Fig. 3c). The NO3− concentrations were much higher than SO42− concentrations.

a SO42− concentrations under the condition of 3% Na2SO4 + 6% NaNO3 solution. b SO42− concentrations under the condition of 6% Na2SO4 + 3% NaNO3 solution. c NO3− concentrations under the condition of 3% Na2SO4 + 6% NaNO3 solution. d NO3− concentrations under the condition of 6% Na2SO4 + 3% NaNO3 solution. N-35: 3% Na2SO4 + 6% NaNO3 solution & 35 °C condition; N-25: 3% Na2SO4 + 6% NaNO3 solution & 25 °C condition; N-15: 3% Na2SO4 + 6% NaNO3 solution & 15 °C condition; S-35: 6% Na2SO4 + 3% NaNO3 solution & 35 °C condition; S-25: 6% Na2SO4 + 3% NaNO3 solution & 25 °C condition; S-15: 6% Na2SO4 + 3% NaNO3 solution & 15 °C condition.

Under the condition of 6% Na2SO4 + 3% NaNO3 solution, the SO42− concentrations of S-15 showed the maximum at 5 cm. The SO42− concentrations of S-25 showed the maximum at 7 cm. The SO42− concentrations of S-35 showed the maximum at 9 cm. As the temperature increased from 15 to 35 °C, the vertical position of maximum SO42− concentration migrated upward (Fig. 3b). The NO3− concentrations of S-15, S-25, and S-35 showed little variations from 1 cm to 5 cm and increased obviously from 5 cm to 9 cm (Fig. 3d).

Mass and P-wave velocity variations

The variations of mass and P-wave velocity after the salt weathering test are shown in Fig. 4. Under the condition of 3% Na2SO4 + 6% NaNO3 solution, the mass of specimens after the salt weathering test greatly increased with the increase of temperatures. Under the condition of 6% Na2SO4 + 3% NaNO3 solution, the mass of specimens showed little variation with the increase of temperatures from 15 to 25 °C, and slightly increased with the increase of temperatures from 25 to 35 °C. At 25 and 35 °C, the mass increases under the 3% Na2SO4 + 6% NaNO3 solution condition were greater than those under the 6% Na2SO4 + 3% NaNO3 solution condition. At 15 °C, the mass increase under the 3% Na2SO4 + 6% NaNO3 solution condition was lower than that under the 6% Na2SO4 + 3% NaNO3 solution condition (Fig. 4a).

At the three temperatures, the P-wave velocities of specimens under the 3% Na2SO4 + 6% NaNO3 solution condition were always greater than those under the 6% Na2SO4 + 3% NaNO3 solution condition. Under the two conditions, the P-wave velocities of specimens both increased with the increase of temperatures from 15 to 35 °C (Fig. 4b).

Pore size distribution

The pore size distribution curves obtained by MIP are shown in Fig. 5. Under the 3% Na2SO4 + 6% NaNO3 solution and 6% Na2SO4 + 3% NaNO3 solution conditions, the porosities of specimens after the salt weathering test both increased with the increase of temperatures. Compared with NS, the proportion of pores between 1 and 10 μm increased evidently after the salt weathering tests. The measured porosity of N-15, N-25, and N-35 was 10.08%, 10.95%, and 17.77%, respectively. At 15 and 25 °C, the 3% Na2SO4 + 6% NaNO3 solution contributed little to the increases of porosity. At 35 °C, the 3% Na2SO4 + 6% NaNO3 solution caused a sharp increase in the proportion of pores between 1 μm and 10 μm, which resulted in a great increase in porosity of N-35. The measured porosity of S-15, S-25, and S-35 was 9.41%, 13.18%, and 14.63%, respectively. The increased porosities of S-25 and S-35 were also attributed to the increase of pores between 1 μm and 10 μm. At 15 and 35 °C, the contribution of a 3% Na2SO4 + 6% NaNO3 solution to the increase of porosity was greater than that of a 6% Na2SO4 + 3% solution. At 25 °C, the contribution of a 6% Na2SO4 + 3% NaNO3 solution was greater.

a Porosity and pore size distribution of sample N-35. b Porosity and pore size distribution of sample S-35. c Porosity and pore size distribution of sample N-25. d Porosity and pore size distribution of sample S-25. e Porosity and pore size distribution of sample N-15. f Porosity and pore size distribution of sample S-15.

Macroscopic and microscopic observations

The macroscopic observations of samples after the salt weathering test are shown in Fig. 6. At 35 °C, a mass of white salt crystals coated the surfaces of samples N-35 and S-35, which was called the efflorescence pattern. The efflorescence pattern developed more widely on sample N-35 than on sample S-35. At 25 °C, the salt crystallizations on the surfaces of samples N-25 and S-25 were not obvious. At 15 °C, a thin layer of salt crystals appeared on the upper half of the N-15 surface. The salt crystallization on the sample S-15 was more severe than that on the sample N-15. More salts crystallized on the surface of the sample S-15. Especially, the salt crystals clustered as a ring attached to the lower part of the sample S-15.

a Macroscopic and microscopic observations of sample N-35. b Macroscopic and microscopic observations of sample S-35. c Macroscopic and microscopic observations of sample N-25. d Macroscopic and microscopic observations of sample S-25. e Macroscopic and microscopic observations of sample N-15. f Macroscopic and microscopic observations of sample S-15.

The microstructure of samples after the salt weathering test is shown in Fig. 6. The salt crystals under these two conditions were mainly composed of O, Na, N, and S elements. It showed that the salt crystals were a mixture of sodium sulfate and sodium nitrate. The microscopic characteristics have great differences under different solution conditions. Under the condition of a 3% Na2SO4 + 6% NaNO3 solution, salt crystals were mainly sodium nitrate crystals. They were individual granules and attached to the surfaces of primary mineral grains (Fig. 6a, c, e). Under the condition of a 6% Na2SO4 + 3% NaNO3 solution, salt crystals were mainly sodium sulfate crystals. They grew in the pores, and the crystal whiskers formed honeycomb phenomena (Fig. 6b, d, f).

Discussion

Under each salt solution condition, the EC values and anion concentrations at the same vertical position of the samples showed increasing trends as the test temperature increased from 15 to 35 °C (Figs. 2 and 3). This was due to the increase in temperature accelerating the capillary rise of salt solutions. The physical properties of a salt solution, such as its viscosity, density, surface tension, and contact angle, control the dynamics of solution flow within the porous network of the sandstone. These properties are highly correlated with temperature. Especially, the effect of temperature on viscosity is very significant. For instance, the viscosities of 10% NaNO3 solution at 10 and 40 °C are 1.38 and 0.72 mPa•s, respectively37. The value of viscosity is reduced by nearly half as the temperature increases from 15 to 35 °C, which would greatly promote the capillary rise of salt solution. In addition, the increase in temperature accelerates the evaporation rate in porous sandstone, which promotes the salt transportation in sandstone. Therefore, temperature controls the salt location and amount in sandstone, which determines the salt crystallization pattern and intensity. More salts crystallized in the pores and destroyed the microstructure, which corresponded to the increases of porosities (Fig. 5). The increases of anion concentrations also resulted in the increases of EC values, mass, and P-wave velocity (Fig. 4). The distributions of the salts were mainly in the upper parts of the samples (Fig. 6). These were because under the combined action of capillarity and evaporation, salt solutions moved upward along the porous network in the sandstone. Once the salt solution reached a supersaturated state, salts crystallized within the sandstone or on the surface38,39.

As shown in Fig. 6, the salt crystallization on the sample S-15 was more severe than that on the sample N-15 at 15 °C, corresponding to the higher EC values and masses of S-15 than those of N-15 (Figs. 2 and 4). At 35 °C, the salt developed more widely on sample N-35 than on sample S-35 (Fig. 6). In addition, the salt accumulation masses and EC values of the sample N-35 were higher than those of the sample S-35 (Figs. 2 and 4). These phenomena illustrated that sodium sulfate precipitation was dominant at low temperatures and sodium nitrate precipitation was dominant at high temperatures. At low temperature, the Na2SO4-H2O system has two stable phases: thenardite (Na2SO4) and mirabilite (Na2SO4·10H2O). At 15 °C & 75% relative humidity, mirabilite would crystallize in the pores or on the surface of the samples. Mirabilite is heavier than thenardite during the crystallization phase because of its higher molar volume40. Therefore, the salt accumulation mass of the sample S-15 was higher than that of the sample N-15.

With the continuous evaporation of water and the recharge of salt solution, more and more salt remained in the pore structure. When the concentration of salt solution in the sandstone exceeded the saturation solubility of salt, the precipitation of NaNO3, Na2SO4, or Na2SO4·10H2O can generate crystallization pressure on the pore wall in the sandstone26,41.

Suppose that the shape of a single crystal is regarded as a regular sphere and crystal/liquid interfacial free energy is γcl, when the solution is supersaturated, the increase in surface energy resulting from crystal growth is shown in Eq. (1):

Where W1 is the increase in surface energy, γcl is the crystal/liquid interfacial free energy, A is the surface area of the crystal, r is the radius of the crystal.

The increase of surface free energy would inhibit the growth of the crystal, which is equivalent to exerting a mechanical force P on the crystal. As the crystal volume increased, the mechanical force P does work as shown in Eq. (3):

Where W2 is the work done by the mechanical force, V is the volume of the crystal.

When the two energies are in equilibrium, W1 = W2, by differentiating Eq. (2) and Eq. (4) and substituting them into Eq. (1) and Eq. (3), respectively, Eq. (5) can be obtained.

For ideal microcrystals, the relationship between solution concentration and the curvature of the crystal is shown in Eq. (6):

where Kcl is the curvature of the crystal, Rg is the gas constant, T is the absolute temperature, Vc is the molar volume of the crystal, C is the concentration of salt solution, C0 is the saturation concentration of salt solution.

Thus, the expression for crystallization pressure is shown in Eq. (7):

where Rg = 8.3145 MPa•cm3/(mol•K), T = 273.15+ambient temperature (15 °C/25 °C/35 °C) K, Vc of NaNO3 is 37.66 cm3/mol, Vc of Na2SO4 is 44.11 cm3/mol. According to the values of salt accumulation mass and anion concentrations (Fig. 3), C/C0 at each temperature can be calculated. The results of theoretical crystallization pressures are shown in Table 4. At 15 °C, mirabilite would crystallize in the pores, so that the crystallization pressure of Na2SO4·10H2O was calculated.

The crystallization pressure of NaNO3 only in the samples N-35 and N-25 exceeded the tensile strength of NS (2.20 MPa). The crystallization pressure of Na2SO4/Na2SO4·10H2O in the samples S-35, S-25, S-15, and N-35 exceeded the tensile strength of NS (2.20 MPa). The tensile strengths of building materials such as stone or concrete hardly exceed values of about 10 MPa. Typically, tensile strengths of building sandstones are below 3 MPa26. The calculated values greatly exceed the tensile strength of nearly any porous building material. However, no obvious damage was observed on the surface of the sample in Fig. 6. This was because these values were the maximum theoretical pressures and correspond to the concentration at the onset of crystallization. The duration of possible stress generation was quite short42.

The results of the calculated crystallization pressure also illustrated why sodium sulfate was more damaging at low temperature and sodium nitrate was more damaging at high temperature. At 15 °C, the maximum crystallization pressure of Na2SO4·10H2O was in sample S-15 (27.42 MPa), and NaNO3 had no crystallization pressure. At 35 °C, the maximum crystallization pressure of Na2SO4 was in sample S-35 (41.35 MPa), far less than the maximum crystallization pressure of NaNO3 in sample N-35 (71.44 MPa).

It appears that sodium nitrate may be more destructive than sodium sulfate due to its higher crystallization pressure. However, it is typically found that sodium sulfate generates much more damage in the field. The calculation of crystallization pressure is theoretical and assumes that a sufficient degree of supersaturation can be readily achieved. In fact, the supersaturation of sodium sulfate is relatively easy to achieve because of its lower solubility, which can be accomplished through rapid cooling and evaporation41. Consequently, the crystallization of sodium sulfate is easier to achieve and can result in severe damage to sandstone.

In the Nankan Grotto, groundwater transported sodium sulfate and sodium nitrate, which infiltrated the internal pores and cracks of the sandstone through capillary absorption32. Under conditions of rapid evaporation or cooling, the salt solution reached a supersaturated state, leading to the crystallization of salts within the sandstone. Due to the constraints of the pore space, significant crystallization pressure was generated, which subsequently damaged the microstructure of the sandstone. As a result, the porosity of the sandstone increased. The process of crystallization damage in sandstone can be divided into the following four stages, as shown in Fig. 7:

Stage I (Fig. 7a): In the parent rock, the microstructure was intact, and minerals were tightly cemented. There were almost no obvious microcracks in the minerals. The pores can be divided into two types: open pores, which are connected with the outside; closed pores, which are the gaps surrounded by matrix and minerals and not connected with the outside.

Stage II (Fig. 7b): The salt solution entered the open pores of the sandstone. The solution first filled large pores, mainly those between 1 and 100 μm. At the initial stage of water absorption, the vulnerable calcite was first attacked and generated erosion pores.

Stage III (Fig. 7c): The salt solution penetrated into the closed pores and erosion pores, and then flowed between the pores under the concentration pressure. When the ambient temperature and humidity changed, the water molecules in the solution evaporated into the air, resulting in an increase in the concentration of the solution. Then, salts crystallize out when the solution reaches saturation, and the acicular crystals begin to grow and adhere to the surface of the minerals.

Stage IV (Fig. 7d): As the crystal whiskers continued to grow, the crystals connected both ends of the pore wall and produced a crystallization pressure on the pore wall. This pressure resulted in the expansion of the cracks and pores. In addition, the clay minerals encountered with water, which led to the expansion of the clay minerals, which further enlarged the pore size.

The sandstone in the Nankan Grotto suffered severe salt weathering issues, which have significantly influenced its preservation conditions. This study implies that different deterioration patterns should be given extra attention in different seasons in the Nankan Grotto. In winter, only mirabilite (Na2SO4·10H2O) crystallized in the sandstone (Table 4). Previous studies have verified that mirabilite was more harmful than thenardite because it usually crystallized below the surface, leading to subflorescence21,43. In summer, Na2SO4 and NaNO3 tend to crystallize on the surface, as shown in Fig. 6a, b. This phenomenon is called efflorescence, which is less harmful than subflorescence to the sandstone. It is noticeable that Na2SO4 was more dangerous than NaNO3, because NaNO3 crystallizes out at need higher concentration. Na2SO4 can crystallize out at low concentration due to its low solubility. Based on the salt weathering characteristics, some measures can be taken to reduce the damage of salt weathering. Firstly, the hydrochemical types of groundwater should be previously investigated to predict the probable types of salt weathering that may occur. Then, the salt crystallization pressures under normal and extreme temperature conditions should be evaluated. The prediction of crystallization pressures can help us respond to possible stone deterioration in advance. Finally, it is necessary to stop the rise of groundwater and the infiltration of rainwater. The drainage measure of the foundation and hydrophobic coating may be feasible. Their water inhibition efficacy on the sandstone will be examined in the follow-up tests.

The mineralogical, major element, microstructure, physical, and mechanical properties analyses were conducted on the sandstone in the Nankan Grotto. In addition, capillary salt weathering tests of sandstone were conducted under different salt types and environmental temperatures. The main conclusions are as follows.

-

(1)

After the two salt weathering tests, the EC values, anion concentrations, masses, P-wave velocities, and porosities of specimens increased as the test temperature was changed from 15 to 35 °C within individual experimental settings. These show that high temperature promotes the salt capillary rise in samples. At each temperature, the EC values and anion concentrations showed increasing trends as the vertical position of the specimens.

-

(2)

At 15 °C, only the crystallization pressure of Na2SO4·10H2O exceeded the tensile strength of the fresh sandstone in the Nankan Grotto (2.20 MPa). At 25 °C, the crystallization pressure of Na2SO4 in 6% Na2SO4 + 3% NaNO3 solution condition and the crystallization pressure of NaNO3 in 3% Na2SO4 + 6% NaNO3 solution condition exceeded the tensile strength of the fresh sandstone (2.20 MPa). At 35 °C, the crystallization pressure of Na2SO4 in both 6% Na2SO4 + 3% NaNO3 and 3% Na2SO4 + 6% NaNO3 solution conditions, and the crystallization pressure of NaNO3 in 3% Na2SO4 + 6% NaNO3 solution conditions exceeded the tensile strength of the fresh sandstone (2.20 MPa). The calculation of crystallization pressure illustrated that sodium sulfate is more damaging at low temperature, and sodium nitrate is more damaging at high temperature.

-

(3)

The microscopic deterioration mechanism of salt weathering can be attributed to the salt crystallization pressure. The salt solution first fills large pores, mainly those between 1 and 100 μm, and the vulnerable calcite is first attacked and generates erosion pores. Subsequently, the salt solution penetrates into the closed pores and erosion pores. When the water evaporates and the solution reaches supersaturation, salt crystals begin to grow and adhere to the surface of the minerals. As the crystal whiskers continue to grow, the crystals connect the pore wall and produce a crystallization pressure on the pore wall, which results in the expansion of the cracks and pores and destroys the microstructure of the sandstone.

-

(4)

In different seasons, different salt weathering types and intensities should be cautiously evaluated in the Nankan Grotto. More attention should be paid to the crystallization damage of sodium nitrate in summer, and more attention should be paid to the crystallization damage of sodium sulfate in winter.

Data availability

Not applicable (this manuscript does not report data generation or analysis).

Code availability

No applicable.

References

Zhang, Y., Zhang, Y. & Huang, J. Experimental study on capillary water absorption of sandstones from different grotto heritage sites in China. Herit. Sci. 10, 25 (2022).

Sun, B. et al. Experimental study on the effects of hydrochemistry and periodic changes in temperature and humidity on sandstone weathering in the Longshan Grottoes. Herit. Sci. 11, 173 (2023).

Bonomo, A. E., Amodio, A. M., Prosser, G., Sileo, M. & Rizzo, G. Evaluation of soft limestone degradation in the Sassi UNESCO site (Matera, Southern Italy): loss of material measurement and classification. J. Cult. Herit. 42, 191–201 (2019).

Maravelaki-Kalaitzaki, P. Black crusts and patinas on Pentelic marble from the Parthenon and Erechtheum (Acropolis, Athens): characterization and origin. Anal. Chim. Acta 532, 187–198 (2005).

Paradise, T. R. Sandstone weathering thresholds in Petra, Jordan. Phys. Geogr. 16, 205–222 (1995).

Fitzner, B., Heinrichs, K. & Bouchardiere, D. L. Weathering damage on Pharaonic sandstone monuments in Luxor-Egypt. Build. Environ. 38, 1089–1103 (2003).

André, M.-F., Etienne, S., Mercier, D., Vautier, F. & Voldoire, O. Assessment of sandstone deterioration at Ta Keo temple (Angkor): first results and future prospects. Environ. Geol. 56, 677–688 (2008).

Liu, R., Zhang, B., Zhang, H. & Shi, M. Deterioration of Yungang Grottoes: diagnosis and research. J. Cult. Herit. 12, 494–499 (2011).

Zhang, J. et al. Surface weathering characteristics and degree of niche of Sakyamuni entering nirvana at Dazu Rock Carvings, China. Bull. Eng. Geol. Environ. 78, 3891–3899 (2018).

Yan, S. et al. Salt weathering of sandstone under dehydration and moisture absorption cycles: an experimental study on the sandstone from Dazu rock carvings. Earth Surf. Process. Landf. 47, 977–993 (2022).

Siegesmund, S. & Snethlage, R. Stone in Architecture: Properties, Durability (Springer Science & Business Media, 2010).

Sun, Q. & Zhang, Y. Combined effects of salt, cyclic wetting and drying cycles on the physical and mechanical properties of sandstone. Eng. Geol. 248, 70–79 (2018).

Wang, K., Xu, G., Li, S. & Ge, C. Geo-environmental characteristics of weathering deterioration of red sandstone relics: a case study in Tongtianyan Grottoes, Southern China. Bull. Eng. Geol. Environ. 77, 1515–1527 (2017).

Török, Á, Licha, T., Simon, K. & Siegesmund, S. Urban and rural limestone weathering; the contribution of dust to black crust formation. Environ. Earth Sci. 63, 675–693 (2010).

Rihosek, J. et al. Gravity-induced stress as a factor reducing decay of sandstone monuments in Petra, Jordan. J. Cult. Herit. 19, 415–425 (2016).

Liu, X., Koestler, R., Warscheid, T., Katayama, Y. & Gu, J. Microbial deterioration and sustainable conservation of stone monuments and buildings. Nat. Sustain. 3, 991–1004 (2020).

Li, X., Yang, H., Chen, C., Zhao, G. & Ni, J. Deterioration identification of stone cultural heritage based on hyperspectral image texture features. J. Cult. Herit. 69, 57–66 (2024).

Gázquez, F. et al. Physical weathering of carbonate host-rock by precipitation of soluble salts in caves: a case study in El Orón-Arco Cave (Region of Murcia, SE Spain). Chem. Geol. 521, 1–11 (2019).

Roussel, E. et al. Quantifying 450 years of limestone weathering induced by salt crystallization on fortifications in Malta and Gozo. Geomorphology 378, 107614 (2021).

Sousa, L., Siegesmund, S. & Wedekind, W. Salt weathering in granitoids: an overview on the controlling factors. Environ. Earth Sci. 77, 502 (2018).

Ruiz-Agudo, E., Mees, F., Jacobs, P. & Rodriguez-Navarro, C. The role of saline solution properties on porous limestone salt weathering by magnesium and sodium sulfates. Environ. Geol. 52, 269–281 (2007).

Germinario, L., Siegesmund, S., Maritan, L. & Mazzoli, C. Petrophysical and mechanical properties of Euganean trachyte and implications for dimension stone decay and durability performance. Environ. Earth Sci. 76, 739 (2017).

Siedel, H. Salt efflorescence as indicator for sources of damaging salts on historic buildings and monuments: a statistical approach. Environ. Earth Sci. 77, 572 (2018).

Espinosa-Marzal, R. M. & Scherer, G. W. Impact of in-pore salt crystallization on transport properties. Environ. Earth Sci. 69, 2657–2669 (2013).

Scherer, G. W. Crystallization in pores. Cem. Concr. Res. 29, 1347–1358 (1999).

Steiger, M. Crystal growth in porous materials—I: the crystallization pressure of large crystals. J. Cryst. Growth 282, 455–469 (2005).

Yu, S. & Oguchi, C. T. Role of pore size distribution in salt uptake, damage, and predicting salt susceptibility of eight types of Japanese building stones. Eng. Geol. 115, 226–236 (2010).

Martínez-Martínez, J., Torrero, E., Sanz, D. & Navarro, V. Salt crystallization dynamics in indoor environments: stone weathering in the Muñoz Chapel of the Cathedral of Santa María (Cuenca, central Spain). J. Cult. Herit. 47, 123–132 (2021).

Germinario, L. & Oguchi, C. T. Underground salt weathering of heritage stone: lithological and environmental constraints on the formation of sulfate efflorescences and crusts. J. Cult. Herit. 49, 85–93 (2021).

Zhang, X., Ling, S., Wu, X. & Xie, J. Microscopic weathering mechanisms of subflorescence and crust patterns in the Nankan Grotto, northern Sichuan, China. Herit. Sci. 11, 181 (2023).

Zhang, X. et al. Microscopic weathering characteristics and deterioration mechanisms of sandstone in the Nankan Grotto, northern Sichuan, China. Bull. Eng. Geol. Environ. 83, 219 (2024).

Zhang, X. et al. Hydrochemistry process and microweathering behaviour of sandstone heritages in the Nankan Grotto, China: insights from field micro‑observations and water–rock interaction experiments. Bull. Eng. Geol. Environ. 82, 356 (2023).

Ling, S., Wu, X., Zhao, S. & Liao, X. Evolution of porosity and clay mineralogy associated with chemical weathering of black shale: a case study of Lower Cambrian black shale in Chongqing, China. J. Geochem. Explor. 188, 326–339 (2018).

Ling, S. et al. Mineralogy and geochemistry of three weathered Lower Cambrian black shale profiles in Northeast Chongqing, China. Geosci. J. 20, 793–812 (2016).

GB/T50266. Standard for Test Methods of Engineering Rock Mass. Ministry of Housing and Urban-Rural Development of the People's Republic of China (2013).

GB/T50123. Standard for Geotechnical Testing Method. Ministry of Housing and Urban-Rural Development of the People's Republic of China (2019).

Liu G., Ma L. & Liu J. Handbook of Chemistry and Chemical Properties. Chemical Industry Press, Beijing (2002).

Chen, C., Yang, H., Li, X., Wang, Y. & Zhao, G. Numerical analysis on crystallization inside porous sandstone induced by salt phase change. Eng. Geol. 341, 107694 (2024).

Yang, H., Chen, C., Zhao, G. & Zhou, J. Electrical resistivity analysis for the internal capillary water migration mechanism of porous stone. Acta Geophys. 72, 213–231 (2024).

Steiger, M. & Asmussen, S. Crystallization of sodium sulfate phases in porous materials: the phase diagram Na2SO4–H2O and the generation of stress. Geochim. Cosmochim. Acta 72, 4291–4306 (2008).

Steiger, M. Crystal growth in porous materials—II: influence of crystal size on the crystallization pressure. J. Cryst. Growth 282, 470–481 (2005).

Shen, Y., Linnow, K. & Steiger, M. Crystallization behavior and damage potential of Na2SO4–NaCl mixtures in porous building materials. Cryst. Growth Des. 20, 5974–5985 (2020).

Tsui, N., Flatt, R. J. & Scherer, G. W. Crystallization damage by sodium sulfate. J. Cult. Herit. 4, 109–115 (2003).

Zhang, X., Wu, X., Ling, S. & Cao, Y. Efflorescence, subflorescence, and crust weathering characteristics of sandstone in Nankan Grotto, China: insights into petrography and environment constraints. Herit. Sci. 12, 244 (2024).

Acknowledgements

We greatly appreciate the colleagues of the Nankan Grotto Research Institute for their support during field investigations. This study was funded by the National Natural Science Foundation of China (No. 42377198), Sichuan Province Science and Technology Support Program (Nos. 2023YFS0364, 2023ZYD0155, 2024YFHZ0154, 2025ZNSFSC1209).

Author information

Authors and Affiliations

Contributions

Xuening Zhang wrote the main manuscript text and prepared Figs. 1, 6, and 7. Sixiang Ling reviewed the manuscript critically. Xiyong Wu prepared Fig. 2. Jiawen Xie prepared Fig. 3. Wei Wei prepared Fig. 4. Xiaoning Li prepared Fig. 5. All authors contributed to the research strategy, the discussion and interpretation of the results, and the final form of the text and figures. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, X., Ling, S., Wu, X. et al. Crystallization characteristic of sandstone under capillary salt weathering test using different salt property and temperature. npj Herit. Sci. 13, 275 (2025). https://doi.org/10.1038/s40494-025-01829-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s40494-025-01829-1