Abstract

In this paper, a scientific experimental study was conducted on the green-gray decorative bricks used in the walls of ancient dwellings from the Qing Dynasty in Southern Anhui Province to deepen the scientific understanding of their production process. Utilizing scanning electron microscopy (SEM), X-ray fluorescence (XRF), X-ray diffraction (XRD), and thermogravimetric analysis (TGA), the study explored the characteristics of the green-gray decorative bricks in terms of their micro-morphology, material composition, structural features, and firing temperature. The results indicated that the firing temperature of the finished bricks was lower than 600 °C. Although the finished bricks exhibited different color cross-sections, their mineral compositions were fundamentally similar, primarily consisting of quartz, potassium feldspar, plagioclase feldspar, and amphibole. Additionally, the significant variation in iron content accounts for the differences in brick color. These findings provide scientific guidance for the restoration of the production process of decorative bricks.

Similar content being viewed by others

Introduction

There is a long history of manufacturing and using fired clay in ancient China. The earliest fired clay building materials were used to construct houses in China as early as 5500 years ago1. The ceramic water pipe appeared during the early Shang Dynasty. Subsequently, in the early Western Zhou Dynasty, tiles were introduced, solving the problem of waterproofing roofs around 3000 years ago2. Thin bricks were primarily used for paving floors during this period. By the Warring States period and into the Qin and Han Dynasties, brick firing technology had significantly advanced3,4. However, it was not until the Ming Dynasty that the technical system of brick making became well-established and widely adopted, thanks to the advancement and popularization of brick-making technology. During this time, fired clay bricks were extensively used in various types of buildings, with the quantity and quality of brick structures, such as the Great Wall, city walls, and brick towers, reaching a historical peak. The use of bricks was especially common in both official and folk buildings5,6. At the same time, due to the complex and strict hierarchy in ancient Chinese society, there were significant differences in the scale, materials, decoration, and colors of buildings7. This resulted in traditional dwellings that appeared more monotonous in appearance and color, lacking variety and impact. Folk brick-making techniques also displayed diversified development. In different regions, influenced by geographic environment, climatic conditions, resource endowment, economic conditions, technological stages, as well as cultural and esthetic orientations, traditional dwellings not only exhibited a variety of complex shapes and colors but also featured distinctive regional characteristics in the brick and tile building materials used.

In recent years, research on fired clay bricks in China has focused on their physical and chemical properties, including density, strength, water absorption, mineral composition, and firing temperature, among others8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24. These characteristics have a direct impact on the performance and service life of bricks in construction. The raw materials used in brick manufacturing and their proportions form the foundation; the firing temperature and atmosphere reveal the characteristics of the firing process. If the temperature is too high or too low, it can lead to brick failure, while the oxidizing or reducing atmosphere during firing determines whether the clay brick appears blue or red. Successfully fired bricks typically exhibit low porosity, low water absorption, and good weather resistance. The quality of bricks significantly affects the overall structure and integrity of a building. Therefore, understanding the material properties of bricks is essential for comprehending the characteristics of ancient bricks and lays the groundwork for the scientific conversation of ancient buildings.

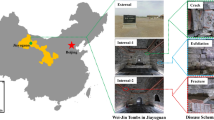

The dwellings featuring decorative bricks represent a traditional architectural style with unique characteristics, located in Jing County, Xuancheng prefecture, southern Anhui province25,26. This area marks the transition from plains to mountains in the middle and lower reaches of the Yangtze River. There are 415 decorative brick buildings constructed during the Qing Dynasty in the townships of Jing County, which is part of Xuancheng Prefecture (Fig. 1). This architectural style is renowned for its distinctive decorative bricks, which enhance the visual impact and esthetic qualities of the buildings while maintaining the constraints of the color hierarchy, Huangtian village, a national key cultural relics protection unit famous for having many decorative brick buildings (Fig. 2). However, due to the limitation of sample sources and the limitation of research perspectives, scientific research on decorative bricks has not been well carried out.

Map of decorative brick buildings in China (The location of Jing county in the map of China and the number of decorative brick dwellings in the township under Jing County, Xuancheng prefecture, Anhui province.) The gray lines are administrative boundaries; Maps’ sources from http://bzdt.ch.mnr.gov.cn/index.html.

Decorative bricks are made from two different layers of clay sourced from the same region and are fired to reveal irregular textures and patterns in blue and gray. There are two main types of decorative bricks: rectangular and square. The dimension of the long brick is generally 260 × 120 x 25 mm, while the square brick typically measures 270 × 270 x 30 mm. These bricks are mainly used for the exterior walls of buildings, walls of indoor public spaces, roofs, as well as for doors and windows (Fig. 3).

Methods

The purpose of decorative bricks used in the residential buildings in southern Anhui in the Qing Dynasty was not only to protect the durability of the walls of the residential buildings but also had an important esthetic function. Unfortunately, the original firing technology of decorative bricks has been lost. The aim of this study was to investigate the characteristics of the decorative bricks used, especially the two-color bricks, including their physical and chemical parameters, the materials used to make the bricks, and the associated firing process. Samples were prepared for comparison based on the specifications of two different colors. Analytical techniques such as scanning electron microscopy (SEM), X-ray fluorescence spectroscopy (XRF), X-ray diffraction (XRD), and thermogravimetric analysis (TGA) were used to investigate the morphology, composition, content, physical phase, and firing temperature of the antique brick samples. The results of the study provide detailed information about the decorative bricks used in residential buildings and provide a valuable reference for the restoration of the manufacturing process of these decorative bricks.

Materials

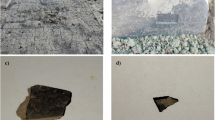

Only a few small pieces of brick samples were collected from fragments of wall bricks from an ancient dwelling known as “Dun Mu Tang,” in Huangtian Village, a national key cultural relics protection unit, which was constructed in 1793 A.D. during the reign of the Jiaqing Emperor of the Qing Dynasty (Fig. 4). The samples could not directly meet the requirements for relevant analytical tests, they were pre-treated before analysis. First, floating dust and bonding mortar were removed from the surface of the sample residue. To avoid cross-contamination, the samples were carefully sanded in separate areas according to their color, ensuring that the internal cores collected were of a single hue. Finally, using an agate mortar, the brick cores of the two different colors were ground separately until they were reduced to a homogeneous powder. The powder from the gray section is designated as NO. 1, while the powder from the blue section is designated as NO. 2.

Physical property

The density, water absorption saturation coefficient, and porosity of brick materials are important factors for evaluating the performance of building materials. The samples were tested and evaluated according to current standards for fired common bricks27.

Density test

The surface of the brick sample was cleaned, and the sample was placed in a blast drying oven at 105 ± 5 °C until a constant mass was achieved. The mass (m) was recorded, and the dimensions of the dried sample were measured to calculate its volume. The density of the sample was calculated using the formula (1).

ρ -Volume density, measured in kilograms per cubic meter(kg/m3).

m-Dry mass of the sample, in kilograms(kg).

υ -Sample volume, unit in millimeters(mm).

The υ is calculated according to the formula (2):

Variables

L - length of the sample, mm; B - width of the sample, mm; H - height of the sample, mm. The sample size is 20 × 20 × 20 mm.

Water absorption test

The prepared sample was cleaned with a brush, then placed in a blast drying oven at 105 ± 5 °C until a constant mass was achieved, yielding a dry mass (M0). The dry specimen was then immersed in water at a temperature of 10 °C to 30 °C for 24 h. After immersion, the specimen was removed, and excess surface water was wiped off with a wet towel, and the mass was weighed immediately. The mass of water seeping from the capillaries on the surface of the specimen into the weighing pan during weighing was also included in the absorbed mass, resulting in the wet mass (M24) after 24 h of immersion. The water absorption rate was calculated according to formula (3), accurate to 0.01%. Where: W24 - water absorption rate of the specimen immersed in water at room temperature for 24 h (%); M0 - dry mass of the specimen in kilograms (kg); M24 - wet mass (kg) of the specimen after 24 h of immersion in water.

Porosity

The porosity was determined using formula (4) to calculate the ratio of voids to the total volume of the brick material.

Variables: P is the Porosity (void: +total), \({V}_{\upsilon }\) is the void volume, Vt is the total volume.

Scanning electron microscopy (SEM)

The elemental composition of the decorative bricks was examined and analyzed using a Quanta 200 environmental scanning electron microscope manufactured by FEI, under the following test conditions: high vacuum mode up to 5 × 10^-3 Pa and an accelerating voltage of 20 kV.

X-ray fluorescence (XRF)

The elemental composition of the samples was accurately analyzed using a Rigaku ZSX Primus III + X-ray fluorescence spectrometer equipped with an end-windowed Rh-targeted X-ray tube, operating at a maximum X-ray tube pressure of 60 kV and a maximum X-ray tube current of 150 mA. The spectrometer has an elemental range from 4Be to 92U, with concentration limits ranging from 6% to 100%.

X-ray diffraction (XRD)

X-Ray diffraction (XRD) analysis was carried out using the Rigaku SmartLab SE diffractometer with CuK α radiation (γ = 0.154056 Å) at 40 kV and 30 mA. The diffraction data for the samples were collected from 5 to 90° of 2θ at a scan rate of 2° 2θ per minute.

Thermal gravimetry analyses (TGA)

Samples were analyzed thermogravimetrically using a PerkinElmer STA 8000 thermal analyzer. The STA 8000 has a temperature range of 15 °C to 1600 °C, mass sensitivity of 0.001 mg, temperature accuracy of 0.001 °C, temperature precision of ±2%, and a temperature ramp rate of 10 or 20 °C per minute. The data presented in this paper are based on typical test conditions, temperature range is from 20 °C to 1000 °C, the ramp rate is 10 °C per minute, sample mass is about 100 mg, and an atmosphere with air.

Results

Physical property

The brick sample was weighed, and its density was calculated using the density formula, resulting in a density of approximately 1.70 g/cm3. The water absorption rate refers to the ability of bricks to absorb and penetrate water, which is one of the important indicators for assessing the quality of sintered clay bricks. After conducting the water absorption test on the brick sample, the water absorption rate was found to be about 19%. Generally, bricks with lower water absorption tend to have higher density, while porosity is a critical parameter for measuring internal voids; the porosity of the brick samples was slightly less than 30% (Table 1).

Scanning electron microscopy (SEM)

Figures 5a, b show secondary electron images of the gray and blue section of the brick samples at 1200x magnification, from which it can be seen that, despite the different colors, there are a large number of flakes, strips, and lumps of mineral particles ranging in size from 10 to 100 µm, with gaps between the particles and surrounded by smaller mineral particles.

X-ray fluorescence (XRF)

The mineral element composition of the different colored sections of the brick sample, as analyzed by X-ray fluorescence (XRF), is listed in Table 2. The analysis indicates that the two-colored sections of the brick are relatively consistent in terms of primary elements (≥1% content). The elements with the highest concentrations in the bricks are Si, Al, Fe, K, Ca, and Na, suggesting the presence of silica and feldspar minerals. Additionally, the X-ray fluorescence (XRF) data revealed that the iron (Fe) content in the blue section of the brick was higher than that in the gray section.

X-ray diffraction (XRD)

Figures 6a, b present the X-ray diffraction (XRD) patterns of the gray and blue sections of the decorative brick, which essentially demonstrate highly consistent phases. The following phases are identified: quartz (SiO₂), potassium feldspar(K-spar) [K(AlSi₃O₈)], albite [Na(AlSi₃O₈)], and amphibole [Na₀.₉K₀.₄Ca₁.₉₄Mg₁.₈₄Fe₂.₇₈Al₂.₃Si₆.₀₈O₂₂(OH)₁.₇₂F₀.₂₈].

Thermal gravimetry analyses (TG)

Figure 7 illustrates the thermogravimetric analysis (TG, black solid line) and the derived thermogravimetric analysis (DTG, red dashed line) curves of the brick sample powder. The TG and DTG curves indicate that the pyrolysis process can be divided into four distinct stages: The first stage is the water evaporation stage, which accounts for 2.48% of the total weight loss of the sample at temperatures ranging from 30 °C to 200 °C, with a maximum weight loss rate occurring at 51.42 °C. The second stage is the pyrolysis stage, during which the weight loss of the sample is about 1.97% in the temperature range from 200 °C to 510 °C, characterized by a relatively flat curve. The third stage is the oxidation stage, occurring from 510 °C to 840 °C, during which the weight loss of the sample is negative, with a maximum weight loss rate at 722.10 °C. The fourth stage is another pyrolysis stage, with a weight loss of about 0.67% at temperatures above 840 °C.

Discussion

By comparing parameters such as density, water absorption, and porosity with relevant literature on modern common clay bricks28, it is noted that the general density value of modern common clay bricks is 1.70 g/cm3, the density of the decorative brick is from 1.67 g/cm3 to 1.69 g/cm3, which is slightly lower than that of modern common clay bricks. Water absorption refers to the capacity of the brick to adsorb and infiltrate water and is one of the most important indicators for assessing the quality of clay bricks. Generally, a low water absorption rate in clay bricks indicates higher densification. The water absorption rate of the decorative brick range is from 18.98% to 19.01%, as stipulated by the standards29, this data essentially meets the 19% requirement for non-severely weathering area. This low water absorption rate enhances their resistance to environmental factors such as rain, snow, freezing, and thawing, providing strong weather resistance.

Porosity is another important parameter for evaluating and predicting the durability of bricks. It reflects the structural characteristics of the material in relation to density and water absorption, thereby affecting other properties of the material30. Decorative bricks with porosity below 30% are essentially aligned with modern brick materials and exhibit good durability. The water absorption and physical properties of decorative bricks can meet the quality standards of modern fired clay bricks. The production and firing process of these decorative bricks has involved consciously selection of raw materials and control over the combustion atmosphere. The finished bricks with their water absorption and void content satisfying the minimum quality requirements for modern fired clay bricks. However, compared to bricks used in higher-grade buildings, the quality of these decorative bricks is not classified as first-rate, as they are primarily employed in low-grade residential construction.

The scanning electron microscope (SEM) secondary electron images of the brick samples reveal a significant presence of granular material (Fig. 5). The particle size and distribution are not uniform, with large gaps between particles, contrasting with the wall bricks typically used, which exhibit smaller particle sizes and higher densities. In contrast, the fired clay bricks utilized in city walls, known for their defensive characteristics, are characterized by smaller particles and higher density31. The SEM images reveal that the microscopic morphology of the decorative bricks is characterized by looser densities and uneven particle size distribution. This observation indicates that the raw materials used for brick production have been consciously selected and processed, but they may not be sufficiently refined.

From the X-ray fluorescence (XRF) data, it can be observed that the two different colors of brick samples are similar in terms of the main elemental quantities, though there are differences in their concentrations. Notably, the iron content differs by 12.12%. According to the literature32, a key step in ancient Chinese brick firing involved a technique known as “Yin shui.” Existing studies on ancient bricks elucidate the scientific rationale behind this step33,34, during the “Yin shui” process, the resulting water vapor creates a reducing atmosphere in the kiln, rich in H₂ and CO, leading to the formation of FeO and Fe3O4, which imparts a bluish-black hue to the clay bricks. It has also been noted that the variation in color is not solely due to iron content but also involves titanium (Ti)35. In this study, the Ti content difference is minimal and falls within the normal fluctuations found in soil36,37, thus the significant difference in Fe content is the primary reason for the unique irregular texture and color of the decorative bricks.

Analysis of the XRD patterns of the powder samples from different colored sections of the bricks indicates that the physical phase composition of the two materials is essentially the same, with no significant differences. Their main components remain largely consistent, consisting of quartz (SiO₂), potassium feldspar(K-spar) [K(AlSi₃O₈)], albite [Na(AlSi₃O₈)], and amphibole [Na₀.₉K₀.₄Ca₁.₉₄Mg₁.₈₄Fe₂.₇₈Al₂.₃Si₆.₀₈O₂₂(OH)₁.₇₂F₀.₂₈]. This finding verifies that the raw materials selected for the decorative brick blanks originate from the same location. Clay bricks are generally categorized into two main types, one of which consists of non-calcareous clays, primarily composed of clay, silica, and iron compounds38. It is evident that the decorative bricks used in the construction of ancient houses in Huangtian village belong to this category. Feldspar is classified as a clay mineral and serves as a clayey cement in common sandstone. Quartz, a mineral primarily composed of silica, acts as a barren raw material that regulates the plasticity of clay before firing and provides structural integrity during the firing process. Iron compounds significantly influence coloration.

The TG and DTG curves reveal that within the temperature range of 0 to 200 °C, the sample undergoes a weight loss of 2.48% of its total mass. This loss is primarily attributed to the evaporation of adsorbed water and free water contained within the pores of the sample particles as the temperature increases. In the temperature range of 200 to 510 °C, the weight loss is 1.97% of the total mass, mainly due to the complexity of the mineral composition and the presence of certain minerals that contain water of crystallization, which decompose upon heating39,40. Notably, the gradual inflection in the thermogravimetric curve beginning around 510 °C and accelerating from approximately 600 °C to 840°indicating that the weight loss of the sample becomes negative. This phenomenon is believed to result from the oxidation of iron oxides in the sample, while the iron within the amphibole structure is also oxidized. The weight loss observed beyond 840 °C may be attributed to the decomposition of amphibole41 or the decomposition of a small amount of carbonates42. Amphibole undergoes three stages of oxidation, dehydrogenation, and decomposition at high temperatures, with a temperature range from 600 °C to about 1500 °C43,44. In summary, considering the crude and imprecise nature of traditional brick kilns, it can be inferred that decorative bricks were likely to be fired at temperatures of 600 °C or lower.

Data availability

The data that support the findings of this study are available on request from the corresponding author.

References

Li, N. A preliminary study on the architectural foundation of the red-burnt clay ruins in Lingjiatan. Sci. Res. Chin. Cult. relics 03, 64–66+63 (2008).

Li, J. K. Influence of Qing brick and Han tile in history. J. Build. Mater. 1, 26–29 (1998).

He, G. X. History and prospect of brick and tile. Brick Tile 7, 62 (2017).

Zhou, Y. J., Wu, X. M. & Liu, S. S. Qin brick Han tile or Zhou tile Qin brick. Jiangsu Geol. 28, 64 (2004).

Pan, G. X. A History of Chinese Architecture. 4th ed.. 45 (China Architecture & Building Press, Beijing, 2015).

Gao, Y. S. Study on the Paradigm of Official Brick Architecture in the Ming Dynasty. Master dissertation, Southeast University, Nanjing (2008).

Shen, S. H. et al. Ritual Department XX, Volume 62, Da-Ming huidian. Ministry of the Interior, 1587.

Han, W. H., Pei, S. M. & Liu, F. Material characterization of the brick in the Ming Dynasty heritage wall of Pianguan County A case study. Case Stud. Constr. Mater. 16, 1–13 (2022).

Li, Y. Experimental Study on the Deterioration of Historical Building Gray Bricks Under Salt. Master's dissertation, Henan University, Zhengzhou (2008).

Li, Y. H., Cai, Y., Xie, H. R. & Zhang, J. Comparison of isothermal sorption properties of gray bricks in different ages in Wenzhou Qiaolou site. J. Southeast Univ. (Nat. Sci. Ed.) 50, 327–333 (2020).

Li, J. F. et al. Research on the material characteristics and structural static properties of brick masonry in Yongzuo Temple, Taiyuan City. Identif. Apprec. Cult. Relics 21, 100–105 (2022).

Chun, Q., Dong, Y., van Balen, K. & Xu, X. Experimental research on material properties of ancient white bricks in the Yichun Region, China. Int. J. Arch. Herit. 11, 554–565 (2017).

Cao, H. H. & Cao, R. Test study on the black bricks of Great Wall in Guangwu, Shanxi. Tradit. Chin. Arch. Gard. 04, 60–61 (2014).

Li, C. Q. et al. Chemical and microscopic investigation of historical wall bricks collected from the City Wall of Xi’an, China. J. Cult. Herit. 64, 144–149 (2023).

Liu, J. B. & Zhang, Z. J. Characteristics and weathering mechanisms of the traditional Chinese blue brick from the ancient city of Ping Yao. R. Soc. Open Sci. 7, 1–19 (2020).

Ma, S., Wu, Y. & Bao, P. Experimental study on the properties of modern blue clay brick for Kaifeng People’s Conference Hall. Sci. Rep. 11, 1–16 (2021).

Wang, Y. P., Lv, C. J., Cai, Y. Z. & Liu, F. Z. Analysis and research of blue bricks unearthed from the Han Tomb of Lingshenghu in Dingtao, Shandong. Relics Museol. 05, 99–107(2024).

Sun, Y. Q. Investigation of basic mechanical properties and damage of ancient brick masonry. Master dissertation, Xi’an University of Technology, Xi’an (2022).

Dong, Z., He, L. et al. Scientific detection of existing Beijing city brick samples at Fengtai Railway Station. Tradit. Chin. Archit. Gard. 06, 103–107 (2024).

Hong, H. & Cao, R. C. Analysis and detection of the blue bricks of the Ming Dynasty Great Wall in Guangwu, Shanxi. Tradit. Chin. Archit. Gard. 04, 60–61 (2024).

Jiang, X. X. et al. Study on properties of ming dynasty great wall black bricks in Northern Shanxi Province. Fly. Ash Compr. Util. 06, 79–85 (2022).

Shen, J. N. & Zhang, Z. J. Influence of firing temperature on physical and mechanical properties of red bricks. Sci. Conserv. Archaeol. 05, 105–111 (2019).

Shen, J. N. & Zhang, Z. J. Measuring the firing temperature of ancient bricks in Pingyao ancient city based on magnetic susceptibility. Sci. Conserv. Archaeol. 05, 81–85 (2020).

Ren, Z. W., Ren, J. G. & Hu, C. F. Investigation and research on brick diseases of Pingyao Ancient City, World Cultural Heritage Site. Sci. Conserv. Archaeol. 02, 115–120 (2021).

Sun, S., Yao, Z. Q. & Hong, T. Investigation and preliminary understanding of decorative brick architecture in Jingxian area. Archit. Eng. Technol. Des. 28, 412–412 (2017).

Zhai, G. K. & Zhai, Y. A traditional finishing material worth researching and developing-Jingchuan decorative brick. China Archit. 06, 31–32 (2003).

General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of the People’s Republic of China. GB/T 2542-2012 Test methods for wall bricks (China Standard Press, Beijing, 2013).

Chen Y., Pan J. M. Hardware Manual 41(China Machine Press, Beijing, 2010).

General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of the People’s Republic of China. GB/T 5101-2017 Fired common bricks (China Standard Press, Beijing, 2017).

Coletti, C., Cultrone, G., Maritan, L. & Mazzoli, C. Combined multi-analytical approach for study of pore system in bricks: How much porosity is there?. Mater. Charact. 121, 82–92 (2016).

Zhang, W. Z. (Ming Dynasty). brick-making map. The Siku Quanshu general summary, vol. 84, history, political book class inventory two.

Gao, H. & Sun, S. The properties of ancient bricks in The Xi’an Circumvallation. J. Ningxia Univ. (Nat. Sci. Ed.). 40, 351–354 (2019).

Sun, S., Ke, Z. B. & Jin, P. J. Analysis of decoration brick for roofing used in traditional residence in Southern Anhui. J. Huangshan Univ. 24, 50–53 (2022).

Houseman, J. E. & Koenig, C. J. Influence of kiln atmospheres in firing structural clay products: II. Color development and burnout. J. Am. Ceram. Soc. 54, 82–89 (1971).

Wang, Y. S., Wang, J. & H.&Wu, X. M. Analysis on decoration characteristics and material performance of Jingxian Patterned Bricks. Urban. Archit. 23, 126–129 (2022).

Wang Su, F. & He, M. Environmental background values and distribution patterns of titanium, zirconium, hafnium and tantalum in soils in China. Arid Environ. Monitor.5, 135–139 (1991).

Tang, Z. M. et al. Geochemical characteristics of soil elements in Xin’an River Basin: constraints from rock formation types. East China Geol. 44, 172–184 (2023).

Brady, G. S., Clauser, H. R. & Vaccari, J. A. Materials Handbook 139 (McGraw-Hill Education, 2002).

Dai, J. H. An Introduction to Inorganic Non-Metallic Materials. 141(Harbin Institute of Technology press, Harbin, 2004).

Ma, T. C. Ceramic Technology(Second Edition) 185(China Lighting Industry Press, Beijing, 2018).

Han K. N. Dehydration kinetics of amphibole and it’s geophysical implication, Master dissertation, Institute of Earthquake Forecasting, Beijing (2021).

Han, K. N. et al. Experimental study on the kinetics of magnesioamphibole dehydration and its implications. Am. Mineral.109, 502–509 (2024).

Liu Y., et al. Inorganic Non-metallic Materials Technology. 59 (University of Science and Technology of China Press, 2015).

Li, Y. L. et al. Raman spectroscopy and XPS study of the thermal decomposition of Mg-amphibole into augite. J. Raman Spectrosc. 53, 820–831 (2022).

Acknowledgements

Thank Xu Cao and Zeng Liu for providing decorative brick samples and photos. This research was funded by the Humanities and Social Science Fund of the Ministry of Education, China. grant number: 19YJCZH145.

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sheng, S., Pu-jun, J. Characterization of decorative bricks from Qing Dynasty dwellings in southern Anhui Province of China. npj Herit. Sci. 13, 331 (2025). https://doi.org/10.1038/s40494-025-01902-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s40494-025-01902-9