Abstract

Understanding the corrosion mechanisms of ancient porcelains and the influence of marine-organism attachment is crucial for the conservation of underwater cultural heritage. In this study, we comprehensively analysed the chemical compositions and structures of the concretions and corrosion layers on the glaze surface of a bluish-white porcelain excavated from the Nanhai No. 1 shipwreck, with a particular focus on the morphological evolution of bubbles in the glaze during the corrosion process. The concretions contained a yellow porous structure that comprised a siliceous skeleton, while the main corrosion products were α-FeOOH and β-FeOOH. Furthermore, plausible hypotheses were formulated regarding the source of the concretions and the mutually beneficial relationship between silicon-rich marine organisms(sponges) and ancient silicate ceramics, providing a unique perspective for the conservation of waterlogged ancient ceramics.

Similar content being viewed by others

Introduction

Nanhai No. 1 was a Chinese merchant ship that sank in the South China Sea along the Maritime Silk Road during the Southern Song Dynasty (1127–1279). The ship was discovered in 1987, ten nautical miles southwest of Xiachuan Island, Guangdong Province, off the south coast of China1. Its cargo included significant quantities of ceramics as well as ironware2. The ceramics excavated from the shipwreck include bluish-white porcelains from the renowned Hutian kiln in Jingdezhen. These porcelains possess several distinct characteristics of the Southern Song Dynasty: (1) a whitish and thin body with a delicate texture; (2) a lustrous and smooth glaze with a bluish-white colour and several entrained bubbles; and (3) decorative motifs produced by incision, carving, or impression3. The porcelains also have an unglazed rim, as they were formed by inverted firing (i.e., with the rim facing down). The excavated artefacts have great artistic, historical, and scientific value. However, submersion in seawater for nearly a millennium has led to varying degrees of corrosion and damage. Certain samples have large concretions attached to the unglazed rim and neighbouring glaze surface or a gel layer covering the glaze; studying these features is crucial to understand and preserve such underwater cultural heritage.

Since the 1980s, materials scientists, marine chemists, and physicists have sought to elucidate the corrosion mechanisms of ancient ceramics. Studies have focused on the corrosion of the glass phase4,5, crystalline regions6,7, and other phase structures in the glaze layer8,9,10,11; the formation of surface concretions and corrosion products and their interactions with the artefact body12; microbial corrosion13,14,15,16,17; and other factors18,19,20. However, few studies have investigated the morphological transformation of bubbles, which are highly prevalent in ancient ceramic glazes and considerably influence the corrosion process, despite their isolation from the external environment. Pertinent studies have found that bubbles in glaze can affect the direction in which corrosion layers arrange on the artefact surface4, influence the chemical composition of the local glaze surface8, create rapid pathways and deposition sites for aqueous solutions and foreign contaminants7,9, and provide space for the growth of corrosion products12. In addition, despite several investigations into the effects of calcium-rich marine-organism attachment on the corrosion of ancient ceramics, including the influence of coralline algae12, bryozoans, and oysters14, few studies have explored the influence of silicon-rich marine organisms.

Consequently, this study investigated the morphological evolution of bubbles during the corrosion process and their correlation with circular/annular dark spots on the glaze surface. Meanwhile, plausible hypotheses were formulated regarding the source of concretions and their synergistic interactions with the bluish-white porcelain. A bluish-white porcelain from the Nanhai No. 1 shipwreck—submerged in a marine environment for approximately 800 years—was subjected to technical analyses to explore the formation mechanisms of the corrosion products, intending to identify methods for the conservation of such porcelain wares. The findings not only enhance our understanding of the corrosion mechanisms of ancient bluish-white porcelain wares in marine environments but also serve as a key reference for future research on the long-term corrosion mechanisms of modern silicate glasses.

Methods

Materials

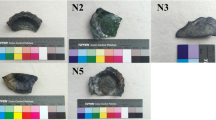

A bluish-white porcelain fragment (Fig. 1a, b) from the Nanhai No. 1 shipwreck was desalinated at the Maritime Silk Road Museum, Guangdong Province, China, for 12 weeks prior to its use in the present study.

The unglazed rim and neighbouring glaze surface of the ceramic were covered by dark concretions. Yellowing was observed on certain parts of the glaze surface, and both the outer and inner walls were densely covered with dark spots. Samples were cut from the porcelain fragment, and the cross-sections were ground and polished using 1500-mesh boron carbide powder. The samples were sequentially washed with deionised water (2 × 15 min) and ethanol (1 × 15 min) in an ultrasonic bath and dried in an oven at 110 °C for 3 h.

Analytical methods

The chemical compositions of the glaze and concretions were quantitatively analysed by energy dispersive X-ray fluorescence (ED-XRF) spectroscopy (Eagle III, EDAX Inc., USA). Testing was performed on the natural surface of the glaze and concretions and the bonding interface of the concretions (where they attached to the glaze surface). The ED-XRF spectrometer had the following specifications: side-window rhodium target, 50 W X-ray tube, downward irradiation, and lithium-drifted silicon (Si(Li)) detector. Samples were tested with an X-ray tube voltage of 50 kV, tube current of 200 μA, vacuum optical path, incident X-ray beam spot diameter of 300 μm, and measurement duration of 200 s. For quantitative analysis, calibration curves were created using a series of 13 standard reference materials for non-destructive ancient ceramics testing, developed by the Shanghai Institute of Ceramics of the Chinese Academy of Sciences (Shanghai, China).

The macromorphology of the natural surface and polished cross-sections of the samples were examined under a three-dimensional (3D) ultra-depth microscope (VHX-6000; Keyence). The micromorphology and microscopic chemical composition were characterised using cold-field-emission scanning electron microscopy (SEM; SU8100, Hitachi, Japan) and energy dispersive X-ray spectroscopy (EDS; Xplore 30, Oxford Instruments, UK). SEM analyses were performed in a low-vacuum environment (10−3 Pa) at an accelerating voltage of 5 kV, with EDS spectra acquisition lasting for 60 s at a working distance of 15 mm. Prior to SEM-EDS analysis, the natural surfaces and polished cross-sections were gold sputter-coated.

The phase compositions of the corrosion products and concretions were characterised by micro-Raman (μ-Raman) spectroscopy (WITec alpha300 R, Oxford Instruments, UK) with a 100× optical lens and 532 nm laser, (0.1 mW laser power). Baseline removal was performed with LabSpec software (Horiba, Japan), and the spectra were smoothed and deconvolved using Origin software (OriginLab, USA). The phase compositions of the concretions were further analysed using X-ray diffraction (XRD; D8 Discover, Bruker, Germany) with Cu Kα radiation (40 kV, 40 mA) in the 2θ range of 5°–80°. The spot diameter and step size were 20 μm and 6°/min, respectively.

Results

Chemical composition of glaze

The porcelain sample was analysed by ED-XRF spectroscopy (Table 1). The uniformity of the glaze surface was degraded by prolonged corrosion, necessitating repeated measurements to account for inherent variability. The results for each type of feature were averaged. For the transparent glaze regions, the chemical composition was consistent with those of bluish-white porcelains produced by Hutian kiln in Jingdezhen during the Southern Song Dynasty. The glaze comprised a quaternary CaO-MgO-Al2O3-SiO2 system, with CaO being the primary fluxing agent. The glaze also contained iron ions. These ions are sensitive to the kiln atmosphere; when the reducing atmosphere is strong, Fe3+ is transformed into Fe2+. This produced a blue–green colour21 that manifested as a bluish-green tint on thicker parts of the glaze. MnO and P2O5 were also present in the porcelain glaze, indicating that glaze ash or plant ash may have been introduced into the glaze formulation. The glaze coefficient b (calculated as b = RO/(RO + R2O), where RO represents the content of alkaline earth metal oxides and R2O represents the content of alkali metal oxides22) had a value of b > 0.76, which is consistent with typical calcium-based glazes.

Table 2 lists the elemental composition of the natural surface and polished cross-section of the glaze, as determined by EDS. The results for the cross-section were taken from a point deep within the glaze, which was free of corrosion and therefore considered to be representative of the original glaze4,5,9,12. The iron and carbon contents of the glaze surface were higher than that of the cross-section, which was ascribed to the gradual deposition of iron ions from ironware on the same ship and other external contaminants carried by seawater. The magnesium, potassium, and calcium contents of the glaze surface were lower than those of the cross-section, which was attributed to cation leaching and ion exchange between the alkali metals and alkaline earth metals in the glaze layer and H+/H3O+ in seawater. The ion concentrations of the marine environment are provided in Supplementary Table 123.

Analysis of concretions

The surface and cross-sections of the concretions attached to the sample surface were examined under a 3D ultra-depth optical microscope (Fig. 2a–d). The concretions had a complex morphology with significant heterogeneity. Porous mesh-like regions with a yellow skeleton structure were observed at the rim of the artefact and on the neighbouring glaze surface. The mesh-like regions had an irregular polygonal pore structure. The pores had diameters ranging from ~3 to 300 μm and were filled with black–brown material or translucent granules. Notably, pits of various depths were observed on the artefact surface beneath the concretions. Furthermore, the interface between the concretions and porcelain body was filled by an ~30-μm-thick corrosion layer.

a Surface of concretions on the exposed body at the rim of the artefact. A longitudinal crack is present at the rim (box 1). To the left of the crack, a brown concretion covers the outermost layer, and to the right, the pores in the yellow region are filled with black–brown material. b Surface of concretions on neighbouring glaze surface. A skeleton of porous structure with a yellow skeleton is present, with the smallest pore having a diameter of 3 μm (indicated by the red arrow), which represents the minimum pore size. c Cross-section of concretions on the exposed body at the rim of the artefact. Box 1 shows the top area of the concretions, with the outermost brown coating visible. Box 2 shows translucent crystals embedded within the yellow skeleton. Box 3 shows a brown interface layer (~30-μm thick) between the concretions and porcelain body, with pits on the body. d Cross-section of concretions. The red line marks a large translucent crystal embedded in a pore of the yellow skeleton, with a diameter of about 300 μm, which represents the maximum pore size. Box 1 shows the presence of pits on the glaze covered by the concretions. The red boxes mark the locations of the SEM images in Fig. 3.

The natural surface and bonding interface of the concretions (where they attached to the glaze) were analysed by ED-XRF (Table 3). The bonding interface did not exhibit black regions; therefore, only yellow–brown areas were analysed. The concretions exhibited severe iron contamination. In particular, the black–brown material filling the pores had an iron content of 73.5 wt%, along with a significantly lower silicon content (16.2 wt%) than the yellow skeleton of the porous structure (41.5 wt%). Therefore, the source of the black–brown material filling the pores is likely to be iron-rich material and sea sand. The potential sources of silicon in the yellow skeleton are discussed in Section “Discussion”. Notably, the bonding interface had a low calcium content (0.4 wt%), indicating an extremely low possibility of a calcareous skeleton. All regions also contained sulfur, which likely originated from sulfate salts from sea mud. Despite the protected subsurface location of the bonding interface, the iron concentration was slightly lower than that of the surface regions; therefore, it is unlikely to be representative of the original chemical composition of the yellow skeleton. This may be due to the 300 μm X-ray beam spot size, which may offer insufficient precision to accurately assess the composition of small features.

SEM-EDS further confirmed that the concretions had a heterogeneous composition (Table 4). The yellow skeleton of the porous structure was siliceous, with iron-based compounds and siliceous granules filling the pores. In addition, the silicon content of the filler material was significantly lower than that of the skeleton. These findings are consistent with the ED-XRF results.

The black–brown filler mainly comprised iron, with the ratio of iron at the surface to that in the cross-section being approximately 2:1. The iron content of the filler on the surface (P1 in Fig. 3a) reached 90.0 wt% (P1 in Table 4), whereas that in the cross-section (P2, P3 in Fig. 3b) decreased significantly to 34.7 wt% with an increase in the acquisition depth (P2 → P3 in Table 4). This indicates that the mesh-like porous structure of the concretions obstructed the penetration of iron-rich contaminants, leading to their deposition in the pores.

a Surface of the concretions (box 1 in Fig. 2a); b Cross-section of the concretions (box 1 in Fig. 2c); c Skeleton of porous structure with embedded material (enlarged image of the box in (a)); d Cross-section of concretion/porcelain body interface, with relatively well-preserved porous structures in the pits (box 3 in Fig. 2c); e Magnified image of porous structure in the porcelain body; f Siliceous granules embedded in the porous skeleton (box 2 in Fig. 2c). P1–P3: Black–brown fillers; P4–P7: Yellow skeleton of porous structure; P8–P10: Brown deposits; P11: A large siliceous granule.

No calcium was detected in the skeleton of the porous structure, and the silicon content was relatively high. The porous structures on the surface of the concretions were severely contaminated by iron-rich compounds (box in Fig. 3a, c; P4 in Table 4). However, the corresponding EDS elemental map (Fig. 4a) indicated that the skeleton was enriched with silicon, oxygen, and carbon. Moreover, further from the fillers, the Fe content of the skeleton decreased and the Si content increased (P4 → P5 → P6 → P7 in Table 4).

Figure 3d and Supplementary Fig. 1 show cross-sectional SEM images of the concretion/porcelain body (and glaze) interface, respectively. Some relatively well-preserved porous structures (Fig. 3d and box in Fig. 3e) were observed in the shallow pits of the porcelain body. The EDS data (P7 in Table 4) revealed that the composition was dominated by oxygen (39.8 wt%), silicon (26.3 wt%), and carbon (17.2 wt%), with negligible iron (1.2 wt%). Given that the position was isolated from the marine environment, this composition was considered to be close to that of the original skeleton.

The brown deposits in the outermost and bottommost layers of the concretions were predominantly composed of iron and oxygen (P8, P9, P10 in Table 4). The elemental map (Fig. 4b) revealed pronounced carbon enrichment in the outermost layer, with the local carbon concentration reaching 71.7 wt% (P9 in Table 4).

Numerous large siliceous granules were embedded within the pores (Figs. 3f and 4b). These granules mainly comprised silicon with a small amount of nitrogen (P11 in Table 4). The porous characteristics of the surrounding skeleton enable it to be clearly distinguished from adjacent phases.

EDS elemental line scans of the concretion cross-section (Fig. 5) showed that the carbon content peaked in the outermost region and declined sharply with depth. The carbon content was also high at the concretion/porcelain interface. The iron content followed a similar trend to the sulfur and oxygen contents, whereas the silicon content exhibited the opposite trend. These trends indicate that the glaze composition was altered by foreign pollutants. The magnesium, potassium, and calcium contents decreased gradually at the glaze surface, which may be ascribed to the high degree of de-alkalinisation of the glaze. The results are consistent with the EDS point analyses.

Figure 6 shows the XRD spectrum of the concretion surface, indicating that the concretions contained quartz, muscovite, albite, and microcline, which likely derived from marine mud. Characteristic regions of the concretions, including the natural surface and bonding interface, were also analysed by μ-Raman spectroscopy. The results indicated that the black–brown filler comprised magnetite and quartz (Fig. 7a, b); and the brown bonding interface at the bottom of the concretions comprised α-FeOOH, β-FeOOH, and γ-FeOOH (Fig. 7c, d). These findings corroborate the ED-XRF, EDS, and XRD results. Notably, the μ-Raman spectroscopy results also confirmed the non-crystalline nature of the translucent siliceous granules with diameters of >100 μm in the pores.

a, b Regions on black–brown filler corresponding to a quartz (RRUFF ID: R040031) and b magnetite (RRUFF ID: R060191); c, d Regions on brown bonding interface at the bottom of the concretions corresponding to c α-FeOOH (Goethite, RRUFF ID: R050142), β-FeOOH (National Museum of China), and γ-FeOOH (Lepidocrocite, RRUFF ID: R050454) and d γ-FeOOH.

Analysis of glaze corrosion

We examined the natural glaze surface and polished cross-section of the ceramic under a 3D ultra-depth optical microscope (Fig. 8). The glaze surface, and particularly the textural characteristics, was analysed at the same positions before and after carefully detaching the concretions (Supplementary Fig. 2). The corrosion features in the glaze were divided into three layers: inner corrosion layer (translucent matte region), intermediate corrosion layer (pale-yellow matte region and brown reflective region), and outer corrosion layer (brown matte region and black–brown shell-like substance). Figure 8a shows the transition zone at the interlayer boundary of different layers. Much of the glaze surface was covered with scratches, pits, and dark spots; these spots were densely distributed individually or in groups, with sizes comparable to the bubbles in the glaze (Fig. 8b). The glaze layer was clear, with interconnected bubbles forming channels that allowed deposits to reach deeper regions (Fig. 8c). Notably, one deep pit contained a residual porous structure, which likely originated from a large bubble within the glaze/porcelain body interlayer (Fig. 8d).

a Transition zone at the interlayer boundary on the glaze surface; b Dense dark spots, scratches, and pits distributed on the glaze surface; c Transparent glaze layer, with interconnected bubbles of various sizes; d Residual porous structure in a pit and large bubbles located at the glaze/porcelain body interlayer.

EDS point analyses (Table 5) revealed the elemental evolution across different corrosion layers and regions of the glaze surface. The iron content increased progressively from the inner corrosion layer to the outer corrosion layer; the silicon, potassium, and calcium contents peaked in the translucent matte region in the inner corrosion layer and declined thereafter; and carbon and sulfur were only detected in the intermediate and outer corrosion layers, with the carbon content peaking in the pale-yellow matte region next to the inner corrosion layer and the black–brown substances in the outer corrosion layer. These findings were consistent with the EDS elemental line scans of the concretion cross-section (Fig. 5).

As shown in Fig. 9, the morphologies of different corrosion layers and regions of the glaze surface differed significantly. The inner corrosion layer, in contact with the original glaze (Fig. 9a), was the corrosion front (Fig. 9b). The high-magnification SEM image (Fig. 9c) and EDS data (Table 5) revealed that this region comprised particulate aggregates with a high silicon content.

a Original glaze; b Inner layer (translucent matte region); c Magnified image of Fig. 9b, showing particulate aggregates; d Intermediate layer (pale-yellow matte region), showing the glaze surface after the concretions were peeled off; e Intermediate layer (brown reflective region); f Outer layer (brown matte region); g Outer layer (black–brown shell-like substance); h Spherical objects on corrosion layers.

The glaze surface (pale-yellow matte region in the intermediate layer) remained relatively well-preserved after concretion detachment, with some locally re-exposed bubble pits (Fig. 9d). The SEM-EDS results of the brown reflective region in the intermediate corrosion layer differed vastly from those of the inner corrosion layer, with the main components being iron (40.6 wt%) and carbon (12.3 wt%) (Table 5). In addition, a small amount of sulfur was present (0.4 wt%). The discrepancy between the compositions of the inner and intermediate corrosion layers was attributed to the spherical amorphous silica precipitates, which generated porous structures that served as open channels and accommodated deposited contaminants. Multiple microcracks were present in this region, as shown in Fig. 9e. Microcracking likely occurred due to volume contraction following ion exchange between the alkali metal and alkaline earth metal ions in the glaze with H3O+ in seawater24; H3O+ ions have a smaller radius than the original cations in the glaze, leading to local volume contraction that culminated in microcracking25. Microcracking may also have occurred due to shrinkage caused by dehydration upon removing the ceramics from seawater.

Figure 9f shows the brown matte region of the outer corrosion layer, which was characterised by a large amount of iron-rich corrosion products. The outermost brown crust (Fig. 9g) had a similar composition to the concretions, containing 78.3 wt% iron (Table 5). Finally, the spherical particles (Fig. 9h) observed on the corrosion layers displayed a typical binary-fission morphology of bacteria, with high contents of carbon (35.3 wt%), oxygen (31.1 wt%), silicon (10.5 wt%), and iron (21.4 wt%) (Table 5).

To explore the state of corrosion within the bubbles in the glaze, four representative spots were selected from regions with an absence of concretions. The results demonstrated that even bubbles enclosed deep in the glaze layer provided preferential sites for corrosion, with external contaminants being deposited within the bubbles. For instance, an open indentation formed by the connection of several circular pits (Fig. 10a); under higher magnification (Supplementary Fig. 3), multiple micro-cracks were observed on the inner walls of the pits. In another bubble, a pore was observed on the bottom surface (Fig. 10b), which connected it to another bubble via a bubble channel. These micro-cracks and pore channels provided pathways and deposition sites for external contaminants to penetrate deep within the glaze layer.

a Open indentation formed by the connection of several circular pits. The area in the box shows multiple micro-cracks on the inner walls of the pits (Supplementary Fig. 3); b A pore on the bottom surface; c Box 1 shows a severely corroded annular pit; Box 2 shows the area where the residual glaze in the annular pit is partially connected to the surrounding glaze surface; d Cross section of an annular pit.

Box 1 in Fig. 10c shows an annular pit with severe corrosion. To elucidate its corrosion mechanism, a cross-section of the pit was also analysed. As shown in Fig. 10d, a piece of residual glaze with an upturned crescent shape was suspended above the pit. A semi-circular gap between this piece of suspended glaze and the glaze layer was filled with Fe-rich contaminants. The other side of the residual glaze was partially connected to the surrounding glaze surface (box 2 in Fig. 10c) and had not yet become detached. Such fragile connections with the glaze surface may be gradually broken due to further corrosion or mechanical forces, causing the residual glaze to become detached. This would transform the annular morphology to a circular one. The corresponding elemental maps are shown in Fig. 11.

μ-Raman spectroscopy indicated that the main corrosion product in the brown reflective regions was β-FeOOH (Fig. 12a), whereas that in the brown matte region comprised both α-FeOOH and β-FeOOH (Fig. 12b). This result is consistent with the μ-Raman spectroscopy results for the bonding interface of the concretions. Differences in the chloride ion (Cl−) concentration may affect whether α- or β-FeOOH forms, as detailed in the Discussion.

Discussion

In this study, we investigated the potential corrosion mechanisms of a bluish-white porcelain of Hutian kiln of the Southern Song Dynasty excavated from the Nanhai No. 1 shipwreck, with a particular focus on the role of the bubbles in the glaze during the corrosion process. The existence of biofouling communities and ecological processes in specialized environments like shipwrecks point to possible sources of the concretions and their interactions with the bluish-white porcelain.

The glass phase, as the primary constituent of ancient ceramic glazes, has similar corrosion behaviour to that of silicate glass materials. When silicate glass contacts water, processes like hydration, hydrolysis, dissolution, diffusion, ion exchange, adsorption, crystal nucleation, and growth work together at the solid/liquid interface to achieve a new equilibrium or steady state26,27,28,29,30. The interactions between the bluish-white porcelain and seawater, therefore, would have involved congruent dissolution of the glaze due to the low silica content in the bulk solution. The dissolution reactions would be spatially and temporally linked to the precipitation of amorphous silica, causing the dissolution/precipitation interface to migrate into the glaze layer. These interactions led to the formation of a surface alteration layer (SAL) with a porous structure and randomly arranged amorphous silica nanoparticles of varying accumulation densities, as shown in Fig. 9c. Such corrosion-induced structural features would have acted as deposition sites for iron-based corrosion products from ironware on the same ship. Meanwhile, bacteria would attach to the organic matter enriched on porcelain surface, forming a biofilm31,32.

As the thickness of the SAL on the glaze increased, the hydrated silica species would have been hindered from diffusing into the bulk solution. This resulted in the accumulation of silicic acid and other glass-derived components at the interface, causing acceleration of the interdiffusion process26,27,28,29. Fe3+ that diffused into the SAL would undergo hydrolysis to form Fe(OH)3 (Eq. (1), where the down arrow indicates deposition), which would subsequently be converted to FeOOH through the action of iron-reducing bacteria (Eqs. (2) and (3). Under the regulation of the formed organic membrane, the microorganisms, as well as their redox enzymes and extracellular macromolecules, would all act as electron transporters on the mineral surface14, causing free iron ions to nucleate at the organic–inorganic interface through physicochemical effects. During this period, exposure to the Cl−-enriched marine environment would have contributed to the formation and stabilization of β-FeOOH, as Cl− could embed within its unique tunnel structure33. The aforementioned reactions resulted in the growth of iron-bearing minerals within the SAL, leading to the formation of brown reflective regions composed of β-FeOOH on the bluish-white glaze surface.

Bubbles were common in ceramic glazes during the Southern Song dynasty due to traditional production techniques. T’ao Ya (Pottery Refinements), a Qing Dynasty monograph on Chinese ceramics, references the aesthetic qualities of these bubbles: ‘Foam in the glaze is known as “spittle” if bubbles exhibit a beaded appearance. A rim that has an absence of foam bubbles but appears like a tear-filled eye is known as a “water eye”’34. However, these bubbles also serve as preferential initiation sites for the corrosion of bluish-white porcelains in marine environments. The dense circular or annular spots on the glaze surface correspond to shallow bubbles in the glaze layer.

The circular corrosion pits may have formed by two potential mechanisms: (1) mechanical fracture or hydrolysis of the thin glaze layer covering the bubble, and (2) spallation of the residual glaze at the centre of annular micro-bubble clusters. Furthermore, progressive reactions at the solid/liquid interface may have resulted in hydrolysis of the glaze layers between bubbles, thereby connecting the bubbles and creating channels for extrinsic contaminants and aqueous media to penetrate deeper into the porcelain body. When large bubbles situated at the glaze/porcelain body interface were exposed, they would promptly provide efficient corrosion pathways and offer significant space for larval colonization.

The concretions attached to the unglazed rim and neighbouring glaze surface exhibited a 3D interconnected porous structure. The well-preserved yellowish skeleton was contained in shallow pits in the glaze and porcelain body primarily comprised silicon, carbon, and oxygen, with no calcium and only a minor content of iron. Given that sponges (phylum Porifera) represent the sole taxon satisfying the dual criteria of (1) porous architecture and (2) siliceous skeletal frameworks35, this unambiguous diagnostic constraint compels the identification of the yellow porous structures within the concretions as sponge remains. However, taxonomic assignment at the species level remains unresolved. The following synergistic interactions may have occurred between the bluish-white porcelain and sponges.

Initially, the porcelain rim had local surface roughness owing to the inverted firing process (i.e., with the rim facing down). This would be exacerbated by mechanical collisions with marine debris and microstructural reorganisation. The extracellular polymeric substances secreted by the biofilm would have coated the rough substrate, forming a viscous layer36,37. Bacteria within the biofilm would therefore directionally attract the invertebrate larvae through quorum sensing-mediated signalling molecules38, and metabolites released by specific bacterial taxa would provide nutritional induction39. These phenomenon would have created suitable conditions for sponge larvae to selectively attach to the unglazed rim and neighbouring glaze surface40,41. Continuous reactions at the solid/liquid interface would lead to gradual hydrolysis of the glass framework, releasing large amounts of silicic acid (H4SiO4)30. As long as the released silicic acid did not exceed its solubility limit in aqueous media (<2 mmol/L), it would continue to diffuse to the external environment and be taken up by the cells or compartments of microorganisms, which would then accumulate and deposit silica in the form of amorphous hydrated silica through a process known as bio-silification42. Sponges actively absorb, accumulate, and deposit silica43,44,45,46,47. Their osteoblasts absorb silicic acid through Na+/HCO3−[Si(OH)4] transporters and store it in specific organelles, thereby forming immature siliceous spicules41.The translucent siliceous grains (>100 μm in diameter) within the pores of the yellow skeleton were amorphous, contrasting with marine sand detected in the black-brown fillers. Therefore, they may be siliceous granules that were stored in spong organelles for skeletal formation. This aligns with their relatively high nitrogen content (2.4 wt%), which is potentially linked to the secretion of nitrogenous alkaloids by sponges.

Alkaloids, which are nitrogen-containing organic compounds, are secreted by sponges as secondary metabolites and then dissolved in the surrounding water48. The binding of nitrogen to H+ releases free OH− ions (Eq. (4), where the alkaloids are represented by B), which then react with Fe2+/Fe3+ in seawater. This would lead to the precipitation of Fe(OH)3 (Eq. (5)) on the artefact surface beneath the attached sponges. Furthermore, sponges are filter-feeders that absorb and decompose large amounts of suspended organic matter in seawater, thereby serving as an important organic carbon sink. Waste-containing mucus is slowly ejected from the ostia of sponges and expelled into the surrounding seawater to ensure it does not obstruct the internal filtration system49. This may have purified the Fe(OH)3 formed by the alkaloids as it was deposited on the glaze surface along with fine sand (through bubble channels and cracks). The organic mucus moves continuously and accumulates on sponge surfaces, which may explain the abundance of carbon in the concretions, especially in the outermost layer.

Consequently, the silicate-based bluish-white porcelain and siliceous sponges would have co-existed through a silicon cycle. Silicon would enhances the structural stability and damage resistance of sponges and promotes their adsorption of bacteria and redox reactions50,51. The pliable mesohyl of the living sponges would have buffered the impact forces from wave-borne debris and suppressed the generation and extension of glaze cracks. Upon their death, the interwoven skeletal remains of the sponges would provide equivalent mechanical protection to the glaze52, while also acting as a filter, trapping contaminants within their mesh-like structure. The Fe(OH)3 that had not been expelled by the sponges would have been deposited at the interface between the concretion and artefact, where it was isolated from the marine environment. The concretions impeded ion transport, resulting in significantly reduced Cl− concentrations. Hence, the long-term ageing of amorphous iron oxyhydroxide may be the cause of α-FeOOH formation (brown matte regions)53. The α-FeOOH species bound to the β-FeOOH species (brown reflective regions) in the SAL via molecular cohesion; thus, these two species jointly constituted the interfacial corrosion layer. These corrosion products form under different pH conditions54. As the biofilm thickness increased, a steep pH gradient would have developed within it, with the exterior being alkaline and the interior acidic38. This pattern is consistent with the observed phenomenon of α-FeOOH forming in the upper layer and β-FeOOH in the lower layer. During this period, through the slow enrichment of the biofilm or organic template at the nucleation site, the local concentration would have slowly exceeded the solubility limit of mineral precipitation, promoting mineral growth14. γ-FeOOH may have formed from spongin fibres through biomineralisation55. It had been shown experimentally that γ-FeOOH reacts with ferrous ions to form magnetite56, which may be related to the black–brown filler in the pores; however, its formation mechanism remains unclear. Additionally, negatively charged functional groups (e.g., –C–O–C and –OH) in the organic mucus would exert strong adsorption effects on positively charged metal ions57,58, facilitating the chemisorption of corrosion products onto the bottom of the sponge remains, where they attached to the artefact.

Ultimately, part of the corrosion layers could be removed by gently peeling the sponge remains from the artefact surface. Irregular shapes with a matte texture, outlined by corrosion products, remained on the bluish-white porcelain glaze surface, resulting in a “map” of past sponge attachment.

Based on the above discussion, a schematic of the corrosion process of bluish-white porcelains in seawater and their complex interactions with siliceous sponges are shown in Fig. 13. The left side of each panel displays the corrosion process of the bluish-white glaze layer, while the right side shows the hypothetical synergistic interactions between the porcelain and sponges.

a Before the sponge adheres to the bluish-white porcelain, the artefact surface begins to undergo physical damage and chemical corrosion; b The sponge adheres to the rough surface, and glaze corrosion continues; c The sponge remains continue to protect the artefact surface after its death, while glaze corrosion continues; d Corrosion morphology of the surface of bluish-white porcelain after sponge peeling.

Data availability

No datasets were generated or analysed during the current study.

References

Wei, J. Archaeology of the shipwreck “Nanhai I” and protection of underwater cultural heritage. Cult. Heritage 1, 148–153 (2008).

Guangdong Institute of Cultural Relics and Archaeology, State Administration of Cultural Heritage Protection Center for Underwater Cultural Heritage. Underwater Archaeology Project of the Southern Song Dynasty Shipwreck “Nanhai I” in Guangdong (Guangdong Institute of Cultural Relics and Archaeology, 2022).

Liu, D. Research on Jingdezhen kiln bluish-white porcelain from the shipwreck “Nanhai I”. J. Cult. Hist. Stud. 2, 83–89 (2020).

He, Y. et al. Research on the degradation mechanism of the lead-glazed cups from the ‘Yangtze River estuary No. 2’ shipwreck. Open Ceram 14, 100360 (2023).

Zhou, B., Ma, Q., Li, Z., Zhang, Z. & Li, N. Corrosion of glaze in the marine environment: study on the green-glazed pottery from the Southern Song “Nanhai I” shipwreck (1127–1279 A.D.). Heritage Sci 11, 134 (2023).

Li, Z., Ma, Y., Ma, Q., Chen, J. & Song, Y. New perspective on Jun glaze corrosion: study on the corrosion of light greenish blue and reddish purple glazes from Juntai Kiln, Yuzhou, Henan, China. Heritage Sci 8, 2 (2020).

Ma, Q., Xu, S., Wang, J. & Yan, J. Integrated analysis of a black-glazed porcelain bowl in Tushan Kiln dated back to Song Dynasty, China. Mater. Chem. Phys. 242, 122213 (2020).

He, Y. et al. Chinese export porcelain in the middle Qing Dynasty: study on the blue-and-white porcelains excavated from the “Xiaobaijiao I” shipwreck. J. Archaeol. Sci. Rep. 38, 103024 (2021).

He, Y., Li, W., Li, J., Xu, C. & Lu, X. Corrosion of Longquan celadons in the marine environment: study on the celadons from the Dalian Island shipwreck of the Yuan Dynasty. Heritage Sci 9, 104 (2021).

Zhou, B., Ma, Q., Li, Z. & Chen, J. Corrosion research on Ru porcelain glazes excavated at Qingliangsi, Baofeng, China. Coatings 13, 1011 (2023).

He, Y., Li, W., Xu, C., Lu, X. & Sun, X. Degradation mechanism of the Ru wares unearthed from the Qingliangsi site in Henan, China. Ceram. Int. 48, 17131–17142 (2022).

Ding, R., Li, W., Yang, Z., Xu, C. & Lu, X. Degradation mechanism of a sauce-glazed ware of the Song Dynasty salvaged out of the water at Dalian Island Wharf: part I—the effect of the surface-attached composite coagula. Materials 16, 1176 (2023).

Yu, W. et al. Corrosion mechanism of ceramic glaze from the Yangtze Estuary II. Sci. China Technol. Sci. 66, 2246–2257 (2023).

Zhao, M. et al. Microbial corrosion on underwater pottery relics with typical biological condensation disease. Heritage Sci 11, 260 (2023).

Zhang, K., Wu, C., Zhao, J., Yu, W. & Zhao, M. The corrosion mechanism of lead-glazed pottery in Han dynasty. npj Materials. Degrad 8, 10 (2024).

Zhang, K., Zhou, W., Zhao, J., Zhao, M. & Luo, H. Research on the corrosion mechanism of ancient celadons from the Dalian Island No. 1 shipwreck. Stud. Conserv. 2024, 1–15 (2024).

Li, Y. et al. Corrosion mechanisms for lead-glazed pottery from Qibi Ming Tomb of the Tang Dynasty in Xianyang, China. Heritage Sci 12, 224 (2024).

Li, Z. Research on corrosion of ancient Chinese Jun glazed porcelain (University of Science and Technology, 2022); https://doi.org/10.26945/d.cnki.gbjku.2021.000383 (2022).

He, Y., Li, W., Li, J., Xu, C. & Lu, X. Research on the degradation of ancient Longquan celadons in the Dalian Island shipwreck. npj Mater. Degrad. 6, 4 (2022).

He, Y. et al. Study on pollutants in blue and white porcelain from the shipwreck of “Yangtze Estuary No. 2”. Cult. Relics Prot. Archaeol. Sci. 35, 1–16 (2023).

Xiong, Y. A Study on the coloring of ancient Chinese high temperature iron glazed porcelain. Cult. Relics Prot. Archaeol. Sci. 2012, 4551 (2012).

Luo, H., Li, J. & Gao, L. Classification criteria of calcium-based glazes in ancient Chinese porcelain and its application in the study of porcelain glazes. Bull. Chin. Ceram. Soc. 2, 50–53 (1995).

Huang, Q. et al. Scientific and technological analysis of the sea mud from the bottom of the Nanhai I shipwreck. J. Guangxi Minzu Univ. 29, 59–64 (2023).

Kunicki-Goldfinger, J. J. Unstable historic glass: symptoms, causes, mechanisms and conservation. Stud. Conserv. 53, 47–60 (2008).

Zanini, R., Franceschin, G., Cattaruzza, E. & Traviglia, A. A review of glass corrosion: the unique contribution of studying ancient glass to validate glass alteration models. npj Mater. Degrad. 7, 38 (2023).

Gin, S. et al. Nuclear glass durability: new insight into alteration layer properties. J. Phys. Chem. C. 115, 18696–18706 (2011).

Gin, S., Ryan, J. V., Schreiber, D. K., Neeway, J. & Cabié, M. Contribution of atom-probe tomography to a better understanding of glass alteration mechanisms: application to a nuclear glass specimen altered 25years in a granitic environment. Chem. Geol. 349-350, 99–109 (2013).

Verney-Carron, A., Gin, S., Frugier, P. & Libourel, G. Long-term modeling of alteration-transport coupling: application to a fractured Roman glass. Geochim. Cosmochim. Acta 74, 2291–2315 (2010).

Verney-Carron, A., Gin, S. & Libourel, G. A fractured roman glass block altered for 1800 years in seawater: analogy with nuclear waste glass in a deep geological repository. Geochim. Cosmochim. Acta 72, 5372–5385 (2008).

Doremus, R. H. Interdiffusion of hydrogen and alkali ions in a glass surface. J. Non Cryst. Solids 19, 137–144 (1975).

Characklis, W. G. & Marshall, K. C. Biofilms (Wiley, 1990).

Qian, P.-Y. et al. Marine Biofilms as mediators of colonization by marine macroorganisms: Implications for antifouling and aquaculture. Mar. Biotechnol. 9, 399–410 (2007).

Refait, P. & Génin, J.-M. R. The mechanisms of oxidation of ferrous hydroxychloride β-Fe2(OH)3Cl in aqueous solution: The formation of akaganeite vs goethite. Corros. Sci. 39, 539–553 (1997).

Chen, L. T’ao Ya (Pottery Refinements) (Jiyuan Book Series, Qing Dynasty, 1910).

Sol90 Editorial (Spain).Invertebrates: National Geographic Animal Encyclopedia (Invertebrados: Enciclopedia de Animales de National Geographic). Hardcover ed. (Shanxi People’s Publishing House, 2019).

Fingerman, M., Nagabhushanam, R. & Thompson, F. (eds). Recent advances in marine biotechnology: biofilms, bioadhesion, corrosion, and biofouling, vol. 3, 147–171 (Enfield, NH: Science Publishers, 1999).

Qian, P.-Y. et al. Relationship between bacterial community profile in biofilm and attachment of the acorn barnacle Balanus amphitrite. Aquat. Microb. Ecol. 33, 225–237 (2003).

Li, Z. et al. Effect of exogenous acylhomoserine lactone 3-oxo-C14-HSL on the performance of biofilm in moving bed biofilm reactor. J. Water Process. Eng. 64, 105595 (2024).

Huang, S. & Hadfield, M. G. Composition and density of bacterial biofilms determine larval settlement of the polychaete Hydroides elegans. Mar. Ecol. Prog. Ser. 260, 161–172 (2003).

Lei, Q. Benthic sessile animals from the Chengjiang Biota in Yunnan: their origin and evolution (Master’s thesis, China University of Geosciences, 2010).

Railkin, A. Marine biofouling: colonization processes and defenses (CRC Press, 2004).

Shi, J. Controllable synthesis of amorphous silica with different morphologies and its biomineralization significance (University of Science and Technology of China, 2013).

Hildebrand, M. Diatoms, biomineralization processes, and genomics. Chem. Rev. 108, 4855–4874 (2008).

Hildebrand, M. & Wetherbee, R. Components and control of silication in diatoms. In Progress in Molecular and Subcellular Biology, vol. 33 (ed. Müller, W. E. G.) 11–57 (Springer, 2003).

Perry, C. C. & Keelin-Tucker, T. Biosilicification: the role of the organic matrix in structure control. J. Biol. Inorg. Chem. 5, 537–550 (2000).

Brutchey, R. L. & Morse, D. E. Silicatein and the translation of its molecular mechanism of biosilicification into low temperature nanomaterial synthesis. Chem. Rev. 108, 4915–4934 (2008).

Sumper, M. & Brunner, E. Learning from diatoms: nature’s tools for the production of nanostructured silica. Adv. Funct. Mater. 16, 17–26 (2006).

Lu, W. Y., Li, H. J., Li, Q. Y. & Wu, Y. C. Application of marine natural products in drug research. Bioorganic Med. Chem. 35, 116058 (2021).

Kornder, N. A. et al. Sponges sneeze mucus to shed particulate waste from their seawater inlet pores. Curr. Biol. 32, 3855–3861.e3 (2022).

Schröer, H. C. et al. Silicase, an enzyme which degrades biogenous amorphous silica: contribution to the metabolism of silica deposition in the demosponge Suberites domuncula. In Progress in Molecular and Subcellular Biology, 33 (ed. Müller, W. E. G.) 249–268 (Springer, 2003).

Parr, J., Sullivan, L., Chen, B., Ye, G. & Zheng, W. Carbon bio-sequestration within the phytoliths of economic bamboo species. Glob. Chang. Biol. 16, 2661–2667 (2010).

Yu, H.-P. & Zhu, Y.-J. Guidelines derived from biomineralized tissues for design and construction of high-performance biomimetic materials: From weak to strong. Chem. Soc. Rev. 53, 4490–4606 (2024).

Misawa, T., Hashimoto, K. & Shimodaira, S. The mechanism of formation of iron oxide and oxyhydroxides in aqueous solutions at room temperature. Corros. Sci. 14, 131–149 (1974).

langmuir, D. & Whittemore, D. O. Variations in the stability of precipitated ferric oxyhydroxides. In Nonequilibrium Systems in Natural Water Chemistry, American Chemical Society Advances in Chemistry Series 106, 209–234 (American Chemical Society, 1971).

Mann, S. Biomineralization principles and concepts in bioinorganic materials chemistry (Oxford University Press, 2001).

Hiller, J.-E. Phasenumwandlungen im Rost. Werkst. Korros. 17, 943–951 (1966).

Jiang, X.-D. et al. Biomineralisation of the ferromanganese crusts in the Western Pacific Ocean. J. Asian Earth Sci 136, 58–67 (2017).

Tan, B. et al. Molecular insight into electron transfer properties of extracellular polymeric substances of electroactive bacteria by surface-enhanced Raman spectroscopy. Sci. China Technol. Sci. 62, 1679–1687 (2019).

Acknowledgements

The authors wish to express their gratitude to WITec for their kind support and assistance with this research. This research was supported by the Key Technologies and Application Demonstrations for the Protection of Marine Ceramic Cultural Relics (2023YFF0906400), the National Archaeological Talent Revitalization Plan Project (2024-276), and Key Project 1 of the National Social Science Foundation of China (23FKGA002).

Author information

Authors and Affiliations

Contributions

Y.Y. provided support and guidance for this study, provided the samples; Y.W. designed and performed all experiments, interpreted the data, and wrote and revised the manuscript; X.C. assisted with the Raman spectroscopy and XRD; N.L. acquired funding; and Q.W. provided assistance. All authors have read and approved the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, Y., Yu, Y., Li, N. et al. Corrosion mechanisms of a bluish-white porcelain of Hutian kiln excavated from Nanhai No. 1 shipwreck. npj Herit. Sci. 13, 359 (2025). https://doi.org/10.1038/s40494-025-01945-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s40494-025-01945-y