Abstract

This study validates the safety and demonstrates the pioneering application of infrared thermography (IRT) in the conservation of Xuan paper used in Chinese paintings. Through controlled halogen lamp simulations replicating 0–1800 thermal excitation cycles, we systematically evaluated effects on the physicochemical properties of Xuan paper, including ΔE color change, crystallinity, oxidation index, pH, and whiteness. The results confirmed minimal material impact (≤2.45% reduction in crystallinity, 1.22 decrease in pH after maximum exposure), thereby establishing operational safety parameters. In its first documented application to Ming Dynasty Xuan paper artworks, IRT identified over 60 concealed reinforcement strips, surface defects, and ink distribution patterns in Xishan Yuqiao Tu (Streams, Mountains, Fishermen and Woodcutters)—features undetectable by conventional visual examination. The technology’s ability to differentiate material properties through thermography highlights its potential as a valuable complement to existing non-destructive analysis methods, offering technical capabilities for the conservation and restoration of traditional Chinese paintings.

Similar content being viewed by others

Introduction

Chinese calligraphy and painting relics are vital cultural artifacts that embody the long history, rich traditions, and artistic achievements of Chinese civilization. However, these artifacts often suffer damage from natural and human factors, obscuring valuable historical information. Traditional inspection methods, such as visual observation and manual palpation, are limited by subjectivity and low efficiency, falling short of modern conservation needs. With technological advancements, a variety of scientific methods have been introduced into the study and preservation of these artifacts. Methods such as UV-Vis1 spectroscopy, Fourier-transform infrared spectroscopy (FTIR)2, hyperspectral imaging (HSI)3, micro-spatial offset Raman spectroscopy (micro-SORS)4, X-ray computed tomography (CT)5, X-ray diffraction (XRD)6, and microscopic analysis7 have been widely employed. These tools have significantly advanced our understanding of material composition8, deterioration mechanisms, and preservation strategies.

Among emerging techniques, infrared thermography (IRT) offers distinctive advantages owing to its non-contact, non-invasive nature and its ability to reveal subsurface features through thermal response analysis. Although IRT has not yet been widely applied to Chinese calligraphy and painting, it has demonstrated promising results in related fields such as historical architecture9, metal artifacts10, ceramics11, and mural or oil paintings12,13. These applications highlight its potential for broader adoption in cultural heritage research and suggest valuable opportunities for exploring its suitability for more delicate and thermally sensitive artifacts, such as calligraphy and painting relics.

Paper-based cultural relics are particularly sensitive to light and heat, raising concerns about the safety of applying IRT to such artifacts. Nevertheless, IRT presents distinct advantages—such as rapid detection, large-area coverage, and non-contact operation14—making it a promising technique for the inspection of large-scale calligraphy and painting works. Investigating its use in this context constitutes an innovative extension of nondestructive testing methods.

This study investigates the feasibility and safety of applying IRT to paper-based cultural heritage. Using Xuan paper—the traditional medium uniquely associated with Chinese calligraphy and painting—we analyze key indicators such as infrared spectral characteristics and pH values to assess potential thermal effects and establish safe operating parameters. In addition, micro-fading testing (MFT) plays a key role in assessing photostability15. By exposing a micro-area to intense visible light and monitoring real-time fading, MFT simulates long-term light exposure and predicts fading risks. These data are essential for evaluating light sensitivity16 and informing appropriate museum lighting standards17.

As the first study to apply IRT to Chinese calligraphy and painting relics, this work identifies potential use cases and lays the foundation for broader applications. The findings help define the scope of IRT and provide a scientific basis for advancing nondestructive testing in the conservation of paper-based artworks. This pioneering approach expands the methodological toolkit available for the study and preservation of thermally sensitive cultural heritage.

Methods

This study evaluates the feasibility of IRT for Xuan paper-based cultural relics through a two-pronged approach: (1) laboratory-based safety assessments using controlled sample experiments, and (2) practical applicability tests conducted on Ming Dynasty paintings.

Safety assessment of IRT on Xuan paper specimens

Before applying IRT to the examination of paper-based cultural relics, a comprehensive safety assessment is essential. Given the inherent photosensitivity and thermal fragility of historical paper artifacts, even minor alterations during inspection may compromise their integrity and cultural value. This study undertakes systematic multi-parametric evaluations of the potential impacts on physicochemical properties of Xuan paper. The findings aim to establish scientifically validated protocols to ensure the safe and responsible application of IRT in the conservation of paper-based cultural heritage.

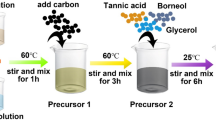

Sample preparation

This study employed Hongxing-brand Xuan paper as a representative surrogate for traditional artifacts. Composed of 80% wingceltis fiber and 20% Shatian rice straw, the paper is produced using traditional techniques. While the exact composition of sizing agents (likely starch or animal glue) and additives (possibly alum) remains proprietary, the overall process reflects historical manufacturing practices. To better simulate real historical artwork, the experimental Xuan paper specimens were subjected to 72 h of ultraviolet aging.

Fabricated using ancient handmade methods, the paper’s fiber structure and physical characteristics closely resemble those of historical Xuan paper relics. Microstructural analysis (Leica S9i Stereo Microscope, 500×) revealed distinct features: semi-transparent wingceltis fibers interwoven with shorter rice straw fibers, forming a porous yet tightly bonded network. The non-uniform fiber lengths and random orientation further confirm traditional manual production (Fig. 1).

To ensure experimental consistency, a single sheet of Xuan paper (35 × 27 cm) was precisely cut into nine equal sections for repeated thermal excitation cycles, as illustrated in Fig. 2.

Characterization methods

Active IRT involves applying an external heat source to stimulate the sample, inducing thermal energy diffusion. Variations in material properties and internal structures cause differences in thermal conductivity, resulting in surface temperature contrasts. In this study, all samples were subjected to repeated thermal excitation using two 1.3 kW halogen lamps to simulate typical IRT conditions. The paper surface exhibited a temperature increase of approximately 7 °C. Each thermal cycle consisted of 3.0 s heating phase (lamp on) followed by a 60.0 s cooling phase (lamp off). Seven groups of samples were exposed to different numbers of thermal cycles: 0 (control), 300, 600, 900, 1200, 1500, and 1800, followed by subsequent analysis. The instruments and equipment used to analyze the Xuan paper after light exposure are listed in Table 1.

Micro-fading testing and ΔE values

Micro-fading testing (MFT) is an emerging nondestructive technique that quantifies color change (ΔE) per unit time. Whitmore et al.17 applied MFT to cultural heritage materials, including woodblock prints, watercolor paintings, and textiles, identifying light-sensitive materials (ΔE/hour > 2). Vannucci et al.18 further compared ΔE kinetics between natural and synthetic dyes, revealing faster degradation rates in natural dyes; these findings directly informed museum lighting guidelines. Notably, Duan et al.19 demonstrated that MFT requires 10–40 times less exposure than standard fading tests. Collectively, prior studies validate the correlating between ΔE magnitude and degradation severity20. Given these advantages, MFT was employed as a primary methodology for this study.

The CIE 1976 (CIELAB)21 standard was adopted for all ΔE measurements. Three measurements were taken at randomly selected areas with similar fiber composition. Each sample underwent three 2-minute exposures under controlled illumination (400–750 nm LED, 0.5 mm spot size, 2 W/cm² irradiance), resulting in a cumulative dose of 245 J/cm².

Crystallinity (Cr)

Paper crystallinity refers to the proportion of crystalline (ordered) regions within the cellulose matrix relative to the total cellulose content. During deterioration, these crystalline structures break down and convert into amorphous (disordered) regions22, leading to reduced crystallinity. Consequently, crystallinity serves as a critical indicator of a paper’s physical properties, structural integrity, and chemical composition.

In this study, crystallinity was assessed using a D8 Advance X-ray diffractometer. Samples were horizontally mounted, and continuous scanning was carried out at a rate of 5°/min over a 2θ range of 10–40° to generate X-ray diffraction (XRD) patterns. To reduce measurement uncertainty, 10 scans were performed at different regions of similar fiber composition. The resulting patterns were processed using Jade software to extract crystallinity parameters. Cellulose crystallinity was calculated using the Segal method23, as follows:

where \({I}_{c}\) is the intensity of the crystalline peak (mainly from the cellulose (200) plane at 22.5° 2θ), and \({I}_{\alpha }\) is the intensity of the amorphous region (measured from the diffuse halo between approximately 15–20° 2θ, representing the non-crystalline cellulose components).

Oxidation index (OI)

The oxidation index reflects the concentration of carbonyl groups formed through oxidative degradation and serves as a critical indicator of paper aging, preservation status, and durability. A higher oxidation index signifies greater carbonyl formation in cellulose, corresponding to enhanced mechanical degradation and advanced aging24.

In Fourier-transform infrared spectroscopy (FTIR), peaks in the 3000–2800 cm−1 region correspond to C-H stretching vibrations related to cellulose degradation, while those in the 1900–1500 cm−1 region are attributed to carbonyl and double-bond vibrations from oxidation products. These two spectral regions respectively represent cellulose degradation and the formation of the oxidation product. The oxidation index is defined as the ratio of the integrated peak areas between these two specific wavenumber ranges25, calculated as:

where A1900–1500 is the integrated area of carbonyl-related peaks (1900–1500 cm−1), and A3000–2800 is the integrated area of C-H stretching peaks (3000–2800 cm−1). FTIR spectra were acquired using a spectrometer equipped with an ATR (Attenuated Total Reflection) accessory, at 1 cm−1 resolution, with 32 scans collected over the range of 4000–400 cm−1. For each sample, 10 replicate measurements were taken at different locations with similar fiber composition.

pH Value

The pH value of paper reflects its acidity or alkalinity and is closely linked to its durability and preservation state. Acidic substances such as lignin, alum, and environmental pollutants can catalyze cellulose hydrolysis, leading to reduced polymerization26. Lower pH values (i.e., higher acidity) accelerate degradation, making paper more prone to aging and damage.

Surface pH measurements were carried out in accordance with the Chinese national standard GB/T 13528-2015 (Paper and board—Determination of surface pH; Standardization Administration of China (SAC), 2015)27. The standard specifies the contact electrode methodology under controlled environmental conditions. A calibrated pen-type pH meter (Model pH5F-E, flat-surface combination electrode) was used, and the testing protocol included: (1) three-point calibration with standard buffers solutions (pH 4.00, 7.00, and 10.01) with automatic temperature compensation; (2) uniform surface moistening per Section 5.2 of the standard; (3) four replicate direct-contact measurements at randomized locations, following the standard’s statistical requirements; and (4) systematic recording of all values with a resolution of ±0.1 pH units as specified.

Whiteness value (WV)

Paper whiteness, expressed as a percentage, quantifies surface light reflectance and serves as an indicator of aging or degradation. As paper ages, cellulose and other components undergo oxidation and hydrolysis, producing chromophores such as carbonyl groups and conjugated double bonds28. These compounds increase light absorption, reduce whiteness, and lead to the characteristic “yellowing” of aged paper. Simultaneously, mechanical strength declines, raising the risk of damage.

In this study, ISO brightness (R457) was measured in accordance with ISO 2470-1:2016 (Paper, board and pulps — Measurement of diffuse blue reflectance factor (ISO brightness), Part 1: Indoor daylight conditions)29 using a WSB-1 whiteness meter, employing a 4 mm measurement aperture and automatic calibration. For each sample, 16 replicate measurements were conducted at randomly selected locations, with results expressed as a percentage relative to a magnesium oxide standard.

Applicability assessment of IRT for Xuan paper paintings

As a promising technique for analyzing Xuan paper, IRT has attracted growing research interest. Chinese calligraphy and painting artifacts, as important cultural treasures, present significant challenges for traditional examination methods. With its unique advantages, IRT offers new opportunities for the non-invasive inspection of these heritage objects.

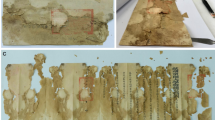

Sample description

This study examined a Ming Dynasty Xuan paper artwork from the History Museum of Capital Normal University: Xishan Yuqiao Tu (Streams, Mountains, Fishermen and Woodcutters, hereafter Streams and Mountains), a vertical scroll ink painting, measuring approximately 131.3 × 32 cm. This is a color-ink painting, containing not only carbon-based ink strokes but also mineral pigments or organic dyes, though the specific pigment types remain unidentified. This composition portrays an idyllic riverside village: houses nestled among dense trees, farmers returning home with hoes, fishermen punting along winding streams, and a lone pagoda rising against verdant mountains. In the upper-left corner, the artist Wen Jia inscribed a poem:

“Pagoda shadows slant across the doorway,

Stream sounds flow straight to the threshold.”

Wen Jia (文嘉, 1499–1582), courtesy name Xiucheng [休承], art name Wenshui Daoren [文水道人]30, was the son of renowned painter Wen Zhengming (文徵明, 1470–1559). He inherited his father’s techniques and excelled in landscape painting, known for elegant brushwork and the serene charm of his colored scenes31.

Experimental Procedures

The experimental setup is illustrated in Fig. 3. Two 1 kW halogen lamps, mounted on a rotating platform to ensure uniform thermal excitation, served as heat sources. Due to the large size of the artwork, it was divided into five sections for sequential scanning. Thermal images were captured using a Blackbird uncooled infrared camera (Jenoptik, Germany; model: Precision), operating in the 8−14 μm spectral range with a thermal sensitivity (NETD, noise equivalent temperature difference) of 30 mK. The working distance was 50 cm, providing a system spatial resolution of 0.45 mm/pixel. For each experiment, a frame rate of 30 Hz was used. The sample was heated for 1 s, followed by 10 s recording period, during which the blanked surface exhibited an 8 °C temperature rise (since aging of the paper increases the optical absorptivity and infrared emissivity). Subsequent image processing and stitching were performed using custom-developed defect detection software.

Results

The experimental results are presented in two sections: the first evaluates the impacts of IRT on Xuan paper to assess safety, while the second demonstrates its diagnostic potential through case studies of Ming Dynasty paintings.

Safety assessment

The experimental data for each safety indicator (ΔE, crystallinity, oxidation index, pH, and whiteness) are presented below.

Micro-fading testing and ΔE values

During the MFT process, ΔE of the samples was recorded before and after each standard 2-minute micro-fading white-light exposure. Average ΔE values were calculated and plotted, as shown in Fig. 4. The histogram reveals a general increase in ΔE values with the number of IRT thermal excitation cycles. Although the MFT results show a progressive increase in ΔE (reaching 0.9 after 1800 cycles), these changes remain below the human perceptibility threshold (ΔE < 1.5) defined by CIE LAB standards. This suggests that accumulated thermal excitation effects of IRT do not produce visually detectable color variations under the tested conditions. Nevertheless, the upward trend in ΔE with increasing thermal cycles indicates gradual degradation of the Xuan paper. Further metrics will be explored to validate this hypothesis.

Crystallinity changes

Figure 5 presents the XRD patterns obtained after different thermal excitation cycles. The diffraction profile exhibits a minor peak around 29.2°, which may indicate the presence of hemicellulose or lignin derived from the wingceltis fiber. The main crystalline peak at 22.5° corresponds to the cellulose (002) plane, while the broad diffraction band between 10° and 20° is attributed to the amorphous regions of the sample.

Statistical analysis was performed on each parallel dataset processed through Jade software and further analyzed using Origin. To illustrate the overall variation trend, mean values and standard deviations were calculated across datasets, and aggregated scatter plots were generated accordingly. Trend analysis was performed using Locally Weighted Scatterplot Smoothing (LOWESS), which applies distance-weighted polynomial regression to local data subsets, effectively capturing nonlinear trends while remaining robust to outliers.

LOWESS regression was applied to the scatter plot data using a span of 0.7, tricube weighting, and 2 iterations. Figure 6 shows the smoothed trendline revealing a slight decrease in crystallinity with increasing thermal excitation cycles. The observed fluctuations likely reflect the paper’s heterogeneous microstructure and localized crystallinity. Crystallinity changes (ΔCr) after different numbers of thermal cycles are summarized in Table 2 (mean ± SD). After 1800 cycles, crystallinity decreased by 2.45%. A paired t-tests comparing 0 and 1800 cycles, yielded p > 0.05, suggesting that the reduction was not statistically significant.

Oxidation Index Changes

The oxidation index (OI) was determined from FTIR spectral, as shown in Fig. 7. Baseline-corrected spectra in the 3000–2800 cm−1 and 1900–1500 cm−1 regions (Fig. 8) were subjected to peak integration. Based on characteristic vibrational modes: (1) The 3000–2800 cm−1 region contains the aliphatic C-H stretching band near 2900 cm−1, characteristic of the cellulose and hemicellulose backbone, and was selected as the internal reference peak; (2) In the 1900–1500 cm−1 region, carbonyl (C=O) and conjugated double bond vibration bands within 1650–1730 cm−1 were analyzed. These include potential subpeaks at 1710 cm−1 (free carboxyl/ketone), 1735 cm−1 (ester/aldehyde), and 1650 cm−1 (amide I). Peak deconvolution was performed using a Voigt profile (Gaussian-Lorentzian hybrid function with a fixed 1:1 G/L ratio), iteratively optimized until a coefficient of determination (R²) ≥ 0.99 was achieved. Only subpeaks with physically meaningful parameters (FWHM < 30 cm−1, peak position deviation < ±2 cm−1) were retained. The sum of integrated areas of these subpeaks was recorded for each spectrum, and the resulting datasets were statistically analyzed (mean ± SD). As shown in Fig. 9, LOWESS-smoothing (span = 0.7, tricube weighting, 2 iterations), revealed a cumulative ΔOI of +0.25 after 1800 thermal cycles. However, a paired t-test comparing the initial and final OI values indicated that this increase was not statistically significant (p > 0.05). Complete numerical results are provided in Table 3.

pH value changes

The pH values were analyzed using Origin to generate scatter plots with means and standard deviations. LOWESS regression (span = 0.7, tricube weighting, 2 iterations) revealed a gradual acidification trend with increasing thermal excitation cycles, as shown in Fig. 10. Mean ΔpH values and standard deviations are listed in Table 4, showing a net pH decrease of 1.22 after 1800 cycles. A paired t-test comparing the 0 and 1800 cycles group indicated that the observed change was not significant (p > 0.05).

According to GB/T 18739-2008 (Geographical indication products—Xuan paper)32 and GB/T 464-2008 (Accelerated aging of paper and board)33, dry heat aging at 105 ± 2 °C provides a standard method to simulate natural aging in traditional Xuan paper. In our experiment, the pH decrease observed after 1800 thermal excitation cycles was comparable to that caused by 30 days of dry heat aging in Hongxing-brand Xuan paper34,35. Previous studies further suggest that 3 days of dry heat aging approximate 18–25 years of natural aging in industrial paper36,37. While no definitive conversion exists for Xuan paper, we used these reported values to estimate the equivalent natural aging duration for our samples.

Given that Xuan paper generally ages more slowly than industrial paper, this approach likely overestimates the actual aging extent. Nonetheless, the conversion is used here solely for preliminary assessment38,39. Based on this correlation, one pair of 1.3 kW halogen lamp excitation may correspond to roughly 0.4 h of dry heat aging or 1–1.5 months of natural aging. However, this estimate should be interpreted with caution, considering the experimental variability (as indicated by the non-significant t-test result) and the inherent differences between photothermal and purely thermal aging mechanisms.

Whiteness Value Changes

Whiteness values were measured using a whiteness tester and analyzed in Origin to calculate mean and standard deviations. Aggregated scatter plots were generated, and a LOWESS smoothing (span = 0.7, tricube weighting and 2 iterations) was applied to reveal the overall trend, as shown in Fig. 11. The results indicated a general decline in whiteness with increasing thermal excitation cycles. The average change in whiteness after each cycle, denoted as ΔWV, along with the corresponding standard deviations, is summarized in Table 5. After 1800 cycles, the whiteness decreased 8.11%. However, a paired t-test comparison of 0 and 1800 cycles showed that the observed change was not statistically significant (p > 0.05).

Despite the lack of statistical significance, the observed trend may still hold research value. As in previous analyses, it can be preliminary estimated that 1800 cycles correspond to approximately 30 days of dry heat aging34,40.

Results from the five assessment methods indicate that a single IRT excitation has a negligible effect on Xuan paper, supporting its suitability for the inspection of calligraphy and painting relics. To further minimize potential impact, subsequent experiments on real artifacts will employ two 1 kW halogen lamps (reduced from 1.3 kW) with a 1 s thermal excitation duration (reduced from 3 s).

Application Evaluation

In this study, Thermal Signal Reconstruction (TSR)41 is employed to analyze time-resolved thermal responses at the pixel level. By applying a natural logarithmic transformation to both temperature and time, the cooling curves are linearized and fitted with a polynomial function. The first- and second-order derivatives of this fitted polynomial are then calculated to suppress noise and enhance contrast. The resulting first-order thermal image, obtained through gradient analysis, highlights subtle features and improves defect detectability within the thermal sequence.

Figure 12 presents different imaging modalities of the artwork: (a) the visible light image, (b) the original thermal image (frame 2), and (c) the first-order thermal image (frame 24). Different frames were selected at specific time intervals after heating to optimize thermal contrast. Due to the large dimensions of the artwork, the IRT experiment was conducted by dividing the scroll into five sections, as shown on the right side of Fig. 12, which were later stitched together. By comparing the original and first-order thermal images with the visible light image, the analysis focuses on identifying reinforcement strips, surface damage, and color filling conditions.

Detection of Reinforcement Strips in Artworks

As illustrated in Fig. 13, thermal anomalies in a section of Streams and Mountains appear as black horizontal lines of varying lengths in the original thermal image. These lines correspond to white horizontal features in the first-order thermal image but are invisible in the visible light image. Upon physical inspection and consultation with conservation experts, these lines were identified as traces of reinforcement strips applied during restoration. These paper strips were used to reinforce cracks and folds in the artwork, as indicated by the red-outlined areas of (Fig. 13b, c). Most reinforcement strips in this painting are approximately 0.35 cm wide, while the thermography system can detect strips as narrow as 0.15 cm (>3 pixels). For the detection of finer details, a higher-resolution IR camera or optimized optical system would be required.

Quantitative analysis of the Streams and Mountains artwork reveals more than sixty reinforcement strips, with a particularly high concentration in the mountainous upper section, suggesting more frequent damage from cracking and creasing in that area.

From a conservation monitoring perspective, the higher density of repairs in the mountainous region may be attributed to the characteristics of the ink pigments, such as variations in ink concentration and brushstroke intensity. The predominantly black mountainous areas, likely formed through multiple layers of ink to enhance depth, may have absorbed more pigment, increasing the paper’s fragility. As a result, these areas are more susceptible to damage during mounting and long-term storage.

Identification of delamination traces on Xuan paper

Delamination refers to the separation between paper, pigment, or mounting layers, typically caused by adhesive deterioration or environmental stress. It represents a common form of structural degradation in cultural heritage materials.

IRT enables the detection of surface damage that is difficult to observe under visible light. As shown in areas ① and ② of (Fig. 14a), the defects are barely perceptible to the naked eye, requiring side lighting and close inspection. For demonstration, area ①, showing more pronounced damage, was selected, magnified, and enhanced in sharpness and contrast (Fig. 14(d), blue box). In contrast, the thermographs, particularly the first-order TSR images (Fig. 14c), clearly delineate the defect boundaries, improving interpretive accuracy.

Careful observation reveals delamination traces are predominantly concentrated in the heavily inked mountainous areas, often aligned with brushstroke directions. In contrast, such defects are less apparent in the middle and lower sections of the painting. This indicates better preservation in the lower part, likely due to storage practices: the scroll was probably rolled from bottom to top, leaving the upper section exposed. Prolonged exposure to humidity and poor ventilation may have made this area more vulnerable to insect infestation and environmental degradation. These findings not only illustrate the spatial distribution of deterioration but also provide insight into the artwork’s storage history, emphasizing the value of IRT in conservation diagnostics and restoration planning.

Assessment of color filling conditions

Pigmentation traces refer to minute, visually imperceptible residues of ink or pigment in ancient Chinese calligraphy and paintings. These include original pigments retained in faded areas, as well as retouching marks from past restorations. Although often invisible to the naked eye, such traces can provide valuable insights into the artwork’s material composition and conservation history.

IRT detects subtle pigmentation traces invisible to the naked eye by capturing surface temperature difference, thereby aiding in the identification of coloration. In the regions marked by red squares (① and ②) in Fig. 15a, pigmentation at the red and blue arrow-indicated spots is difficult to discern visually, yet IRT analysis reveals distinct thermal contrasts. Areas between bridges, along building edges, and among tree branches appear darker in the original thermal image and brighter in the first-order thermal image.

In thermal images, unpainted areas appear cooler and darker due to their low optical absorptivity and infrared emissivity. The broader background may have been lightly underpainted, either by the artist or later conservator to stabilize the artwork. The sharp boundaries of the dark regions (red arrows) in the original thermal image suggest that some areas were deliberately left unpigmented to prevent ink bleeding. Although indistinguishable under visible light, thermography reveals these subtle material differences. Notably, such variations are more apparent in the original thermal image than in the 1st order thermal image. This is because the original thermal image directly reflects surface temperature, while the 1st order derivative emphasizes temperature gradients. Thus, the original thermal image offers a more reliable basis for assessing color application in conservation.

Comparison with visible-light imagery shows that black ink lines and heavily pigmented regions generate strong thermal signals due to their higher optical absorptivity and IR emissivity, demonstrating the utility of IRT in analyzing traditional Chinese ink paintings. By contrast, red seal marks, shown in Fig. 16, are nearly invisible in thermal images, likely due to their thermophysical properties being similar to those of the surrounding blank areas. Limitations in the sensor’s spectral range or materials sensitivity may also play a role. This offers a new perspective for studying ancient seal paste materials. However, the thermophysical properties of traditional Chinese pigments and seal paste (e.g., absorptivity, emissivity, thermal conductivity) remain poorly understood, underscoring the need for further research to support IRT interpretation in heritage studies.

Discussion

In terms of safety, the preliminary multi-parameter evaluations have verified the safety of applying IRT to the UV-aged Xuan paper samples. However, further investigation is needed to fully assess its impact, considering the physicochemical properties of Xuan paper artifacts.

In this study, even after 1800 thermal cycles, the Xuan paper samples exhibited only a 2.45% decrease in crystallinity, a pH variation of 1.22, and a color change (ΔE) below the human perception threshold (ΔE < 1.5). Considering that one thermal cycle is approximately corresponds to 1–1.5 months of natural aging, these results indicate a minimal impact of thermal excitation on the samples. However, this study is limited by the exclusive use of Hongxing-brand Xuan paper, which contains 80% wingceltis fiber. Factors such as brittleness, fiber composition, and lignin content may influence the thermal response of Xuan paper. For example, highly brittle paper could be more susceptible to microstructural deformation under thermal excitation, while variations in fiber packing density might cause localized temperature differences due to uneven heat conduction. Additionally, areas with higher lignin content may be more prone to oxidation and related degradation processes. Therefore, the results may differ for Xuan paper produced from different raw materials or manufacturing techniques, as well as for other types of calligraphy and painting materials. Moreover, environmental factors such as temperature, humidity, and lighting further influence results—high humidity, in particular, affects paper moisture content, altering heat conduction and potentially distorting thermal images.

In terms of application, this study employed IRT to examine the museum-held Xuan paper artwork Xishan Yuqiao Tu, demonstrating the method’s potential in the non-invasive inspection of Chinese paintings on Xuan paper. IRT proved particularly effective in detecting structural damage, pigment layer variations, and concealed restoration traces, showcasing its unique advantages in heritage conservation.

The accuracy of such detection is closely tied to the precision of the instrumentation used. For example, higher spatial resolution and better NETD in thermographic systems significantly enhance the ability to identify fine or subtle damage. As technology advances, improvements in sensor performance will further extend IRT’s applicability in detecting micro-defects.

To further contextualize IRT’s role, it is important to consider complementary imaging methods commonly used in cultural relic analysis. Transmitted Light Photography (TLP), which utilizes visible light to image semi-transparent materials, and Hyperspectral Imaging (HSI), integrating spatial and spectral data for material identification, each offer distinct benefits. TLP excels in revealing subsurface lines beneath surface layers but requires access to both sides of the artifact and has limited penetration depth. HSI effectively detects hidden ink traces and pigment compositions, yet its capability for probing deeper structural information remains limited. In contrast, IRT leverages thermal properties to non-invasively penetrate multilayer structures, enabling the identification of concealed flaws such as creases, patches, and deeper issues beneath opaque pigment layers. Particularly for artifacts mounted on rigid substrates or those inaccessible from both sides, IRT provides critical insights into mounting adhesion and internal deterioration. Together, these techniques present complementary strengths that suggest great potential for synergistic application in heritage research and conservation. TLP offers high-resolution surface detail, HSI reveals hidden pigments and inks, and IRT assesses deeper structural defects. Future integration and data fusion of these modalities could enable comprehensive, multidimensional diagnostics of painting and calligraphy damage. Further interdisciplinary research is needed to optimize these collaborative approaches and develop advanced, integrated detection methodologies.

Given the potential for long-term cumulative effects, caution is especially warranted for aged paper relics with already degraded fibers. Future studies should focus on methodological improvements, including: (1) systematic classification of Xuan paper samples by age and composition (e.g., varying wingceltis fiber content); (2) stricter control of environmental conditions during experiments; (3) optimization of halogen lamp parameters such as power output and irradiation duration; and (4) integration of scanning electron microscopy (SEM) for detailed analysis of fiber microstructural changes. These steps are essential for developing a robust safety assessment framework. Moreover, systematic investigations into the thermal properties (e.g., absorptivity, emissivity, and thermal conductivity) of traditional Chinese pigments remain scarce. Further simulation studies on diverse calligraphy and painting materials are needed to elucidate the characteristic infrared thermography signatures of various pigments. Consequently, the detection performance of IRT for traditional Chinese cultural relics requires further validation and in-depth exploration.

In summary, as a non-invasive diagnostic technique, IRT shows considerable promise for the conservation and restoration of Xuan paper-based cultural artifacts. Although its safety has been supported by multiple indicators, parameter optimization tailored to specific artifact conditions is necessary to mitigate potential risks. Compared with existing methods, IRT offers unique advantages in detecting subsurface defects, and its integration with complementary technologies can enhance diagnostic accuracy. Through such multi-modal approaches, IRT can provide comprehensive analytical tools and theoretical foundations for cultural heritage preservation, fostering continuous innovation in the protection of traditional paintings and calligraphy. Ongoing research and practical application of this technology will undoubtedly contribute significantly to safeguarding and perpetuating invaluable cultural heritage.

Data availability

Data sets generated during the current study are available from the corresponding author on reasonable request.

References

Dang, R., Yang, Y., Kang, Y. & Tan, H. Revealing the photochemical damage behavior of acidified Xuan paper based on the spectroscopic investigation and principal component analysis. Spectrochim. Acta A Mol. Biomol. Spectrosc. 303, 123244 (2023).

Yao, J. et al. Spectroscopic detection and analysis for micro structure of aged traditional handmade paper. Spectrosc. spect. anal. 41, 1559–1565 (2021).

Legrand, S. et al. Examination of historical paintings by state-of-the-art hyperspectral imaging methods: from scanning infra-red spectroscopy to computed X-ray laminography. Herit. Sci. 2, 1–11 (2014).

Vermeulen, M., Conti, C., Matousek, P., Lora, V. A. & Alessandra, B. Unravelling hidden text and figures in paper-based archival documents with micro-spatially offset Raman spectroscopy imaging. Spectrochim. Acta A Mol. Biomol. Spectrosc. 329, 125591 (2025).

Mocella, V., Brun, E., Ferrero, C. & Delattre, D. Revealing letters in rolled Herculaneum papyri by X-ray phase-contrast imaging. Nat. Commun. 6, 5895 (2015).

Hajji, L. et al. Conservation of Moroccan manuscript papers aged 150, 200 and 800 years. Analysis by infrared spectroscopy (ATR-FTIR), X-ray diffraction (XRD), and scanning electron microscopy energy dispersive spectrometry (SEM-EDS). Spectrochim. Acta A Mol. Biomol. Spectrosc. 136, 1038–1046 (2015).

Castillo-Hernández, D., Sánchez-Ramírez, F., Jiménez-Pérez, J. L., Cruz-Orea, A. & Correa-Pacheco, Z. N. Study of ancient paper and detection of microbiological contamination using photoacoustic technique. Int J. Thermophys. 41, 36 (2020).

Gu, A. & Shen, W. Nondestructive identification of book and painting seals using near-infrared spectroscopy combined with Chemometrics (in Chinese). Sci. Conserv. Archaeol. 25, 59–64 (2013).

Avdelidis, N. P. & Moropoulou, A. IRT in the investigation of buildings and historic structures. Proc. Spie. 5405, 150–157 (2004).

Yang, X. et al. Pulsed Infrared Thermographic Study of a Chinese Bronze Lei. Herit. Sci. 10, 152 (2022).

Zhang, Z. et al. Revealing hidden flaws: Infrared thermography for detecting delamination in Chinese cloisonné enamels. npj Herit. Sci. 13, 92 (2025).

Jiang, G. et al. Simulation-aided infrared thermography with decomposition-based noise reduction for detecting defects in ancient polyptychs. Herit. Sci. 11, 223 (2023).

Williams, J. et al. Application of non-invasive active infrared thermography for delamination detection in fresco. Int. J. Therm. Sci. 171, 107185 (2022).

Qu, Z., Jiang, P. & Zhang, W. Development and application of infrared thermography non-destructive testing techniques. Sensors20, 3851 (2020).

Morales-Merino, C., Röhrs, S., Meyer, F., Marten, S. & Reiche, I. Micro-fading testing on modern ink based pens and contemporary drawings from the Kupferstichkabinett Berlin. In Archäometrie, Kunsttechnologie und Konservierungswissenschaft (eds Reiche, I. et al.), 89–102 (Berlin, 2016).

Lerwill, A., Pesme, C., Beltran, V. & Druzik, J. Investigating the Validity of Microfading Spectroscopy to Predict Photochemically Induced Color Change at Lower Light Levels. NIP Digit. Fabric. Conf. 31, 123–128 (2015).

Whitmore, P. M., Bailie, C. & Connors, S. A. Micro-fading tests to predict the result of exhibition: progress and prospects. Stud. Conserv. 45, 200–205 (2000).

Vannucci, G. et al. Micro fading test for textile single yarns: a new methodology applied to the Reformation Tapestry to assess its sensitivity to light. Herit. Sci. 11, 47 (2023).

Duan, H. Predicting the long-term light stability of color photographic prints: comparing macro and micro-fade testing results. Microsc. Microanal. 30, 125–126 (2024).

del Hoyo-Meléndez, J. M. & Mecklenburg, M. F. The use of micro-fading spectrometry to evaluate the light fastness of materials in oxygen-free environments. Spectrosc. Lett. 44, 113–121 (2011).

Commission Internationale de l’Éclairage. CIE 1976. CIE Standard. (1976).

Herzog, R. O. & Jancke, W. Röntgenographische Beobachtungen an Cellulose. Naturwissenschaften 16, 618 (1928).

Segal, L., Creely, J. J., Martin, A. E. & Conrad, C. M. An empirical method for estimating the degree of crystallinity of native cellulose using the X-Ray Diffractometer. Text. Res. J. 29, 786–794 (1959).

Łojewska, J., Lubańska, A., Łojewski, T., Miśkowiec, P. & Proniewicz, L. M. Kinetic approach to degradation of paper. In situ FTIR transmission studies on hydrolysis and oxidation. E-Preserv. Sci. 2, 1–12 (2005).

Bagniuk, J. et al. How to estimate cellulose condition in insulation transformers papers? Combined chromatographic and spectroscopic study. Polym. Degrad. Stab. 168, 108951 (2019).

Barrow, W. J. Deterioration of Book Stock, Causes and Remedies (ed. Church, R. W.) 49–55 (Virginia State Library, 1959).

Standardization Administration of China. GB/T 13528-2015. Paper and Board—Determination of Surface pH. China National Standard. (2015).

Conte, A. M. et al. Role of cellulose oxidation in the yellowing of ancient paper. Phys. Rev. Lett. 108, 158301 (2012).

International Organization for Standardization. ISO 2470-1:2016. Paper, board and pulps—Measurement of diffuse blue reflectance factor—Part 1: Indoor daylight conditions. ISO Standard. (2016).

Wen Han (文含, 1672–1735). Wen Shi Zupu Xuji (in Chinese,《文氏族谱续集》, 1725) [Genealogical manuscript]. In: Qushi Congshu (《曲石丛书》) (Republic of China reprint, 5, 13). (Beijing: Private Collector’s Edition, 1929).

Zou Yuanbiao (邹元标, 1551–1624). Zou Gong Cunzhen Ji (in Chinese,《邹公存真集》, 1604) [Literary manuscript]. In: Ming Bieji Congkan (《明别集丛刊》) (Modern reprinted edition, 4, 247–248). (Hefei: Huangshan Press, 2016).

Standardization Administration of China. GB/T 18739-2008. Geographical Indication Products—Xuan Paper. China National Standard. (2008).

Standardization Administration of China. GB/T 464-2008. Dry Heat Accelerated Aging of Paper and Board. China National Standard. (2008).

Huang, Y., Wei, Q., Luo, Y. Comparison of Paper Properties Between Modern Jiajiang Calligraphy and Painting Paper and Anhui Xuan Paper (in Chinese). The Proceedings of the 9th Academic Annual Conference of the Chinese Association for Conservation Technology of Cultural Heritage (ed. Li, H., Xing, J.), 183–196 (2016).

Gong, M., Chen, G. A Study on the Durability of the Matching Paper for Restoration Dyed by Traditional Chinese Pigment (in Chinese). The Proceeding of the Second Symposium of the Society for Conservation of Cultural Heritage in East Asia (ed. The Society for Conservation of Cultural Heritage in East Asia, Inner Mongolia Museum, China & China Association for Conservation Technology of Cultural Heritage), 298–307 (2011).

Wilson, W. K., Harvey, J. L., Mandel, J. & Worksman, T. Accelerated aging of record papers compared with normal aging. Tappi J. 38, 228–233 (1955).

Porck, H. J. Rate of paper degradation: the predictive value of artificial aging tests. European Commission on Preservation and Access, Amsterdam. 19 (2000).

Dong, L., Zhu, Y., Wu, J. & Yu, H. Comparison of aging performances and mechanisms: super-durable fire-resistant “Xuan Paper” versus Chinese traditional Xuan paper. Molecules 30, 263 (2025).

Sun, H., Shen, K. & Wang, H. Understanding the endurance of Xuan paper based on aging mechanism of paper materials. China Pulp Pap. 39, 84–89 (2020).

Li, F. Study on Durability and Anti-aging of Cultural Paper (in Chinese). Master’s thesis, Guangzhou: South China University of Technology https://doi.org/10.27151/d.cnki.ghnlu.2023.003543 (2023).

Shepard, S. M. et al. Reconstruction and enhancement of active thermographic image sequences. Opt. Eng. 42, 1337–1342 (2003).

Acknowledgements

The authors wish to express their sincere gratitude to Dr. Xiaolou Li and Dr. Momei Zhang of The Palace Museum for their invaluable discussions and insightful suggestions. This work was supported by the National Natural Science Foundation of China (62305234), Open Project of the Key Scientific Research Base of Metal Conservation (National Museum of China) (2024JSBH007), and Beijing Social Science Fund (23LSC011).

Author information

Authors and Affiliations

Contributions

S.Y., B.C., and Z.Y. proposed the idea for the article. S.Y., H.T., G.W., and X.Y. conducted the experiment. S.Y. analyzed data and prepared the original draft. X.Y. and B.C. revised the manuscript. G.Y. supervised the work and reviewed the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yue, S., Chen, B., Yang, X. et al. Infrared thermography evaluation for Xuan Paper: safety validation and applications in Chinese painting conservation. npj Herit. Sci. 13, 372 (2025). https://doi.org/10.1038/s40494-025-01952-z

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s40494-025-01952-z

This article is cited by

-

Multimodal non-destructive analysis of bronze mirror combining IR thermography and 3D scanning

npj Heritage Science (2025)