Abstract

The calcium oxalate film exhibits great potential for surface protection of carbonate stone heritage due to its excellent acid resistance and insolubility in water. However, the artificial calcium oxalate film is often loose in structure and weak in cohesion, resulting in limited protective performance. For the performance improvement of the film, glycerol was used as a growth regulator of calcium oxalate crystals, and the effect was investigated by SEM, EDS, IR, XRD, molecular dynamics simulation, Scotch tape test, acid attack resistance, water absorption, porosity, and color difference analyses. Results show the growth mode of the calcium oxalate film is altered due to the preferential adsorption of glycerol on the crystal surfaces of whewellite. Consequently, the calcium oxalate film becomes compact, cohesive, and crack-free, significantly improving the protective performance. This work is meaningful for the preparation and application of calcium oxalate film for the conservation of carbonate stone heritage.

Similar content being viewed by others

Introduction

Since the 1850s, natural calcium oxalate film has been found on the surface of the calcareous substrate such as marble, limestone, and even lime mortar in the wild1. It is weather-resistant and can protect carbonate substrate against the erosion of natural precipitation and acid air pollutants. The film was believed to be from the surface reaction between carbonate substrate and oxalate acid or its derivatives, which are the exudates of microbes such as lichen, fungi, and algal1,2. Inspired by this, the preparation and testing of artificial calcium oxalate films for the protection of carbonate heritages have gradually thrived in recent years2.

The artificial calcium oxalate film can be prepared by biology or chemistry methods. In the biology method, suitable microbes are introduced to the carbonate substrate and the formation process of calcium oxalate film is almost the same as the natural ones. As early as 2003, Monte reproduced the formation process of calcium oxalate on marble specimens by airborne fungi3. However, no sufficient coverage of calcium oxalate film was observed after even six months of airborne fungi treatment of marble in his study. It shows that the biological methods are time-consuming. In the chemistry method, the calcium oxalate film is produced by the direct reaction between oxalic acid or its derivates (such as ammonium oxalate and monomethyl oxalate) and carbonate substrate (marble, limestone and Iceland crystal). For example, oxalic acid was adopted in the preparation of calcium oxalate protective film by Wilkins et al.4. Ammonium oxalate was utilized by Cezar et al.5. The ammonium salts of oxamate and monomethyloxalate were used as a protectant for the calcareous stones by Maiore et al.6. In contrast, chemistry methods are much faster and the artificial calcium oxalate film with enough thickness can be produced in just several days. Chemistry methods were tried out in the conservation of Florentine monuments in Italy7, the historical buildings on the Mediterranean Island of Malta8 and the Longmen Grottoes in China9. However, it was found that the calcium oxalate film from the chemistry method was not as good as expected in protective performance. It is mainly due to the presence of film defects including loose structure10, cracks, and weak adhesion11. To improve the performance of the chemical calcium oxalate films, bionic principles were considered in the recent investigations. It means, some special additives were used to regulate the growth of the calcium oxalate film. The work of Burgos-Cara et al. indicated that the growth of calcium oxalate grains was affected in the presence of citrate additives12. Chondroitin sulfate was utilized to induce the deposition of a calcium oxalate film from its supersaturated solution by Liu et al.13. The studies above indicate that the bionic method is desirable in the preparation of mineral films with increased performance.

Polyols are common metabolites of the microbes. As special polar organic molecules, maybe they can also act as a growth regulator of the calcium oxalate film. Unfortunately, relevant studies are few in the open literature. Glycerol was used as a model regulator for the growth of calcium oxalate film in the aqueous ammonium oxalate solution-marble system in this study. Glycerol is a non-toxic and bio-friendly natural product. The action mechanism of glycerol was discussed and the effect of glycerol on the protective performance of the calcium oxalate film was studied.

Methods

Sample preparation

Ammonium oxalate and glycerol were analytical grade and purchased from Sinopharm Chemical Reagent Co., Ltd, China. The marble with the trade name of Guangxi White was purchased from Guangxi, China. It was composed of almost pure calcite. Specimens with the size of 2.5 cm × 2.5 cm × 1.5 cm were cut from the marble blocks by an electric saw, as shown in Fig. 1. Before treatment, the marble samples were polished with silicon carbide paper of 320Cw and washed with distilled water in an ultrasonic cleaner and dried in an oven at 40 °C to constant weight Fig. 2.

The composition of the treating solution is listed in Table 1. The samples were designated as follows: BS (blank sample), AmOx (sample treated with ammonium oxalate solution), and HG1–HG3 (samples treated by ammonium oxalate-glycerol solutions, where the water/glycerol volume ratios were 95:5, 90:10, and 85:15, respectively), as shown in Table 1.

The specimens were immersed in the corresponding solutions at 25 °C for 48 h. Then, the specimens were taken out and washed with distilled water three times and dried naturally to constant weight before all kinds of tests.

Characterization

The surface and cross-section morphology of the samples were observed by the SE mode in 10 kV and BSE mode in 13 kV of a scanning electron microscope (SEM, VEGA 3XM, TESCAN, Czech Republic), respectively. The elemental distribution of the samples was analyzed by an energy-dispersive X-ray spectroscopy (EDX, Genesis 2000XMS, EDAX, USA). The composition of the samples was examined by a LUMOS Fourier transforms infrared spectrometer in the ATR mode (IR, Bruker, Germany, scanning wave number 4000–600 cm–1, resolution 4 cm–1, scanning times 16 times). The crystal phase of the samples was investigated by a rotating target X-ray diffractometer (XRD, Rigaku Smartlab, scanning range 10–90°, step length 0.01°, scanning speed 10°/min). Computer molecular simulation was conducted to investigate action mechanism of GI on the crystal growth of calcium oxalate. Molecular simulation was performed with the software Material studio (BIOVIA, San Diego, CA).

A density tester (MZ-C300, Shenzhen Second Scientific Instruments Co., Ltd.) was used to measure the porosity and water absorption of the specimen. The measurement methods are as follows: the dry weight of the sample was recorded as M1, its water-saturated weight was recorded as M2, and the weight of the saturated sample in suspension in water was recorded as M3. The water absorption and porosity were calculated by the following formulae:

The cohesion of the films was evaluated using the Scotch Tape Test (STT). The translucent pressure-sensitive tape was applied to the surface of the samples and quickly pulled off at an angle as close to 180° as possible, and the change in the tape’s mass was measured. This process was repeated three times for each sample, and the total shedding mass was recorded and calculated14. The acid resistance of the samples was evaluated as follows. The specimens were immersed in sulfuric acid solution with pH 5.0 for about 6 h, and the pH change curve of the solution was automatically recorded every minute by a pH tester (PHSJ-3F, Shanghai INESA Scientific Instrument Co., Ltd.). A WSC-2B colorimeter (Shanghai INESA Optical Instrument Co., Ltd.) was used to measure the color difference of the samples before and after treatment. Color difference (ΔE) was calculated by Eq. 315:

ΔL, Δa, and Δb represent the difference in brightness, red/green difference and yellow/blue difference, respectively.

Molecular dynamic modelling

Molecular simulations were performed to evaluate the energy of interaction between GI and different whewellite facets with the software Material Studio (BIOVIA, San Diego, CA)12,15,16,17,18. The unit cells of calcium oxalate monohydrate were obtained from the crystallography data of Echigo et al. (2005)19. First-principles calculation of whewellite was achieved with the CASTEP module using the exchange-correlation energy electrons of GGA-PBE12,18,19. The BFGS algorithm was used for geometry optimizations. The cutoff energy was set at 610 eV and k-meshes of 3 × 1 × 2 were applied. To construct the cleavage surfaces, a whewellite crystal composed of five layers of a 3 × 4 unit cell was modeled under periodic boundary conditions12,18,19. The optimized structures of whewellite facets and the GI molecule were obtained via geometric optimization. One GI molecule was introduced into the solution phase near the crystal surface along the z-direction, with its initial position randomly distributed to simulate realistic adsorption behavior12,18,19.

Dynamic simulations were performed at a constant temperature of 298.0 K with the Forcite module and the COMPASS force field12,17,18, which is suitable for studying the interactions between organic and inorganic materials. The total time was set to 1000 ps, with an equilibration phase lasting 200 ps and the time step was set to 1 fs. The energy for the global system (ETotal) and each element separately (ECOM and EGI) were calculated after dynamic simulations. Equation 412,16 was then used to calculate the interfacial adsorption energy (EInt).

Results

SEM-EDS analysis

Figure 3 shows the morphology changes of the samples. Figure 3a shows the microstructure of blank sample, which is presented somewhat rough and uneven. After treatment by ammonium oxalate solution, a film composed of grain crystals is produced and most of the surface of the marble substrate is covered (Fig. 3b). From the increased carbon element in Fig. 3a, b (inset), this new film-like structure should be calcium oxalate in composition. However, the grainy crystals are large and isolated from each other, showing a loose structure (Fig. 3b). Glycerol addition in the ammonium oxalate solution induces significant variations in the crystal growth behavior, which can be seen from Fig. 3b–e. At a water/glycerol volumetric ratio of 95/5, a trend of crystal fusion growth is observed (Fig. 3c). At a water/glycerol volumetric ratio of 90/10, a noticeable reduction in crystal size is evident, while the trend of crystal fusion growth persists (Fig. 3d). Further increasing the glycerol concentration to a water/glycerol volumetric ratio of 85/15 results in a further reduction in crystal size, while the trend of crystal fusion growth is still maintained (Fig. 3e). Reduced crystal size may indicate the crystal growth was inhibited as the concentration of GI increases. A possible reason for the morphology change is that the low concentration of GI will promote the preferred orientation growth of COM crystal, resulting in the formation of dense crystal whiskers and a tendency of COM crystals tight integration. Similarly, in the study of Si Li. et al., it was demonstrated that the promotion of COM crystals growth resulted in the formation of dense crystal whiskers and layer spreading on COM (010) surface in the presence of low concentration of polyphenols20. Previous studies reported that some additives may show the similar effects on crystals growth12,20,21. It was observed that the growth of COM crystal displayed the initial acceleration and then gradually retardation with increasing ellagic acid20. So, the change of the calcium oxalate film in structure should be closely related to the growth regulation of glycol additive. This will be discussed further according to the results of molecular dynamics simulation later.

Figure 4 shows the SEM images of the cross-section of samples under the BSE mode. The cross-section of the blank sample is showed in Fig. 4a. After treatment with AmOx (Fig. 4b), a calcium oxalate layer is formed on the substrate. However, the calcium oxalate film is composed by coarse particles and cracks are visible in it, showing a loose and rough structure. When the water/glycerol volumetric ratio is 95/5, the particles in the film become more compact, and cracks are reduced (Fig. 4c). At a water/glycerol volumetric ratio of 90/10, the grain size decreases significantly, and the grains exhibit tighter cohesion (Fig. 4d). Further increasing the glycerol concentration to a water/glycerol volumetric ratio of 85/15 results in nearly invisible gaps between grains, with further reduction in grain size (Fig. 4e). The compact and cohesive film is ideal from the view of protective performance.

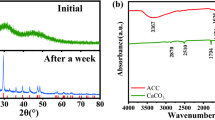

Fourier infrared spectrum analysis

Figure 5 shows the infrared spectra of samples. For the blank sample in Fig. 5a, the absorption bands at 1369, 872, and 705 cm–1 correspond to the asymmetric stretching vibration peak, asymmetric bending vibration peak, and symmetric bending vibration peak of the \({{\rm{CO}}}_{3}^{2-}\) from calcite, respectively22,23,24. After treatment by AmOx solution, the peaks of calcite at 1369, 872, and 705 cm–1 disappear, while the new characteristic absorption peaks at 1600, 1310, 865, 775, 660 cm–1 from COM10,25,26,27 appear. The identification of COM is confirmed by the symmetric O-C-O stretching vibration located at 1310 cm–1 28. In addition, the anti-symmetric carbonyl stretching band is detected at 1600 cm–1 10, along with the band around 775 cm–1, which is assigned to C-O stretching27. Moreover, the C-C stretching, and O-C-O plane bending vibrations were assigned to the absorption peaks at 865 cm–1 and 660 cm–1 25, respectively. These peaks shown in Fig. 5b indicate the surface layer of the marble is transformed into COM. After the addition of GI to the AmOx solution, the infrared spectra (Fig. 5c, d) show no new absorption peaks compared to the control sample (Fig. 5b), indicating that the product remains calcium oxalate monohydrate (COM). However, for the COM generated after AmOx treatment, absorption peaks emerge in the 4000–3500 cm⁻¹ range, indicating that some crystalline water molecules may exist in weakly hydrogen-bonded environments, with their O–H vibrational frequencies approaching those of free O–H stretching. Notably, after the addition of GI, a broad peak is observed in the 3500–3000 cm⁻¹, attributed to the stretching vibrations of O–H in crystalline water27. These findings suggest that the incorporation of GI may enhance the stability or density of the hydrogen bond network within the calcium oxalate crystal, potentially inducing microscopic structural rearrangements.

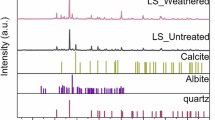

XRD analysis

The XRD results of marble samples are shown in Fig. 6a. The diffraction peaks at 23.055°, 29.400°, and 43.162° indicate its calcite composition. After treatment by ammonium oxalate solution, the new diffraction peaks of calcium oxalate monohydrate at 2θ = 15.070°,15.378°,24.587° and 30.410° appear in Fig. 6b–d, corresponding to the planes (100), (021), (040) and (200) of COM19(The peaks of calcite still exist due to the penetration depth of the X-ray is greater than the thickness of the film, this is also the case in the study by Sassoni et al.29). However, the relative intensity of diffraction peaks varies with the addition quantity of GI in the ammonium oxalate solution. It means that the growth mode of COM is affected12,30,31,32,33.

To further investigate the action mechanism of GI, the data from the XRD pattern are analyzed. The relative peak areas of the corresponding peaks and the highest substrate peak—that is, the peak area ratio (PAR)34—can be calculated as Eq. (5).

Where A2θ represents the peak area when the diffraction angle is 2θ, AMAX represents the area of the strongest peak in the sample, which is the (104) crystal plane of calcite. Next, the crystal planes of calcium oxalate in the absence and presence of GI additive are compared, and the change in the peak area ratio (PAR) is calculated as Eq. (6):

Figure 7 presents the PAR of the COM crystal under different H2O/GI ratios. The results show that when the H2O/GI ratio is 95/5, the PAR of all crystal planes increases significantly, indicating that at low GI concentrations, the growth of all crystal planes is promoted. However, as the H2O/GI ratio increases to 90/10, the PAR of all crystal planes decreases significantly, suggesting that the growth of all crystal planes is inhibited. When the H2O/GI ratio reaches 85/15, the PAR decreases even further, indicating a stronger inhibitory effect on crystal growth.

These findings suggest that the addition of GI significantly influences the growth behavior of COM crystals30, and the degree of this effect is closely related to the GI concentration. At low concentrations (95/5), GI may act as a mild growth promoter, possibly enhancing hydrogen bonding interactions and facilitating crystal nucleation. However, at higher concentrations (90/10 and 85/15), the excess GI likely interferes with the attachment of calcium and oxalate ions to the crystal surface, thus inhibiting crystal growth more effectively. This dual effect highlights the concentration-dependent role of GI in regulating crystal morphology and growth dynamics.

Results of molecular dynamics simulation

Figure 8 illustrates the ΔPAR of the crystal in relation to the interfacial adsorption energy (Eint). Molecular dynamics simulations reveal that the interfacial adsorption energy of GI on different whewellite crystal faces follows the trend: (100) > (021) > (010).

At a low GI concentration (H2O/GI = 95/5), all crystal faces exhibit some degree of promotion, which is inversely correlated with the adsorption energy. The (100) crystal face, with the highest adsorption energy, shows the smallest promotion, while the (010) face, with the lowest adsorption energy, exhibits the greatest promotion. This phenomenon can be attributed to the role of GI in enhancing hydrogen bonding interactions. At low concentrations, GI molecules adsorb onto crystal faces, introducing additional hydrogen bonds. The hydrogen bonds facilitate local crystal nucleation and growth by strengthening the attachment of growth units to the crystal lattice20,21. However, GI molecules preferentially adsorb onto high-energy crystal faces12,20, the promotion effect is weaker on high-energy faces compared to low-energy faces, where fewer GI molecules adsorb and less steric hindrance occurs, allowing for greater growth.

As the GI concentration increases (H2O/GI = 90/10), all crystal faces experience inhibition, and the degree of inhibition is positively correlated with the adsorption energy. The (100) crystal face, with the highest adsorption energy, experiences the strongest inhibition, while the (010) face, with the lowest adsorption energy, is inhibited the least. Furthermore, at a higher concentration of GI (85/15), the inhibitory effect becomes more pronounced across all crystal faces, reflecting a stronger adsorption and more effective suppression of crystal growth12,20. The increased inhibition at higher concentrations explains the observed reduction in overall crystal size, as shown in Fig. 3d and Fig. 3e.

This inhibitory effect can be attributed to the sufficient availability of GI molecules at higher concentrations. When GI molecules are abundant, they cover all crystal faces, particularly high-energy faces where adsorption is strongest. This coverage effectively blocks active sites on the crystal surfaces, preventing the attachment of growth units and thereby suppressing further growth.

In conclusion, the preferential adsorption of GI on different crystal facets significantly influences the growth habits of COM crystals. GI can act as either a growth promoter or an inhibitor, depending on its concentration. Generally, when the volume ratio of GI is 5%, crystal growth is obviously promoted, while at volume ratios greater than or equal to 10%, crystal growth is apparently inhibited.

Porosity and water absorption

Figure 9 illustrates the changes in porosity and water absorption. Compared with the blank sample, the porosity of the sample treated with AmOx decreases from 0.375 to 0.330%, while the water absorption decreases from 0.135 to 0.112%. When the ratios of H2O/GI are 95/5, 90/10, and 85/15, the porosity decreases to 0.329%, 0.313%, and 0.263%, and the water absorption decreases to 0.107%, 0.103%, and 0.097%, respectively. The reduction in porosity and water absorption can be attributed to the forming of calcium oxalate film on the surface35,36. The addition of GI to the ammonium oxalate solution further reduces the porosity and water absorption of the specimen. The observed decrease in porosity and water absorption is within an acceptable range37.

STT experiments

From the results of the Scotch Tape Test (STT) in Fig. 10, the GI ratio negatively correlates with mass loss. During the 3 cycles of STT experiments, the mass loss of the blank sample is 1.805 mg/cm2. The sample treated by ammonium oxalate solution alone is 0.099 mg/cm2. When the ratios of H2O/GI are 95/5, 90/10, and 85/15, the mass loss reduces to 0.039 mg/cm2, 0.020 mg/cm2 and 0 mg/cm2, respectively. The results show that adding GI to ammonium oxalate solution is effective to improve the adhesion of artificial calcium oxalate film. Combined with the microstructure characteristics of the film obtained by SEM analysis (Figs. 3, 4), the calcium oxalate film prepared with ammonium oxalate solution alone consists of independent and loose crystal particles (as shown in Fig. 4b), which can be easily peeled off under external force. The calcium oxalate film prepared by ammonium oxalate solution with GI additive is composed of dense and fused crystals (Fig. 3c–e), which is tightly combined with the marble substrate and is not easy to peel off. The modified film exhibits strong cohesion, which endows it with good protective performance of the marble relics.

Acid resistance

Figure 11 shows the test results of acid resistance. As shown in Fig. 12, with the reaction of hydrogen ions and calcium carbonate, the pH of the blank sample rapidly increased. After 6 h, the pH rises to 7.95. The pH curve of the samples treated with ammonium oxalate solution is significantly lower than that of the blank samples, gradually increasing to 7.39 after 6 h. When the ratios of H2O/GI are 95/5, 90/10, and 85/15, the pH decreases further to 7.14, 7.08, and 6.70, respectively. In comparison, the acid resistance of the films is further enhanced when GI is added in the ammonium oxalate treating solution. The acid resistance of the sample treated with GI is more significant, indicating that GI can make the film have stronger corrosion resistance13. The significant improvement in acid resistance is due to the stronger adhesion of the new crystal form calcium oxalate film. The film formed after the addition of GI can effectively prevent stone samples from being damaged by the external environment38,39, which has potential application value in the field of cultural relic protection.

Color variation of samples

Figure 12 shows the color changes of the samples. The color difference of the sample treated by AmOx is 0.531. When the ratios of H2O/GI are 95/5, 90/10, and 85/15, ΔE of the treated samples are risen to 0.602, 0.687, and 0.846, respectively. The GI ratio is positively correlated with ΔE, and the increase in Δb and decrease in ΔL indicate that the addition of GI makes the samples slightly darkening and yellowing. However, the color changes of samples are within acceptable limits, considering that the color alteration is much lower than the minimum visible of color change detectable by the naked eye (ΔE = 3.0)40.

Discussion

Preparation of calcium oxalate film with high protective performance using a growth regulation method was explored in this study. It was found that the regulating agent of GI changed the structure of the calcium oxalate film from the marble-ammonium oxalate solution system. That is, the size of the calcium oxalate crystals in the film is reduced and the fusion growth of the crystals is induced. As a result, the film is more closely bound with the marble substrate. According to the results of molecular dynamics simulation, it is due to the growth mode change of the films by the specific interaction of GI and crystal planes of calcium oxalate crystals. In addition, the results of experiments demonstrate that the adhesion and acid resistance of calcium oxalate film have greatly improved, and the color change is acceptable in the field of cultural heritage protection, exhibiting a promising application in the conservation of the open-air limestone relics.

Data availability

The authors declare that the data supporting the findings of this study are available within the paper and its Supplementary Information files. Should any raw data files be needed in another format they are available from the corresponding author upon reasonable request.

References

Rampazzi, L. Calcium oxalate films on works of art: A review. J. Cult. Herit. 40, 195–214 (2019).

Liu, Y. et al. Research review of calcium oxalate protective material for the conservation of carbonate cultural relics. J. Northwest Univ. (Nat. Sci. Ed.) 51, 390–396 (2021).

Monte, M. Biogenesis of oxalate patinas on marble specimens in fungal culture. Aerobiologia 19, 271–275 (2003).

Wilkins, S. J., Compton, R. G. & Viles, H. A. The effect of surface pretreatment with polymaleic acid, phosphoric acid, or oxalic acid on the dissolution kinetics of calcium carbonate in aqueous acid. J. Colloid Interface Sci. 242, 378–385 (2001).

Cezar, T. M. Calcium oxalate: A surface treatment for limestone. J. Conserv. Mus. Stud. 4, 6 (1998).

Maiore, L. et al. Synthesis, characterization and DFT-modeling of novel agents for the protection and restoration of historical calcareous stone substrates. J. Colloid Interface Sci. 448, 320–330 (2015).

Doherty, B. et al. Durability of the artificial calcium oxalate protective on two Florentine monuments. J. Cult. Herit. 8, 186–192 (2007).

Dreyfuss, T. & Cassar, J. Onsite testing of ammonium oxalate treatment applied to historical salt-infested limestone. David Publ. Co. 11, 175–183 (2017).

Liu, Q., Zhang, B. & Yang, G. Investigation on application of biomimetic technology to the conservation of longmen grottoes. Appl. Mech. Mater.43–47 (2010)..

Doherty, B. et al. Efficiency and resistance of the artificial oxalate protection treatment on marble against chemical weathering. Appl. Surf. Sci. 253, 4477–4484 (2007).

Liu, Q. & Zhang, B. Syntheses of a novel nanomaterial for conservation of historic stones inspired by nature. Mater. Lett. 61, 4976–4979 (2007).

Burgos-Cara, A., Putnis, C. V., Ortega-Huertas, M. & Ruiz-Agudo, E. Influence of pH and citrate on the formation of oxalate layers on calcite revealed by in situ nanoscale imaging. CrystEngComm 25, 3420–3429 (2017).

Liu, Q., Zhang, B., Shen, Z. & Lu, H. A crude protective film on historic stones and its artificial preparation through biomimetic synthesis. Appl. Surf. Sci. 253, 2625–2632 (2006).

ASTM D3359-17: Standard Test Methods for Measuring Adhesion by Tape Test, ASTM International, West Conshohocken, PA, 2017.

Yang, J. & Xu, F. Preparation and properties of organic-inorganic composite hydrophobic silica films. Sci. Conserv. Archaeol. 30, 10–19 (2018).

Qin, S. et al. Effects of additives on anhydrous calcium sulfate whisker growth and molecular dynamics simulation. Bull. Chin. Ceram. Soc. 42, 2551–2562 (2023).

Grohe, B. et al. Control of calcium oxalate crystal growth by face-specific adsorption of an osteopontin phosphopeptide. J. Am. Chem. Soc. 129, 14946–14951 (2007).

Shang, S., Zhao, Q., Zhang, D., Sun, R. & Tang, Y. Molecular dynamics simulation of the adsorption behavior of two different drugs on hydroxyapatite and Zn-doped hydroxyapatite. Mater. Sci. Eng.: C. 105, 110017 (2019).

Echigo, T., Kimata, M., Kyono, A., Shimizu, M. & Hatta, T. Re-investigation of the crystal structure of whewellite [Ca(C2O4)·H2O] and the dehydration mechanism of caoxite [Ca(C2O4)·3H2O]. Mineralogical Mag. 69, 77–88 (2005).

Li, S., Kang, X., He, Q., Tang, W. & Gong, J. Dual Mechanism of Natural Polyphenols on crystal whiskers formation on calcium oxalate monohydrate crystal surface. Appl. Surf. Sci. 592, 153355 (2022).

Wu, H., Chen, Y. & Guo, Y. Ethylene glycol-water binary system control synthesis of convex lens-like calcium carbonate. Mater. Mech. Eng. 39, 52–57 (2015).

Zhu, Y. et al. Middle and far infrared spectroscopic analysis of calcite, dolomite and magnesite. Earth Sci. Front. 29, 459–469 (2022).

Solotchina, ÈP. & Solotchin, P. A. Composition and structure of low-temperature natural carbonates of the calcite-dolomite series. J. Struct. Chem. 55, 779–785 (2014).

Kim, Y., Caumon, M. C., Barrès, O., Sall, A. O. & Cauzid, J. Identification and composition of carbonate minerals of the calcite structure by Raman and infrared spectroscopies using portable devices. Spectrochimica Acta Part A: Mol. Biomol. Spectrosc. 261, 119980 (2021).

Chen, L., Man, R. & Li, Z. Analysis of calcium oxalate crystalline phases by infrared spectrophotometry. J. Instrumental Anal 4, 582–584 (2007).

Tan, Y., Ouyang, J., Ma, J. & Feng, H. F. The application of infrared spectrophotometry on the study of calcium oxalate calculi. Spectroscopy and Spectral Analysis 4, 700–704 (2003).

Verganelaki, A., Kilikoglou, V., Karatasios, I. & Maravelaki-Kalaitzaki, P. A biomimetic approach to strengthen and protect construction materials with a novel calcium-oxalate–silica nanocomposite. Constr. Build. Mater. 62, 8–17 (2014).

Petrov, I. & Šoptrajanov, B. Infrared spectrum of whewellite. Spectrochimica Acta Part A: Molecular Spectroscopy 31, 309–316 (1975).

Sassoni, E., Graziani, G., Franzoni, E. & Scherer, G. W. New insights on protective treatments for marble by FIB-SEM. IOP Conf. Ser. Mater. Sci. Eng. 364, 012092 (2018).

Tanaka, S., Yamamoto, N., Kasahara, K., Ishii, Y. & Matubayasi, N. Crystal growth of urea and its modulation by additives as analyzed by all-atom MD simulation and solution theory. J. Phys. Chem. 126, 5274–5290 (2022).

Yao, M., Han, L., Bai, W., Zhu, J. & Xu, G. Morphology simulation and structure analysis of CH3NH3HgI3 crystal. J. Xi’ Technol. Univ. 41, 263–268 (2021).

Guo, S., Ward, M. D. & Wesson, J. A. Direct visualization of calcium oxalate monohydrate crystallization and dissolution with atomic force microscopy and the role of polymeric additives. Langmuir 18, 4284–4291 (2002).

Farmanesh, S. et al. Specificity of growth inhibitors and their cooperative effects in calcium oxalate monohydrate crystallization. J. Am. Chem. Soc. 136, 367–376 (2013).

Kwon Y., Chang I., Cho, G. Xanthan biopolymer-based soil treatment effect on kaolinite clay fabric and structure using XRD analysis. Sci. Rep. 13 (2023).

Chen, W., Zhang, Y., Zhang, J. & Dai, P. Consolidation effect of composite materials on earthen sites. Constr. Build. Mater. 187, 730–737 (2018).

Chen, Z. et al. Application of epoxy resin in cultural relics protection. Chin. Chem. Lett. 35, 109194 (2024).

Sassoni, E. et al. Phosphate treatments for stone conservation: 3-year field study in the Royal Palace of Versailles (France). Mater. Struct. 54, 140–161 (2021).

Shu, H., Song, Y., Liu, Q. & Luo, M. The study of rod-shaped TiO2 composite material in the protection of stone cultural relics. Green. Process. Synth. 9, 359–365 (2020).

Wang, J. & Chen, J. Current status and future development of cave temples protection in China. Southeast Culture 1, 127–128 (2018).

Benavente, D. et al. Influence of surface roughness on color changes in building stones. Color Res. Appl.: Endorsed Inter-Soc. Color Counc. 28, 343–351 (2003).

Acknowledgements

This work was supported by Shaanxi Province Key Research and Development Program (2025GH-YBXM-068), the Natural Science Foundation of China (B050121975202, 52108031), the Shaanxi Provincial Natural Science Foundation General Program (2023-JC-YB-097) and the Open Project of the Academic Prosperity Program of Archaeology of Northwestern University in 2022.

Author information

Authors and Affiliations

Contributions

Y.L. made substantial contributions to the conception and design of the work, as well as the acquisition and analysis of data. Y.J. and X.R. contributed to the interpretation of data. Y.J., J.L., W.J., G.H., Y.X., and F.Y. drafted the work and revised it critically for important intellectual content. K.Z. and X.C. contributed to the literature review and drafted the discussion section. All authors approved the final version to be published and agree to be accountable for all aspects of the work, ensuring that questions related to the accuracy or integrity of any part of the work are appropriately investigated and resolved.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Jiang, Y., Liu, J., Jiang, W. et al. Growth regulation of calcium oxalate film for surface protection of carbonate stone heritage. npj Herit. Sci. 13, 424 (2025). https://doi.org/10.1038/s40494-025-01985-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s40494-025-01985-4