Abstract

Leaded oil medium, historically used by artists to modify paint properties, was prepared by treating oil with litharge (α-PbO), massicot (β-PbO), or minium/red lead (Pb3O4), forming lead soaps. Alongside lead soaps, recent synchrotron-based structural micro-probe analyses revealed presence of lead formate (Pb(HCOO)2), lead formate hydroxide (Pb(HCOO)(OH)), shannonite (Pb₂OCO₃), plumbonacrite (Pb5(CO3)3O(OH)2) and neo-formed hydrocerussite (Pb3(CO3)2(OH)2). This study reviews their occurrence in historical and model systems and explores their early formation and distribution in leaded oil model systems. Model systems were analyzed using optical microscopy, GC-MS, ATR-FTIR, µ-FTIR, and SR-µ-XRPD. This study shows that, beyond lead soaps, various lead-based compounds form heterogeneously in leaded oil systems. Lead formate crystallizes and migrates within the first days of curing, while lead formate hydroxide and lead carbonates (shannonite, plumbonacrite and neo-formed hydrocerussite) tend to concentrate in the globule areas. This paper proposes potential chemical formation pathways for these unusual lead-based products in leaded oil systems.

Similar content being viewed by others

Introduction

Oil paint layers are intricate and highly heterogeneous systems, especially when driers such as lead(II) oxide (α-PbO), massicot (β-PbO), and minium or red lead (Pb3O4) are introduced. As a highly reactive drying agent, PbO may interact with linseed oil (LO) to form a variety of reaction products1. Among these, lead soaps are the most frequently reported and studied compounds in the field of heritage science2,3. Detecting both original and non-original compounds in oil paint layers using conventional laboratory-based analytical methods remains challenging. These challenges arise from their organic and/or inorganic, amorphous and/or crystalline nature, heterogeneous spatial distribution at the nano- and micro-scale and the often-low concentrations in a complex and multi-layered paint matrix. Therefore, a combination of bulk and spatially resolved laboratory- and synchrotron-based analytical techniques is crucial for their detection. Recent applications of advanced synchrotron radiation techniques have led to the discovery of various, previously undetected non-original lead compounds, beyond common lead soaps, in both historical and model paint systems4. Among these are lead formates and lead carbonates. The rare detection and underexplored nature of these lead-based products in oil paintings, including instances where they coexist in the same painting or micro-fragment, led us to review their occurrence in the literature.

As detailed in Table S1, these lead-based products have been detected in a few historical paintings (Table S1). More precisely, in 2015, Vanmeert et al. reported the presence of an unusual lead-carbonate product - plumbonacrite (Pb5(CO3)3O(OH)2, PN) - in Van Gogh’s Wheat Stack Under a Cloudy Sky5. Four years later, another study reported PN in the impasto layers of three paintings by Rembrandt Van Rijn: Portrait of Marten Soolmans, Bathsheba and Susanna6. In 2023, PN was detected again in Rembrandt’s The Night Watch, alongside lead(II) formate (Pb(HCOO)2, LF), reported for the first time in an oil painting7. Additionally, recent research revealed PN in two works by Leonardo da Vinci - The Mona Lisa and The Last Supper - with the latter also containing shannonite (Pb₂OCO₃, SH), a rare lead oxycarbonate in paintings8. In the Night Watch, neo-formed hydrocerussite (Pb3(CO3)2(OH)2, nHCer) was reported as well7. Distinguishing between original HCer present in the lead white pigment and the nHcer is often challenging, as they share the same crystal structure. However, the former usually exhibits larger crystallite size than the latter, resulting in sharper X-ray powder diffraction (XRPD) signals. Therefore, determining the Full Width at Half Maximum (FWHM) of the XRPD peaks can allow for the distinction of the two forms9. The presence of neo-formed lead carbonates has been already reported in early works on lead soaps protrusions. For instance, Higgitt et al. used µ-FTIR spectroscopy to analyze a large corpus of “inclusions” taken from 35 paintings dating from the 13th to the 18th century10. FTIR revealed not only the presence of lead soaps in all these inclusions, but also of basic lead carbonates in 32 of them. Almost in the same period, Boon et al. reported metal soap formation together with lead carbonates formed from remineralization processes in protrusions in a series of 17th century paintings11. SEM can also provide clues about the presence of neo-formed carbonates in protrusions12.

The chemical origin of these rarely detected lead carboxylate- and carbonate-containing compounds has been previously individually studied in historical paintings. However, due to their rare detection, they have not yet been studied collectively, correlated with one another or related to a common source. Therefore, Table S1 presents a detailed summary of the detection of lead carboxylates (including lead salts of fatty acids, mainly of palmitic and stearic acid, here referred to as “lead soaps”, and short fatty acid chain lead carboxylates, such as LF) and unusual lead carbonates (shannonite, plumbonacrite, and neo-formed hydrocerussite) in historical oil paintings. In this literature review, we documented only the occurrence of nHCer when its presence was highlighted by the XRPD FWHM analysis. In the following sections, we studied the possible role of PbO in the formation of these lead compounds. Therefore, we have also included in Table S1 the presence of lead oxides (litharge α-PbO, massicot β-PbO, and minium or red lead Pb3O4), whenever reported. Table S1 compiles information on the detection of the lead-based products, their spatial distribution in the historical paint layers and the employed analytical techniques. This data highlights an unsystematic detection and heterogeneous distribution of lead-based compounds in each painting. In some cases, these compounds were detected in the ground layer (Mona Lisa and The Night Watch), in the imprimatura layer (Last Supper), in the colored layers (Last Supper, Portrait of Marten Soolmans, Batsheba and Susanna), at the surface (The Night Watch) and in protrusions (The Night Watch and Wheat Stack Under a Cloudy Sky)5,6,7,8,13. It is important to note that while one technique may effectively detect a specific compound, it may not be suitable for the detection of another. Therefore, the absence of a compound in a certain painting or paint layer does not necessarily imply that it has not formed, but rather that it was not detected.

Multiple chemical pathways could explain the formation of the detected lead phases. These pathways may be influenced by various factors, including the nature of the materials selected by the artist and their formulation following a specific technique, environmental conditions, conservation treatments etc. However, the specific presence of PN and SH, which are stable only in a highly alkaline environment, has led us to investigate one particular hypothesis14. This hypothesis directly links the formation of PN and SH to the use of oil recipes based on lead(II) oxide PbO, a Brønsted base, to create a thickened leaded oil medium, historically used in paint formulation for its improved chemical and mechanical properties1,3,6,15,16,17,18.

The use of PbO in oil mixtures has been extensively documented in historical treatises dating from the 16th century until the 20th century, when lead was substituted by alternative compounds due to its toxicity3,18,19,20. One of the most notable recipes for the preparation of thickened PbO/oil medium in the paint domain, known also as huile de litharge (litharge oil), was written by Théodore Turquet de Mayerne in 1633. This procedure involves mixing PbO with oil in a 1:4 weight ratio, heating the mixture, and then adding hot water3,15,16. This method likely served to partially saponify the oil, creating a complex mixture of lead carboxylate species21. The saponified medium promotes thorough and uniform curing throughout the entire film thickness, from the surface to bottom, providing a film with a good balance of hardness, toughness, flexibility and chemical resistance22. Historical records also suggest that this medium not only facilitated faster solidification and improved paint workability but also enhanced aesthetic qualities, including gloss and pigment saturation, while mitigating yellowing23. Reproductions of the leaded oil recipe by Cotte et al. demonstrated that insufficiently ground PbO can result in the formation of protrusions in the paint film3,15. Interestingly, such formation of protrusions is sometimes referred to as “lithargeage” by French curators24. The formation of rare lead carboxylates and lead carbonates in these protrusions poses important research questions and challenges for scientists and paint conservators3,15. Therefore, understanding the chemistry of both original and non-original leaded oil products through model systems studies is necessary.

As shown in Table S2, which presents a detailed literature review of studies on model mixtures made of PbO and oil, most research in this field focused solely on the formation of lead soaps, with no specific mention of other shorter chain fatty acid lead carboxylates or lead carbonate-containing products. For instance, studies by Ferreira et al. (2006), Cotte et al. and De Viguerie et al. investigated the De Mayerne huile de litharge model system, and primarily focused on the formation of lead soaps under varying preparation and treatment conditions16,18,25. In 2008, Mazzeo et al. examined model systems based on litharge (PbO) and minium (Pb₃O₄) mixed with LO, identifying both lead soaps and lead carbonates; however, these compounds were not characterized using methods other than ATR-FTIR spectroscopy26. In 2007, Cotte et al. addressed the early formation of lead soap protrusions in paint models prepared according to De Mayerne’s recipe15. Using SR-µ-FTIR, the authors analyzed a three-month-old huile de litharge sample and detected lead soaps. The same samples were re-analyzed after nine years of natural aging using µ-FTIR combined with synchrotron radiation micro-X-ray powder diffraction (SR-µ-XRPD) and revealed presence of PN in both protrusions and as small particles throughout the paint film3. More recently, in 2023, Gonzalez et al. investigated a vast set of model systems based on the huile de litharge recipe with the aim of shedding light on Leonardo da Vinci’s and Rembrandt’s painting techniques and materials7,8. These two studies reported detection of multiple lead-based products of interest in the model systems, including LF, lead formate hydroxide (Pb(HCOO)(OH), LFH), mixed crystallized lead soaps (notably Pb(C16)(C18)), PN, SH and nHCer. LF was also detected by XRPD in model paint thin films containing minium and different oils, including LO, and in simple models of minium powder exposed to oil vapors27.

In summary, both Tables S1 and S2 show that while these lead carboxylates and carbonates compounds can be detected in historical and model systems, their detection is often sporadic and challenging, despite the use of sophisticated analytical techniques. For instance, LF was identified in 12 out of 26 macro-scale structural distribution maps of The Night Watch using macro-X-ray powder diffraction (MA-XRPD) and in only three micro-samples analyzed with SR-µ-XRPD. Conversely, LF was not detected at the macro-scale in certain areas, but was observed at the micro-scale in the tiny paint fragments sampled from those regions. These inconsistent observations may be attributed to differences in instrumental configurations between MA-XRPD and SR-µ-XRPD7.

The gathered background information on the detection of unusual lead carboxylates and carbonates in historical and model systems (Tables S1 and S2) motivated the present study, which investigates their sporadic detection by exploring their early formation and microscale spatial distribution in model systems. Model systems were prepared based on historical recipes - notably the De Mayerne recipe - by boiling LO with PbO (litharge and massicot), denoted as Group 1. To simulate conditions favorable for the formation of protrusions, an incomplete dissolution of PbO in oil was obtained by adding excess PbO to the leaded oil at room temperature denoted as Group 2. Early formation, growth and mobility of crystals in the fresh paint was monitored during curing at room temperature using optical microscopy, bulk ATR-FTIR spectroscopy, and GC-MS. µ-FTIR and SR-µ-XRPD were then used to reveal the spatial distribution of lead-based products in micro-fragments of naturally aged paint films, some of them previously studied by Gonzalez et al.7,8. This sample set was selected as it showed the highest co-occurrence of unusual lead-based products (listed and abbreviated in Table S3) within a common system. The combined methodological approach provided insights into the early-stage reactions and the spatial distribution of lead formate and unusual lead carbonates in model paint systems, representative of historical cases.

Methods

Preparation of model paint films

Model paints were prepared following historical recipes, in particular the huile de litharge provided by Turquet De Mayerne15. A list of samples, their names/abbreviations and composition were summarized in Table S4. First, linseed oil (LO, Kremer pigmente 73020, 12 g) was cooked for 3 h at 100 °C either alone for reference, and in combination with additional PbO (Alfa AEsar, 99.9%, 23 w% litharge, α-PbO, 77 w% massicot, β-PbO, 2.25 g) with and without 12 g of water - denoted PaWet and PaDry, respectively (Pa stands for “paint”). For PaWet, PbO and water were added to LO at room temperature all at once, and the mixture was heated and continuously stirred using a magnetic stirrer.

As listed in the previous work by Cotte et al. many historical texts warned about the importance of grinding PbO well when mixed with oil to avoid the formation of protrusions3,15. Accordingly, to simulate an incomplete dissolution/reaction of PbO and evaluate the local formation of lead compounds around the unreacted PbO particles, two additional types of samples were prepared. First, a simplified model (LO_PbO) was prepared by gently depositing PbO particles on a film of pure cooked LO spread on a window (on glass slides for optical microscopy and SR-µ-XRPD; and on BaF2 window for 2D µ-FTIR mapping). Second, ~1/3 of the PaDry and PaWet media were briefly mixed with additional PbO at room temperature (named PaDry_PbO and PaWet_PbO) to reach a final weight ratio of 4-4-1 oil/water/PbO as described in De Mayerne’s recipe, but mimicking an incomplete saponification reaction. A film of each fresh media (PaDry, PaWet, PaDry_PbO, PaWet_PbO) was applied on a glass slide and aged at room temperature conditions (Fig. S1). In several cases, oil and of lead white (Kremer, HCer:Cer ratio of 90:10 w%, noted with the suffix _LW, 7.5 g/mL of each) were mixed to mimic a pigmented paint layer.

All the Pa samples were aged for three years at room temperature, while the LO samples were first aged at 60 °C for one year and then stored at room temperature for other two years.

These samples were regularly observed with optical microscopy and some fragments were taken occasionally for SR-µ-XRPD analysis.

FTIR spectroscopy

Bulk ATR-FTIR spectra of uncured media (LO, PaDry and PaWet) were acquired with a Perkin-Elmer Frontier FT-IR spectrometer fitted with a Pike GladiATR module including a diamond ATR-FTIR (University of Amsterdam). Spectra were recorded with a 4 cm−1 resolution, in the range 4000–450 cm−1 and averaged over 50 scans.

To follow the molecular evolution of PaDry medium during curing, bulk ATR-FTIR spectra were repeatedly acquired at room temperature using a Thermo Nexus spectrometer (ID21, ESRF). A droplet of paint (thicker than 10 μm) was deposited on top of the ATR crystal without pressure application. Spectra were acquired as an accumulation of 120 scans, with a spectral resolution of 4 cm-1 using an automated acquisition set-up in Macros basic (an extension of the OMNIC software). A spectrum was acquired every five minutes for seven days and then every 30 min for the following 85 days (2044 h in total).

In order to explore the local impact of PbO in oil during curing, µ-FTIR maps of the LO_PbO film were acquired in transmission mode (BaF2 substrate) with a Perkin Elmer Spectrum 100 FTIR spectrometer combined with a Spectrum Spotlight 400 FTIR microscope equipped with a 16 × 1 pixel linear MCT array detector at 8 cm−1 resolution (University of Amsterdam). Spectra were collected in a 4000–750 cm−1 range and averaged over 15 scans. The pixel size was set to 6.25 µm. Maps were acquired over ~3 × 3 mm² regions, covering several PbO particles. The curing of the film was monitored over time (at 0, 7, 42, 84, and 110 days). For the comparison of the FTIR maps upon ageing, maps were realigned based on integrated count rate and cropped to the same size. Integrated net intensity maps were calculated for four FTIR bands: ν2(CO3) of lead carbonate 824–858 cm−1, νas(CO) of lead soaps 1498–1598 cm−1, ν(OH) of lead hydroxide 3512–3564 cm−1 and νs(CO) of LF 1324–1362 cm−1.

FTIR data analyses were carried out using the ROI (Region of interest) calculations in the PyMca software package17.

Optical microscopy

Early formation, growth and mobility of crystals in fresh PaDry paint during curing was first carried out using a Leica binocular at ID21, ESRF. A fresh drop was deposited on a microscope glass slide with concave depression and cured for 60 days at room temperature with visible images acquired in different intervals: after application, after 1, 2, 3, 9, 18, 30 and 60 days.

To continuously follow the formation of crystals in the fresh PaDry medium at RT, a dedicated optical microscopy setup was designed in collaboration with PSCM, ESRF. A visible image was acquired every five minutes for 30 days using Leica Wild M3Z with a camera: ToupCam UCMOS (5.1MP 1/2.5“APTINA CMOS Sensor) and a modified LED light source. Software used for the acquisition was Toupview and software used for data processing was ImageJ28.

Synchrotron radiation micro-X-ray powder diffraction (SR-µ-XRPD)

To obtain a deeper insight into the spatial distribution and exact composition of the crystalline phases, fragments were taken from cured paint films and mapped using 2D SR-µ-XRPD.

Many preliminary results were obtained thanks to experiments at the P06 beamline, Petra III29, at the I18 Beamline, DLS30, and at the XALOC beamline, ALBA31. The results presented here were obtained at ID13 (ESRF) within the Historical Materials BAG4. ID13 is an ESRF undulator beamline dedicated to high-lateral-resolution diffraction and scattering experiments using focused monochromatic X-ray beams32. Samples were analyzed on the micro-branch end-station. Paint fragments were glued on tape and mounted vertically, perpendicular to the X-ray beam. The energy of the incident beam was set to ~13.0 keV. The beam was focused to ~2 × 2 µm2 using a compound refractive lens (CRL) set-up mounted in a transfocator. SR-µ-XRPD maps were obtained by raster-scanning the samples and collecting 2D XRPD patterns, in transmission, with a Dectris EIGER 4 M single photon counting detector that acquires frames with 2070 × 2167 pixels (75 × 75 μm2 pixel size) at a rate up to 750 Hz. The first experiments in this study were conducted using high flux ( ~ 2 × 1012 ph/s) conditions offered by the ESRF-EBS (Extremely Brilliant Source) upgrade33. High flux conditions occasionally led to the reduction of Pb(II) to Pb(0) and amorphization of lead phases. To avoid radiation alteration of sensitive paint micro-fragments, low flux (~1011 ph/s) conditions were applied by detuning the undulator4.

Azimuthal integration and visualization of crystalline phases through linear fits were performed using dedicated Jupyter Notebooks34. Individual or averaged diffraction patterns were extracted and background subtracted using PyMCA.

Gas chromatography-mass spectrometry (GC-MS)

Headspace solid-phase microextraction-gas chromatography–mass spectrometry (HS-SPME-GC-MS) was implemented with the aim to follow the formation of formic acid in the boiled LO, PaDry and PaWet medium (shown in SI, Fig. S8). The samples (~2 mg) were placed in a 10 mL headspace sample vial (Supelco) with a 20 mm aluminium screw cap and a PTFE/silicone septa (Supelco). The vial was closed 1 h before each sampling to accumulate the volatiles in the headspace. The vial was kept open at room temperature between measurements. After the equilibration time, the fiber was inserted in the vial for 30 min and immediately transferred into the injector port where the analytes were thermally desorbed and transferred onto the chromatographic column for separation prior to detection into the mass spectrometer. The SPME fiber selected for this study, Carboxen/Polydimethylsiloxane (CAR/PDMS, Supelco), was conditioned before each experiment in the GC injection port at 250 ◦C. The measurements were ran in triplicates. The peaks were normalized to the weight of each sample. No quantitative analyses were performed in this study, however, normalized relative peak areas were used to semi-quantitatively compare the concentration of formic acid observed in the analyzed samples.

Results

This section presents the experimental results obtained on model systems, while their interpretation is detailed in the discussion section.

Chemical evolution of PbO-oil model systems during preparation

ATR-FTIR spectra were acquired during the synthesis of PaDry and PaWet media. Full spectra and detailed interpretations are provided in the Supplementary Information (SI, Fig. S2). In brief, the spectra of both PaDry (Fig. S2, spectrum C) and PaWet (Fig. S2 spectrum D) mainly show the decrease of the ν(C = O) ester peak at 1743 cm-1 and the formation of the νs(CO) and νas(CO) lead soap peaks at 1405 cm−1 and 1522 cm−1. These peaks are more intense in the PaWet medium, than in the PaDry medium. This agrees with previous results showing that saponification is favored by the addition of water in the mixture of oil and PbO16.

Chemical modifications of the PaDry medium during curing

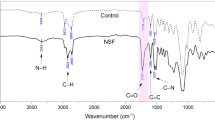

Early stage curing of PaDry medium was followed by ATR-FTIR spectroscopy over the period of 90 days at RT. The spectrum of PaDry at t = 0 is shown in Fig. 1Aa. The difference spectrum (t = 90 days - t = 0 shown in Fig. 1Ab) exhibits positive peaks corresponding to the newly formed products and negative peaks correlated to the compounds that have disappeared during curing. As a comparison, transmission µ-FTIR spectrum of LF, extracted from the PaDry sample thin section obtained using NNMA statistical analysis is shown in Fig. 1Ac (see SI, Gonzalez et al. for details)7. Peak assignment was done based on literature and summarized in Table S517,18,35. Most notable spectral changes were highlighted and monitored by calculating peak intensity over wavenumber regions of interest (ROI) shown in Fig. 1A and B.

A comparison of: a) ATR-FTIR spectrum of uncured PaDry medium; b) ATR-FTIR difference spectrum between the first and last point acquired (after 90 days of curing at room temperature), c) transmission µ-FTIR spectrum of LF extracted from the cured PaDry sample thin section obtained using NNMA statistical analysis (SI of Gonzalez et al.)7. B kinetic profiles during the first 30 days of curing for: ν(OH) (3196–3554 cm−1), ν(C-H) in cis C = C-H (2991–3032 cm−1), ν(C = O) ester (1737-1776 cm−1), ν(C = O) acids, aldehydes and ketones (1690–1736 cm−1) and νs(C-O) bend of LF (758–783 cm−1).

The difference spectrum (Fig. 1Ab) shows a first set of spectral modifications within the first 5 h: an increase of the organic ν(OH) peak at 3422 cm-1 indicative of the formation of hydroperoxides, alcohols and acids, a decrease of the ν(C-H) in cis C = C-H peak at 3009 cm−1 attributed to the unsaturated cis bonds, a decrease of ν(C = O) ester peak at 1740 cm−1 and an increase of the ν(C = O) peak at 1715 cm−1 characteristic of acids, aldehydes and ketones. These spectral changes display continuous variations over the period of 90 days (for simplicity, only the first 30 days of curing were shown in the Fig. 1B). They are indicative of several chemical reactions notably, isomerization, oxidation and hydrolysis, commonly observed during oil curing18.

Interestingly, the formation of LF occurred suddenly, at a later stage (after ~2.5 days), reached a plateau after 4 days and remained stable for the following 90 days. The strongest peak of LF is the asymmetric C-O stretch at 1549 cm−1 which falls within the range of νas(CO) of lead soaps at 1505 cm−1, formed in the medium during curing27,36. Accordingly, other LF peaks were considered as markers of its presence, such as the in-plane C-H bend at 1374 cm−1, the symmetric C-O stretch at 1339 cm–1 and the symmetric C-O bend at 762 cm−1 35. In Fig. 1B, the latter was used to follow the formation of LF.

Lead carbonate and lead hydroxide were not detected with bulk ATR-FTIR spectroscopy during this experiment.

ATR-FTIR acquisitions were repeated four times on different drops of fresh PaDry medium taken from the same closed vial. The difference spectra calculated for the four acquisition runs, acquired during first 10 days of curing, were compared to a LF reference (Fig. S3). LF peaks seem to be present in the second and the third run, but are less obvious in comparison to the first run. The first run shows clear presence of the in-plane C-H bend of LF at 1374 cm−1, a symmetric stretch of LF at 1339 cm−1 and the symmetric C-O bend at 762 cm−1. The fourth run does not show clear presence of LF characteristic peaks, indicating that despite the use of the same material, ageing conditions and analytical setup, LF was not always detected.

Addressing the unsystematic detection and heterogeneous distribution of unusual lead compounds

The sudden formation of LF in the first run after ~2.5 days of curing, the lack of repeatability of detection of LF in the four runs, and the inability to detect lead carbonate and lead hydroxide using bulk ATR-FTIR spectroscopy raised questions about the homogeneity of the leaded oils, particularly during curing. To investigate this, visual observation of PaDry paint film deposited on a glass slide with a concave depression was carried out using optical microscopy by recording images over 60 days of curing. This experiment revealed the formation and motion of crystals (Fig. 2A). After the first day, only a change in paint volume was observable, while around the second day, micrometric particles had begun to form. On the third day, these particles were more concentrated in the center of the paint, where the layer was thicker, and less prevalent on the edge of the paint, where the layer was thinner due to the concave shape of the glass slide. After 30 days, no further changes were observed. The PaDry medium was subsequently sampled after three years of natural drying and characterized using SR-µ-XRPD mapping in transmission mode. The distribution map (Fig. 2B) and the corresponding extracted average diffraction pattern (Fig. S4A) identified the elongated particles primarily as LF. In addition to LF, lead stearate (Fig. S4B) and mixed lead soaps (Fig. S4C), notably Pb(C16)(C18) (palmitate and stearate), were also detected in this paint.

A Optical microscopy images acquired on a fresh PaDry paint drop inside a concave depression glass slide, cured for 60 days at room temperature conditions. Tracking of paint curing over the period of first four days is shown in SI (Movie S1.); B SR-µ-XRPD distribution map of LF in three years old sample (map size: 1592 × 1194 µm2, step size: 2 × 2 µm2, the map location is represented by the turquoise rectangle in A), t = 60 d. Extracted average SR-µ-XRPD patterns of LF are given in Fig. S4A, lead stearate in Fig. S4B and of a mixed lead soap/carboxylate (palmitate and stearate) in Fig. S4C.

The continuous formation and movement of particles in the fresh PaDry medium was further studied by acquiring images every five minutes over 30 days of curing at room temperature on a second sample. Movie S1 shows the first four days of curing as the system reaches a stable state by that time. More particularly, this animation highlights one tracked particle which formed in the thinner region of the paint, migrated through the paint as it cured and eventually aggregated in a thicker area with other neo-formed particles. The edges of the droplet, where the paint is thinner, contain less crystals. During the initial four days of curing, the PaDry medium exhibits dynamic and mobile behavior, leading to a heterogeneous particle distribution.

Addition of undissolved PbO to LO medium: early stage reactions of curing

To further address the unsystematic detection and heterogeneous distribution of the unusual lead compounds as observed in historical paintings, a simplified model system was developed by depositing PbO particles on a pure cooked LO film (LO_PbO). This model allowed us to investigate the localized effects of PbO on oil, particularly focusing on the early formation of reaction products and oil curing reactions.

Figure 3 shows 2D µ-FTIR maps acquired on LO_PbO film over the period of ~110 days. Spectral modifications are mainly visible in the areas where PbO particles were added according to visible images. These regions are marked as Area 1 (red rectangle) and Area 2 (yellow rectangle) in Fig. 3A, t = 110 days. Contrary to the bulk ATR-FTIR analyses, presence of lead carbonate and lead hydroxide containing compounds, together with lead soaps and LF, was noticeable already on the first day (maximum five hours after preparation) across the globule core in Area 1. During the first day, uniform formation of lead soaps was observed across the globule core in Area 1. Area across the globule core also showed the presence of lead carbonate and hydroxide containing compounds, surrounded by an additional layer of LF. By the seventh day, lead soaps formed as a halo around the LF. Lead soaps also uniformly formed across the globule core in Area 2, while lead carbonate and hydroxide containing compounds and LF were not detected in this region. The intensities of these compounds increased over the first 42 days and remained structurally stable over the following 68 days. Extracted average µ-FTIR spectra of νs(C-O) of LF 1324–1362 cm−1; νas(CO) of lead soaps 1498–1598 cm−1; ν2(CO3) of lead carbonate 824–858 cm−1 and ν(OH) of lead hydroxide 3512–3564 cm−1 over the Area 1 are shown in Fig. S5.

A Visible image and 2D µ-FTIR maps of LO_PbO cured at 60 °C after 0, 7, 42, 84 and 110 days; B Integrated intensity maps calculated over the four regions: a) lead carbonate: ν2(CO3) 824–858 cm−1, b) lead soaps: νas(CO) 1498–1598 cm-1, c) lead hydroxide: ν(OH) 3512–3564 cm-1 and d) LF: νs(C-O) 1324–1362 cm-1, e) ν(CH) unconjugated cis double bonds 2989–3014 cm−1, C Schematic illustration of the detected functional groups.

To assess the impact of PbO on LO curing reactions, the presence and distribution of ν(CH) unconjugated cis double bonds was mapped as well (Fig. 3e). At d = 0, unconjugated cis double bonds were uniformly present across the entire integrated intensity map, regardless of PbO presence. By the seventh day, these bonds persisted only around PbO globules in Area 1 and across the globule in Area 2. These bonds were completely consumed in the pure LO film. After d = 42, unsaturations remained only around the PbO globule in Area 1, and persisted even after 84 days of curing.

Several LO_PbO samples were also analyzed using SR-μ-XRPD mapping. These results have been previously published and are included in Table S67.

Addition of undissolved PbO to leaded oils: heterogeneous distribution observations

The local reactivity of undissolved PbO in leaded oils was studied on the model systems containing PaDry and PaWet media with additional PbO (denoted as PaDry_PbO, PaWet_PbO) at room temperature. FTIR analysis of newly formed lead carbonates and formates was challenging due to spectral overlap with the main absorption bands of the carboxylate-rich matrix. Therefore, SR-μ-XRPD mapping was preferred over µ-FTIR for microscopy analyses of Pa samples, as it provided better distinction between various carboxylates and carbonates. However, limited access to synchrotron X-ray instruments and potential radiation alteration restricted data acquisition to a single mapping session per region, conducted after three years of natural aging, precluding kinetic analysis.

Optical microscopy observations of PaDry_PbO sample in Fig. 4A show a highly heterogeneous paint film, with micrometric crystals dispersed in the matrix, non-uniformly (in some areas absent, and in some highly concentrated). Additionally, few globules (~100–200 µm in size) were observed. The scanned region (highlighted by the purple rectangle) was selected over the (i) crystal-free matrix (which appear thinner under the optical microscope), (ii) crystal-rich matrix and (iii) three globules (each globule is noted as Area 1, Area 2, and Area 3). SR-μ-XRPD distribution maps shown in Fig. 4B exhibit the varying concentrations of mixed lead soaps, LFH, LF, and nHCer in the crystal-containing paint matrix. Crystalline phases, particularly LF, were concentrated mostly in thicker areas of the paint film. Neo-formed HCer was found dispersed in the paint matrix in LF rich areas, while PN was detected in the entire paint film as dispersed particles, with no notable variation in concentration or formation in the PbO globules. The edges of the globules in all three areas contained residual litharge (α-PbO) and massicot (β-PbO). Mixed lead soaps, LFH, LF and nHCer were distributed both within and along the edges of the globules. In all three areas, LFH was found either across or along the edge of the globule, surrounded by a layer of LF. Mixed lead soaps, composed of crystallized lead palmitate and lead stearate, were identified by comparison to the literature37. These lead soaps were distributed across the globule core in Area 1 and 3 and along the edge of the globule in Area 2. Neo-formed HCer was detected in the edges in Area 1 and Area 3 and across and along the edge of the globule in Area 2. Lastly, presence of an unknown compound was detected across the PbO globule in Area 2. This unknown compound was detected in all PaDry_PbO samples (Figs. 4B, S6B and S7B) with a d-spacing value similar to that of lead myristate (Pb C14), but with an unusual, rapidly decreasing intensity pattern in the diffraction peaks that has been associated previously with liquid crystal lead soap phases that only have very short-range order38. A similar pattern was observed in PaDry (Fig. S4B), though in that sample the d-spacing strongly matched the reference value of lead stearate. The unknown phase was found mainly concentrated across the globule core, encircled by a ring of mixed Pb C16/18 (Figs. 4B–D, S6B, S7B). A more precise identification of the source of this diffraction signal was beyond the scope of this study.

A Optical microscopy image of sample PaDry_PbO. The purple rectangle indicates the area scanned via SR-μ-XRPD and the red rectangle indicates the zoomed in RGB map; B SR-μ-XRPD distribution maps (map size: 2700 × 2250 μm2; step size: 3 × 3 μm2); C RGB map of Area 2 of an nHCer (red), mixed lead soaps (blue) and LF (green). D Schematic illustration of the newly formed crystalline phases.

The detection and spatial distribution of lead-based phases appear respectively unsystematic and heterogeneous across the three areas. For example, the unknown compound and LFH were specifically detected in Area 2, whereas mixed soaps were found in all three areas but with a different distribution; in Area 2 they were found in the rim and in Area 1 and 3 across the globule (Fig. 4B). Other regions of the same sample have been examined and exhibited a similar trend (Figs. S6B and S7B).

Figure 5 shows optical microscopy images and SR-μ-XRPD distribution maps of a globule formed in PaWet_PbO sample, naturally aged for three years. It is interesting to note that while the matrix and the globule edge have a yellow color, the center of the globule appears white. Remaining PbO, and newly formed LFH, SH, PN and nHCer were detected across the globule core. The first layer formed surrounding PbO (corresponding more or less to the white region) shows the presence of mixed lead soaps, LFH, LF, SH, PN and nHCer. The second outer layer contains LF and PN. Finally, the surrounding paint film contains particles of mixed lead soaps, SH, LF and nHCer.

Main observations on the detection and spatial distribution of crystalline phases in model systems

In addition to the few representative results shown above, in total, 17 SR-μ-XRPD maps were acquired on nine samples of varying compositions. These samples include PaDry, PaWet, PaDry_PbO, PaWet_PbO, PaDr_LW, PaWet_LW, PaDry_PbO_LW, PaWet_PbO_LW, and LO_PbO (Table S4 and Fig. S1). The detailed spatial distribution of crystalline lead-based products observed in these samples is summarized in Table S6. Based on these spatial distribution observations, the following trends were identified between the three sample groups, notably, Group 1) leaded oils: PaDry and PaWet, Group 2) linseed oil or leaded oil with additional PbO: LO_PbO, PaDry_PbO and PaWet_PbO and Group 3) leaded oils mixed with LW pigment: PaDry_LW, PaWet_LW, PaDry_PbO_LW and PaWet_PbO_LW.

-

Remaining litharge was detected in seven maps (in PaWet in Group 1 and in PaDry_PbO in Group 2), while massicot was detected in nine maps (in PaWet in Group 1 and in LO_PbO, PaDry_PbO and PaWet_PbO in Group 2). In PaWet and PaDry_PbO samples, massicot and litharge were observed as particles dispersed in the paint matrix. This illustrates that even when PbO has been mixed and heated with oil for 3 h (Group 1), small crystals can still be present in the leaded oil. In Group 2, where additional PbO has been added after the preparation of the leaded oil (PaDry_PbO and PaWet_PbO), or deposited on a film of LO (LO_PbO), globules containing litharge and massicot were observed, even after three years of ageing.

-

LF was detected in 15 maps (in all the samples from Group 1, Group 2 and 3). In two PaDry, one PaWet, six PaDry_PbO and in each PaDryLW, PaWet_LW, PaDryPbO_LW, PaWetPbO_LW map, LF was found as particles dispersed in the paint matrix, but with a highly variable concentration at the millimetric scale (not detected in thin regions). In LO_PbO, PaDry_PbO, PaWet_PbO and PaWet_PbO_LW maps, LF was also concentrated across the globule core and as the first layer around the globule.

-

LFH was detected in 10 maps, and specifically in samples from Group 2. In four maps of PaDry_PbO samples, LFH was detected as particles dispersed in the paint matrix, most concentrated in LF rich regions. In two LO_PbO, five PaDry_PbO and in one PaWet_PbO sample, LFH was also concentrated across the globule core and along the edge of the globule. LFH was found in only one sample from Group 3, namely PaWet_PbO_LW.

-

Crystallized lead soaps (notably C18 and C16/18) were detected in 10 maps. Lead stearate was detected in only one sample (PaDry in Group 1), while mixed lead soaps were detected in one PaDry sample in Group 1, in LO_PbO, PaDry_PbO samples in Group 2 and PaWet_PbO_LW sample in Group 3). In PaDry and PaDry_PbO samples, they were found as particles dispersed in the paint matrix. They were also found more concentrated across and around the PbO globules in samples LO_PbO, PaDry_PbO, PaWetPbO and PaWet_PbO_LW samples, surrounding shannonite and LFH.

-

The unknown compound with diffraction peak positions that are similar to those of lead myristate was detected in three samples, notably the PaDry_PbO samples, only located in the core of the globules. In these three samples, the unknown phase is surrounded by crystallized mixed lead soaps (Pb C16/C18).

-

SH was detected in only two samples, in LO_PbO surrounding the globule core and in PaWet_PbO surrounding the globule core and as particles dispersed around this globule.

-

PN was detected in 14 maps (PaDry in Group 1, in LO_PbO, PaDry_PbO, PaWet_PbO samples in Group 2 and in PaDry_LW, PaDry_PbO_LW, PaWet_PbO_LW in Group 3). In PaDry, PaDry_PbO, PaDry_LW, PaDry_PbO_LW and PaWet_PbO_LW samples PN was found as more homogeneously dispersed particles in the paint matrix. In LO_PbO, PaDry_PbO, PaWet_PbO and PaWet_PbO_LW PN was also detected across the entire globule core and surrounding layers.

-

Finally, nHCer was detected in 11 maps (PaDry in Group 1, LO_PbO, PaDry_PbO and PaWet_PbO in Group 2), excluding the samples to which LW was intentionally added (Group 3). nHCer was detected as dispersed particles in the paint matrix in PaWet and PaDry_PbO samples, and in such a case usually in LF rich regions. This compound was also detected in LO_PbO, PaDry_PbO and PaWet_PbO samples across the core and along the edge of the globules.

In summary, the paint films contain mainly a partially saponified oil. Crystals present in these films are mainly made of LF, occasionally with LFH, lead soaps, PN and nHCer. When PbO is added after the preparation of leaded oil, globules containing a core of remaining lead oxides (litharge and/or massicot), carbonates (rarely SH, commonly PN and nHCer) and lead carboxylates (commonly LFH and LF and crystallized lead soaps) were observed.

Discussion

In summary, the preparation of historical leaded-oil media can contribute to the formation of several unusual lead carboxylates and lead carbonates. The sporadic detection of these lead-based products in historical paint samples from iconic works of art - such as The Night Watch, Mona Lisa and The Last Supper - motivated us to investigate their early-stage formation and distribution across a large corpus of mock-up leaded oil samples. These samples were prepared based on the De Mayerne’s huile de litharge recipe and analyzed using a combination of optical microscopy, bulk ATR-FTIR, HS-SPME-GC-MS, 2D µ-FTIR, and SR-µ-XRPD. Building on our previous studies which focused on individual lead products - particularly on LF (Gonzalez et al.) and PN (Gonzalez et al. and Vanmeert et al.) - this study explores the co-occurring formation of carboxylates and carbonates, including LFH, SH and nHcer5,6,7,8. It also brings new results on the kinetics of rare lead-based products, their distribution and motion within (saponified) oil films. For clarity, the discussion is structured around two experimental groups: Group 1 (media obtained directly from the De Mayerne recipe), Group 2 (media or linseed oil with additional PbO added at room temperature and gently mixed) (Fig. 6A, B). It should be noted that residual PbO was occasionally detected in samples from Group 1 (1 out of 3 maps), indicating that local reactions around PbO, discussed in Group 2 (Fig. 6B), may also occur in Group 1 under certain conditions.

The following section discusses the trends observed in Group 1, containing leaded oils (PaDry and PaWet) (Fig. 6A). As shown in the ATR-FTIR spectra of uncured PaDry and PaWet, these two media consist of partially saponified oil (Fig. S2, spectra C, D). The saponification is accelerated by the elevation of temperature and the addition of water during preparation, as observed in the PaWet system (Group 1, Fig. S2, spectrum D). In agreement with a previous study by De Viguerie et al., kinetic bulk ATR-FTIR analysis experiments of PaDry medium (Fig. 1) showed that within the first five hours of curing, two important chemical reactions occur: oxidation of C = C bonds in side chains and hydrolysis of triglycerides (Fig. 1A, B)18. Both reactions produce carboxylic acids: oxidation yields mono- and di-carboxylic acids, including the short formic acid, while hydrolysis releases glycerol and long aliphatic chain fatty acids39,40. The presence of formic acid in pure cooked LO and saponified leaded-oil media was further investigated using HS-SPME-GC-MS analyses (Fig. S8). The highest emission of free formic acid was observed in the pure cooked LO. This result agrees with the study of Švarcová et al., who detected formic acid in the vapors of linseed oil, stand oil and walnut oil and suggested its formation via an oxidation pathway: after the abstraction of a bis-allylic hydrogen from polyunsaturated fatty acids, free radicals, and subsequently, hydroperoxides are formed. These hydroperoxides can decompose to generate aldehydes. These aldehydes might further oxidize to form short carboxylic acids, including formic acid27,41. When PbO is cooked together with LO (PaDry and PaWet), HS-SPME-GC-MS analyses noted a significant decrease of the emission of volatile free formic acid (Fig. S8). This could be due to the reaction of formic acid with Pb(II) ions to form LF or due to slower oxidation reactions in charge of formic acid formation. The latter may be a result of a surface “skin” formation which prevents oxygen diffusion to deeper layers of the thick oil film near PbO, as shown in Fig. 3e. Emitted formic acid concentrations were found higher in the PaWet medium than in the PaDry. This observation is consistent with the findings of Baij et al., who demonstrated that the higher relative humidity promotes oxidation reactions which lead to an increased formation of carboxylic acids42.

Bulk ATR-FTIR kinetic experiments revealed that, besides the above-mentioned products, LF forms within approximately first 2.5 days by the reaction of formic acid and Pb(II) coming from lead carboxylate matrix (Fig. 6A) and from undissolved PbO (Fig. 6B). Optical microscopy combined with SR-µ-XRPD (Fig. 2 and Movie S1) confirmed that the formation of LF occurs within approximately two days and further revealed that LF crystallizes as micrometric particles. Interestingly, the movie also showed that LF crystals can migrate over distances of several millimeters during the first four days of drying, until cross-linking hinders their mobility. These crystals tend to concentrate in thicker regions, resulting in a heterogeneous film at the millimeter scale. This spatial variation could explain the unsystematic detection of LF in the four bulk ATR-FTIR kinetics acquisitions (Fig. S3). Furthermore, in our previous study, LF was imaged in transversal sections of cured PaDry films, with a higher concentration in the bottom layers. The movie supports our earlier hypothesis that this specific spatial distribution of LF is due to formic acid volatilization from thinner or more superficial regions (Fig. 6A)7. LF was detected by SR-µ-XRPD in all three samples from Group 1. However, this result may be unrepresentative of the entire sample, as the mapped areas were selected based on the visible presence of crystals under the microscope.

In one of the PaDry samples - such as the one shown in Movie S1 - crystals of lead soaps, including lead stearate and mixed lead soaps, were also detected (Fig. S4B, C). Mixed lead soaps were characterized by the d-spacing values between those of pure lead palmitate and lead stearate (d-spacing value 49.32 Å, 24.67 Å, 16.44 Å, 12.33 Å and 9.86 Å). Detection and spatial distribution of the phases (Table S6) using SR-μ-XRPD analyses, indicated that both pure and mixed lead soaps form in the paint matrices. While many studies report presence of metal soaps in model and historical paintings, they most often generalize the carboxylate component under the term “fatty acids” or they do not firmly characterize them as crystalline phases of fatty acids soaps (in this case mixed lead palmitate and stearate). This is often due to the choice of analytical technique combined with the insufficient degree of crystallinity and aggregate size36,39,43,44. Recently, mixed lead soaps were firmly characterized using SR-µ-XRPD in The Night Watch micro-fragment, colocalized with LF, PN and nHCer7.

Lead carbonates and hydroxides were not detected by bulk ATR-FTIR; however, SR-µ-XRPD revealed the presence of PN crystals in one PaDry sample and nHcer crystals in one PaWet sample. As previously mentioned, residual PbO particles may still be present in the paint films prepared from Group 1 media and contribute to the formation of PN and nHCer. Therefore, it is challenging to firmly conclude if carbonates form only from residual PbO or if carboxylates (lead soaps, LF and LFH) also transform into carbonates, as suggested by Švarcova et al.27. Additional experiments with lead soaps and/or LF - not synthesized from PbO - are required to assess this specific pathway. Finally, the more alkaline forms, LFH and SH, have not been detected in any of the three Group 1 samples.

In addition to analyzing the leaded oil mock-up films, we investigated the reactions occurring at the interface between PbO and (saponified) oil film, denoted here as Group 2, containing linseed oil or leaded oil with additional PbO (LO_PbO, PaDry_PbO and PaWet_PbO) (Fig. 6B). Two-dimensional µ-FTIR mapping over a period of 110 days, focused around PbO particles deposited on a LO film and aged at 60 °C, provided initial insights into spatially- and time-resolved formation of both lead carboxylates and carbonates (Fig. 3). Lead carboxylates were detected in both Area 1 and Area 2 in Fig. 3b, immediately after preparation (d = 0, within five hours), with their intensity and spatial distribution increasing over time. In our µ-FTIR data, a clear distinction between crystalline structures of lead soaps was not possible, due to limited crystallization and small aggregate size. Nevertheless, Plater et al. demonstrated that FTIR can distinguish specific lead soap structures by identifying alkyl chain vibrations that can be linked to specific chain lengths and levels of crystallinity, as seen with lead palmitate in Hobbema’s The Avenue at Middelharnis45. Additionally, Cotte et al. observed similar spectroscopic features in FTIR spectra collected on protrusions from a 17th century anonymous portrait15. Our SR-μ-XRPD analyses of samples PaDry_PbO and PaWet_PbO revealed the presence of both pure and mixed crystallized lead soaps (Figs. 4B–D, 5B, C, S6B and S7B). Consistent with the µ-FTIR maps, these soaps are predominantly concentrated across the core of the globules and around their larger peripheries. These soaps can have different sources: (i) lead soaps already present in the leaded oil which crystallize around the PbO particles, and (ii) new lead soaps forming from the reaction of PbO with unreacted oil ester and acid groups, as well as with new carboxylic acid groups formed during film curing (mentioned above). These include formic acids, leading to the production of the different lead formates. While LFH was not detected in samples from Group 1, it was successfully detected in 9 out of 11 maps from Group 2. LFH was found mainly concentrated across the core of the globules, while LF was usually distributed at the edge and around the globules. As illustrated in Fig. 6B, this spatial distribution may be associated with a gradient of alkalinity and the progressive conversion of LFH into LF through the reaction with formic acid.

Increasing alkalinity and Pb(II) concentration closer to PbO further impacts the formation and spatial distribution of lead carbonates. The most alkaline form, SH, was occasionally detected in the innermost parts of the globules where alkalinity is highest. In two specific samples containing additional PbO (LO_PbO and PaWet_PbO), residual massicot was also detected. These observations are representative of the phase distribution previously observed in historical fragments, notably The Last Supper. SH most likely formed from PbO carbonation of unreacted PbO, which is not commonly found in historical systems. As the most alkaline form, SH can further transform into PN and subsequently nHCer8. This transformation pathway best explains the rare detection of SH in historical and mock-up systems. PN and nHCer were also found more concentrated within the globules. µ-FTIR map of Area 1 in Fig. 3a, c shows that carbonates and hydroxides form within a few hours, with a higher concentration at the globule cores, while carboxylates tend to form a ring around the globule edges. All three carbonates can coexist within the same globule, as in Fig. 5, or be found individually, as in Fig. 4 where only the most carbonated nHCer is detected. The distribution of these phases can be influenced by their proximity to the surface and exposure to environmental CO2 and H2O, as well as by the possible presence of an overlying oil film (Fig. 6B)46. As an example, in Fig. 3 both lead carbonate and hydroxide were detected in Area 1 and not in Area 2. Optical microscopy revealed that PbO in Area 1 is directly exposed to the environment, whereas PbO in Area 2 remains covered by a layer of oil (Fig. 3a, b). Beyond environmental CO2, other sources of carbonation (not shown in Fig. 6B) may contribute to formation of lead carbonates. Carbonate may come from the decarboxylation of fatty acids or lead soaps, as proposed in previous studies3,6,10 or it may come from the decomposition of formic acid (original or after exchange of Pb2+ and H+ with another carboxylic acid). Boddien et al. suggested that formic acid, which is an unstable compound, may further undergo catalytic decomposition into CO₂ and H₂ in the presence of transition metals, such as Fe-containing driers or pigments47.

In Group 3, containing leaded oils mixed with LW pigment (PaDry_LW, PaWet_LW, PaDry_PbO_LW and PaWet_PbO_LW), lead carbonates - including nHCer, cerussite (Cer) and PN - were detected (Group 3 is not shown in Fig. 6). However, distinguishing between original HCer and Cer present in the LW pigment and the neo-formed phases is often challenging, due to their structural similarities and the need for additional data processing based on the diffraction peak widths. In our systems, HCer was detected in all three groups, but its presence in Group 3 (with additional LW) was not further discussed, as it remains unclear whether it is original or the result of secondary formation. Cer (which is present in LW) was detected only in Group 3 and was likewise excluded from the tables and discussion. Nevertheless, the formation of lead carbonates such as HCer, Cer and PN as secondary products from LW cannot be ruled out. For instance, PN detected in Group 3 might have formed from saponified oil, as previously shown, or from carbonation of PbO or in the presence of LW. Indeed, a recent XRPD study of a mixture of PbO:Cer 70:30w/w without any binder showed the formation of PN and nHCer after a few days at room temperature in an environment rich in water vapor. After 7 days, Cer was fully converted46.

In conclusion, this large dataset reflects a dynamic interplay between solubilization, chemical reactions, diffusion and crystallization over the different (saponified) oil and PbO interfaces. Additionally, spatial gradients of alkalinity and Pb(II) concentration, formic and other fatty acids, and environmental gases (O₂, CO₂, H₂O) influence the formation and spatial distributions of these products. Beyond the choice of a suitable analytical technique, these variations in formation and spatial distribution may also contribute to the rare and often sporadic detection of these lead-based products in historical paintings. As shown here, the use of microscopic techniques was crucial for identifying and locating phases at the micrometric scale, although they are limited to two-dimensional observations. In the future, we plan to further exploit advanced 3D imaging methods to obtain a comprehensive view of both the in-depth and in-plane distribution of these compounds, similar to approaches used in the study of protrusions in Van Gogh’s Wheat Stack Under a Cloudy Sky and in model systems developed for monitoring lead soap protrusions formation in oil paintings5,48.

It is important to note that the model systems investigated in this study are simplified in comparison to historical systems, focusing primarily on PbO and (leaded) oil as main reactants. In historical paintings, other lead-based pigments or other additives could contribute to the formation of these products (such as in the case of Van Gogh’s painting, which contains minium)5. Beyond lead carbonates, unusual lead sulfates may also form through reactions of Pb(II) ions released from lead-based driers/pigments or lead-based products. These ions may react with fatty acids to form lead soaps, diffuse to the paint surface and subsequently react with atmospheric compounds to form unusual lead sulfates (palmierite (K2Pb(SO4)2), anglesite (PbSO4), lanarkite (Pb2(SO4)O), leadhillite (Pb4SO4(CO3)2(OH)2)) or react with sulphur and/or sulphate containing species present within the paint layers49,50. These compounds were previously detected in several Old Master’s paintings50,51.

By tracking the formation of lead carboxylates and carbonates and addressing the detection challenges of the lead-based products through model systems, this research supports future identification of these compounds in both previously explored and unexplored historical paintings. Given the novel and underexplored nature of these compounds in oil paintings, further research is needed to investigate their potential role as chemical markers within paint systems, and to assess whether their presence is beneficial, detrimental or neutral to the artwork. Ultimately, this information could provide insights into historical artistic practices and improve conservation strategies, potentially extending the lifespan of the painted artworks.

Data availability

All relevant data supporting the conclusions of this paper are provided in the main text and/or Supplementary Materials. Additional data may be requested from the authors if needed.

References

Zumbühl, S. & Zindel, C. In Historical Siccatives for Oil Paint and Varnishes - The Use of Lead Oxide, Alum, White Vitriol, Pumice, Bone Ash and Venetian Glass as Driers: Historical Written Sources-Production and Raw Material Quality - Technological Significance. (eds Zumbühl, S. & Zindel, C.) 6-21 (Bern, HDW Publications Bern, Research for Conservators, 2022).

Casadio, F. et al. Metal Soaps in Art (Springer, 2019).

Cotte, M. et al. Lead soaps in paintings: friends or foes?. Stud. Conserv. 62, 2–23 (2017).

Cotte, M. et al. The ‘Historical Materials BAG’: a new facilitated access to synchrotron X-ray diffraction analyses for cultural heritage materials at the European Synchrotron Radiation Facility. Molecules 27, 1997 (2022).

Vanmeert, F., Vandersnickt, G. & Janssens, K. Plumbonacrite identified by X-ray powder diffraction tomography as a missing link during degradation of red lead in a Van Gogh painting. Angew. Chem. Int. Ed. 54, 3607–3610 (2015).

Gonzalez, V. et al. Unraveling the composition of Rembrandt’s impasto through the identification of unusual plumbonacrite by multimodal X-ray diffraction analysis. Angew. Chem. Int. Ed. 58, 5619–5622 (2019).

Gonzalez, V. et al. Lead(II) formate in Rembrandt’s Night Watch: detection and distribution from the macro-to the micro-scale. Angew. Chem. Int. Ed. 62, e202216478 (2023).

Gonzalez, V. et al. X-ray and infrared microanalyses of Mona Lisa’s ground layer and significance regarding Leonardo da Vinci’s palette. J. Am. Chem. Soc. 145, 23205–23213 (2023).

Gonzalez, V., Cotte, M., Vanmeert, F., de Nolf, W. & Janssens, K. X-ray Diffraction mapping for cultural heritage science: a review of experimental configurations and applications. Chem. A Eur. J. 26, 1703–1719 (2020).

Higgitt, C., Spring, M. & Saunders, D. Pigment-medium interactions in oil paint films containing red lead or lead-tin yellow. Natl. Gallery Tech. Bull. 24, 75–95 (2003).

Boon, J. J., van der Weerd, J., Keune, K., Noble, P. & Wadum, J. Mechanical and chemical changes in old master paintings: dissolution, metal soap formation and remineralization processes in lead pigmented ground/intermediate paint layers of 17th century paintings, In Preprints of the ICOM Committee for Conservation 13th Triennial Meeting (ed. Antomarchi, C.) 1, 401–406 (Rio de Janeiro, James and James, 2002).

Keune, K., van Loon, A. & Boon, J. J. SEM backscattered-electron images of paint cross sections as information source for the presence of the lead white pigment and lead-related degradation and migration phenomena in oil paintings. Microsc. Microanal. 17, 696–701 (2011).

Broers, F. T. H. et al. Correlated X-ray fluorescence and ptychographic nanotomography on Rembrandt’s The Night Watch reveals unknown lead ‘layer’. Sci. Adv. 9, eadj9394 (2023).

Taylor, P. & Lopata, V. J. Stability and solubility relationships between some solids in the system PbO-CO2-H2O1. Can. J. Chem. 62, 395–402 (1984).

Cotte, M., Checroun, E., Susini, J. & Walter, P. Micro-analytical study of interactions between oil and lead compounds in paintings. Appl. Phys. A. 89, 841–848 (2007).

Cotte, M. et al. Kinetics of oil saponification by lead salts in ancient preparations of pharmaceutical lead plasters and painting lead mediums. Talanta 70, 1136–1142 (2006).

Cotte, M. et al. Watching kinetic studies as chemical maps using open-source software. Anal. Chem. 88, 6154–6160 (2016).

De Viguerie, L., Payard, P. A., Portero, E., Walter, P. & Cotte, M. The drying of linseed oil investigated by Fourier transform infrared spectroscopy: Historical recipes and influence of lead compounds. Prog. Org. Coat. 93, 46–60 (2016).

Tumosa, C. S. & Mecklenburg, M. F. The influence of lead ions on the drying of oils. Stud. Conserv. 50, 39–47 (2005).

Meneghetti, S. M. P., De Souza, R. F., Monteiro, A. L. & De Souza, M. O. Substitution of lead catalysts by zirconium in the oxidative polymerization of linseed oil. Prog. Org. Coat. 33, 219–224 (1998).

Laporte, L. et al. Multiscale organisation of lead carboxylates in artistic oil binders. Phys. Chem. Chem. Phys. 26, 2657–2665 (2024).

Soucek, M. D., Khattab, T. & Wu, J. Review of autoxidation and driers. Prog. Org. Coat. 73, 435–454 (2012).

White, R. & Kirby, J. Rembrandt and his Circle: seventeenth-century Dutch paint media re-examined. Natl Gallery Tech. Bull. 15, 64–78 (1994).

Bergeon, S. & Faillant-Dumas, L. Restauration des peintures. 21, 16-25 (Éditions de la Réunion des Musées Nationaux, 1980).

Ferreira, E. S. B., Morrison, R., Keune, K. & Boon, J. J. Reporting highlights of the De Mayerne programme. (eds Boon, J. J. & Ferreira, E.S.B) 53–62 (The Hague, Nederlandse Organisatie voor Wetenschappelijk Onderzoek, 2006).

Mazzeo, R. et al. Attenuated total reflection micro-FTIR characterisation of pigment-binder interaction in reconstructed paint films. Anal. Bioanal. Chem. 392, 65–76 (2008).

Švarcová, S. et al. Uncovering lead formate crystallization in oil-based paintings. Dalton Trans 49, 5044–5054 (2020).

ImageJ, Image Processing and Analysis Software. (https://imagej.net/ij/).

Schroer, C. G. et al. Hard X-ray nanoprobe of beamline P06 at PETRA III. AIP Conf. Proc. 1741, 030007-1–030007-5 (2016).

Diaz-Moreno, S. et al. The spectroscopy village at diamond light source. J. Synchrotron Radiat. 25, 998–1009 (2018).

BL13 - XALOC Beamline, Alba Synchrotron. (https://www.cells.es/en/instruments/beamlines/bl13-xaloc).

Riekel, C., Burghammer, M. & Davies, R. Progress in micro- and nano-diffraction at the ESRF ID13 beamline. IOP Conf. Ser. Mater. Sci. Eng. 14, 012013 (2010).

Cotte, M. et al. New opportunities offered by the ESRF to the cultural and natural heritage communities. Synchrotron Radiat. News. 35, 3–9 (2022).

Jupyter Notebook Software. (https://jupyter.org/).

Schutte, C. J. H. & Buijs, K. The infra-red spectrum of the formate ion. Spectrochim. Acta. 20, 187–195 (1964).

Garrappa, S., Kočí, E., Švarcová, S., Bezdička, P. & Hradil, D. Initial stages of metal soaps formation in model paints: the role of humidity. Microchem. J. 156, 104842 (2020).

Kočí, E. et al. Mixed lead carboxylates relevant to soap formation in oil and tempera paintings: The study of the crystal structure by complementary XRPD and ssNMR. Dalton Trans 48, 12531–12540 (2019).

Martínez Casado, F. J. et al. Intermediate rotator phase in lead(II) alkanoates. J. Phys. Chem. C. 111, 6826–6831 (2007).

Izzo, F. C., Kratter, M., Nevin, A. & Zendri, E. A critical review on the analysis of metal soaps in oil paintings. Chem. Open 10, 904–921 (2021).

Hermans, J. J., Keune, K., Van Loon, A. & Iedema, P. D. Metal Soaps in Art (eds Casadio, F. et al.) 47–67 (Cham, Springer, 2019).

Frankel, E. N. Volatile lipid oxidation products. Prog. Lipid Res. 22, 1–33 (1982).

Baij, L., Chassouant, L., Hermans, J. J., Keune, K. & Iedema, P. D. The concentration and origins of carboxylic acid groups in oil paint. RSC Adv 9, 35559–35564 (2019).

Keune, K. & Boon, J. J. Analytical imaging studies of cross-sections of paintings affected by lead soap aggregate formation. Stud. Conserv. 52, 161–176 (2007).

Hermans, J. & Helwig, K. The identification of multiple crystalline zinc soap structures using infrared spectroscopy. Appl. Spectrosc. 74, 1505–1514 (2020).

Plater, M. J. The characterisation of lead fatty acid soaps in ‘protrusions’ in aged traditional oil paint. Polyhedron 22, 3171–3179 (2003).

Gonzalez, V. et al. Révéler les choix matériels et techniques de Léonard de Vinci par l’analyse chimique: le cas du pigment blanc de plomb. Technè Hors Série. 162–171 (2024).

Boddien, A. et al. Iron-catalyzed hydrogen production from formic acid. J. Am. Chem. Soc. 132, 8924–8934 (2010).

Duivenvoorden, J. R. et al. How to approach long-term monitoring of chemical dynamics in oil paintings?. npj Herit. Sci. 13, 24 (2025).

Simoen, J. et al. Combined micro- and macro scale X-ray powder diffraction mapping of degraded Orpiment paint in a 17th century still life painting by Martinus Nellius. Herit Sci. 7, 83 (2019).

Price, S. W. T. et al. Unravelling the spatial dependency of the complex solid-state chemistry of Pb in a paint micro-sample from Rembrandt’s Homer using XRD-CT. Chem. Commun. 55, 1931–1934 (2019).

Gonzalez, V., van Loon, A., Price, S. W. T., Noble, P. & Keune, K. Synchrotron micro-XRD and micro-XRD-CT reveal newly formed lead-sulfur compounds in Old Master paintings. J. Anal. At. Spectrom. 35, 2267–2273 (2020).

Acknowledgements

The authors thank Pierre Lloria (PSCM, ESRF, Grenoble, France) for providing the equipment and designing the set-up for optical microscopy monitoring. We are grateful to M. Burghammer (ID13, ESRF) J. Garrevoet (P06, DESY), K. Ignatiev (I18, DLS) and N. Salvado (Universitat Politècnica de Catalunya) for their help with the synchrotron experiments. We thank W. De Nolf and L. Huder (ESRF, Grenoble, France) for providing the support and software tools for the SR-μ-XRPD data processing. IF has received funding from the European Union’s Horizon 2020 research and innovation program under the Marie Skłodowska-Curie actions (COFUND Programme “InnovaXN” #847439). The funder played no role in study design, data collection, analysis and interpretation of data, or the writing of this manuscript. Franco-Dutch collaborations have been supported through the PHC van Gogh grant (project number 48020ZB) provided by the French Ministries of European and Foreign Affairs, and of Higher Education, Research and Innovation. The ESRF beamtime was granted through the peer-reviewed BAG proposal HG-172 at ID13, supported by the European Union’s Horizon 2020 research and innovation program (grant No 870313, Streamline). Beamtime at DESY was granted at P06 through proposals N° I-720190926 EC and I-20200185 EC.

Author information

Authors and Affiliations

Contributions

I.F. led the preparation of the manuscript and coordinated its submission. I.F. was also primarily responsible for data acquisition, processing, and interpretation. V.G. and M.C. contributed to the development of model systems and synchrotron radiation-based analyses. M.C. also supported the collection of spectroscopic data. V.G. and F.V. assisted with SR-μ-XRPD data processing. A.A.M. acquired and processed GC-MS data. M.C., K.K., and J.H. contributed to the interpretation of spectroscopic results. J.F. and B.B. provided guidance on data interpretation. K.K. and M.C., as principal investigators, jointly funded and supervised this work and the project. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Fazlic, I., Gonzalez, V., Vanmeert, F. et al. Early formation and detection of lead-based products from PbO-oil paint systems. npj Herit. Sci. 13, 430 (2025). https://doi.org/10.1038/s40494-025-01986-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s40494-025-01986-3