Abstract

Ancient artifacts like bronze often suffer corrosion from water and soil, requiring effective surface coatings to prevent further decay. Herein, we developed a vacuum-assisted method to prevent bronzes as a model from surface corrosion. The graphene oxide (GO)-based coatings can be toughly infiltrated into the rough bronze surfaces with freezing drying. Scanning transmission electron microscopy and energy dispersive X-ray spectroscopy demonstrate the advantages of this method in micro-nano coating protection, namely, the complete coating covering the crack channels. The coated bronze still has a lower corrosion rate than the uncoated sample, confirmed by electrochemical methods under 3 wt.% NaCl solutions. Focused ion beam cross-section imaging confirms a continuous protective layer in the coated sample, contrasting with the compact oxide layer on uncoated bronze. This method offers a promising solution for the sustainable preservation of bronze artifacts and other metal relics.

Similar content being viewed by others

Introduction

Metal artifacts and archaeometallurgy rely on historical relics but face heavy corrosion problems. These artifacts have been corroding from underground or underwater defamed surfaces1. The surface of these artifacts has not only been changed by natural corrosion or natural disasters, also been polluted by human activities, particularly modern cultural relic restoration and protection or disaster recovery in the artifact fields. Researchers have realized the bronze artifacts will corrode in organic acid environments2,3,4. These organic acid contained inhibitors can be replaced by economic and environmental materials as alternatives5,6. Nevertheless, developing an eco-friendly method for anticorrosion and conservation of metal artifacts is highly demanded but still pending.

A promising way is using an inorganic coating to protect metals such as bronze from corrosion. Graphene oxide (GO) is a good anti-corrosion material that has been widely used in materials field including batteries, supercapacitors and fuel cells7. These materials have been noticed to be applied in bronze corrosion inhibitors8,9,10. However, few studies focus on graphene oxide-coated bronze artifacts. This might be because the binding of the metal and graphene is not easy due to the difficulty in interfacial wetting. The porous corroded surface of bronze cannot be fully covered by corrosion inhibitors, even adding organic surfactants or binders11,12. How to solve the problem of wettability has always hindered the development of green coating technology.

Here, we developed a vacuum-coated method composited by graphene oxides, polytetrafluorethylene (PTFE), and Nafion solutions, which can be toughly adsorbed on the surfaces with the help of capillary forces. Because the GO with the oxygen-containing group and Nafion have a sulfonate group13,14, it will interact with the bronze surface, while PTFE has effectively hydrophobic properties to better improve the anticorrosion layer15. It is a freeze dryer that can maintain capillary force infiltration and coating film formation on a bronze rough surface. We found that GO-coated bronze has higher corrosion potential and higher corrosion resistance compared to uncoated bronze through electrochemical analysis. We further explore the surface structure of the sample has fully covered by capillary-induced infiltration under vacuum conditions, even the grooves and porous areas also have been covered. According to the cross-section image, we proposed that the uncoated surface has much corrosion to oxide layers while the coated one was protected well. These findings are of great significance for vacuum coating, which is promising for green corrosion inhibitors industrialization.

Methods

Synthesis method

10 mL solution of graphene oxide (1 mg/mL, Sigma-Aldrich) was mixed with 0.5 mL of Nafion 117 solution (~5% in a mixture of lower aliphatic alcohols and water, Sigma-Aldrich) and 0.5 mL of polytetrafluoroethylene (PTFE) solution (60 wt % dispersion in water, Sigma-Aldrich). The mixture was stirred evenly at 25 °C. The resulting solution was then sprayed onto the sample using a wash bottle with a nozzle. After spraying, the sample was washed with deionized water and ethanol, then dried for several days in a drying dish containing silica gel particles under nitrogen flow to remove surface moisture. Immediately after spraying, the sample was transferred to liquid nitrogen, frozen for 60 s, and then placed in a pre-cooled freeze dryer at -40 °C for 12 h. After freeze-drying, the sample was removed and prepared for the next experiment.

Electrochemical characterization

All electrochemical experiments were conducted out on SP300 Bio-Logic electrochemical workstation. A standard three-compartment electrochemical cell was used for corrosion test, using a Pt wire separated by porous ceramics as the auxiliary electrode and a Ag/AgCl electrode as the reference electrode. The working electrode is fixed by a removable clamp. The immerse area of the bronze sample was 0.5 cm2. The cyclic voltammetry (CV) curves of samples were evaluated in 3 wt.% NaCl solution (~ 50 mL). The electrochemical impedance spectroscopy (EIS) tests were conducted after 12 h of immersion at the open-circuit potential (OCP), in the frequency range of 100 kHz–10 mHz. The simulation of impedance spectra with equivalent circuits were calculated by EC-Lab software. The polarization curves measurements were subsequently conducted with a scan rate of 1 mV/s, started from a cathodic potential of −30 mV relative to the OCP and stopped at 30 mV relative to the OCP. The samples were also assessed after being soaked for 60 days. All electrochemical tests were performed at 25 °C.

Material characterization

The bronze samples were loaded on FEI Xe-plasma FIB/SEM (Helios PFIB, FEI, Hillsboro, OR, USA) stage with free rotated holder. The deposition current of Pt under electron beam was 1.6 nA and the ion beam was 1.0 nA. First, a ~ 200 nm thick Pt layer was deposited using an electron beam, followed by the deposition of a ~ 1 μm thick Pt protection layer using an ion beam. Then, the milling process with plasma source under 60 nA and cleaning current under 0.3 nA with 30 kV. The back scatter image and Energy dispersive X-ray spectroscopy (EDX) mapping were performed using a Zeiss Sigma scanning electron microscope (SEM, Carl Zeiss SMT, AG, Germany). EDX was performed on Zeiss Sigma SEM with an acceleration voltage of 15 kV. The transmission electron microscopy (TEM) lamella was prepared with the traditional lift out method16,17. The sample was cut into approximately 10 µm long, 0.1 µm thick, and 8 µm wide, as shown in Fig. S1. All the final polishing process choose 5 kV with 8 ~ 30 pA current for 30 s. To track the elemental distribution of the coating during EDX imaging, we used dimethylsiloxane (5 wt.%) as a tracer additive during the coating preparation. The scanning TEM (STEM) and EDX spectra and elemental mappings of TEM were conducted by a JEM 2100 Plus (JEOL, Ltd., Tokyo, Japan) microscope under 200 kV.

Results

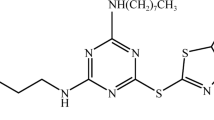

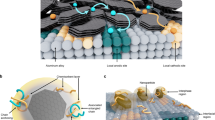

A graphene oxide-based coating, incorporating PTFE and Nafion (depicted in Fig. 1A), was prepared using magnetic stirring, spray coating, liquid nitrogen freezing, and vacuum freeze drying to form a uniform, corrosion-resistant nanolayer on bronze surfaces (Fig. 1B). The carton series shows the evolution of the entire coating process at the microscale (Fig. 1C). We use TEM to demonstrate the coating on bronze; the lamella of TEM has been shown in Fig. S1. During the milling process, organic materials, including PTFE and Nafion, tend to break into large molecular fragments rather than small volatile species. Unlike metals (which form volatile oxides), these fragments remain nearby and redeposit onto the surface. Therefore, we added silicon-contained dimethicone in the coating layer as a benefit to cutting and tracing of TEM lamella preparation. By comparing the bright field (BF) and dark field (DF) images of the STEM, it can be found that there are many holes on the surface of the sample, as well as the pore structure in the cracks (Fig. 1D and E). Further large-scale pictures show that the sample has a clear sandwich structure after focused ion beam (FIB) thinning, that is, the Pt deposition protection layer on the surface and the coating on the middle layer of sandwich structure (Fig. 1F).

A The chemical structure of composition of coating solution. Graphene oxide (GO), Polytetrafluoroethylene (PTFE) and Nafion solution. B Preparation process of vacuum coating. C The drying microstructures description of coating film with freeze-dry method. D The bright field image of cross-section of coated sample. The blue arrow denotes the incoming direction of the ion beam. The bright arrows indicate the pores of lamella. The green arrow indicates the region of coating layer. The dark arrow indicates the crack channel of the surface. E The corresponding dark field image of (D). F Enlarged view of the white dotted frame shown in E. the olive, green, and teal of false colored STEM image separately indicate the coating layer, the particulate exfoliated surface, and matrix surface of sample. G, H The EDX spectra in (F). The Si signal from PDMS was used as labeled indicator for coating layer. The Fe signal might come from pole pieces of JEOL TEM, which can be identified as the background level. I The corresponding EDX element mapping of (F). Ga signal comes from FIB ion source during milling and redepositing of ions. The ion beams also damaged the coating surface where the Si had been redeposited during milling.

Further elemental analysis by EDX showed that the tracer content (Si) in the coating was significantly higher than that in the original surface of the sample (Fig. 1G, H). The analysis found that the coating was evenly distributed without holes or breaks (Si elemental mapping of Fig. 1I). The nanoparticles on the surface may come from natural corrosion or redeposition after FIB cutting (Cu elemental mapping of Fig. 1I). However, the cracks on the surface were perfectly covered by the coating, and even the nanoscale channels were filled with the coating. This shows that the vacuum-assisted coating structure preparation method can effectively cover the sample surface and fill the cracks due to capillary action.

To further illustrate the advanced nature of the coating, we first analyzed the mixture of the coating solution. The digital graphs of several mixture solutions clearly show the different properties of the coating solution (Fig. S2). The color of the mixture solution is closer to bronze than that of each two-solution mixture, so it could have a minimal impact on the overall bronze appearance. More importantly, each material contributes its unique advantages: GO provides anti-oxidation properties, PTFE offers chemical resistance, and Nafion serves as a binder. Therefore, each group would not be considered an effective covering layer separately. We further used SEM to characterize the coating effects of the respective materials to highlight the advanced nature of the method we emphasized. The GO coating obviously does not have a continuous protective layer and has no use value (Fig. 2A). The Nafion coating is uniform and continuous, but its hydrophilic surface limits the scope of practical application (Fig. 2B). The non-conductivity and high roughness of the PTFE coating make the curled surface lack adhesion to the substrate (Fig. 2C). Although the mixed coating of GO and Nafion improves the coating ability of graphene, the hydrophilic surface has the same limitations as the single-component coating (Fig. 2D). The mixed surface of PTFE and Nafion still cannot overcome the problems of voids and discontinuities (Fig. 2E). Only the mixed coating of Nafion+PFTE + GO has a dense, continuous surface, and no curling at the edges, making it suitable for use as a protective layer (Fig. 2F). Thanks to the hydrophilic and hydrophobic chains of formed GO coating layer, the surficial charge of bronze will be changed after this modification—GO, PTFE and Nafion mixture covering. This will have a direct impact on the corrosion path and reflect in the corrosion test.

A The graphene oxide-coated layer has an incomplete surface coating. B The Nafion coated layer has smooth surface. C PTFE features patterned layers with raised edges. D Graphene oxide and Nafion hybrid layer has a rough surface and pore structure. E PTFE and Nafion hybrid layers have discontinuous rough surfaces and curled edges. F The hybrid layer of graphene oxide, PTFE and Nafion has complete surface coverage and smooth edges. The false colored SEM images: sky blue represents the top surface of sample. teal represent the crossed section of surface.

We further used electrochemical tests to determine the differences between coated and uncoated bronze samples. Firstly, the EIS spots show that coated samples have much higher interfacial resistance than the uncoated ones (Fig. 3A). Bode plots for coated and uncoated samples clearly show the phase angle gradually increases from 10° to about 50°, indicating an enhanced diffusion impedance feature (Fig. 3B). The phase angle decreases at low frequencies (f < ≈10 Hz) and as a function of the frequency. It is probably due to the un-coating surface degradation and another diffusion process from the interfacial reaction. Even though the solution resistance of the samples is much smaller than resistance of the oxide layers, it still influences the impedance modulus and phase angle in the high-frequency region. Therefore, the ohmic-resistance-corrected Bode plot is shown in Fig. 3C. Compared to Fig. 3B (uncorrected), the higher phase angle observed in the coated sample at high frequencies reflects its capacitive character, arising from the dielectric nature of the coating. This indicates that the coating acts as an effective insulating layer, delaying charge transfer and enhancing surface protection.

A EIS curves of two samples. B Without correction and (C) ohmic-resistance-corrected Bode plots of coated and uncoated samples in 3 wt% NaCl electrolyte; (D) CV curves of two samples in 3 wt% NaCl electrolyte. E The potentiodynamic polarization curve of two samples. F EIS curves of two samples after electrochemical test. The linear polarization and cyclic voltammetry measurements were performed without applying explicit ohmic drop compensation.

Modeling the EIS response could provide evidence to investigate the electrochemical behavior of the electrode (Fig. 4)18,19. The resistance of the solution was denoted by Rs, which can be obtained from the high-frequency region20,21. For the uncoated sample (Fig. 4A), the surface formed a natural oxide film, while Cd and Rd correspond to the capacitance and resistance of the oxide film, respectively. The charge transfer resistance at the electrical double layer between the interface of the passivation layer and the substrate was denoted as Rct, where the corresponding capacitance was denoted as Cdl. For the coated sample (Fig. 4B), Rpw and Cpw represent the resistance and capacitance of the pore walls in the coated layer. Due to the high resistance value of the pore wall, Rpw was excluded21. Rp is the resistance of the porous layer, and Cp is the associated non-ideal capacitance, i.e., a constant phase element. The a1 and a2 represent the degree of deviation from ideal capacitance for the porous coating layer and the dense oxide film, respectively. The extracted parameters fitting of EIS data are listed in Table 1. The fitting results show that the resistance of the porous and dense oxide layers is several orders of magnitude higher than that of the natural oxide film, which indicates the good anti-corrosion ability of the coating layers.

Coated and uncoated samples’ CV curves were evaluated in 3 wt % NaCl solution. The CV curve of the coated sample has a much smaller current density than the uncoated one. More importantly, the uncoated sample has clear Cu oxide and its reduction peak around 0 V vs Ag/AgCl electrode, while the coated one does not have a clear Cu oxidation peak and the reduction peak has shifted to a lower potential (Fig. 3D). The peak of Cu oxide/reduction couple for the uncoated sample is insisting with the literature12, while the coated one has no clear peak due to the coating layer blocking the reaction.

We further conduct potential dynamic polarization (Tafel) curves in a corrosive media of 3.5 wt% NaCl solution to evaluate the corrosion resistance of coated and uncoated samples (Fig. 3E). The corrosion potential (Ecorr) of the coated sample was more positive than that of the uncoated sample (−0.07 V vs. −0.105 V), exhibiting similar polarization behavior but indicating greater resistance to corrosion compared to the uncoated bronze. More interestingly, the coated sample maintained a similar EIS performance after the corrosion test as it had before the test (Fig. 3F). While the uncoated one shows larger corrosion resistance after the CV and EIS tests, that implies the surface of the uncoated sample has changed. The fitting data of these curves indicated the coated sample showed larger resistance of the porous layer after electrochemical test (Table 1). Although the coating introduces additional ohmic resistance that may influence both kinetic and resistive aspects of the measurements, the comparison between coated and uncoated bronze samples remains valid, as both were evaluated under identical conditions. Thus, the observed trends still offer meaningful insights into the protective performance of the coating.

To understand why the coated sample exhibits significantly higher corrosion resistance, it is necessary to characterize the bronze surface structures after the electrochemical test. We first used focused ion beam scanning electron microscopy (FIB/SEM) to examine the cross-sectional profile of the bronze sample. A standard protocol was followed (see details in the experimental section, and supporting image Fig. S3), utilizing a 52° tilted stage for deposition and milling with the gas injection system (GIS)22,23. Both electron beam and ion beam deposition were subsequently applied (Fig. S3A). The green area of SEM images represents the Pt deposited region to protect the surface from milling damage. We obviously see cracks (see white arrow in Fig. S3B and C) and porous (see white dotted circle in Fig. S3C) from top to bottom by SEM image of the sample surface. These defects will lead to the easy appearance of air entrapment during surface coating, which together with the rough and undulating surface will make it not easy to obtain a continuous coating. We also observed newly formed pore structures on the surface after cutting (see blue dotted circle in Fig. S3C). This is due to the damage caused by ion beam cutting. In further analysis, it is important to distinguish these features from the defects present on the surface.

We further use SEM cross-section energy dispersive X-ray spectroscopy (EDX) imaging to prove the well-coated layer. The backscatter image in Fig. 4A shows the coated sample, which was protected by Pt deposition prior to FIB cutting. The coated layer formed by GO successfully prevents the solution from reacting with the material surface, so there is no obvious subsurface oxidation and corrosion segregation near the surface. More importantly, the SEM image clearly shows the V-shaped groove of the surface was protected well, the GO membrane has perfectly fitted the V-shaped groove to form a complete coating (see triangular dotted frame in Fig. 5A). The EDX imaging the distribution of C has a clear layer, and the O elemental map also has a concentration region representing O-contained species (see white arrow in Fig. 5B). It is noted that the Pt distribution might differ from the carbon map (indicated by the blue ellipse), possibly due to deposition damage, as highlighted by blue ellipse enclosed area in Fig. 5C. However, the Cu elemental imaging has a clear curve for interface, is consistent with the concentration zone of carbon elements. Compared to O mapping, the V-shape O distribution mapping imply that surface Cu was not fully oxides by covering GO membrane. Sn and Pb elements are segregated to the lower right corner, indicating that the element inhomogeneity near the surface of the sample is obvious. Here we draw out a diagram to demonstrate the covered surface with fully coating GO membrane. Both sides of GO membrane have grifted to Nafion and PTFE species. Because the film is formed under vacuum, the air in the cracks is extracted, the film infiltrates well to the V-shape surface. The arrows in Fig. 5A also label the small pores and cracks, graphene either fills the pore or covers the tiny channel due to the size of GO.

The uncoated sample also have segregation to porous surface, while the inner layer is oxides of bronze. We obviously observed several dark spots of SEM image from Fig. 6A. However, by using the EDX chemical imaging, we can see the concentrated spot on Cu map, as O, Pb, and Sn elements do not have, which are consistent with uncoated one. This might be because most of the samples was oxide and spot represents metallic Cu. According to O distribute mapping, the uncoated one have a higher concentration (70 wt % vs 65 wt %) than coated one. Meanwhile, the distribution of the entire mapping figure is almost full of O, and the O in the coated sample can be seen in a clear distribution area (area below the V-shape). The elemental mappings show a slight presence of carbon on the surfaces, but the bulk materials still have segregation patterns on the inner (Fig. 6B). Thanks to the EDX spectra on the samples, the content of C is clearly difference (arrow in Fig. 6C). It causes carbon to come from contamination and does not impact the comparison of coating performance. We hereby safely conclude that GO membrane would give a protection layer to prevent metallic Cu from further oxides and enhance the surface anti-corrosion properties.

To confirm the long-term effectiveness of the coating, we extended the corrosion test to 60 days. Through electrochemical testing, the coated bronze has been compared to the uncoated one after being soaked for 60 days. The CV curves of two samples were first assessed (Fig. 7A). We have observed the CV curve of the coated sample, which closely resembles the initial state. However, the uncoated sample exhibits more redox peaks, indicating a more complex surface interaction. Additionally, the Tafel curve of the coated sample still shows a more positive potential (−0.05 V) compared to that of the uncoated bronze (−0.08 V) (Fig. 7B). We extracted icorr values by extrapolating the linear regions of the anodic and cathodic branches to the corrosion potential, following standard electrochemical protocols. The negative sign in the corrosion current density (icorr) reflects its electrochemical meaning, which is related to the direction of electron flow and the type of reaction occurring. In our work, we follow the convention that current is defined as positive for cathodic (reduction) reactions and negative for anodic (oxidation) reactions. Therefore, the negative value of icorr indicates that the metal is undergoing oxidation (i.e., corrosion), with electrons flowing out of the metal. This sign convention highlights the anodic nature of the corrosion process, where the metal loses electrons as it corrodes. The coated sample exhibited a lower icorr (−2.3 mA·cm−2) compared to the uncoated bronze (−2.5 mA·cm−2), confirming that the coating slows the corrosion rate. These data confirmed that the new coated method effectively covered the bronze surface, even after 60 days of corrosion test. We would conclude this coating has much higher stability and anti-corrosion properties.

Discussion

The inherent properties of graphene oxide (GO) have been extensively studied and leveraged for corrosion protection applications24. In this work, we incorporated polytetrafluoroethylene (PTFE) and Nafion as additives in the coating solution to enhance its performance15. PTFE, with its highly electronegative fluorine atoms bonded to carbon, exhibits excellent hydrophobicity due to its low surface energy, which inhibits the formation of hydrogen bonds with water molecules. Nafion, containing –SO3H groups, serves as an effective binder and can adsorb onto metal surfaces, contributing to improved surface coverage and corrosion protection14,25. During the coating process, the mixed solution of GO, PTFE, and Nafion infiltrates the microstructures of the bronze surface, and capillary forces ensure thorough filling of interfacial voids. Upon freeze drying, a uniform nanoscale coating layer is formed. This capillary-assisted infiltration approach has been previously demonstrated to effectively fill surface voids and produce uniform coatings26,27, and it is successfully applied here to achieve robust corrosion resistance.

To summarize, we have developed a facilitated vacuum coating method to coat the bronze artifacts. With the help of capillary-induced infiltration, the GO-contained layers are well-covered on the surface of the sample, which have been proved by STEM-EDX mapping. The GO-coated bronze has ca. 35 mV positive corrosion potential, which signifies that the GO membrane effectively hinders the corrosion. We also observed the cross-sectional image of GO uncoated and coated bronze, where the coated sample has a carbon layer on the surface. Despite the presence of micro-cracks, the coating remains well-covered, suggesting that capillary-induced infiltration under vacuum conditions enhances the integrity of the coating. The graphene coating method requires further optimization; however, the capillary-induced vacuum coating technique presents an opportunity to create a durable protective layer for bronze artifacts.

Data availability

All data generated or analyzed during this study are included in this published article and its supplementary information files.

References

Oudbashi, O. A methodological approach to estimate soil corrosivity for archaeological copper alloy artefacts. Heritage Sci. 6, 2 (2018).

Rocca, E., Rapin, C. & Mirambet, F. Inhibition treatment of the corrosion of lead artefacts in atmospheric conditions and by acetic acid vapour: use of sodium decanoate. Corros. Sci. 46, 653–665 (2004).

Zhao, W. et al. Initial atmospheric corrosion studies of copper from macroscale to nanoscale in a simulated indoor atmospheric environment. Corros. Sci. 195, 109995 (2022).

Chiantore, O. & Poli, T. Indoor air quality in museum display cases: volatile emissions, materials contributions, impacts. Atmosphere 12, 364 (2021).

Albini, M. et al. Comparison of a bio-based corrosion inhibitor versus benzotriazole on corroded copper surfaces. Corros. Sci. 143, 84–92 (2018).

Abdel-Karim, A. M. & El-Shamy, A. M. A review on green corrosion inhibitors for protection of archeological metal artifacts. J. Bio- Tribo-Corros. 8, 35 (2022).

El-Kady, M. F., Shao, Y. & Kaner, R. B. Graphene for batteries, supercapacitors and beyond. Nat. Rev. Mater. 1, 16033 (2016).

Zhao, Y., Jiang, F., Chen, Y.-Q. & Hu, J.-M. Coatings embedded with GO/MOFs nanocontainers having both active and passive protecting properties. Corros. Sci. 168, 108563 (2020).

Jena, G. & Philip, J. A review on recent advances in graphene oxide-based composite coatings for anticorrosion applications. Prog. Org. Coat. 173, 107208 (2022).

Galvagno, E. et al. Present status and perspectives of graphene and graphene-related materials in cultural heritage. Adv. Funct. Mater. 34, 2313043 (2024).

Chiavari, C. et al. Atmospheric corrosion of fire-gilded bronze: corrosion and corrosion protection during accelerated ageing tests. Corros. Sci. 100, 435–447 (2015).

Wu, W. et al. Multifunctional organic-inorganic hybrid coating for enhanced bronze corrosion protection. J. Cult. Herit. 69, 113–125 (2024).

Li, J. et al. Modification of graphene and graphene oxide and their applications in anticorrosive coatings. J. Coat. Technol. Res. 18, 311–331 (2021).

Ding, J., Liu, P., Zhou, M. & Yu, H. Nafion-endowed graphene super-anticorrosion performance. ACS Sustainable Chem. Eng. 8, 15344–15353 (2020).

Li, G. et al. Investigating the effect of polytetrafluoroethylene on the tribological properties and corrosion resistance of epoxy/hydroxylated hexagonal boron nitride composite coatings. Corros. Sci. 210, 110820 (2023).

Schaffer, M., Schaffer, B. & Ramasse, Q. Sample preparation for atomic-resolution STEM at low voltages by FIB. Ultramicroscopy 114, 62–71 (2012).

Langford, R. M. & Rogers, M. In situ lift-out: Steps to improve yield and a comparison with other FIB TEM sample preparation techniques. Micron 39, 1325–1330 (2008).

Lou, Y. et al. Accelerated degradation of stainless-steel passive film by humic acid-mediated extracellular electron transfer. Corros. Sci. 245, 112696 (2025).

Qiao, C. et al. Material selection in making electrochemical impedance spectroscopy sensor for electrolyte thickness measurement in marine atmosphere. Corros. Sci. 221, 111373 (2023).

Qiao, C. et al. In-situ EIS study on the initial corrosion evolution behavior of SAC305 solder alloy covered with NaCl solution. J. Alloys Compd. 852, 156953 (2021).

Hou, M. et al. Improving the cavitation corrosion resistance of 6061 aluminum alloy by anodizing. Electrochim. Acta. 503, 144890 (2024).

Woods, E. V., Kim, S. H., El-Zoka, A. A., Stephenson, L. T. & Gault, B. Scalable substrate development for aqueous sample preparation for atom probe tomography. J. Microsc. 299, 104–117 (2025).

Woods, E. V. et al. A versatile and reproducible cryo-sample preparation methodology for atom probe studies. Microsc. Microanal. 29, 1992–2003 (2023).

Wang, X. et al. Highly orientated graphene/epoxy coating with exceptional anti-corrosion performance for harsh oxygen environments. Corros. Sci. 176, 109049 (2020).

Wei, Y. et al. Novel composite Nafion membranes modified with copper phthalocyanine tetrasulfonic acid tetrasodium salt for fuel cell application. J. Mater. 5, 252–257 (2019).

Xu, W. L. et al. Self-assembly: a facile way of forming ultrathin, high-performance graphene oxide membranes for water purification. Nano Lett. 17, 2928–2933 (2017).

Zhang, H., Guo, J., Wang, Y., Sun, L. & Zhao, Y. Stretchable and conductive composite structural color hydrogel films as bionic electronic skins. Adv. Sci. 8, 2102156 (2021).

Acknowledgements

This work was financially supported by the National Cultural Heritage Administration, research on the current status and prospects of the application of scientific and technological detection in the identification of metal cultural relics (No. 2023182).

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

P. F. and Y. K. contributed equally. P. F. provided the bronze sample. Y.K. wrote the main manuscript text and prepared the figures. M.Q. secured funding. All authors contributed to the discussion of the results, edited the manuscript, and have approved the final version.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Fu, P., Kang, Y., Guo, M. et al. Capillary action-induced nanosurface infiltration for vacuum-assisted graphene oxide coating in bronze protection. npj Herit. Sci. 13, 440 (2025). https://doi.org/10.1038/s40494-025-02012-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s40494-025-02012-2