Abstract

More than one hundred tin-covered clay ritual vessels unearthed from the Shijia Cemetery have been dated to the Spring and Autumn period. Multi-method analyses confirm a production process involving molding and drying of the clay body, followed by physical adhesion of pre-formed tin or lead-tin alloy foils to the clay body’s surface. Distinct from traditional bronze or pottery ritual vessels, such artifacts not only reflect an innovative application of tin to clay ritual vessels during this period but also establish a novel technical approach for ritual production and possess significant archaeological value. The origin, production motivations, and technical characteristics of these objects require further systematic investigation.

Similar content being viewed by others

Introduction

Surface decoration emerged early in pottery production. During the Middle-Late Neolithic period, the practice of using pottery slips, also known as “color slips,” became widespread in China. These slips consisted of specially processed, levigated fine clay slurry applied to pottery surfaces, primarily serving decorative purposes. After firing, pottery coated with slip developed a smooth and finely textured surface. In some cases, the fired slips underwent secondary burnishing to achieve an even finer finish, enhancing both luster and aesthetic appeal. Functionally, slips reinforced vessel walls and reduced liquid permeability. Archeological evidence from Yellow River Basin sites such as Anban, Xipo, Taosi, Wadian, Tonglin, and Erlitou reveals four principal slip colors with corresponding material compositions, specifically celadon-toned slips potentially utilizing plant ash, white slips employing kaolinitic clay, red slips incorporating calcareous clay with iron oxides, and black slips combining magnetite-enriched high-alumina clay1. The polychrome sophistication characterizing Yangshao and Majiayao painted pottery emerged from synergistic slip-and-pigment techniques. Beyond augmenting visual appeal and utilitarian function, these practices likely embodied contemporaneous ritual symbolism and cosmological concepts2.

Later, metals were used to decorate non-metallic containers, such as tin-covered pottery. Tin-covered pottery refers to pottery vessels covered with a metallic layer predominantly composed of tin. As an early metal used by humans, pure tin is inherently soft and thus unsuitable for functional objects, explaining its primary use for ornamentation or burial. Nevertheless, tin’s principal role is as an alloying agent, notably in manufacturing copper-tin bronze, lead-tin alloys, and ternary systems like copper-lead-tin. Pure tin or lead-tin alloys also form surface layers on metallic substrates via treatments such as tinning and foiling. Crucially, archeological contexts reveal tin-covered technology applied to non-metallic materials, especially pottery. This process, termed “tin-covered pottery,” imparts metallic luster and texture to non-metallic substrates. This technology exhibits trans-regional prevalence, with archeological evidence attested in multiple European prehistoric contexts (Austria, France, Germany, Hungary, Italy, Switzerland) and Macedonia in the late Classical and Hellenistic period, Cyprus Iron Age3,4,5. Around 1400–1150 BC, tin was used in thin sheets to decorate Mycenaean pottery, mainly kylikes and conical cups6,7,8. This is generally considered a Mycenaean phenomenon, but subsequent archeological discoveries have confirmed its cross-regional distribution. Cases of covering tin metal to pottery can be traced back to the late Middle Minoan period9, the Early Iron Age in Central Europe10,11, northern and central Italy12,13,14, the La Tène site in mid-late Europe15, the Iron Age in Cyprus16, and the late 5th century BC in the Pydna region of Macedonia, Greece, where tin-covered pottery appeared, and it was common in Macedonia in the second half of the 4th century BC3.

In China, the earliest known tin-covered pottery dates to late Phase IV of the Yinxu culture. Predominant vessel types include ding, gui, jue, you, gu, zun, zhi, and jia. Crafted from low-fired gray earthenware with relatively soft fabric, these artifacts meticulously replicate bronze counterparts in form, decorative motifs, and ritual assemblages, which demonstrates intentional morphological emulation (Fig. 1). Physiochemical analysis identified tin-based compounds (mainly cassiterite and romarchite), with thicknesses of 20–50 μm. The original metallic tin layer was likely applied via adhered foil cladding techniques17. Following the Shang period, such objects persisted through the Spring and Autumn, Warring States, and Han periods18. The tin-covered pottery imparts a distinctive silver-gray luster, thereby mimicking the appearance of metal ritual vessels. Essentially, while tin-covered pottery served functionally equivalent roles to bronze ritual vessels in pre-Qin mortuary contexts, the application of tin surfacing enhanced their visual resemblance to metallic objects. Through ritual assemblages, notably ding and gui vessels, these tin-covered pottery replicated the ceremonial significance of bronze ritual paraphernalia.

The archeological distribution of tin-covered pottery reveals complex spatial-temporal patterns in ancient China. In Shaanxi, a Western Zhou tin-covered pottery ritual vessel from Tomb M36 at Qijia, Zhouyuan, has been proposed to be associated with Yin descendants based on mortuary contexts18. In Shandong, a large number of Spring and Autumn, and Warring States Period tin-covered pottery ritual vessels were unearthed in the old agricultural bureau cemetery at the ancient city of Lu in Qufu, Zhoujiazhuang cemetery in Xintai, Dahan cemetery in Tengzhou, and Dubei cemetery in Changle19. Tin-covered pottery also appeared in the ancient city of Zhenghan in the Central Plains, dating back to the early Spring and Autumn Period. The silver-white layer on the surface of pottery unearthed from the Warring States tombs in Dongyiyuan has a tin content of nearly 70%, but most of them are pottery fragments20. It was also unearthed in the relatively late Han tombs in the Kekou cemetery in Zaozhuang.

In Hunan, pottery from Zidanku Chu Tomb (Changsha) bore a silver-gray tin foil layer, including ding, bowls, and jars21. Sixteen tin-covered vessels from Mawangdui M1 comprised ding, hu, fou, yan steamers, etc22. Tin foil decorations were identified on polychrome pottery from Taoyuan Chu tombs23, with the coating confirmed as metallic tin. Tin-covered pottery also existed in the Western Han Tomb in Wujialing, Changsha. Tin-covered pottery was found in Hubei Province, such as the Warring States Chu Tomb No. 20 in Taihuiguan, Jiangling, the Chu Tomb in Huangfu Temple, Jingmen, the Western Han Tomb in Huoshan, Anhui Province, the Eastern Han Tomb in Weicheng District, Xianyang, Shaanxi Province, and the Warring States Chu Tomb in Chengyangcheng Ruins, Xinyang, Henan Province. After the Han Dynasty, the use of tin-covered pottery disappeared. Some scholars believe that the disappearance of tin-covered pottery may be related to the emergence of low-temperature glazed pottery24.

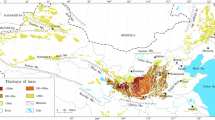

In summary, tin-covered pottery technology emerged in China during the Shang dynasty, the heyday of the Bronze Age. It appeared by the middle 11th century BCE (Yinxu Phase IV) and became prevalent in the Spring and Autumn to Warring States periods. Despite limited preservation of complete vessels, its chronological span reflects a sustained tradition. Tin-covered pottery is mainly distributed in Shaanxi, Henan, Shandong, Hunan and Hubei in China. Among them, the largest number of unearthed pottery was found in Changsha, Hunan Province, and they date mostly from the Warring States Period to the Han Dynasty. The earliest examples of this type of artifact were found in the Yinxu period. They were mainly distributed in Guanzhong during the Western Zhou Dynasty, spread to Shandong and Hunan during the Eastern Zhou Dynasty, and were highly concentrated in Hunan during the Han Dynasty. In the Pre-Qin period, tin-covered pottery was mainly used as a ritual vessel, imitating the shape of bronze ware, and in the Han Dynasty, it was also made more into containers. The production technology of China’s tin-covered pottery, what are its functional characteristics compared with foreign countries, and what is the development context are still not very clear, and the discovery of tin-covered clay vessels in the Shijia cemetery provides a new research perspective for thinking about these issues.

The Shijia Cemetery and the Yucun Site may have the relationship of residential and burial areas, and are important Zhou Dynasty sites discovered in northeastern Gansu in recent years. A large number of bronze artifacts were unearthed from the sites. Through the excavation of the cemetery and the residential sites, the Zhou dynasty archeological cultural sequence in the eastern Gansu region was established. At Shijia Cemetery, the practice of burying miniature copper containers with the deceased emerged in the late Western Zhou25. This tradition evolved into the use of clay imitation bronze ritual vessels during the early Spring and Autumn period, and continued through its late phase. Based on preliminary statistics, more than 100 such imitation ritual tin-covered clay vessels have been unearthed from the cemetery. Most exhibit distinct white or gray-black surface layers, varying in thickness. Crucially, none show evidence of high-temperature firing, indicating they are low-fired clay objects rather than true pottery; their fragile nature is further evidenced by instances of breakage upon excavation.

The primary vessel types consist of ritual forms such as ding, gui, pan, hu, he, and yan. These objects exhibit relatively simple shapes and decorative patterns, with notably small dimensions. Some specimens directly imitate miniature bronze vessels found within the same tombs, with overall heights not exceeding 15 cm (Fig. 2). Notably, all vessels feature solid-filled cavities and completely plain surfaces devoid of ornamentation. A representative clay gui displays a lid cast integrally with its body, solid construction, twin handles. On the whole, it is the same as the casting mold that produces bronze ware. The production of its clay body draws on the possibility of bronze ware casting mold. Whether it was made directly from the mold is currently more likely, but of course, further research is needed.

Upon excavation, the tin-covered ritual vessels exhibited surface encrustations of burial mud (Fig. 3). Subsequent exposure to air caused rapid desiccation and extreme fragility, leading in some cases to large-scale flaking or detachment. Most surfaces had oxidized to a blackened state, making them difficult to distinguish from burial accretions and liable to be misidentified as soil deposits. Laboratory analysis later confirmed that the underlying silvery-white layer consists of tin or lead-tin alloy. Within the cold tomb environment, tin is susceptible to “tin plague”—a phase transformation where metallic tin (β-Sn) converts to a powdery, non-metallic allotrope (α-Sn) at temperatures below 13.2 °C. This process, accelerated by oxidation, causes disintegration into powder and eventual exfoliation. Given the cold, arid winters characteristic of their burial location in northwest China, tin plague occurrence was highly probable. Consequently, these artifacts were in a severely deteriorated state upon discovery and easily overlooked. While tin-covered pottery (clay) vessels production methods and socio-ritual functions require further investigation, tin-covered clay ritual vessels from Gansu’s Shijia Cemetery-notable for its quantitative significance (over 100 specimens) and exceptional preservation-provide crucial material insights into these unresolved questions.

Methods

To investigate the production technology of tin-covered clay ritual vessels unearthed from Shijia Cemetery, this study selected 14 specimens. The sample types were mainly ding, gui, hu, and pan, all of which were small objects (Fig. 4). Representative samples of different object types and those with good integration of the body and the tin layer were selected. Macroscopic observation shows that their texture is fragile and has not undergone high-temperature firing. It is speculated that it has only been subjected to low-temperature baking or natural drying. Among them, the surface of the hu (M151:34) is covered with white and black substances, and some of them have fallen off. Although the pan (M151:39) is incomplete, a black and white covering layer can be seen on the surface. The ding (M151:36) is severely incomplete, with only the ding legs remaining at the bottom of the abdomen, and the shape is unclear. The outer surface of the 14 pieces can be seen with a white covering layer, and some areas are peeling off in layers. Unlike the clearly identifiable metal foil, the tin residue on the surface of the clay vessels gives the impression of gray and white sediments.

In addition, in order to conduct comparative studies, the undisturbed soil under the settlement adjacent to the cemetery, and the active soil layer on the surface of the settlement were sampled (Table 1). In addition, the casting cores of the bronze ware unearthed from the cemetery were also sampled and analyzed, and a comparative study was conducted with the tin-covered clay ritual vessel body.

Microscopy (OM)

Microstructural and surface processing details were analyzed using a Keyence VHX-6000 ultra-depth 3D digital microscope. For petrographic examination, soil samples, clay vessel bodies, and casting cores were prepared into 30-μm-thick sections and observed under a Leica DM2700P polarized light microscope.

X-ray diffraction (XRD)

To analyze the mineral characteristics and investigate the raw material composition of the artifact’s clay body, the samples were ground into a powder, sieved through a 200-mesh sieve, and subsequently analyzed using an Olympus portable X-ray diffractometer. This technique is well-suited for such studies as it requires only minimal sample material.

Fourier transform infrared spectroscopy (FTIR)

The firing temperatures of the clay components were determined using a Thermo Fisher Scientific IS5 Fourier Transform Infrared Spectrometer (FTIR) with an iD1 transmission accessory and a scanning range of 4000 cm to 400 cm. Infrared spectroscopy has been frequently used to study the structure, bonding and chemical properties of clay minerals. Their spectra change irreversibly with increasing firing temperatures, so they can be used as thermometers for clay-based materials. The effect of heat mainly changes the bands associated with Si-O-Si stretching vibration (1000−1, 100 cm−1), Si-O-Al bending vibration (510–580 cm−1) and hydroxyl stretching vibration (3600, 3700 cm−1)26,27. By observing the movement and attenuation of the bands in these ranges, the firing temperature of archeological deposits or artifacts can be explored. The slight decrease in infrared absorbance at 1030 cm−1, when fired below 500 °C, the infrared spectra of clay minerals such as montmorillonite, illite, and kaolinite have no obvious band shift, but the absorbance of the 1030 cm−1 band continues to decrease. This negative correlation can be used as a thermometer for low-fired materials28,29.

Raman spectroscopy (RS)

The metal layer was identified using a Horiba Xplora Plus Raman spectrometer. After calibrating the instrument with a silicon wafer, the sample was placed under the objective lens. Once the target point was determined, detection was performed using a 785 nm laser with an integration time of 60 s.

Scanning electron microscope energy spectrum analysis (SEM-EDS)

Micro-morphology and elemental composition were characterized using a TESCAN VEGA3 XMU scanning electron microscope coupled with a Bruker Nano GmbH 610 M energy-dispersive X-ray spectrometer (SEM-EDS), operated at 20 kV accelerating voltage and 15 mm working distance.

The SEM-EDS analyses were performed using an instrument at the Institute of History of Science and Cultural Heritage, University of Science and Technology Beijing. Quantitative accuracy was validated through certified reference materials, specifically six Cultural Heritage Alloy Reference Materials (CHARMS from the Getty Conservation Institute, USA) for bronze alloys and four CGSG-series geological reference materials (China National Center for Geological Experimentation and Testing) selected based on compositional affinity with unfired clay samples30. Repeated measurements yielded relative errors against certified values with tin content exhibiting variations from 0.8 to 8.3 wt%, while lead content below 15.4 wt% had variations ranging from −15.0 to 8.3 wt% in CHARMS alloys. For geological reference materials, major oxides including MgO, Al2O3, SiO2, K2O, and FeO had errors ranging from −7.9 to 9.5 wt%. Minor oxides such as Na2O and CaO showed variations from 2.5 to 19 wt%, and trace elements exceeded ±20 wt% in relative error due to detection limitations.

Results

Observation of the appearance of the covering layer

Systematic surface examination of block samples (SJNL01 to SJNL14) using 3D video ultra-depth microscopy revealed that all specimens exhibit a continuous metal covering distinct from the clay substrate composition. The coating displays a gray-white coloration with differential metallic luster—predominantly matte in oxidized regions but retaining distinct metallic reflectivity in preserved zones. A sharply defined interface demarcates the coating from the clay matrix, exhibiting localized delamination.

Surface analysis of sample SJNL07 reveals an upper layer of lead-tin alloy foil. Partial exfoliation of this metallic layer exposes the underlying argillaceous body, while the lower layer retains the clay base material. In specimen SJNL12, detached tin-lead foil fragments directly confirm the flaky distribution characteristic of the tin layer (Fig. 5). Comprehensive analysis demonstrates a continuous, uniformly thick coating across the artifact’s surface. Although portions of this coating detached during excavation, it exhibits distinct physical properties compared to the substrate. The tin or tin-lead layer consistently exfoliated in flakes during sampling. Combined with microstructural evidence, these observations indicate that the coating represents an intentionally applied metal foil.

Composition and distribution characteristics of the metal layer

During cross-section preparation, metal-clay composite samples were extracted as intact blocks to preserve interfacial integrity. Eleven specimens were resin-embedded, four of which exhibited severe tin corrosion that compromised structural stability. Consequently, these samples underwent irreversible fragmentation during mechanical grinding and polishing despite meticulous handling protocols. Subsequently, three samples were tested directly on their surface.

Seven specimens exhibit distinct stratified structures characterized by well-defined interfacial boundaries and relatively uniform thickness distribution (Fig. 6). These tin-based layers (52–280 μm thick) consist primarily of tin oxide or lead-tin alloys. SEM-EDS analysis identifies SJNL04 as a predominantly tin-based layer with undetectable lead (below detection limits), contrasting with six lead-tin alloy samples containing 0.9–10.7 wt% Pb and 42.3–80 wt% Sn (Table 2). Representative microstructural configurations reveal that in SJNL04, a 100-μm-thick tin oxide phase (70 wt% Sn) is covered by a superimposed tin oxide layer and overlies a tin-enriched soil matrix (25 wt% Sn) resulting from post-depositional corrosion. In contrast, SJNL06 exhibits a 280-μm-thick uniform lead-tin alloy layer (66 wt% Sn, 5 wt% Pb) bearing a surface-applied lead-tin stratum (Fig. 6a). Analysis of the surface samples of samples SJNL12-SJNL14 showed that the main metal components were lead and tin, without any other metal elements, and showed a higher oxygen content than the cross-section and more severe rust. Elevated oxygen content within metal layers indicates corrosion, with potentially affected components designated as reference values. These findings, combined with exfoliation patterns and applied layer characteristics, support the interpretation that the stratified layers originated as intentionally attached pure tin or lead-tin foils.

Compositional analysis of the matrices reveals significant variations in calcium content (Table 3). Specimens SJNL01, SJNL02, SJNL04 and SJNL07 exhibit low calcium levels below 5.1 wt%, whereas the remaining samples contain calcium exceeding 8.6 wt%. The consistently low calcium concentrations in the former group suggest the use of inherently low-calcium clay raw materials since calcium content cannot be reduced through clay washing procedures, and this likely indicates the selection of palaeosol with intrinsically low calcium content. Furthermore, the overall matrix composition aligns with northern Chinese loess characteristics, which typically feature elevated calcium concentrations.

Compositional analysis via SEM-EDS revealed that the metallic coating primarily consists of tin or tin-lead, while its microstructure and high oxygen content indicate severe corrosion. To further investigate the properties of the metallic layer, Raman spectroscopy was employed. The results show that the material composition is primarily associated with two metals: corrosion products related to lead include PbO, lead white (2PbCO₃·Pb(OH)₂), and lead carbonate (PbCO₃, Fig. 7b). Tin-related compounds identified were Romarchite (SnO), characterized by a primary peak at 203 cm⁻¹ (Fig. 7a, d). A broad peak observed at 560–580 cm⁻¹ corresponds to amorphous Sn(OH)₄ (i.e., SnOₓ·nH₂O) formed during the initial stages of tin corrosion (Fig. 7a). When corrosion products undergo partial dehydration to form microcrystalline SnO₂, grain size effects cause the persistence of the 571 cm⁻¹ peak, accompanied by the emergence of a medium-intensity peak at 633 cm⁻¹. As crystal growth proceeds, the 628 cm⁻¹ peak gradually intensifies while the 571 cm⁻¹ peak weakens and eventually disappears31. Lead-tin yellow type II, which may be represented as PbSnO₃ (Rooksby) or PbSnₓSi₁₋ₓO₃ (Clark et al.), was also identified (Fig. 7c). Micrographs showing its characteristic yellow coloration corroborate the Raman findings32. The main corrosion products of lead-tin alloy are PbCO₃ and SnO₂33, with tin metal initially corroding into a mixture of divalent oxides and hydroxides before undergoing slow oxidation and dehydration to transform into crystalline SnO₂—a prolonged process. Raman spectroscopy, IR, and XRD typically detect only diffuse SnO₂ peaks or may fail to capture signals from tin compounds31. Analysis of the corrosion products confirms that the predominant phases are exclusively associated with tin and lead-tin metals, with no other metallic phases detected. Collectively, the SEM-EDS and Raman spectroscopy results indicate that the metallic layer was originally tin foil or lead-tin foil.

Characteristics of mud body raw materials

In order to explore the body craft characteristics and origin of the tin-covered clay ritual vessels, the activity surface of the settlement to the cemetery, and undisturbed soil were sampled. Petrographic analysis of the samples showed that the three undisturbed soil samples of the site had relatively small mineral particles as a whole, brown-yellow under Plane-Polarized Light (PPL) and black under Crossed-Polarized Light (XPL), and contained a small number of mineral species, containing a large amount of uniform and fine silt with similar particle sizes. The mineral composition of the silt particles of the three samples was similar, mainly including quartz, feldspar, mica, etc., which were fine silty clays without large particles of minerals. The body of the analyzed tin-covered clay ritual vessel was reddish brown under PPL, and the background was black under XPL. It contained some quartz minerals, including feldspar minerals (Fig. 8).

Mineralogical comparison between the tin-covered clay vessels of bodies and soil samples revealed high compositional consistency. Most specimens utilized clay with reduced quartz content, containing no intentionally added temper—indicating usage of naturally pure clay (absence of anthropogenic additives was confirmed).To further authenticate mineral constituents, XRD phase analysis was conducted. Results identified quartz, calcite, feldspar, and muscovite as dominant phases across all samples, comprising primarily primary silicate minerals (Fig. 9).

The mineral composition of Chinese loess exhibits relative homogeneity, with quartz, feldspar, and calcite constituting the dominant phases. Accessory minerals include mica-group minerals (illite, chlorite), while kaolinite and montmorillonite are exceptionally rare authigenic components34.

Some scholars have conducted TGA and XRD tests on loess in the eastern Gansu region, showing that carbonates in loess are mainly composed of calcite and dolomite35. The clay in this region is mainly loess accumulation. The high calcium content in loess is mainly due to the large amount of carbonate substances. China’s loess generally contains silt-sized, rounded calcite particles, and the number is positively correlated with the CaCO3 content in loess. Some of them are secondary carbonates brought to loess by atmospheric precipitation, groundwater and biological activities. The two sources of carbonates in loess depend on drought conditions. The more arid, the higher the CaCO3 content. The CaCO3 content of Malan loess in the middle reaches of the Yellow River increases from southeast to northwest36. Some scholars have studied the mineral composition of Shaanxi loess. For example, the loess in Baoji is mainly composed of quartz and muscovite and contains a small amount of potassium feldspar and serpentine. The FTIR spectrum shows that kaolinite and calcite are also important components of loess samples37. The site area is typical loess soil from the stratigraphic soil to the raw soil layer, and the site is also located in the loess area of the Loess Plateau.

Among the tin-covered clay ritual vessels, SJNL01 and SJNL02 are earthy red, while SJNL04 and SJNL05 are earthy gray. The characteristic peak of calcite in SJNL02 is not obvious, and it has a low calcium content (Fig. 9). The soil color of SJNL03 is dark black, and it may have used the local black loess oil. Since the main phases of black loess are also quartz, calcite, feldspar, and muscovite, they are the same as the loess phase. The biggest feature of black loess is the presence of a deep black loess layer, which develops from the Malan Loess parent material of the Loess Plateau. It is a zonal soil formed through a long-term soil formation process under grassland or forest-steppe vegetation under semi-arid and semi-humid climate conditions. It is found on loess plateaus, high terraces, and hilltops in eastern Gansu, northern Shaanxi, northwestern Shanxi, and central Gansu38,39. Since the tin-covered clay vessels have not been subjected to high temperatures, they retain the original soil texture and color. Judging from the soil texture and color, at least two types of soil were used, namely black loess and loess. The tin-covered clay vessels from the same tomb exhibit identical forms and nearly uniform dimensions and imitate the bronze vessel styles characteristic of this cemetery. The composition and phase analysis of the clay body show that they are highly consistent with the local soil, indicating that they are likely to be produced locally.

Firing temperature

In order to explore whether the tin-covered clay ritual vessels have been fired at high temperatures, infrared spectroscopy detection was carried out on them. Some infrared spectra are shown in Fig. 10. There are obvious peaks at 3620 cm−1, 1031 cm−1, and 522 cm−1, indicating that they have not experienced high-temperature activities. Even if they have been baked, the temperature has not exceeded 400 °C. Because the Si-O-Si bond bending vibration peak in the clay structure is around 520 cm−1 or 525 cm−1, it still appears sharp after experiencing high-temperature activities below 400 °C, and it begins to passivate and disappear under high-temperature activities of 400 °C, 500 °C or 600 °C. This peak is not seen in high-temperature remains above 600 °C. The Si-O-Si bond stretching vibration peak 1030 cm−1 in the clay is sharp after experiencing high temperatures below 300 °C. As the temperature increases, the height of 1080 cm−1 increases, and the 1030 cm−1 peak gradually becomes passivated.

There is a relationship of residence and burial between Shijia Cemetery and Yucun Site. In the Spring and Autumn Period, the Yucun Site, which is adjacent to Shijia Cemetery, was a pottery workshop. The clay used to make pottery included selected, relatively fine clay pottery, and another type of sand-tempered pottery containing mixed materials. Pottery was mostly formed by coiling clay strips and wheel repair. Fast wheel throwing and molding splicing were rarely used. Gray pottery was fired in a vertical pit rising flame kiln. The pottery handicraft industry of Yucun Site has formed a specialized and centralized management production model40. However, no tin covering layer was found on the pottery containers of Shijia Cemetery, but clay bodies that had not been fired at high temperatures were selected, indicating that the production of this kind of artifact was for a specific expression.

Sample porosity, silt, sand and clay extraction

The backscattered electron (BSE) images obtained by scanning electron microscopy (SEM) have grayscale for each pixel, and its tone is related to the average atomic number of the analyzed point, so they are used to detect areas with different compositions (mineral phases)41. The samples were selected for digital image processing (digital image analysis), and the porosity, silt and sand, and clay matrix were extracted using CT-AN software. Then the photos were binary processed42, and the particle size distribution and morphological characteristics were obtained using ImageJ software (Fig. 11). The binary images were statistically analyzed, and the clay matrix at the contact edge of all silt and sand was excluded. The total percentage area of silt and sand was extracted, and the extracted particle size was controlled to be above 6 μm.

Through the statistics of clay matrix, it is found that the porosity of typical loess raw soil samples in this area is relatively uniform, with an average porosity of 15.9 wt%, comprising sand and silt at 38.2 wt%, and clay matrix at about 46 wt%. It can be seen that the clay matrix of mud-like bronze ritual vessels is relatively high, with an average value of more than 61 wt%, while the porosity is relatively low, and the silt and sand contained are less than the local raw soil and the casting cores of the bronze ware in this cemetery, indicating that it may have been washed and precipitated, thereby increasing the clay content. However, the clay morphology of the tin-covered clay ritual vessels presents two distinct forms. One group (SJNL01, SJNL02, and SJNL05) exhibits extremely low porosity and a relatively fine clay matrix. The other, SJNL03, has relatively higher porosity compared to the other tin-covered clay ritual vessels, though it is still lower than that of other casting cores. The clay used in SJNL03 is overall black (brown-black) and distinctly different in color from other soils. Furthermore, SJNL03 shows extremely uneven mineral particle size and porosity. Both the lithology and backscattered photos show such characteristics, which further confirms the use of black loess and yellow soil from the morphological characteristics.

Discussion

Although there are many controversies among scholars about the application process of tin-covered pottery (clay) vessels, it can be summarized that there are mainly three ways to make it, namely the immersion method (dipping method), the tin-sheet cladding technique, and tin plating.

Krister Holmberg shows that vases made of kaolin were dipped into molten tin. As a result, the metal did not adhere to the ceramic surface, but traces of nitrogen-containing compounds, probably animal glue, were detected on some objects43. This was done by first applying a protein-based glue to the surface. After a short drying period, the vase was dipped into the molten tin. The ceramic was now well wetted by the metal and a thin layer of tin formed on the surface. If appropriate surface preparation was performed before the metal coating, the tin could have been applied simply by the dipping technique7. Using this method would explain why the bottom of the base is sometimes coated, even on closed shapes44.

Two tin-covered pottery jars unearthed from Chu Tomb No. 17 in the Bullet Library in Changsha, Hunan Province, China, were decorated with a thin silver-gray glaze on the surface. Zhou Shirong believed that the thin silver-gray glaze was tin covering21. In 1998, Li Jianmao analyzed the tin-covered pottery unearthed from the Chu-Han Tombs in Changsha. All pottery tin coverings were made by the immersion method. After the pottery was fired, it was placed in a tin solution, so that a layer of tin was attached to the surface, which then oxidized to form a silvery-white tin dioxide protective film. The tin was hot-dip plated by the immersion method24. Some scholars believe that the tin covering can be obtained by immersing the container in tin liquid or by immersing the container in molten tin multiple times45.

Of course, opponents believe that this suggestion should be ruled out because it is actually very difficult, economically demanding, and does not conform to the properties of metals. Once the metal is exposed to air after melting, it will immediately become very hard, and it is impossible to obtain a uniform surface46.

Analysis of the coating on the pottery surface of the Mawangdui Han Tomb showed that there were a large number of wrinkles on the surface of the tin-covered pottery22. The main component of the coating was elemental tin. Simulation experiments showed that the tin foil layer was likely attached to the surface of the vessel with an adhesive. Guo Meng studied the tin-covered pottery from Yinxu and believed that the methods of cassiterite reduction, hot-dip tinning, and tin plating did not match the observed characteristics. The stratification of the corroded tin covering layer may be related to forging, and was applied to the surface of the vessel by tin foil. Zhao Zhiqiang conducted infrared spectroscopy analysis on the tin-covered pottery unearthed in Taoyuan, Hunan. There was raw lacquer in the tin foil. If the tin covering was applied by tin plating, the tin liquid would cause the raw lacquer base layer to deteriorate and warp. It is possible that the room temperature tin-sheet cladding was used, and the tin foil was bonded with an adhesive.

For Mycenaean tin-covered pottery vessels, usually found in tombs, Gillis suggests that the tin covering was produced by gluing thin strips of tin foil to the surface with an organic binder6, which Holmberg suggests was probably pine resin rather than butter or animal glue, rather than by dipping the vessel in molten tin7. Some fragments from the site of Asiney have wrinkles on the surface comparable to those produced by overlapping strips of tin foil47, and the tin has flaked off the surface of the ceramic, which can only happen if the tin is made into foil48. On some vessels, the foil may have extended to the bottom4,49.

In a series of experiments, various tin covering methods were tested, and only the use of foil consistently produced a shiny, smooth and uniform surface. Analysis of the underside of the coating suggests the use of a binder, most likely a resin (rosin), which would have held the foil in place and filled in imperfections in the ceramic surface to produce a more uniform finish in areas with complex surface morphology, such as near and on the handles50,51. On the other hand, less tin is required than would be required for a molten tin bath. Although most evidence points to the use of foil, different workshops may have used one or the other technique or a combination of the two, and some scholars believe that the tin on Asine pottery was subjected to a special heat treatment that caused it to oxidize to a golden color47,52.

Analysis of tin-covered pottery from the Eastern Han tomb in Weicheng District, Xianyang, Shaanxi Province, shows that the tin layer is stratified. The two stratified parts have the same composition. It is believed that the single tin is oxidized to form SnO2 corrosion products. The hot-dip method cannot form a uniform coating on the surface of the pottery, so tin amalgam was used for tin plating53. It is also believed that the Warring States tomb in Yiyuan, Shandong Province, also used tin amalgam to tin. Some scholars believe that the C/O ratio of the tin-plated spots on a vase in the Asine tomb is often similar to the corresponding value of modern gold-plated tin foil, rather than untreated tin foil54.

In general, the production of tin-covered pottery presents a variety of methods, and its formation method is not unique. Some details will provide references for the judgment of the process, such as whether there is an adhesive, wrinkles, whether the whole body is covered with tin layer, the thickness and uniformity of the tin layer, etc. These are all technical details for judging the production process. Judging from the alloy composition of pottery (clay) tin-covered containers unearthed in China, the main metal component of the tin-covered pottery in Yinxu in the late Shang Dynasty is tin, containing trace amounts of copper or iron, etc., and no lead. The tin covering in the tombs of the Warring States Period in Yiyuan is mainly composed of tin, containing 6 wt % iron, and the tin content in the silvery-white surface layer is close to 70 wt %. The tin covering in the tombs of the Warring States Period unearthed in Taoyuan, Hunan, is mainly tin, without other metal components. The tin covering in the Mawangdui Han Tomb is mainly composed of elemental tin and trace amounts of iron. The tin layer of the tin covering vessels unearthed in the Eastern Han Dynasty tombs in Xianyang, Shaanxi, is also mainly tin, without other metal elements. From the Shang Dynasty to the Eastern Han Dynasty, tin covering was dominated by high-purity tin, while the tin layer of the tin covering vessels in the Shijia cemetery was mainly lead-tin alloy. From the production of tin (lead-tin) foil, the presence of the soft lead phase makes it more ductile, easy to process, stretch, and form without cracking, so the use of lead-tin alloy for the production of tin covering vessels implies regional technological innovation and adaptation strategies.

Tinware is applied to pottery or clay containers. Such objects often have no practical use, but this practice is found in the Late Bronze Age Aegean, in Cyprus, in the Iron Age cemetery of Salamis, in Late Classical and Hellenistic Macedonia, and in prehistoric Italy, Austria, Hungary, France, Germany and Switzerland above5,6,7,55. Kotitsa Z believes that such objects appeared in Macedonia in the second half of the 4th century BC. This technology is mainly related to funerals, giving luster and value to less valuable objects and visually impressing those attending the funeral. Therefore, it is to highlight the importance of burial3. Some believe that the motivation for coating so many unusual shapes with tin was to hide their worn paint. Tin plating can be understood as a more luxurious method of imitation. The reason for this practice is that some scholars believe that tin-covered objects are more subtle than pure precious metal imitations. Their use is an obvious and powerful act of ostentation and irreversible consumption. It is a permanent sacrifice from the living to the dead. In addition, the decay of tin, leaving the exposed body, may be related to the decay of the flesh of the dead, leaving the exposed bones6,56. Gillis believes that the combination of yellow and white shiny objects is more about the symbolic meaning of color rather than imitating metal containers57.

In terms of the type of objects, the vast majority of those unearthed in China are ritual vessels imitating copper shapes, while those abroad are more cups. In Macedonia, people have found almost all the tin-covered pottery in the shapes commonly seen in funeral homes in the 4th century BC3. The tin ceramic containers of the Aegean Sea in the late Bronze Age were initially believed to be mainly intended to imitate metals, especially silver vessels, as a direct imitation or even a substitute for silver containers. Of course, some people have raised objections. Aulsebrook S placed tin containers in the ceramic tradition, thus considering them as an enhanced form of ceramics rather than an inferior form of metal containers56.

In addition, after tin is attached to the surface, the color will soon become dull, and this silver-white color will not last long. Some scholars believe that heating such silver-colored objects to about 232 °C will produce gold, so the maker can choose to create a silver or gold surface51. Regardless of the color, the decoration will quickly deteriorate due to the “tin plague” phenomenon, turning gray and peeling off. In fact, another type of pottery coating can also produce a metallic luster, that is, graphite coating technology. In the Eastern Alps and the Carpathian Basin, it can be traced back to 1300 BC to 1250 BC (Bz D). It is speculated that these exquisite vessels are representative elements of tableware. The graphite-coated/polished vessels found are likely to be accessories for funeral banquets, imitating the texture and appearance of metal vessels58.

Judging from the background and combination form of such objects unearthed in China, more shapes in the pre-Qin period imitated bronze ritual vessels, which was an expression of ritual system, and was completely different from foreign countries. The imitation bronze clay tin-covered ritual vessels in the Shijia cemetery can be found in the cemetery. Similar objects are found in this cemetery, and they are relatively simple in production and small in size, so that the tin covering layer can be more easily applied to the surface of the objects. From the unearthed background, some of them appeared in groups, and some of the tombs where such objects appeared were also buried with bronze ritual vessels, indicating that they were not completely used as substitutes for matching. These imitation tin-covered pottery (clay) vessels unearthed in China, first of all, imitate bronze ritual vessels in shape. In addition, tin is an important alloy for bronze ware, and it is particularly difficult to obtain this resource in the northwestern border of the Zhou Dynasty. Therefore, the purpose of using clay tin-covered ritual vessels is to save tin and also serve as a substitute for bronze ritual vessels.

The emergence of tin-covered pottery depends on the knowledge of tin metal, the development of tin smelting technology, and the technical tradition of decorating pottery with pottery coating. In the middle of the fifth millennium BC, a piece of bronze foil with a tin content of 11.7% was unearthed in the Vinca cultural site Pločnik in Serbia, Balkan Island. This is the earliest known tin bronze product in the world. The foil shows traces of hot forging. Combined with its appearance and the situation found in pottery remains, scholars speculate that it may be used to wrap around pottery containers59. This discovery shows that as early as this time, the phenomenon of combining pottery and metal had already appeared. Although it is still an isolated case in this period, it at least proves that the practice of combining tin metal and pottery has appeared in prehistoric times.

In the late fourth millennium BC and the early third millennium BC, tin bronze began to appear in Mesopotamia and western Iran. The earliest tin bronze artifacts confirmed in Eurasia so far were unearthed in Near Eastern sites in the early third millennium BC60. Few pure tin products were found in the early period, which may suggest that ancient bronze craftsmen used more cassiterite. It is generally believed that tin ore was deliberately added to copper ore (co-melting) or copper metal (gluing). It was not until after 1000 BC that the number of pure tin products began to increase, and more tin ingots were found61. Although pure tin products appeared later, the application of lead-tin alloy was earlier than this period. Regardless of the specific process path, the deepening of ancient craftsmen’s understanding of the properties of tin and lead-tin alloy materials laid the material foundation for the emergence of tin-covered pottery technology. Another key premise is the maturity of prehistoric pottery surface decoration technology. Natural mineral pigments (such as iron-based ochre, manganese-based chromatic acid, kaolin, limestone and carbon black) and artificial synthetic materials (such as Egyptian blue) have been widely used in surface treatment. The cognition of tin metal properties and the development and maturity of pottery surface technology ultimately contributed to the birth of tin-covered pottery54.

Tin-covered clay ritual vessels imitating bronze, unearthed from the Shijia cemetery in Longdong, Gansu Province, and dating to the Spring and Autumn Period. Examination shows the metal layer is uniform in thickness, with visible flakes detaching, indicating that tin and tin-lead foil were adhered during production. It is speculated that the specific process involved first making a clay body container, followed by drying or low-temperature baking, after which the prefabricated tin or tin-lead foil was affixed to the surface of the body, likely using an adhesive. Initial analysis did not reveal the type of adhesive used, possibly because the residual amount did not reach the instrument’s detection limit. Further comprehensive testing of freshly excavated samples should be conducted to provide supporting evidence for the use of adhesives.

Morphologically, these vessels are relatively small in overall height but accurately imitate the shape of bronze vessels. Furthermore, in some tombs, they were used in combination with bronze ritual vessels. In some tombs containing only such miniature clay ritual vessels, these vessels mainly replace the ritual function of bronze vessels. This type of vessel, characterized by a tin covering applied to a clay body fired at low temperatures (below 400 °C). Analysis of compositional and phase characteristics combined with typological distribution suggests probable local production of the material, although definitive provenance attribution requires integrated lead and strontium (Pb and Sr) isotope analyses.

Such artifacts appeared in large quantities only in this area, which was a tin-deficient region on the northwestern border of the Zhou Dynasty. This shows that resources had a profound impact on technology and were a driving force at the edge of the Zhou Dynasty’s territory, so they had to make technological innovations in maintaining the ritual system under the scarcity of resources. In addition, such artifacts are usually corroded and peeled in various tones, such as gray and black, after being unearthed, which are easily confused with white coatings with fungal stains. They are ignored and removed during excavation or restoration. More attention should be paid to such artifacts in the future.

Data availability

No datasets were generated or analyzed during the current study.

References

Lu, X., Fang, Y., Li, W. & Li, X. A study on the development of pottery coating technology in the Yellow River Basin during the Middle and Late Neolithic Period. Huaxia Archaeol. 2, 66–73 (2017).

Lu, X., Li, W., Luo, H., He, N. & Li, X. The black pottery coating of Longshan times from Taosi Site. Sci. China Tech. Sci. 54, 1708–1714 (2011).

Kotitsa, Z., Drougou, S. & Touratsoglou, Y. Metal-coated pottery in Macedonia in late Classical and Hellenistic period. Topics on Hellenistic Pottery in Ancient Macedonia, 108–125 (Archaeological Receipts Fund, 2012).

Noll, W. & Heimann, R. Ancient Old World Pottery: Materials, Technology and Decoration, Vol. 16, 331 (Schweizerbart Science Publishers, 2016).

Gillis, C. The use of color in the Aegean Bronze Age. Color in the Ancient Mediterranean World (eds Cleland, L. et al.) 56–60 (Hedges, 2004).

Gillis, C. Tin-covered pottery and chemical analyses: a summary. Archaeometry Issues in Greek Prehistory & Antiquity (eds Bassiakos, Y. et al.) 451–458 (Hellenic Society of Archaeometry and Society of Messenian Archaeological Studies, 2001).

Holmberg, K. Application of tin to ancient pottery. J. Archaeol. Sci. 10, 383–384 (1983).

Pantelidou, M. L. H. Il Al vases covered with tin foil. Archaeol. Anal. Athinon 4, 433–438 (1971).

Alberti, L. Costumi funerari medio minoici a Cnosso: la necropoli di Mavro Spileo. Stud. Micenei Ed. Egeo-Anatolici 43, 163–187 (2001).

Stjernquist, B. Ornamentation metallique sur vases d’argile (Metallic ornamentation on clay vases). Meddelanden fran Lunds Universitets Historiska Museum (ed. Arbman, H.) 107–169 (Papers of the Archaeological institute, University of Lund, 1958).

Stjernquist, B. Ein ungarischer fund mit metallverzierter keramik. Meddelanden fran Lunds Universitets Historiska Museum 1964–1965, 136–147 (Lunds universitets historiska museum,1965).

Andrén, A. An Italic lron Age Hut Um. Bull. Mus. Mediterr. East. Antiq. 4, 30–37 (1964).

Jucker, I. & Camporeale, G. Italy of the Etruscans (eds Jucker, I. & Avida, U.) 312 (Israel Museum, 1991).

Bartoloni, G. & Delpino, F. Un tipo di orciolo alamelle metalliche. Stud. Etruschi. 43, 3–45 (1975).

Süß, L. Schwarze schüsseln mit zinnapplikationen aus Bad Nauheim. Marburger Beiträge zum Archäologie der Kelten. Festschr. f. Wolfgang Dehn zum 60. Geburtstag am 6. Juli 1969 (ed. Frey, O.-H.) 288–327 (Habelt, 1969).

Kotitsa, Z., Adusumalli, C. & Chiaradia, M. Tin-foiled ceramics from Macedonia. Modern Trends in Scientific Studies on Ancient Ceramics (eds Kilikoglou, V. et al.) 163–170 (The Basingstoke Press, 2002).

Guo, M., He, Y., Li, J. & Wu, M. The discovery of tin-covered bronze vessel-imitating ceramics at Yinxu. Acta Archaeol. Sin. 2, 291–308 (2020).

Guo, M. Tin-covered pottery from the Eastern Zhou period in Shandong region. China Cult. Relics News 6, 291–308 (2019).

Hao, D., Zhang, J., Du, X., Huang, B. & Chen, J. Analysis of Eastern Zhou bronzes unearthed at Dubei Cemetery. J. Natl. Mus. China 6, 111–121 (2021).

Lu, X., Li, W., Li, Q., Rong, B. & Zhou, T. Analysis of painted potteries unearthed from the Qingzhou and Yiyuan districts in Shandong province. J. Conserv. Archaeol. Sci. 26, 1–8 (2014).

Zhou, S. & Wen, D. 57th Excavation report of tomb no.17. Chin. Cult. Relics 1, 63–79 (1960).

Wang, Y. Research on the tin-covered pottery making technique of the Han Tombs at Ma Wangdui. In Proc. Seventh Academic Annual Conference of the China Conservation Technology Association, 393–403 (Science Press, 2013).

Zhao, Z., Zhou, J., Jing, B. & Fu, Q. Scientific analysis of polychrome potteries of the Warring States period in Taoyuan County, Hunan Province. J. Conserv. Archaeol. Sci. 32, 51–58 (2020).

Li, J. An investigation of tin-covered pottery found in the Chu-Han Tombs of Changsha. Archaeology 3, 71–75 (1998).

Gansu Provincial Institute of Cultural Relics and Archaeology. Longyuan Yu Zhou: A Collection of Cultural Relics Found at the ShiJia Cemetery in Ning County, Gansu Province (Cultural Relics Press, 2024).

Shoval, S. The firing temperature of a Persian-period pottery kiln at Tel Michal, Israel, estimated from the composition of its pottery. J. Therm. Anal. 42, 175–185 (1994).

Berna, F. et al. Sediments exposed to high temperatures: reconstructing pyrotechnological processes in Late Bronze and Iron Age Strata at Tel Dor (Israel). J. Archaeol. Sci. 34, 358–373 (2007).

Yan, B., Liu, S., Chastain, M., Yang, S. & Chen, J. A new FTIR method for estimating the firing temperature of ceramic bronze-casting moulds from early China. Sci. Rep. 11, 3316 (2021).

Gao, Y., Liu, S. & Sun, Z. Determining firing temperature of clay-based archaeological materials with FTIR absorptivity method. Archaeometry 2025, 1–16 (2024).

Wang, Y. The Error Analysis and Methodologically Development for SEM-EDS Chemical Investigation of Ancient Porcelain Glaze and Bronze (University of Science and Technology Beijing, 2020).

Zou, F., Liu, J., Liu, H. & Qu, L. Review of the research on tin corrosion products of ancient bronze: properties, characterization methods and corrosion models. Sci. Conserv. Archaeol. 36, 128–142 (2024).

Clark, R., Cridland, L., Kariuki, B., Harris, K. & Withnall, R. Svnthesis, structural characterisation and Raman Spectroscopy of the inorganic pigments lead tin yellow types I and II and lead antimonate yellow: their identification on Medieval paintings and manuscripts. J. Chem. Soc. Dalton Trans. 26, 2577–2582 (1995).

Jin, P. et al. Corrosion resistant mechanism of lead-tin based alloy cultural relics of Warring States in Hubei Province. J. Chin. Soc. Corros. Prot. 26, 162–166 (2007).

Gao, G. Microstructure of loess in China relative to geographic and geologic environment. Acta Geol. Sin. 3, 265–272 (1984).

Liang, L., Sun, Y., Christiaan, J. & Song, Y. Characteristics of carbonate minerals in loess and its implication for chemical weathering. Quat. Sci. 34, 645–653 (2014).

Liu, D. Yellow Soil and the Environment (Science Press, 1985).

Fan, C., He, L., Zhang, Y., Wang, J. & Ma, H. Spectral identification of fingerprint spectrum of loess of arid farmland in northwest China. Spectrosc. Spect. Anal. 33, 1697–1700 (2013).

Guan, W. A New Chapter on the Engineering Properties of Collapsible Loess, 54–58 (Xi’an Jiaotong University Press, 1992).

Guo, Z. Soils in Shaanxi Province (Science Press, 1992).

Wang, Y. Research on the Handicraft Remains of the Spring and Autumn Period at Yucun Site in Ning County, Gansu Province, 54–68 (Nanjing University, 2020).

Cheng, W. & Shen, C. Bronze casting clay moulds and production sequences: understanding knowledge and organization of the artisans in Late Shang (14th-11th century BC). Asian Archaeol. 6, 137–151 (2022).

Sun, Z. et al. Material characterization uncovers sophisticated mould-making techniques of the middle-Shang period (14th-13th BCE). J. Archaeol. Sci. 160, 105870 (2023).

Noll, W., Born, L. & Holm, R. Mineralogie und technik zinnapplizierter antike keramik. Neues Jahrbuch Mineral. Abhandlungen 139, 26–42 (1980).

Mountjoy, P. Mycenaean Pottery: An Introduction (Oxford University Committee for Archaeology, 1993).

Kotitsa, Z. & Schüssler, U. Zinn auf keramik: entstehung und verwendung eines statussymbols in Makedonien. Archäol. Anz. 2, 65–84 (2002).

Kotitsa, Z. Shining vessels: transferring the technology of tin-foiled pottery in the Mediterranean (eds Rembart, L. & Waldner, A.) Manufacturers and markets. The contributions of Hellenistic pottery to economies large and small. In Proc. 4th Conference of IARPotHP, 141–160 (2022).

Gillis, C., Clayton, R., Pernicka, E. & Galet, N. Tin in the Aegean Bronze Age. J. Hell. Stud. 104–110 (University of Liege, 2003).

Gillis, C. All that glitters is not gold. In The Museum of Mediterranean and Near Eastern Antiquities: Medelhavsmuseet (ed. rystedt, E.) 26–27, 24–32 (Medelhavsmuseet, 1992).

Noll, W., Born, L. & Holm, R. Mineralogie und technik zinnapplizierter antiker keramik. Proc. Mineral. Yearbook 139, 26–42 (1980).

Gillis, C. Binding evidence, tin foil and organic binder on Aegean Late Bronze Age pottery. Op. Ath. 20, 57–61 (1994).

Gillis, C. Tin-coated ceramic vessels in the Aegean Late Bronze Age: results and implications from TOF SIMS and ESCA surface analyses. Estudis Sobre Ceràmica Antiga: Actes del Simposi Sobre Ceràmica Antiga (eds Vendrell-Saz, M. et al.) 35–40 (1995).

Gillis, C., Betancourt, P., Karageorghis, V., Laffineur, R. & Niemeier, W. D. The significance of color for metals in the Aegean Bronze Age. Meletemata: Studies in Aegean Archaeology presented to Malcolm H. Wiener as he enters his 65th year, 98–289 (1999).

Liang, J. & Ding, Y. Compositional and technical study of polychrome layers on Eastern Han ceramics excavated from Xianyang. J. Conserv. Archaeol. Sci. 31, 86–93 (2019).

Jones, R. The decoration and firing of ancient Greek pottery: a review of recent investigations. Adv. Archaeomater. 2, 67–127 (2021).

Pouilloux, J. Review of excavations in the necropolis of Salamis, III (Salamis, vol. 5). Rev. Archéol. 2, 346–349 (1977).

Aulsebrook, S. Chicken or egg? Rethinking the relationship between the silver and tinned ceramic vessel assemblages. Ann. Br. Sch. 113, 75–118 (2018).

Gillis, C. Color for the dead, status for the living. Kosmos: jewellery, adornment and textiles in the Aegean Bronze Age. In Proc. 13th International Aegean Conference (eds Nosch, M.-L. & Laffineur, R.) (Peeters, 2012).

Kreiter, A. et al. Shine like metal: an experimental approach to understand prehistoric graphite coated pottery technology. J. Archaeol. Sci. 52, 129–142 (2014).

Radivojević, M., Rehren, T., Kuzmanović-Cvetković, J., Jovanović, M. & Northover, J. P. Tainted ores and the rise of tin bronzes in Eurasia, c. 6500 years ago. Antiquity 87, 1030–1045 (2013).

Thornton, C. The emergence of complex metallurgy on the Iranian plateau: escaping the Levantine paradigm. J. World Prehist. 22, 301–327 (2009).

Pernicka, E., Begemann, F., Schmitt-Strecker, S. & Grimanis, A. On the composition and provenance of metal artefacts from Poliochni on Lemnos. Oxf. J. Archaeol. 9, 263–298 (1990).

Acknowledgements

We sincerely thank the Institute of History of Science and Cultural Genetics of the University of Science and Technology Beijing for providing the testing experimental equipment. This work was supported by the National Key Jiangxi Provincial Social Science Fund Project (No. 24LS14), National Social Science Foundation of China (No. 23BKG008), and Jiangxi Province Early Career Youth Science and Technology Talent Training Project (No. 20244BCE52209).

Author information

Authors and Affiliations

Contributions

Investigation, W.Y., S.F.; conceptualization, C.J., L.Y.; methodology, C.J.; data curation, W.Q., Z.M.; writing—original draft preparation, W.Q., C.J.; writing—review and editing, W.Q., C.J., W.Y. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wei, Q., Li, Y., Chen, J. et al. Research on tin-covered clay ritual vessels from Shijia Cemetery in Gansu Province, China. npj Herit. Sci. 13, 498 (2025). https://doi.org/10.1038/s40494-025-02058-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s40494-025-02058-2