Abstract

The development of micro-electro-mechanical system (MEMS) alkali metal vapor cells offers the potential for the batch fabrication of micro-quantum sensors for atomic clocks, atomic magnetometers and atomic gyroscopes. The sealing of MEMS vapor cells is traditionally achieved by anodic bonding. However, high-temperature and high direct-voltage conditions during anodic bonding adversely affect the performance of the vapor cell. In this study, a fabrication method based on ultrafast laser welding integrated with a microfabrication process was developed for MEMS alkali metal vapor cells, and the energy-coupling mechanism of welding was analyzed. This method confined high temperatures to a localized area during laser welding. The cross-sections of the welding samples were analyzed, the element distribution was characterized, and the results showed that this method achieved high-strength sealing. Additionally, a platform for alkali metal injection and buffer gas charging was developed to enable the fabrication of MEMS vapor cells with ultrafast laser welding. The MEMS vapor cells were tested using absorption spectra, and the leakage rate under high-temperature vacuum conditions proved that high hermeticity could be achieved by ultrafast laser welding. Finally, MEMS vapor cells were used to fabricate a single-beam magnetometer, and its measurement sensitivity was determined experimentally. This process provides a new method for the efficient fabrication of MEMS vapor cells.

Similar content being viewed by others

Introduction

Alkali metal vapor cells serve as the core of sensitive devices for quantum sensors1,2,3,4. The glass blowing method is commonly used for vapor cell fabrication; however, it poses challenges in achieving consistent mass production at low cost5,6,7. The wafer-level fabrication process enables the batch production of low-priced, well-consistent alkali-metal vapor cells8,9. The micro-electro-mechanical system (MEMS) alkali metal vapor cell mainly utilizes wet etching or dry etching processes to fabricate holes on silicon wafer, which is sealed by wafer-level processes. This method was first proposed by Kitching of NIST10, and established a standard for the fabrication of MEMS vapor cells.

In general, MEMS vapor cells are mainly sealed by an anodic bonding process11,12,13,14, which requires high-temperatures and high direct-voltage15,16,17. However, high bonding temperatures can lead to the evaporation of alkali metals in the interface resulting in bonding failure, and increase pressure inside the bonding chamber. To address this issue, researchers have performed studies in the area of low-temperature anodic bonding based on surface activation, including wet methods18,19 and dry methods20,21,22. However, these surface activation methods are generally achieved using water, plasma, and free radicals, which readily react with alkali metals. Meanwhile, low-temperature anodic bonding still has problems, such as low bonding strength, poor sealing, and low success rate. Additionally, contaminants such as water and residual oxygen produced during anodic bonding process react with the alkali metals23. Moreover, under working temperature conditions of the vapor cells, alkali metals are absorbed by borosilicate glass24,25,26. Al2O3 coatings on borosilicate glasses or aluminosilicate glasses can effectively reduce the absorption of alkali metals26. However, the use of Al2O3 coatings increases the complexity of the anodic bonding process and the difficulty of low-temperature anodic bonding, while aluminosilicate glasses increased the cost of vapor-cell fabrication.

Ultrafast laser welding provides a new method for the fabrication of MEMS vapor cells with a high spatial resolution that realizes the micro-welding of materials via heating at the optical contact interface to create micro-melting regions. The low heat-affected zone, high welding dependability, and lack of an intermediary layer are the defining characteristics of this technique27,28,29, which avoids the drawbacks of anodic bonding that requires a high electric field and high temperature, and does not generate contaminating gases, and is not affected by intermediate films such as Al2O3. Ultrafast laser welding between silicon and glass has been widely demonstrated and has achieved a performance comparable to that of anodic bonding30,31. However, this process has not been applied to the fabrication of MEMS vapor cells due to its complexity, and the hermetic performance of the process remains to be verified.

In this study, a method for fabricating MEMS alkali metal vapor cells based on ultrafast laser welding was proposed. This method utilizes the high-resolution capability of ultrafast laser welding to seal MEMS vapor cells, avoiding the influence of high-temperature and high direct-voltage environments during the anodic bonding process. First, the principle of ultrafast laser welding was explained using the Fokker-Planck model and two-temperature model, and its energy coupling mechanism was determined. A scanning electron microscope (SEM) and an electronic universal testing machine were used to analyze the welding samples and determine the optimal welding parameters, followed by an elemental analysis of the welding interface using energy dispersive spectrometer (EDS) to characterize the elemental distribution of the welding seam. Subsequently, a fabrication platform for MEMS vapor cells was developed, and the fabrication of MEMS vapor cells was realized. To demonstrate the validity of this method, the absorption spectra of the vapor cells and their pressure variation under high-temperature vacuum conditions were tested. Finally, the MEMS vapor cells were used in single-beam spin-exchange relaxation free (SERF) magnetometer to obtain a sensitivity of 40 fT/Hz1/2.

Mechanism of ultrafast laser welding

Given that the study used ultrafast laser welding of silicon-glass to achieve the sealing of the MEMS vapor cells, a brief description of the welding process is given here. For ultrafast laser welding between silicon and glass, neglecting the nonlinear absorption effect of glass32,33, the laser passes through the glass to the welding interface and is absorbed by the silicon to cause carrier excitation. Due to the high laser intensity, this process primarily excites electrons in the valence band into the conduction band to produce free electrons and collisions between free electrons and valence band electrons, which mainly involves photoionization and collisional ionization34. Among them, the photoionization \({W}_{PI}\) is described by the Keldysh photoionization model35,36, as follows:

where

where \(\omega\) is the laser frequency, \(\hslash\) is the reduced Planck constant, \({m}_{red}\) is the effective electron mass, \(\gamma\) is the Keldysh coefficient and, \({\gamma }_{1}={\gamma }^{2}/(1+{\gamma }^{2})\), \({\gamma }_{2}=1/(1+{\gamma }^{2})\), \(K(\gamma )\) and \(E(\gamma )\) are the elliptic integrals of the first and second kind, respectively, \({E}_{g}\) is the energy band gap, \(< \varDelta +1 >\) means to take an integer for \(\varDelta +1\), and \(\varphi (x)\) is the Dawson equation.

The collisional ionization \({W}_{II}\) is linearly related to the incident laser intensity37,38:

where \({\alpha }_{i}\) is the collisional ionization constant, I is the ultrafast laser intensity, and Ne is the free electron density. Assuming that the laser is focused on the welding interface, the variation of the laser intensity I(x,y,t) with time and position for ultrafast laser light consistent with a Gaussian distribution is given by:

where F is the laser energy density, \({t}_{p}\) is the pulse duration, \(({x}_{0},{y}_{0})\) is the laser focal position, and \({r}_{0}\) is the radius of the laser beam.

Based on the Fokker-Planck equation35, the equation for the evolution of the free electron density Ne on the silicon surface over time is as follows:

where \({N}_{\max }\) is the maximum electron density, and \({\tau }_{r}\) is the free electron composite time.

The free electrons in the conduction band absorbed the energy of the incident laser, increasing in the temperature of the free electrons, and the energy of the free electrons was transferred to the lattice by the coupling of the free electrons, leading to an increase of the lattice temperature, which could be described by two-temperature model, as follows:

where \({T}_{e}\) is the electron temperature, \({T}_{l}\) is the lattice temperature, \({C}_{e}\) is the free electrons heat capacity, \(\nabla\) is the Nabla operator; \({k}_{e}\) is the electrical thermal conductivity, \(G\) is the electron-lattice coupling coefficient, \(R\) is the laser reflectivity, \({\alpha }_{abs}\) is the laser absorption coefficient, \(\rho\) is the lattice density, \({c}_{l}\) is the lattice heat capacity, and \({k}_{l}\) is the lattice thermal conductivity.

At a high repetition frequency, the number of free electrons in the conduction band and the electron temperature increases, and energy is transferred to the lattice. The lattice temperature rises continuously due to the thermal accumulation effect and reaches the melting points of silicon and glass in the focus region. Subsequently, molten silicon and glass mix to fill the gap at the interface and solidify, realizing the hermetic silicon-glass welding. Therefore, repetition frequency and single pulse energy are key parameters for ultrafast laser welding of silicon-glass, which will be optimized in the next section.

Experiment

As shown in Fig. 1a, b the overall size of the MEMS alkali metal vapor cell was 9 mm × 7 mm × 2.5 mm. The glass wafer was a 500 μm thick BOROFLOAT 33 (BF33) double-sided polished glass with 20 nm Al2O3 coatings, and the silicon wafer was 1.5 mm thick double-sided polished monocrystalline silicon. The MEMS vapor cell consisted of two chambers and connecting channels. The working chamber size was Φ4 mm × 1.5 mm to achieve the polarization and detection of alkali metals; the auxiliary chamber size was 2 mm × 1.5 mm × 1.5 mm to store excess alkali metals; the connecting channel size was 500 μm × 50 μm × 100 μm to connect working and auxiliary chambers. When the MEMS vapor cell worked, the vapor cell was heated, and the alkali metal vapor went from the auxiliary chamber to the working chamber by connecting channels. Finally, the alkali metals in working chamber were polarized and detected.

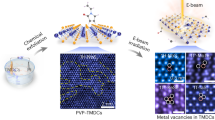

a Schematic and b fabricated of MEMS vapor cell; c sputtering of Al and Au hard mask layers, d patterning of the hard mask layers, e etching the chambers and the connecting channels, f chemical polishing, g removing hard masks, h sputtering of Al2O3 coatings on BF33 glass, i wafer clamping for optical contact, j first ultrafast laser welding, k injection of Rb, l buffer gas filling, m wafer clamping for optical contact, n second ultrafast laser welding, o wafer dicing; morphology of silicon chamber sidewalls (p) before and (q) after chemical polishing

Fabrication of silicon chambers and connecting channels

MEMS alkali metal vapor cells based on ultrafast laser welding were fabricated, and its processing flow is shown in Fig. 1c-o.

The silicon chambers and connecting channels was fabricated using combination of inductively coupled plasma (ICP) dry etching and chemical polishing, as shown in Fig. 1c–g. First, Cr, Au and Al were sputtered on one side of the silicon wafer, and Cr and Au were sputtered on the other side, as shown in Fig. 1c. Subsequently, metal masks patterning was achieved using a photolithographic process, in which the pattern was transferred to the silicon wafer by removing the bare metal layer using a wet etching solution, as shown in Fig. 1d.

After patterning, ICP dry etching was used to fabricate the connecting channels and silicon cavities, as shown in Fig. 1e. Following dry etching, numerous defects were generated on the surface of the silicon cavity sidewalls, as shown in Fig. 1p. To minimize the effect of the etching defects on the vapor cell, the sidewalls of the silicon cavities were treated under ultrasonic conditions for 150 s using HF: HNO3 = 1: 3 chemical polishing solution, as shown in Fig. 1f. This process realized a sidewall roughness of Ra= 20 ± 5 nm, and the sidewall morphology was shown in Fig. 1q. Subsequently, the Cr and Au masks on the surface of the silicon wafer were removed, and the silicon wafer was cleaned to remove contaminants, as shown in Fig. 1g.

As shown in Fig. 1h, 20 nm Al2O3 coatings were sputtered on both sides of the BF33 glass to minimize the absorption of alkali metals at high temperatures.

Ultrafast laser welding

An optical contact was a prerequisite for realizing ultrafast laser welding between glass and silicon. When there was a gap between the glass and silicon, the molten droplets in the melt pool spread at the interface between them, and shrinkage stress was present in the welding region as it cooled. As the shrinkage stress was greater than the breaking strength of the material, the welding seam generated holes or cracks, which affected the welding sealing. Therefore, it was necessary to force the silicon and glass to ensure optical contact between them. The silicon and glass wafers were clamped using the constructed clamping platform shown in Fig. 1i, and were left stationary for a period to achieve optical contact at the welding interface.

In this study, the ultrafast femtosecond laser was Gaussian beam with a wavelength of 1064 nm, a pulse duration of 484 fs, repetition frequencies of 25 kHz-1 MHz, and a focused spot diameter of 30 μm, as shown in Fig. 2a. The laser power was controlled by a λ/2 plate and polarizing beam splitter (PBS). Subsequently, the femtosecond laser passed through the laser collimation system (LCS) and was focused by the objective lens onto the interface, realizing welding between the glass and silicon wafers.

a The schematic diagram of ultrafast laser welding device (λ/2: half-wave plate, PBS: polarizing beam splitter; LCS: laser collimation system; M: mirror; OL; objective lens), b first and c second femtosecond laser welding paths for single vapor cell; d overall view of alkali metal injection and buffer gas charging system; e ultrafast laser welding sealing chamber; f femtosecond laser welding system; g schematic diagram of manufacturing platform

MEMS alkali metal vapor cells must maintain the hermetic welding between silicon and glass wafers. However, at low pulse energies or low repetition frequencies, it was difficult to form stable welding seams, resulting in leakage; at high pulse energies, the nonlinear absorption of glass caused the laser energy to be absorbed by the glass to produce glass ablation, resulting in welding failure; at high repetition frequencies, the accumulation of heat led to thermal micro-lensing near the focal point39,40, deteriorating the welding effect. For this purpose, welding samples were fabricated under different single pulse energies and repetition frequencies at a welding speed of 25 mm/s, considering the large mass of the ultrafast laser welding sealing chamber (welding chamber, shown in the next section), the limited power of the movable platform and the shaking of the welding chamber due to limitations in alignment and fixation of the welding equipment. Subsequently, the welding cross-sectional morphology and tensile strength of the samples with different welding parameters were characterized using SEM and an electronic universal testing machine to determine the optimal welding parameters, as shown in Fig. 3.

a–d Ultrafast laser welding cross-section at a single pulse energy of 4 μJ and repetition frequencies of 100 kHz, 300 kHz, 500 kHz, and 800 kHz, respectively; e–h ultrafast laser welding cross-section at repetition frequency of 500 kHz and single pulse energy of 2 μJ, 4 μJ, 6 μJ, and 8 μJ, respectively, and the arrow in (a) is the scanning direction of laser in (a)–(h); i and j samples after tensile test for welding parameters shown in (a)–(d) and (e)–(h), respectively (from left to right); k tensile strength test system; l variation of tensile strength with single pulse energy and repetition frequency

Figure 3a–d showed the variation of the welding cross-section morphology with repetition frequency at a single pulse energy of 4 μJ after passing the objective, and the welding scanning direction was shown in Fig. 3a. Figure 3a showed the ultrafast laser welding cross-section at a repetition frequency of 100 kHz. Under this condition, the laser pulse reached the interface and was absorbed by silicon, and the laser absorption coefficient of silicon increased with temperature41. This led to an increase in the surface temperature of the silicon wafer, which continued to rise and produce silicon fragments, molten silicon, and silicon vapor. As a result, the high evaporative recoil pressure generated at the silicon-glass interface caused the molten silicon to flow out of the laser irradiation zone and condense on its flanks, realizing welding between the silicon and glass. However, due to the recoil pressure, the laser irradiation zone produced visible holes, which affected welding hermeticity.

Figure 3b, c showed the welding cross-sections at repetition frequencies of 300 kHz and 500 kHz, respectively. First, the silicon at the interface absorbed the laser energy, and the heat accumulation effect was more evident because the repetition frequency increased; hence the melting zone of silicon increased. Due to the presence of recoil pressure, molten silicon flowed toward the glass, resulting in decreasing in transmittance and improving absorption of the glass. Subsequently, the glass absorbed the laser energy, causing it to melt. Finally, high-quality and hole-free silicon-glass welding occurred in the laser-irradiated area. Compared to Fig. 3b, the welding cross-section shown in Fig. 3c adopted a higher repetition frequency, which produced a larger heat-affected zone and welding cross-section.

Figure 3d showed the welding cross-section at a repetition frequency of 800 kHz, which was similar to that at 300 kHz. This occurred because as the laser repetition frequency increased, the laser was focused by micro-lensing created in the glass region near the focal spot of the laser beam. At this point, the laser focus at the welding surface decreased, resulting in a corresponding decrease in the size of the welding seam.

Figure 3e–h showed the variation in welding cross-section morphology with single pulse energy after passing the objective at a repetition frequency of 500 kHz, and the welding scanning direction was also shown in Fig. 3a. Figure 3(e) was the welding cross-section at a single pulse energy of 2 μJ, and its morphology was similar to that shown in Fig. 3a. Several fine holes were generated at the silicon-glass welding interface due to the high evaporation recoil pressure. When the single pulse energy was increased to 4 μJ, as shown in Fig. 3f, the morphology of this cross-section was the same as that of Fig. 3c, which produced well-formed and hole-free welding at the silicon-glass interface. As the single pulse energy was increased to 6 μJ, glass ablation was generated as shown in Fig. 3g. At this point, the laser energy reaching the interface was reduced, and the size of the welding seam decreased due to the nonlinear absorption effect of glass; however, this parameter still enabled welding between silicon and glass. When the single pulse energy was increased to 8 μJ, as shown in Fig. 3h, the nonlinear absorption effect was intensified, and the laser energy was mainly absorbed by glass, which prevented reliable welding at the silicon-glass interface.

To optimize the welding parameters, tensile strength testing was used. First, the welding samples were fabricated under different welding parameters at a line spacing of 50 μm and cut into 10 mm × 10 mm pieces. Subsequently, the welding pieces were bonded to the fixture using epoxy resin glue, the samples were subjected to a tensile test with an electronic universal testing machine, and the tensile strengths were calculated, as shown in Fig. 3k. The samples for each parameter were tested five times; examples were shown in Fig. 3i, j. Most of the tensile samples did not break at the welding surface, indicating that the welding strength was greater than the breaking strength of the silicon. The averaged test results were shown in Fig. 3l. Among them, the red line was the variation of tensile strength with the repetition frequency at a single pulse energy of 4 μJ; the blue line was the variation of tensile strength with the single pulse energy at a repetition frequency of 500 kHz. With an increase in both the repetition frequency and single pulse energy, the welding strength increased, due to the thermal accumulation effect at the silicon-glass interface with the increase in laser energy, resulting in high-strength welding at the interface. However, when the single pulse energy increased further, the glass underwent ablation due to nonlinear absorption, which led to a reduction in the welding seam strength or even failure. Meanwhile, when the repetition frequency increased further, the welding area decreased due to micro-lensing effect, which led to a reduction in the welding strength. The tensile strength of about 14.2 MPa was achieved at a single pulse energy of 4 μJ and a repetition frequency of 500 kHz (4 μJ and 500 kHz), which was comparable with the anodic bonding strength42.

In order to characterize the elemental distribution of the welding seam, elemental analysis of the welding cross-section at 4 μJ and 500 kHz was performed using EDS. As shown in Fig. 4a, the test spots included five locations: silicon, glass, edges, and the center of the welding seam. Their energy spectra were shown in Fig. 4c–g, and the relative contents of elemental oxygen and silicon were listed in Table 1. As the testing spots transitioned from glass to silicon, the oxygen content decreased, and the silicon content increased, as shown in Fig. 4b. However, spot 3 showed an increase in silicon content and a decrease in oxygen content compared to point 4, which was opposite to the overall trends of silicon and oxygen. This occurred due to the convective flow of molten silicon produced by the recoil pressure during silicon melting, which led to the transfer of silicon from the molten pool to the interface to create a silicon glass mixture, resulting in a decrease in the silicon content at spot 4 and an increase in the silicon content at spot 3. Simultaneously, the diffusion flow of the molten glass into the silicon wafer resulted in an increase in the oxygen content at spot 4 and a decrease in the oxygen content at spot 3. Convective diffusion between the molten glass and molten silicon prevented violent evaporation of the silicon, achieving hole-free welding at the silicon-glass interface.

a Testing spots of the welding seam cross-section; b Trends in the relative atomic content of silicon and oxygen elements according to Table 1; c–g Results of EDS analysis from spot 1 to spot 5

The first ultrafast laser welding was accomplished under the condition of 4 μJ and 500 kHz along the welding line shown in Fig. 2b with a line spacing of 50 μm, as shown in Fig. 1j. Subsequently, acetone and anhydrous ethanol were used to clean the welded wafer to remove impurities.

Alkali metal injection and the MEMS vapor cells package

As shown in Fig. 2d, a processing platform was set up for fabricating MEMS vapor cells. This platform could perform vacuum drying of welding wafers, alkali metal injection, clamping of welding sheets, vacuum pumping, residual gas analysis, and gas charging.

The alkali metal Rb was injected using a micropipette in the glove box shown in Fig. 1k, which was filled with nitrogen and equipped with a circulation system to maintain water and oxygen contents were below 0.01 ppm.

The welding chamber shown in Fig. 2e was placed in the glove box. Its structure was shown in Fig. 2f, including sealed ball valves, an air cylinder, a reversing valve, a wafer spacer and fixing clamps. After connecting it to the vacuum and gas charging unit, the samples to be welded were placed in the welding chamber and clamped in position using wafer clamps; a wafer spacer was adopted to maintain a particular gap between them, ensuring vacuum and gas filling. Finally, the welding chamber was sealed with screws, as shown in Fig. 1l.

A schematic diagram of the vacuum pumping and gas charging system was shown in Fig. 2g. First, valves 3 and 7 were switched on, and the welding chamber was evacuated to 5E-5 mbar using a molecular pump unit. Subsequently, valves 5–6 and 8–10 were switched on, and valves 11 and 12 were switched on depending on the type of gas charged, while the gas pressure was monitored using vacuum gauges. After gas charging was completed, external switches were used to remove the clamps and spacer. Valves 1,2 were then switched on to make the base of the welding chamber move upward and remain stationary for a while, realizing the clamping of the wafers and optical contact, where the clamping force was controlled by the gas pressure, as shown in Fig. 1m. Subsequently, all valves were closed to seal the welding chamber and ensure optical contact between the wafers. Finally, the welding chamber was removed through the transfer chamber quickly and placed on the femtosecond laser welding system, as shown in Fig. 2f, to ready for sealing the vapor cells.

As shown in Fig. 1n, the sealing of the MEMS vapor cells was also fabricated at 4 μJ and 500 kHz. Before sealing of the vapor cells, it is required to pre-seal the welding plate edges to minimize the effect of pressure fluctuations of the buffer gas in the welding chamber on the vapor cells. When sealing the MEMS vapor cells, the welding line was rearranged and designed to minimize the effect of localized high temperatures on the buffer gas pressure during ultrafast laser welding. First, the edges of the vapor cell were welded to achieve pre-sealing, as indicated by the red line in Fig. 2c. After that, the vapor cells were welded and sealed according to the green line, which maintained a distance of 200 μm from the sidewalls of the vapor cell to avoid ablation of chambers due to alignment errors. This path enhanced the reliability of the welded vapor cells while reducing the effect of temperature gradients on the vapor cell pressure.

Finally, the vapor cell wafers were cut into individual vapor cells, as shown in Fig. 1o. The dimensions of the single vapor cells were 9 mm × 7 mm × 2.5 mm.

Results

Absorption spectrum and leakage rate test

Magnetometers based on the SERF regime require alkali metals with high atomic densities. In general, the atomic densities required to achieve atomic SERF states range from 1013/cm3 to 1014/cm3, and the temperature range of approximately 110 °C to 150 °C for rubidium. At high temperatures, the leakage rate of the alkali metal vapor cells increased rapidly. The leakage rate of the vapor cells can be obtained by the hermeticity test method provided by GJB 548B-2005-1014.2, which specifies that the leakage rate must less than 5 × 10−9 Pa·m3/s; however, the test method provided by this standard is realized at room temperature and cannot be used to obtain the leakage rate under operating conditions. Considering this, the buffer gas pressure was tested for an extended period at 150 °C and under vacuum conditions to determine the leakage rate, and the procedure was as follows:

MEMS vapor cells were fabricated using the ultrafast laser welding process described above, and the buffer gas was He with a gas pressure of about 2 amg. Subsequently, the absorption spectra of the MEMS vapor cells were measured. The transmitted light intensity of the vapor cells at different laser frequencies using a linearly polarized laser was recorded. The optical depths (OD) at various frequencies were obtained from the incident light intensity of the laser as well as the solution of Eq. (8), and then fitted to the Lorentz function given in Eq. (9), as indicated by the blue dots and red line in Fig. 5a, respectively. Based on the fitting results, the full width at half maximum (FWHM) of the vapor cell was determined to be 36.20 GHz. Based on pressure broadening factor of the Rb D1 line in He at 18 GHz/amg43, the buffer gas pressure inside the vapor cell was determined to be about 2.01 amg. Finally, the vapor cells were put into the vacuum drying oven and heated at 150 °C for 15 days, and the whole process used a mechanical pump to evacuate the drying oven to ensure that the pressure was less than 200 Pa, about 1‰ of the pressure in the vapor cells. The pressure in the vapor cell was measured every 36 h, and the test results were shown in Fig. 5b,

where I(l) is the transmitted light intensity, and I0 is the incident light intensity.

where ν0 is the resonant frequency, ν is the laser frequency, ΓL is the FWHM of absorption spectroscopy caused by pressure broadening, and a and b are the fitting coefficients.

a Absorption spectrum of vapor cells with He as buffer gas, b pressure broadening (blue line) and He pressure (red line) versus time for vapor cells heated at 150 °C for 15 days, c absorption spectrum of vapor cell filled with N2; d schematic of the test system (DFB: distributed feedback laser; PBS: polarized beam splitter; λ/2: half-wave plate; PD: photodiode; λ/4: quarter-wave plate; CL: convex lens; R: reflector; TIA: transimpedance amplifier; LIA: lock-in amplifier; DAQ: data acquisition system), e test platform for MEMS vapor cell; f the magnetometer response signal at 50% polarization rate, g sensitivity signal of the magnetometer

The red and blue lines in Fig. 5b represented the variations in the pressure broadening and buffer gas pressure over vacuum heating time, respectively. With the heating time increased, the pressure broadening and buffer gas pressure of the vapor cell decreased. After heating at 150 °C under vacuum for 15 days, the pressure broadening of the vapor cell dropped from 36.20 GHz to 28.90 GHz, and accordingly, the He pressure dropped from 2.01 amg to 1.60 amg. The He leakage rate inside the vapor cells was accelerated, primarily due to the permeation leakage of the glasses. As the experiment proceeded, the amount of He in the glass increased due to permeation, and at the same time, the leakage rate of He was further accelerated due to the increase in the amount of He in the glass, meanwhile, the presence of the Al2O3 coating slowed down the leakage of He and prolonged the time to reach saturation of the gas, which led to the described leakage trends to be more significant. It was consistent with the increased gas permeation rate through the glass due to gas saturation inside the glass, as described by DELLIS et al.44. Therefore, de-watering and de-gassing of wafers before vapor cell fabrication, as well as the use of low penetration glass were essential for improving the vapor cell lifetime. The average leakage rates of vapor cells in 15 days were about 7.40 × 10−10 Pa·m3/s. The results of the leakage rate were compared with other sealing methods as shown in Table 2, which showed that the leakage rate of the vapor cells fabricated by this method was comparable to that of anodic bonding, but higher than that of metal bonding. However, metal bonding method would introduce metal, increasing fabrication costs. Meanwhile, the leakage rate obtained by ultrafast laser welding under high-temperature vacuum conditions was much higher than the leakage rate of the vapor cells measured at room temperature45.

Additionally, the MEMS vapor cell filled with N2 was tested for gas pressure. As illustrated in Fig. 5c, the pressure broadening was 36.50 GHz, and based on the pressure broadening factor to be 17.8 GHz/amg43, the buffer gas pressure inside the vapor cells was found to be about 2.05 amg. Meanwhile, the MEMS alkali metal vapor cells filled with N2 were heated under vacuum at 150 °C for 15 days. The results showed that the pressure of the vapor cell did not change significantly, proving that the vapor cells fabricated using this method had good hermeticity and stability.

Magnetometer sensitivity test

The schematic of the magnetometer detection system based on the differential method was shown in Fig. 5d and the overall system was shown in Fig. 5e. The distributed feedback laser (DFB) generated a beam with a center wavelength of 795 nm, which was split into two beams by passing through a λ/2 plate and PBS. One of the beams was received by the fiber port after passing through the λ/2 plate and directed into the probe by the polarization maintaining fiber. Then, the linearly polarized light was transformed into circularly polarized light after passing through the convex lens and the λ/4 plate. Subsequently, the circularly polarized light passed through the working chamber to pump alkali metals as well as the probing of the magnetic field, and the intensity of the transmitted light was detected and converted into an electric signal by photodiode 2 (PD2). The other laser beam was detected by another identical photodiode 1 (PD1), in which the intensity of the laser was adjusted by a λ/2 plate and a PBS to ensure that the current magnitude of PD1 was equal to that of PD2. When the two currents passed through the differential system, the total current magnitude in the transimpedance amplifier (TIA) becomes zero, suppressing the effect of laser power fluctuation noise on the signals. Finally, the signal was passed through a lock-in amplifier (LIA) and data acquisition system (DAQ) for signal acquisition and processing. Before testing, the MEMS alkali metal vapor cell was kept in a magnetic shield cylinder consisting of one layer of Mn-Zn ferrite and four layers of permalloy, which limited the residual magnetic field to less than 10 nT, and then the residual magnetic field in the shield cylinder was actively magnetically shielded to the order of pT using three-dimensional magnetic field coils, meanwhile, the modulated magnetic field was also applied by three-dimensional magnetic field coils. During operation, the MEMS vapor cell was heated using a laser with a wavelength of 1550 nm.

Based on the fabricated vapor cells with N2 as the buffer gas, the signal of the single-beam magnetometer was tested. As shown in Fig. 5d, the heating laser was used to heat the MEMS vapor cell to make the alkali metals in SERF state. Then, a modulated magnetic field with an amplitude of 180 nT and a frequency of 1 kHz was applied in the x direction. Subsequently, a beam of circularly polarized light was transmitted through the vapor cell to achieve 50% polarization of Rb atoms, and it was then differentiated. The x-direction transversely biased magnetic field Bx was scanned, the output signal of the magnetometer in 90° phase was recorded after the LIA, and the data were fitted using the dispersion function, as shown in Eq. (10). The half width at half maximum of the dispersion curve was 10.26 nT, and the scale factor near-zero field was about 0.2 V/nT, as seen in Fig. 5f.

where A is the scaling factor, B0 is the residual magnetic field in the x-direction and ΔB is the half width at half maximum of the dispersion curve.

Under zero bias magnetic field conditions, the noise signal of the magnetometer was acquired after passing through an LIA with an acquisition frequency of 3384 Hz and a sampling time of 20 s. Based on the slope of the linear part of the dispersion curve, a power spectral density analysis was performed to determine the sensitivity of the single-beam magnetometer as 40 fT/Hz1/2, as shown in Fig. 5g.

Discussion

Given the large mass of the welding chamber, the limitations of the moving platform and minimizing the shaking of the welding chamber due to limitations in alignment and fixation of the welding equipment, a welding speed of 25 mm/s was chosen to seal the MEMS vapor cell. Under these conditions, it takes approximately 2 h to batch-fabricate MEMS vapor cells of this size on 4-inch wafers, which was comparable to the sealing efficiency of vapor cells fabricated using anodic bonding42. However, the welding efficiency could be further improved; for example, Okamoto et al.31 realized silicon-glass welding at a repetition frequency of 2 MHz, a single pulse energy of 2 μJ and a welding speed of 2 m/s. Therefore, higher welding efficiencies could be achieved using this fabrication process with appropriate equipment capabilities.

The performance of micro-quantum sensors declines as the vapor cell size decreases due to wall collisional relaxation in miniaturized vapor cells46. Compared with filling buffer gases, the use of anti-relaxation coatings suppresses magnetic field gradient while reducing wall relaxation47,48. However, the primary limitation of the fabrication of anti-relaxation coatings in MEMS vapor cells is the failure of the anti-relaxation coatings due to the high temperature during the sealing process49. Initially, the effect of ultrafast laser welding on the sidewall temperature of the silicon chamber was evaluated. The vapor cell sample was fabricated with the green line as shown in Fig. 2c, where the innermost line was 200 μm away from the silicon chamber sidewalls, and its temperature was measured using a thermistor. The results indicated that the maximum temperature of the silicon chamber sidewalls of the vapor cell during fabrication was about 90 °C, which was much lower than the failure temperatures of the octadecyltrichlorosilane (OTS) anti-relaxation coating of 170 °C (with alkali metals) and 230 °C (without alkali metals). Therefore, the ultrafast laser welding technique provides a new approach for fabrication of MEMS vapor cells integrated with OTS anti-relaxation coatings, which is the focus of subsequent studies.

Conclusion

A new method was proposed for the fabrication of MEMS vapor cells relied on ultrafast laser welding, which ensured high hermeticity of the vapor cells while avoiding the adverse influence of on the MEMS vapor cells during the anodic bonding process. The mechanism of ultrafast laser welding was analyzed, the cross-section morphology and strength of the silicon-glass welding were characterized, and the optimal welding parameters were determined. The elemental distribution of the welding seam was analyzed to clarify the ultrafast laser welding process. A fabrication platform was developed for MEMS alkali metal vapor cells which could achieve alkali metal injection, gas charging, and ultrafast laser welding. The MEMS vapor cells were maintained under a vacuum at 150 °C for 15 days and tested for pressure, which indicated that the equivalent standard leakage rate was 7.40 × 10−10 Pa·m3/s, comparable to that of anodic bonding. Finally, the MEMS vapor cell was applied to a single-beam SERF magnetometer, and a sensitivity of 40 fT/Hz1/2 was obtained. The results demonstrated the MEMS vapor cells fabricated using this method had excellent hermeticity and satisfied the requirements for quantum sensors.

References

Degen, C. L., Reinhard, F. & Cappellaro, P. Quantum sensing. Rev. Mod. Phys. 89, 035002, https://doi.org/10.1103/RevModPhys.89.035002 (2017).

Shen, Q., Lin, H. X., Deng, J. L. & Wang, Y. Z. Pulsed optically pumped atomic clock with a medium- to long-term frequency stability of 10-15. Rev. Sci. Instr. 91, 045114, https://doi.org/10.1063/5.0006187 (2020).

QShu, Q. et al. Suppression of ambient stray field for alkali magnetometer of nuclear magnetic resonance gyroscopes: Modeling and experiment. Rev. Sci. Instr. 91, 095005, https://doi.org/10.1063/5.0018011 (2020).

Zhao, B. B. et al. High-sensitivity pump-probe atomic magnetometer based on single fiber-coupled. Opt. Laser Technol. 159, 109025, https://doi.org/10.1016/j.optlastec.2022.109025 (2023).

Kitching, J. Chip-scale atomic devices. Appl. Phys. Rev. 5, 031302, https://doi.org/10.1063/1.5026238 (2018).

Laliotis, A., Villalba, S. & Failache, H. Simple fabrication of miniaturized glass cells for atomic vapor spectroscopy. Appl. Phys. a-Mater. Sci. Process. 38, 193–195, https://doi.org/10.1007/s00339-022-05569-y (2013).

Knappe, S. et al. A microfabricated atomic clock. Appl. Phys. Lett. 85, 1460–1462, https://doi.org/10.1063/1.1787942 (2004).

Maurice, V. et al. Wafer-level vapor cells filled with laser-actuated hermetic seals for integrated atomic devices. Microsyst. Nanoengineering 8, 129, https://doi.org/10.1038/s41378-022-00468-x (2022).

Kiyose, S., Hirai, Y., Tabata, O. & Tsuchiya, T. Microfabricated alkali metal vapor cells filled with an on-chip dispensing component. Jpn. J. Appl. Phys. 60, SCCL01, https://doi.org/10.35848/1347-4065/abe203 (2021).

Kitching, J., Knappe, S. & Hollberg, L. Miniature vapor-cell atomic-frequency references. Appl. Phys. Lett. 81, 553–555, https://doi.org/10.1063/1.1494115 (2002).

Han, R. Q., You, Z., Zhang, F., Xue, H. B. & Ruan, Y. Microfabricated vapor cells with reflective sidewalls for chip scale atomic sensors. Micromachines 9, 175, https://doi.org/10.3390/mi9040175 (2018).

Ji, Y., Shang, J. T., Li, G. L., Zhang, J. & Zhang, J. F. Microfabricated shaped rubidium vapor cell for miniaturized atomic magnetometers. IEEE Sens. Lett. 4, 1–4, https://doi.org/10.1109/lsens.2020.2965737 (2020).

Li, X. J., Shi, Y., Xue, H. B., Ruan, Y. & Feng, Y. Y. Atomic magnetometer with microfabricated vapor cells based on coherent population trapping. Chin. Phys. B 30, 030701, https://doi.org/10.1088/1674-1056/abc2b9 (2021).

Bopp, D. G., Maurice, V. M. & Kitching, J. E. Wafer-level fabrication of alkali vapor cells using in-situ atomic deposition. J. Phys.-Photonics 3, 015002, https://doi.org/10.1088/2515-7647/abcbe5 (2021).

Yu, M. et al. Microfabricated atomic vapor cells with multi-optical channels based on an innovative inner-sidewall molding process. Engineering 35, 46–55, https://doi.org/10.1016/j.eng.2023.08.016 (2023).

Vecchio, F., Venkatraman, V., Shea, H. R., Maeder, T. & Ryser, P. Dispensing and hermetic sealing Rb in a miniature reference cell for integrated atomic clocks. Sens. Actuators a-Phys. 172, 330–335, https://doi.org/10.1016/j.sna.2011.03.045 (2011).

Maurice, V. et al. Microfabricated vapor cells filled with a cesium dispensing paste for miniature atomic clocks. Appl. Phys. Lett. 110, 164103, https://doi.org/10.1063/1.4981772 (2017).

Lo, F. S., Chiang, C. C., Li, C. & Lee, T. H. Increasing more bonding energy in nitrogen plasma-activated wafer bonding by HF-Dip. Ecs Solid State Lett. 3, P102–P104, https://doi.org/10.1149/2.0031408ssl (2014).

Jia, S. et al. The microfabricated alkali vapor cell with high hermeticity for chip-scale atomic clock. Appl. Sci.-Basel 12, 436, https://doi.org/10.3390/app12010436 (2022).

Hao, F. F., Wang, J. Q. & Li, M. W. Low-temperature anodic bonding for wafer-level Al-Al interconnection in MEMS grating gyroscope. Ieee Trans. Compon. Packaging Manuf. Technol. 11, 19–24, https://doi.org/10.1109/tcpmt.2020.3044751 (2021).

Choi, S. W. et al. The analysis of oxygen plasma pretreatment for improving anodic bonding. J. Electrochem. Soc. 149, G8–G11, https://doi.org/10.1149/1.1419187 (2002).

Yao, F. R., Pan, M. Q., Zhu, Z. J., Liu, J. Z. & Wang, Y. J. Ultra-low temperature anodic bonding of silicon and glass based on nano-gap dielectric barrier discharge. J. Cent. South Univ. 28, 351–360, https://doi.org/10.1007/s11771-021-4607-z (2021).

Karlen, S., Haesler, J., Overstolz, T., Bergonzi, G. & Lecomte, S. Sealing of MEMS atomic vapor cells using Cu-Cu thermocompression bonding. J. Microelectromechanical Syst. 29, 95–99, https://doi.org/10.1109/jmems.2019.2949349 (2020).

Samuneva, B., Djambaski, P. & Avramova, K. Interaction between glasses and alkali-metal vapors. J. Non-Crystalline Solids 112, 385–391, https://doi.org/10.1016/0022-3093(89)90559-0 (1989).

Brinker, C. J. & Klein, L. C. Behavior of silicate and borosilicate glassed in contact with metallic sodium. Phys. Chem. Glasses 22, 22–28 (1981).

Dural, N. & Romalis, M. V. Gallium phosphide as a new material for anodically bonded atomic sensors. Apll. Mater. 2, 086101, https://doi.org/10.1063/1.4891375 (2014).

Zhang, G. D., Bai, J., Zhao, W., Zhou, K. M. & Cheng, G. H. Interface modification based ultrashort laser microwelding between SiC and fused silica. Opt. Express 25, 1702–1709, https://doi.org/10.1364/oe.25.001702 (2017).

Zhang, J. J. et al. Microwelding of glass to silicon by green ultrafast laser pulses. Opt. Laser Technol. 120, 105720, https://doi.org/10.1016/j.optlastec.2019.105720 (2019).

Nordin, I. H. W., Okamoto, Y., Okada, A., Jiang, H. & Sakagawa, T. Effect of wavelength and pulse duration on laser micro-welding of monocrystalline silicon and glass. Appl. Phys. a-Mater. Sci. Process. 122, 400, https://doi.org/10.1007/s00339-016-9849-5 (2016).

Miyamoto, I. et al. High speed, high strength microwelding of Si/glass using ps-laser pulses. Opt. Express 23, 3427–3439, https://doi.org/10.1364/oe.23.003427 (2015).

Okamoto, Y., Miyamoto, I., Vihinen, J. & Okada, A. Novel micro-welding of silicon and glass by ultrashort pulsed laser. Mater. Sci. Forum (Switz.) 783-786, 2792–2797, https://doi.org/10.4028/www.scientific.net/MSF.783-786.2792. (2014).

Wei, C. R., Ito, Y., Shinomoto, R., Nagato, K. & Sugita, N. Simulation of ultrashort pulse laser drilling of glass considering heat accumulation. Opt. Express 28, 15240–15249, https://doi.org/10.1364/oe.390289 (2020).

Jia, X. & Zhao, X. Numerical study of material decomposition in ultrafast laser interaction with metals. Appl. Surf. Sci. 463, 781–790, https://doi.org/10.1016/j.apsusc.2018.08.225 (2019).

Pan, P., Ji, P., Lin, G., Dong, X. & Zhao, J. Theoretical and experimental research of femtosecond laser processing fused silica. Acta Phys. Sin. 71, 247901 (2022).

Stuart, B. C., Feit, M. D., Rubenchik, A. M., Shore, B. W. & Perry, M. D. Laser-induced damage in dielectrics with nanosecond to subpicosecond pulses. Phys. Rev. Lett. 74, 2248–2251, https://doi.org/10.1103/PhysRevLett.74.2248 (1995).

Azzouz, I. M. Investigation of photoionization processes in ultrashort laser induced damage in optical materials. J. Phys. B-At. Mol. Optical Phys. 37, 3259–3264, https://doi.org/10.1088/0953-4075/37/16/003 (2004).

Jiang, L. & Tsai, H. L. A plasma model combined with an improved two-temperature equation for ultrafast laser ablation of dielectrics. J. Appl. Phys. 104, 093101, https://doi.org/10.1063/1.3006129 (2008).

Sahoo, P. K., Feng, T. & Qiao, J. Dynamic pulse propagation modelling for predictive femtosecond-laser-microbonding of transparent materials. Opt. Express 28, 31103–31118, https://doi.org/10.1364/oe.402493 (2020).

Li, C. D., Vatsya, S. R. & Nikumb, S. K. Effect of plasma on ultrashort pulse laser material processing. J. Laser Appl. 19, 26–31, https://doi.org/10.2351/1.2402521 (2007).

Zhan, J. et al. Mechanism and optimization of femtosecond laser welding fused silica and aluminum. Appl. Surf. Sci. 640, 158327, https://doi.org/10.1016/j.apsusc.2023.158327 (2023).

Miyamoto, I., Cvecek, K. & Schmidt, M. Advances of laser welding technology of glass -science and technology. J. Laser Micro Nanoeng. 15, 63–76, https://doi.org/10.2961/jlmn.2020.02.1001 (2020).

Yu, M. Z. et al. Plasma-activated high-strength non-isothermal anodic bonding for efficient fabrication of the micro atomic vapor cells. J. Mater. Res. Technol.-JmrT 27, 1046–1057, https://doi.org/10.1016/j.jmrt.2023.10.029 (2023).

Seltzer, S. J. Developments in alkali -metal atomic magnetometry PhD thesis, Princeton University, https://www.proquest.com/docview/275671021?pq-origsite=wos&accountid=16294&sourcetype=Dissertations &Theses (2008).

Dellis, A. T., Shah, V., Donley, E. A., Knappe, S. & Kitching, J. Low helium permeation cells for atomic microsystems technology. Opt. Lett. 41, 2775–2778, https://doi.org/10.1364/ol.41.002775 (2016).

Liu, Z. et al. Lifetime estimation model of vapor cells in atomic magnetometers. J. Phys. D.-Appl. Phys. 55, 285003, https://doi.org/10.1088/1361-6463/ac677b (2022).

Li, S. G., Dai, P. F., Liu, J. S., Xu, Z. K. & Chida, K. Spin relaxation of rubidium atoms in an octadecyltrichlorosilane anti-relaxation and anti-reflection coated vacuum multipass cell. Optical Mater. Express 12, 4384–4398, https://doi.org/10.1364/ome.462911 (2022).

Pustelny, S., Kimball, D. F. J., Rochester, S. M., Yashchuk, V. V. & Budker, D. Influence of magnetic-field inhomogeneity on nonlinear magneto-optical resonances. Phys. Rev. A 74, 063406, https://doi.org/10.1103/PhysRevA.74.063406 (2006).

Chi, H. T. et al. A comprehensive study of the effects of different factors on anti-relaxation properties of octadecyltrichlorosilane-coated rubidium vapor cells. J. Phys. D.-Appl. Phys. 55, 055001, https://doi.org/10.1088/1361-6463/ac2f13 (2022).

Straessle, R. et al. Microfabricated alkali vapor cell with anti-relaxation wall coating. Appl. Phys. Lett. 105, 043502, https://doi.org/10.1063/1.4891248 (2014).

Zhang, L., Zhang, W. D., Zhang, S. G. & Yan, S. B. Micro-fabrication and hermeticity measurement of alkali-atom vapor cells based on anodic bonding. Chin. Opt. Lett. 17, 100201, https://doi.org/10.3788/col201917.100201 (2019).

Yu, M. Z. et al. Plasma-activated silicon-glass high-strength multistep bonding for low-temperature vacuum packaging. Chem. Eng. J. 471, 144719, https://doi.org/10.1016/j.cej.2023.144719 (2023).

Wang, Y. Q. et al. Micro-fabricated alkali vapor cells sealed at low temperature using asymmetric Au-In transient liquid phase (TLP) bonding. Jpn. J. Appl. Phys. 58, SDDL03, https://doi.org/10.7567/1347-4065/ab0ac9 (2019).

Acknowledgements

This work was supported in part by the National Key Research & Development (R&D) Plan (2024YFB3212500), the National Natural Science Foundation of China (62473305), the Chongqing Natural Science Basic Research Project (cstc2021jcyj-msxmX0801), the National Natural Science Youth Foundation of China (52305615) and the National Natural Science Youth Foundation of China (52305618).

Author information

Authors and Affiliations

Contributions

Yanbin Wang: Conceptualization, Methodology, Validation, Formal Analysis, Investigation, Writing-Original Draft; Mingzhi Yu, Yao Chen, Libo Zhao: Validation, Investigation, Resources, Data Curation, Writing-Review & Editing; Yintao Ma, Xiangguang Han, Yong Xia, Ju Guo: Data Curation, Resources, Writing-Review & Editing, Supervision; Ping Yang, Qijing Lin, Shujiang Ding: Project Administration, Supervision, Funding Acquisition.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, Y., Yu, M., Chen, Y. et al. The fabrication of MEMS alkali metal vapor cells based on ultrafast laser welding for single beam magnetometer. Microsyst Nanoeng 11, 153 (2025). https://doi.org/10.1038/s41378-025-00976-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41378-025-00976-6