Abstract

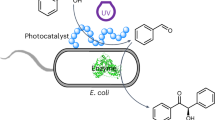

Enzyme condensates are powerful tools for controlling enzymatic reactions in living cells. Recent advances in polymer science have enabled the design of artificial enzyme condensates in vitro, providing a promising approach to enhance enzymatic activity and stability for various biotechnological applications. In this review, we describe a systematic approach to engineering enzyme condensates through polymer-based strategies. First, we consider the design principles for tailoring the state of the enzyme condensates using charged polymers, including approaches that utilize enzymes as scaffolds or clients, and compare these condensates with other enzyme activation methods, highlighting the advantages and potential limitations of enzyme condensates. Second, we review the major factors that affect enzyme performance within the condensates, including size-dependent effects and local environmental changes. These data are supported by recent mechanistic studies using various enzyme systems, including oxidoreductases. Finally, we focus on possible applications and outline the key challenges in expanding the utility of enzyme condensates from single-enzyme to multienzyme systems and from solution-based to surface-bound architectures. Our comprehensive overview of enzyme condensate engineering provides a new perspective to bridge cellular organization principles and innovations in enzyme catalysis.

Similar content being viewed by others

Introduction

Enzymes are highly valued in a wide range of biotechnology applications because of their ability to catalyze reactions under mild conditions and inherent biocompatibility [1]. However, challenges such as their intrinsically low stability and loss of activity often hinder their practical application. Therefore, various techniques have been developed to increase enzyme stability and activity, including rational engineering [2] and directed evolution [3]. While these approaches focus primarily on modifying enzyme molecules for adaptation to extracellular environments, exploring and mimicking the mechanisms that enable efficient enzymatic function within the cellular environment is a promising and innovative alternative strategy.

Metabolic enzymes often organize into dynamic condensates within cells [4]. Enzyme condensates have been observed across various biological species and metabolic pathways, suggesting their role as a common mechanism for spatiotemporal enzymatic reaction control [5]. Previous seminal studies, particularly those on glycolysis [6, 7] and the de novo purine biosynthetic pathway [8, 9], have revealed that multiple metabolic enzymes can assemble into condensates in response to external stimuli. The dynamic nature of the enzyme condensates suggests that they act as transient reaction hubs, assembling the required enzymes to activate specific metabolic pathways. This function of enzyme condensates in metabolic activity raises the possibility that they may provide a novel method to control enzyme activation. The development of design principles for condensates that activate target enzymes, even in vitro, could unlock the potential of enzymes and greatly benefit various enzyme-based industries [10].

Enzyme condensates in living cells are unstable entities that temporarily form in response to external stress, yet the complex mechanisms underlying their formation remain poorly understood. Thus, our previous work to date has focused on mimicking enzyme condensates using polymers in vitro. We can effectively mimic enzyme condensates and investigate their effects on enzyme activity via the use of multivalent charged polymers that interact with enzymes or coenzymes. Although these condensates, called complex coacervates or polyion complexes, have been studied in the field of polymer science over the last century, they have received more attention recently because of the emergence of liquid-like intracellular enzyme condensates [11, 12]. Although the methods for mimicking enzyme condensation have been relatively well studied, the functional changes in enzymes within the condensates and the factors driving these changes are still being elucidated. In this review, we explore how enzyme condensates can be reconstructed and fine-tuned to increase enzyme activity, identify emerging factors that potentially influence enzyme functionality, and outline future fundamental studies aimed at practical applications. This analysis is primarily based on our research and significant contributions from other research groups.

Design strategies for enzyme condensates

Enzyme‒polymer condensates: enzymes as scaffolds

A simple method to form enzyme condensates is to use charged polymers that can interact with the enzyme [13]. In this case, the enzyme is a component of the condensate and serves as a scaffold for condensate formation (Fig. 1). On the basis of the target enzyme’s predicted isoelectric point (pI), a complementary charged polymer is selected, and the reaction solvent conditions, including the mixing ratio of the enzyme and the polymer or pH, are explored (Fig. 1a). For example, L-lactate oxidase (LOX) from Enterococcus faecium, which has a pI of approximately 6, forms condensates that lead to its activation in the presence of poly-L-lysine (PLL), a polycationic polymer with a pI of approximately 10 (Fig. 1b) [14]. An optimal mixing ratio of LOX and PLL has been determined, and if the amount of either component is too high, the rate of condensate formation decreases (Fig. 1c). Additionally, a solution pH between the pI values of the components leads to the formation of droplet-like condensates; however, if the pH is biased toward one component, the interaction between the enzyme and the polymer may be too strong, resulting in aggregation, or too weak, making condensate formation difficult (Fig. 1d). Similar condensation formation and enzyme activation have been observed with PLL and four other types of oxidoreductases with different pI values [15]. Upon comparison of condensate formation with each enzyme at pH 7, the ease of condensate formation did not correlate with the predicted pI. Thus, it may be necessary to consider the enzyme’s overall charge and the local surface charge distribution upon its interaction with charged polymers [16]. Thus, enhancing enzyme condensate formation requires carefully selected and designed polymers tailored to the surface characteristics of the enzyme.

Enzymes as scaffolds for condensates. a Formation of enzyme‒polymer condensates. b Localization of enzymes and polymers within the condensates. The left image is a bright-field microscopy image, whereas the middle and right images are fluorescence microscopy images showing the localization of LOX (via the intrinsic fluorescence of flavin mononucleotide) and PLL (labeled with rhodamine B isothiocyanate). Scale bar: 10 µm. c Dependence of enzyme condensate formation on the enzyme‒polymer mixture ratio. The LOX concentration was fixed at 5 µM. Scale bar: 20 µm. d pH dependence of enzyme condensates. All the samples contained 5 µM LOX and 1 mM PLL. Scale bar: 20 µm. b–d are adapted with modifications from [14], published by the Springer Journal

Substrate/coenzyme‒polymer condensates: enzymes as clients

Another approach is to incorporate enzymes as clients into condensates comprising other scaffold molecules. This approach is effective when condensates do not form by simply mixing the enzymes with polymers. In particular, we have investigated the incorporation of enzymes as clients into condensates formed with nucleotides and polycations (Fig. 2). Nucleotide and polycation scaffold systems have been studied as models for condensates formed from simple components [17] (Fig. 2a). For example, adenosine triphosphate (ATP), an energy currency in many enzyme reactions, easily forms condensates with cationic polymers [17, 18] and basic proteins [19] through multivalent interactions between its linked phosphate groups and nucleic acid base moieties. However, there have been no reports to date about ATP forming condensates in cells. Elucidating the condensate-forming ability of molecules such as ATP, which are widely involved in enzyme reactions, will help design enzyme condensates in vitro. On the basis of the similarity of its structural features to those of ATP, we discovered the high condensate-forming ability of NADPH, which acts as an electron acceptor and donor in redox reactions (Fig. 2b, c) [20]. Additionally, we and other research groups have reported that nucleotide/polycation condensates improve reaction efficiency by incorporating nucleotide-utilizing enzymes. For example, ATP–PLL condensates facilitate the incorporation of hexokinase (glucose + ATP → glucose 6-phosphate + ADP) [17, 20], and NADPH/PLL condensates promote the incorporation of glucose-6-phosphate dehydrogenase (glucose-6-phosphate + NADP → glucono-1,5-lactone-6-phosphate + NADPH) (Fig. 2d, e) [20, 21]. Notably, nucleotides such as ATP and NADPH tend to form condensates with polyelectrolytes, and ATP tends to form condensates more easily than does ADP, which is reminiscent of living cells [20, 21]. These results suggest that enzymes are more easily incorporated into condensates that form with molecules that have a high affinity for them.

a Enzyme incorporation into nucleotide‒polymer condensates. b, c ATP and NADPH easily form droplets with PLL. Scale bar: 10 µm. d, e Coupling of nucleotide‒polymer condensates to incorporated enzyme reactions. d Assembly of hexokinase, which uses ATP as a substrate, into ATP‒PLL condensates. e Assembly of glucose-6-phosphate dehydrogenase, which produces NADPH as a product, into NADPH condensates. b–e are adapted with modifications from [20], published by The Royal Society of Chemistry

Polycation–polyanion condensates: enzymes as clients

With respect to complementary charged polymer‒polymer systems, folded proteins, including enzymes, have been widely studied for their incorporation into preformed condensates [22, 23] (Fig. 3a). We explored the conditions for incorporating enzymes of different charge states into formed condensates of poly(diallyldimethylammonium chloride) (PDDA) and carboxymethyl dextran (CMDX) systems [24]. We first revealed that the surface charge of the condensates depends on the mixing ratio of PDDA to CMDX; specifically, when there is more PDDA, the condensates have a positive surface charge, and vice versa (Fig. 3b). We then investigated the incorporation of three folded proteins with various charge states into these condensates with different zeta potentials, and we found that positively charged proteins were more likely to be incorporated into negatively charged condensates, and vice versa (Fig. 3c, d). The observation that enzymes are homogeneously distributed within the condensates rather than remaining on their surface suggests that the condensates maintain a fluid-like nature, allowing internal rearrangement of their molecular components, including the incorporated enzymes. This finding indicates that electrostatic complementarity between enzymes and condensates facilitates their incorporation and contributes to the stabilization of the enzyme within the condensate.

a Incorporation of enzymes into polycation–polyanion complex condensates. b The zeta potentials of PDDA–CMDX condensates depend on the mixture ratio of PDDA (polycation) and CMDX (polyanion). c Incorporation of three types of folded proteins with different charge states (lysozyme, pyruvate oxidase, and ovalbumin) into PDDA–CMDX condensates with different charge states. d Localization of pyruvate oxidase, an acidic enzyme, in PDDA–CMDX condensates. Green indicates the intrinsic fluorescence of pyruvate oxidase–flavin mononucleotide. Scale bar: 10 µm. b–d are adapted with modifications from [24], published by The Royal Society of Chemistry

Rational selection of polymer-based condensate formation strategies

The three main strategies described above (enzyme–polymer, substrate/coenzyme–polymer, and polycation–polyanion) are each suitable for different conditions and purposes (Scheme 1). When an enzyme displays a pronounced surface charge bias, such as an extreme isoelectric point (pI) or biased charge distribution, forming enzyme‒polymer condensates is the most straightforward approach. The surface charge of enzymes can be calculated and visualized using the Adaptive Poisson-Boltzmann Solver (APBS) plugin in PyMOL on the basis of experimentally or computationally determined structural information [25]. If the enzyme itself lacks notable charge characteristics, the charge properties of its substrates or coenzymes should be considered. When the reaction involves charged substrates or coenzymes with linked phosphate groups, such as ATP or NADPH, the formation of substrate/coenzyme‒polymer condensates may be an effective strategy. Enzymes that utilize RNA or DNA as substrates may also be suitable candidates for this approach. However, if the enzyme‒polymer or substrate/coenzyme‒polymer combinations fail to form condensates or undesirably aggregate (particularly for enzymes with low stability that may irreversibly aggregate upon their interaction with polymers), forming polycation‒polyanion complex condensates serves as an alternative approach.

Although these studies focused on different properties that allow enzymes to be incorporated into condensates, integrating their findings may allow enzyme incorporation to be fine-tuned and controlled. For example, changing the ratio of the nucleotide and polymer in the system could optimize enzyme incorporation. Similarly, adjusting the ratio of the polycation and polyanion in complex condensates can create optimal electrostatic environments for specific enzymes. This design flexibility across different condensate formation strategies is promising for achieving enzyme activation and stabilization.

Rather than simply incorporating enzymes into condensates, the focus should be on enhancing their functionality, such as activation and stabilization. A previous study on antibodies provided a relevant example, as it showed that the thermal stability of a charged polymer/antibody condensate improved under conditions slightly different from those that maximize condensate formation [26]. This improvement was attributed to repulsive forces between condensates, which likely reduced excessive aggregation and improved molecular dispersion. Similarly, in the case of enzymes, once the conditions for condensate formation are identified, examining the function of the enzyme under similar conditions will provide insights into the condensate properties required for enhancing enzyme performance.

Mechanisms of enzyme activation in condensates

The mechanism by which enzyme reaction efficiency is controlled in enzyme condensates has been conceptualized in several excellent reviews [27,28,29], but many of these mechanisms remain to be experimentally demonstrated. In brief, the local assembly of molecules necessary for the enzymatic reaction (i.e., the substrate and enzyme) in the condensate simply increases the frequency of collisions between the substrate and the enzyme [30, 31]. Additionally, scaffold proteins promote interactions between the enzyme and the substrate [32]. In addition to these factors, other crucial factors involved in enzyme activation were discovered in our research and related studies.

The size of the enzyme condensate could be critical for enzyme activation (Fig. 4). The size of a condensate in vitro could differ from that of an intracellular condensate, which is approximately hundreds of nanometers. In fact, enzyme condensates are often reconstructed in vitro to a size of a few to tens of micrometers, which is close to the size of a whole cell [33]. Using LOX, an enzyme whose activity significantly changed upon condensate formation, we examined how the size of the enzyme condensate influences enzyme activity (Fig. 4a). This focus stems from evidence suggesting that condensate size is crucial for substrate influx into the condensate. Our results revealed that the size of the LOX condensates could be modulated by the addition of small amounts of salts as cosolutes to the LOX–PLL system. Specifically, the addition of ammonium sulfate increased the size of the condensates from the submicron scale to several microns (Fig. 4b, c). These findings emphasize the importance of cosolute selection in controlling the size and physical properties of enzyme condensates. We also investigated how changing condensate size by modifying the ammonium sulfate concentration affected enzyme activity and found that, compared with micron-sized enzyme condensates, submicron-sized enzyme condensates exhibited greater activation (Fig. 4d). These data suggest that metabolic pathways in living cells may be modulated by the size of the enzyme condensates [34]. The size-dependent enzyme activity of the condensates is not limited to LOX; a similar tendency was confirmed for NADH oxidase (NOX) from Thermus thermophilus [35]. The increased surface area-to-volume ratio of the condensate benefits the enzymatic reaction. Enzyme-active condensates formed within a cell are on the submicron level in terms of size; however, maintaining this size is challenging because condensates frequently fuse and mature.

a Schematic of how salt modulates condensate size and enzymatic activity. b Bright-field microscopy images showing the change in the size of LOX–PLL condensates upon the addition of 10 mM ammonium sulfate. Scale bar: 20 µm. c Dynamic light scattering analysis of the salt-induced changes in the size of LOX–PLL condensates. d Enzyme activity of LOX in the presence of ammonium sulfate and PLL. Relative enzyme activity was defined as the initial reaction rate under each condition divided by the reaction rate in the absence of PLL and ammonium sulfate. All figures are adapted with modifications from [14], published by the Springer Journal

Conformational changes in enzymes may lead to enzymatic activation due to the distinct solvent environment inside the condensates, which differs significantly from that of the bulk solution (Fig. 5a) [36]. For example, the dielectric constant of a condensate is comparable to that of organic solvents [37], and changes in this constant can influence the conformation of an enzyme, potentially altering its activity [38]. Additionally, the high concentration of macromolecules within condensates compared with that in the bulk solution [39] can affect the protein structure through molecular crowding effects [40]. Studies on intrinsically disordered proteins have revealed that conformational changes in enzymes occur within condensates [41]. Thus, how does this distinct solvent environment affect the conformation of enzymes that are globally folded but exhibit local flexibility? We investigated the changes in secondary structure of oxidoreductases during condensate formation using circular dichroism spectroscopy and found evidence suggesting that local structural alterations occur although the overall secondary structure is preserved (Fig. 5b) [15]. Studies on enzyme-activated condensates with horseradish peroxidase and glucose oxidase have reported similar trends in CD spectra [42]. The surface of the condensate may also be a crucial factor for protein structural changes [43]. Moreover, the fact that the condensate is submicron-sized rather than micron-sized suggests that the surface environment of the condensate affects the structural changes of the enzyme. Importantly, interactions with other polymers within the condensate may also affect the enzyme conformation. For example, the activity of some enzymes is affected by the concentration of factors that induce conformational changes inside the condensate [44], and some enzymes exhibit increased activity upon interaction with specific polymers [45, 46]. The macromolecular composition of the condensate, in addition to its solution environment, may drive the conformational change of the enzyme.

a Factors influencing the enzyme structure within the condensate. b Secondary structure of LOX in the enzyme condensate analyzed using far-UV circular dichroism (CD) spectroscopy. CD spectra of LOX (solid line), poly-(D,L)-lysine (PDLL) (dotted line), and the LOX-PDLL condensate (dashed line) are shown. All figures are adapted with modifications from [14], published in the Springer Journal

Comparison with other enzyme activation methods

Table 1 summarizes the differences in enzyme activation and stabilization between the condensate system and other methods. Condensate systems can be roughly divided into two types: those based on the addition of a charged polymer [10, 47, 48], as in our example, and those based on the fusion of a peptide tag that promotes condensate formation, such as low-complexity disordered domains or coiled‒coil domains [10, 49]. The advantage of the latter approach is that it enables phase separation by fusing these domains to the enzyme of interest. However, this approach requires recombinant expression of the enzyme, which may reduce the expression levels and activity.

Enzyme engineering is one of the most powerful methods for enzyme activation. Rational design involves introducing mutations on the basis of structural information to improve enzyme performance and is typically applied to enzymes whose structure and mechanism of activity are well understood [2]. In contrast, directed evolution mimics natural selection by introducing random mutations followed by functional screening, enabling the identification of variants with enhanced activity. Successful examples of iterative random mutation and functional screening have demonstrated remarkable activation, with increases on the order of several tens to hundreds of times [3, 50]. The advantage of enzyme engineering is that it provides valuable structural insights into the mechanisms behind enzyme activation. However, this method requires a high-throughput enzyme expression and functional screening system, which may present technical challenges.

Enzyme immobilization is an essential method for practical enzyme applications [51]. Enzymes often exhibit reduced structural stability upon dispersion in solution; however, immobilizing them on a surface helps maintain their stability and prolong their activity. Common immobilization methods include covalent bonding, physical adsorption, and entrapment [51, 52]. The advantage of immobilization is that it enables the easy reuse and recovery of enzymes, enhancing the practicality of using the enzyme for industrial applications. However, the immobilization process may sometimes restrict enzyme mobility or limit substrate diffusion, potentially affecting the reaction efficiency.

Micellar systems are similar to condensates in that they sequester enzymes from the bulk phase. Certain micelle systems use hydrophilic and hydrophobic segments to compartmentalize enzymes and maintain enzyme function even in oil-based systems [53]. Polyion complex micelles, which resemble polymer‒polymer condensates, employ poly(ethylene glycol)-fused charged regions to improve resistance to nonspecific adsorption and degradation [54, 55]. The advantage of micellar systems is their clearly defined compartmentalization, which enhances enzyme stability. However, this stability gain may come at the cost of limited substrate influx, making condensates superior in this regard.

Compared with these systems, charged polymer-based condensate systems are distinguished by their simplicity, as they can be formed simply by adding a charged polymer. One major concern regarding condensates is that their metastable nature may lead to stability issues. Consequently, the feasibility of their use in practical environments remains uncertain; for example, it is essential to investigate whether condensates can form and remain stable under the shear stress caused by stirring or mixing processes. To use this technology in practical applications, it will be necessary to address these concerns through further research and to stabilize the enzyme’s activated state.

Future directions and challenges

Although enzyme condensates display great potential for enhancing enzyme activity, their application is currently limited to a few enzymes and in vitro condensate systems. Several essential research directions must be pursued to fully realize their potential in practical applications and improve our fundamental understanding of condensate-based enzyme control. For example, immobilizing artificial enzyme condensates (i.e., through interactions with solid surfaces) could be of interest (Fig. 6a). The interaction of enzyme condensates with the membranes of intracellular organelles is a commonly observed phenomenon in living cells [56], and understanding these interactions is also key to integrating enzyme condensates into functional devices, such as electrodes and biosensor platforms. Biofuel cells and biosensors, which are the most prominent applications of the activated oxidoreductases in our studies, require the immobilization of enzymes on solid surfaces [57, 58]. Exploring whether enzymes can be stably fused to solid surfaces and whether they can maintain high activity even after drying and rehydration is essential. Modifying the solid surface and tuning the surface charge of the condensate may also contribute to efficient condensate adsorption and stabilization [59].

Designing optimized condensate-forming polymers for specific target enzymes represents another crucial research direction (Fig. 6b). Tuning the charge properties of a polymer is one promising approach to this aim, and recent studies have shown that polymers that combine charged and neutral groups can efficiently incorporate folded proteins to form artificial condensates [60]. Additionally, by varying the polymer length, even at the same molar ratio on a monomer basis, multivalent interactions can facilitate stronger and more effective interactions with folded proteins [61]. Designing block copolymers, which are composed of two or more distinct polymer blocks with different properties, could be a powerful approach for controlling the properties of enzyme condensates [61]. For example, by loading uncharged water-soluble groups (e.g., polyethylene glycol) onto a charged polymer, it may be possible to prevent condensate fusion by a micelle-like structure [62], enabling the stabilization of submicron-sized condensates with high enzymatic activity. Furthermore, by incorporating segments responsive to stimuli (e.g., temperature or pH), the assembly and disassembly of condensates may be controlled [63]. A more specialized approach involves developing synthetic polymers targeted at interacting with the surface residues of target enzymes. Recent studies using synthetic polymers designed to complement enzyme surface patches have demonstrated enhanced enzyme‒polymer complex formation and subsequent functionalization, including improved enzyme stability and activity in nonbiological environments [64, 65]. Combining these strategies can create smart enzyme condensates that respond to environmental cues while maintaining optimal enzyme activity.

Enzyme condensates designed to perform multistep reactions such as those found in cells, rather than the single reactions described above, are currently difficult to construct (Fig. 6c). It is possible that reproducing the multistep enzyme reactions in test tubes requires a method that is completely different from the mechanism in living cells. The efficient design of in vitro enzyme condensates that can perform multistep enzyme reactions is expected to have various applications, including in biofuel cells that mimic enzyme-based redox reactions [66], the synthesis of complex molecules that are challenging to produce chemically [67], and the construction of synthetic biological systems for advanced functionalities [68]. Several studies have investigated two-step enzymatic reactions using enzymes fused to the condensation domains of intrinsically disordered proteins, which are the main drivers of condensation in cells [32, 69], and additional condensate-forming domains are being discovered and engineered. However, as more enzymes are used, fusing the condensate-forming domains to all the enzymes, expressing them, and purifying them takes more effort. Thus, would it be possible to exploit polymers to more easily construct enzyme condensates that activate multistep enzymatic reactions? For example, if ATP or NADPH, which easily form condensates with polymers, are used in multistep enzymatic reactions, the necessary enzymes may be incorporated and activated in a stepwise manner as the enzymatic reaction progresses [20, 70]. Additionally, recent research into intracellular enzyme condensates has revealed that, rather than multiple types of enzymes gathering at once, enzymes form condensates in stages and one enzyme serves as the condensate core [9, 71]. On the basis of these findings, it may be valuable to consider promoting condensate formation or gathering other enzymes by selecting a polymer to be added while focusing on a specific enzyme in a multistep reaction.

Finally, what can be done to further enhance enzyme activation by condensate formation? One concept is to combine condensate formation with other activation methods to create a synergistic effect (Fig. 6d). For example, one of the most powerful strategies to improve enzyme performance is to introduce mutations at or around the active site, based on the crystal structure of the enzyme. By introducing mutations, polymer-induced enzyme activation can be enhanced by strengthening the attractive interaction between the polymer and the enzyme [16]. Additionally, mutations that increase the surface charge of folded proteins can promote the formation of condensates with charged polymers [71], and this approach is expected to be applied to enzymes. Thus, finding mutations that further increase condensate formation or promote the evolution of enzymes toward condensate formation may be an effective approach. Recently, combining these strategies with de novo enzyme design has also been proposed [72]. Engineering that focuses on the molecular structure of the target enzyme and on the state of the condensate (i.e., how the enzyme works in cooperation with other polymers) may be the best way to utilize enzymes.

Conclusion

We summarized the available data on enzyme activation by enzyme condensates, the recent progress in this area, and future directions. Although intracellular enzyme condensates temporarily form through a complex mechanism, artificial enzyme condensates that derive the benefits of enzyme activation can be constructed in vitro by adding charged polymers that interact with enzymes in a multivalent manner. This approach, although simple, has been efficient in activating multiple enzymes and two-step sequential reactions. Furthermore, our findings suggest that certain factors, including the size of the condensate and the structural changes in the enzyme induced by the unique solution environment in the condensate, improve enzymatic activity. A deeper understanding of these mechanisms may provide valuable guidelines for designing enzyme condensates. Furthermore, we outlined the basic research directions and challenges for applying enzyme condensates, such as their synergistic integration with functional polymers and enzyme engineering. We hope that this review inspires researchers in related fields and contributes to the progress of enzyme condensate research.

References

van Beilen JB, Li Z. Enzyme technology: an overview. Curr Opin Biotechnol. 2002;13:338–44.

Eijsink VGH, Bjørk A, Gåseidnes S, Sirevåg R, Synstad B, van den Burg B, et al. Rational engineering of enzyme stability. J Biotechnol. 2004;113:105–20.

Eijsink VGH, Gåseidnes S, Borchert TV, van den Burg B. Directed evolution of enzyme stability. Biomol Eng. 2005;22:21–30.

H Stamatis, Multienzymatic assemblies: Methods and protocols, 1st ed., Springer, New York, NY, 2022.

Schmitt DL, An S. Spatial organization of metabolic enzyme complexes in cells. Biochemistry. 2017;56:3184–96.

Miura N, Shinohara M, Tatsukami Y, Sato Y, Morisaka H, Kuroda K, et al. Spatial reorganization of Saccharomyces cerevisiae enolase to alter carbon metabolism under hypoxia. Eukaryot Cell. 2013;12:1106–19.

Jin M, Fuller GG, Han T, Yao Y, Alessi AF, Freeberg MA, et al. Glycolytic enzymes coalesce in G bodies under hypoxic stress. Cell Rep. 2017;20:895–908.

An S, Kumar R, Sheets ED, Benkovic SJ. Reversible compartmentalization of de novo purine biosynthetic complexes in living cells. Science. 2008;320:103–6.

Pedley AM, Benkovic SJ. A new view into the regulation of purine metabolism: the purinosome. Trends Biochem Sci. 2017;42:141–54.

Lim S, Clark DS. Phase-separated biomolecular condensates for biocatalysis. Trends Biotechnol. 2024;42:496–509.

Yewdall NA, André AAM, Lu T, Spruijt E. Coacervates as models of membraneless organelles. Curr Opin Colloid Interface Sci. 2021;52:101416.

Nakashima KK, André AAM, Spruijt E. Enzymatic control over coacervation. Methods Enzymol. 2021;646:353–89.

Horn JM, Kapelner RA, Obermeyer AC. Macro- and microphase separated protein-polyelectrolyte complexes: Design parameters and current progress. Polymers. 2019;11:578.

Ura T, Kagawa A, Sakakibara N, Yagi H, Tochio N, Kigawa T, et al. T. Mikawa, Activation of L-lactate oxidase by the formation of enzyme assemblies through liquid–liquid phase separation. Sci Rep. 2023;13:1–9.

Ura T, Sakakibara N, Hirano Y, Tamada T, Takakusagi Y, Shiraki K. T. Mikawa, Activation of oxidoreductases by the formation of enzyme assembly. Sci Rep. 2023;13:1–8.

Cummings CS, Obermeyer AC. Phase separation behavior of supercharged proteins and polyelectrolytes. Biochemistry. 2018;57:314–23.

Koga S, Williams DS, Perriman AW, Mann S. Peptide-nucleotide microdroplets as a step towards a membrane-free protocell model. Nat Chem. 2011;3:720–4.

Baksi A, Zerze H, Agrawal A, Karim A, Zerze GH. The molecular picture of the local environment in a stable model coacervate. Commun Chem. 2024;7:222.

Kota D, Prasad R, Zhou H-X. Adenosine triphosphate mediates phase separation of disordered basic proteins by bridging intermolecular interaction networks. J Am Chem Soc. 2024;146:1326–36.

Ura T, Tomita S, Shiraki K. Dynamic behavior of liquid droplets with enzyme compartmentalization triggered by sequential glycolytic enzyme reactions. Chem Commun. 2021;57:12544–7.

Jaworek MW, Oliva R, Winter R. Enabling high activation of glucose-6-phosphate dehydrogenase activity through liquid condensate formation and compression, Chem. Eur. J. 2024;30:e202400690.

Blocher McTigue WC, Perry SL. Chapter Ten - Incorporation of proteins into complex coacervates, in: CD Keating (Ed.), Methods in Enzymology, Academic Press, 2021: pp. 277–306.

Blocher McTigue WC, Perry SL. Protein encapsulation using complex coacervates: What nature has to teach us. Small. 2020;16:e1907671.

Sakakibara N, Ura T, Mikawa T, Sugai H, Shiraki K. Transient formation of multi-phase droplets caused by the addition of a folded protein into complex coacervates with an oppositely charged surface relative to the protein. Soft Matter. 2023;19:4642–50.

Jurrus E, Engel D, Star K, Monson K, Brandi J, Felberg LE, et al. Improvements to the APBS biomolecular solvation software suite. Protein Sci. 2018;27:112–28.

Nomoto A, Shiraki K. Thermal aggregation of immunoglobulin G depending on the charge state of protein-polyelectrolyte complexes. Int J Biol Macromol. 2025;296:139500.

O’Flynn BG, Mittag T. The role of liquid-liquid phase separation in regulating enzyme activity. Curr Opin Cell Biol. 2021;69:70–79.

Dindo M, Bevilacqua A, Laurino P. Enzymes and liquid-liquid phase separation: a new era for the regulation of enzymatic activity. Seibutsu Butsuri Kagaku. 2023;63:12–15.

Zhang Y, Narlikar GJ, Kutateladze TG. Enzymatic Reactions inside Biological Condensates. J Mol Biol. 2021;433:166624.

Freeman Rosenzweig ES, Xu B, Kuhn Cuellar L, Martinez-Sanchez A, Schaffer M, Strauss M, et al. The Eukaryotic CO2-concentrating organelle is liquid-like and exhibits dynamic reorganization. Cell. 2017;171:148–.e19.

Du M, Chen ZJ. DNA-induced liquid phase condensation of cGAS activates innate immune signaling. Science. 2018;361:704–9.

Peeples W, Rosen MK. Mechanistic dissection of increased enzymatic rate in a phase-separated compartment. Nat Chem Biol. 2021;17:693–702.

Forman-Kay JD, Ditlev JA, Nosella ML, Lee HO. What are the distinguishing features and size requirements of biomolecular condensates and their implications for RNA-containing condensates?. RNA. 2022;28:36–47.

Kohnhorst CL, Kyoung M, Jeon M, Schmitt DL, Kennedy EL, Ramirez J, et al. Identification of a multienzyme complex for glucose metabolism in living cells. J Biol Chem. 2017;292:9191–203.

Gil-Garcia M, Benítez-Mateos AI, Papp M, Stoffel F, Morelli C, Normak K, et al. Local environment in biomolecular condensates modulates enzymatic activity across length scales. Nat Commun. 2024;15:3322.

Tibble RW, Gross JD. A call to order: Examining structured domains in biomolecular condensates. J Magn Reson. 2023;346:107318.

Nott TJ, Petsalaki E, Farber P, Jervis D, Fussner E, Plochowietz A, et al. Phase transition of a disordered nuage protein generates environmentally responsive membraneless organelles. Mol Cell. 2015;57:936–47.

Lee M-Y, Dordick JS. Enzyme activation for nonaqueous media. Curr Opin Biotechnol. 2002;13:376–84.

Visser BS, Lipiński WP, Spruijt E. The role of biomolecular condensates in protein aggregation. Nat Rev Chem. 2024;8:686–700.

Dong H, Qin S, Zhou H-X. Effects of macromolecular crowding on protein conformational changes. PLoS Comput Biol. 2010;6:e1000833.

Abyzov A, Blackledge M, Zweckstetter M. Conformational dynamics of intrinsically disordered proteins regulate biomolecular condensate chemistry. Chem Rev. 2022;122:6719–48.

Saini B, Mukherjee TK. Biomolecular condensates regulate enzymatic activity under a crowded milieu: Synchronization of liquid-liquid phase separation and enzymatic transformation. J Phys Chem B. 2023;127:180–93.

Scholl D, Deniz AA. Conformational freedom and topological confinement of proteins in biomolecular condensates. J Mol Biol. 2022;434:167348.

Tibble RW, Depaix A, Kowalska J, Jemielity J, Gross JD. Biomolecular condensates amplify mRNA decapping by biasing enzyme conformation. Nat Chem Biol. 2021;17:615–23.

Kurinomaru T, Tomita S, Hagihara Y, Shiraki K. Enzyme hyperactivation system based on a complementary charged pair of polyelectrolytes and substrates. Langmuir. 2014;30:3826–31.

J. Thiele M, Davari MD, König M, Hofmann I, Junker NO, Mirzaei Garakani T, et al. Enzyme–polyelectrolyte complexes boost the catalytic performance of enzymes. ACS Catal. 2018;8:10876–87.

Ito-Harashima S, Miura N. Compartmentalization of multiple metabolic enzymes and their preparation in vitro and in cellulo. Biochim Biophys Acta Gen Subj. 2025;1869:130787.

Harris R, Berman N, Lampel A. Coacervates as enzymatic microreactors, Chem Soc Rev. 2025. https://doi.org/10.1039/d4cs01203h.

Wan L, Ke J, Zhu Y, Zhang W, Mu W. Recent advances in engineering synthetic biomolecular condensates. Biotechnol Adv. 2024;77:108452.

Arnold FH. Design by directed evolution. Acc Chem Res. 1998;31:125–31.

Maghraby YR, El-Shabasy RM, Ibrahim AH, Azzazy HME-S. Enzyme immobilization technologies and industrial applications. ACS Omega. 2023;8:5184–96.

Garcia-Galan C, Berenguer-Murcia Á, Fernandez-Lafuente R, Rodrigues RC. Potential of different enzyme immobilization strategies to improve enzyme performance. Adv Synth Catal. 2011;353:2885–904.

Perumal S, Atchudan R, Lee W. A review of polymeric micelles and their applications. Polymers. 2022;14:2510.

Harada A, Kataoka K. Novel polyion complex micelles entrapping enzyme molecules in the core: Preparation of narrowly-distributed micelles from lysozyme and poly(ethylene glycol)−Poly(aspartic acid) block copolymer in aqueous medium. Macromolecules. 1998;31:288–94.

Sun J, Li Z. Polyion complexes via electrostatic interaction of oppositely charged block copolymers. Macromolecules. 2020;53:8737–40.

Wang H, Vant JW, Zhang A, Sanchez RG, Wu Y, Micou ML, et al. Organization of a functional glycolytic metabolon on mitochondria for metabolic efficiency. Nat Metab. 2024;6:1712–35.

Zhou J, Liu C, Yu H, Tang N, Lei C. Research progresses and application of biofuel cells based on immobilized enzymes. Appl Sci. 2023;13:5917.

Sassolas A, Blum LJ, Leca-Bouvier BD. Immobilization strategies to develop enzymatic biosensors. Biotechnol Adv. 2012;30:489–511.

Nobeyama T, Yoshida T, Shiraki K. Interfacial and intrinsic molecular effects on the phase separation/transition of heteroprotein condensates. Int J Biol Macromol. 2024;254:128095.

Biplab KC, Nii T, Mori T, Katayama Y, Kishimura A. Dynamic frustrated charge hotspots created by charge density modulation sequester globular proteins into complex coacervates. Chem Sci. 2023;14:6608–20.

Yoshida T, Sakakibara N, Ura T, Minamiki T, Shiraki K. Cationic polyelectrolytes prevent the aggregation of l-lactate dehydrogenase under unstable conditions, Int J Biol Macromol. 2023;257:128549.

Voets IK, de Keizer A, Cohen Stuart MA. Complex coacervate core micelles. Adv Colloid Interface Sci. 2009;147–148:300–18.

Wei M, Gao Y, Li X, Serpe MJ. Stimuli-responsive polymers and their applications. Polym Chem. 2017;8:127–43.

Panganiban B, Qiao B, Jiang T, DelRe C, Obadia MM, Nguyen TD, et al. Random heteropolymers preserve protein function in foreign environments. Science. 2018;359:1239–43.

Waltmann C, Mills CE, Wang J, Qiao B, Torkelson JM, Tullman-Ercek D, et al. Functional enzyme-polymer complexes. Proc Natl Acad Sci Usa. 2022;119:e2119509119.

Macazo FC, Minteer SD. Enzyme cascades in biofuel cells. Curr Opin Electrochem. 2017;5:114–20.

Lopez-Gallego F, Schmidt-Dannert C. Multi-enzymatic synthesis. Curr Opin Chem Biol. 2010;14:174–83.

Bowie JU, Sherkhanov S, Korman TP, Valliere MA, Opgenorth PH, Liu H. Synthetic biochemistry: The bio-inspired cell-free approach to commodity chemical production. Trends Biotechnol. 2020;38:766–78.

Liu M, He S, Cheng L, Qu J, Xia J. Phase-separated multienzyme biosynthesis. Biomacromolecules. 2020;21:2391–9.

Nakashima KK, Baaij JF, Spruijt E. Reversible generation of coacervate droplets in an enzymatic network. Soft Matter. 2018;14:361–7.

Miura N. Condensate Formation by Metabolic Enzymes in Saccharomyces cerevisiae. Microorganisms. 2022;10:232.

Kluczka E, Rinaldo V, Coutable-Pennarun A, Stines-Chaumeil C, Anderson JLR, Martin N. Enhanced catalytic activity of a de novo enzyme in a coacervate phase. ChemCatChem. 2024;16:e202400558.

Acknowledgements

This work was supported by the Japan Society for the Promotion of Science (JSPS) KAKENHI (grant numbers 23KJ2179, 24K01970 and 24K17833).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ura, T., Yoshida, T., Mikawa, T. et al. Polymer-engineered condensates for enzyme activation. Polym J 57, 885–896 (2025). https://doi.org/10.1038/s41428-025-01042-8

Received:

Revised:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41428-025-01042-8