Abstract

Organic redox polymers, composed of earth-abundant elements, offer rapid charge storage and are promising electrode-active materials for aqueous batteries, potentially replacing metals and overcoming their resource and performance limitations. However, the hydrophobicity of many organic redox molecules hinders their application using aqueous electrolytes. This necessitates molecular designs that impart hydrophilicity while immobilizing redox-active moieties onto electrodes. Polyallylamine, with its high density of hydrophilic amino groups, serves as an effective backbone. In this work, functionalizing it with hydroquinone enabled the use of the polymer in aqueous batteries. While hydroquinone provides high theoretical capacity, irreversible quinhydrone formation limits its reversible and thorough charge storage. We addressed this by covalently attaching hydroquinone to polyallylamine via condensation. The resulting polymer exhibited reversible and thorough charge storage, which was attributed to electrostatic repulsion between amino groups that suppressed quinhydrone formation. A polymer–air secondary battery was fabricated with the polymer, Pt/C, and a 0.5 M H2SO4 aqueous solution as the anode, cathode, and electrolyte, respectively, without any separator. This polymer–air secondary battery displayed a constant discharge voltage with high cyclability (>99% capacity retention after 100 cycles) and high-rate capability. Moreover, the polymer demonstrated recyclability, as raw materials were generated simply by acid treatment. This work demonstrates a polymer design strategy for integrating typically hydrophobic organic redox molecules into recyclable aqueous batteries.

Similar content being viewed by others

Introduction

Organic redox polymers are bearing organic redox molecules that can reversibly store electric charge by reduction and oxidation [1]. Organic redox polymers are composed of abundant elements and are characterized by the ability to store charges quickly and thoroughly based on the fast charge transport phenomenon in their condensed layers [1, 2]. Therefore, these polymers have attracted attention as electrode-active materials capable of storing electric charge at high current densities and have been the subject of vigorous research [3,4,5,6,7,8,9,10,11,12]. In addition, batteries utilizing these polymers for their electrode-active materials are called organic batteries, and many organic batteries have been proposed as next-generation batteries for a sustainable society [13, 14].

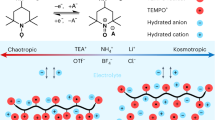

In recent years, to overcome the weaknesses of metal electrodes (e.g., decreases in cycle performance due to dendrite formation [15, 16]) in aqueous batteries, research into replacing metal electrodes with organic electrodes has proceeded [14, 17, 18]. However, the organic redox molecules responsible for storing electric charge are often hydrophobic. Therefore, to apply organic redox polymers to aqueous batteries, a molecular design strategy is essential that imparts hydrophilicity to organic redox molecules while immobilizing them on the electrode to prevent dissolution in the electrolyte.

To apply organic hydrophobic and functional molecules to aqueous environments, we have focused on polyallylamine, which has a high density of hydrophilic amino groups. We have demonstrated that grafting organic redox molecules onto polyallylamine endows them with hydrophilic properties [19,20,21,22,23,24]. Polymers in which these organic functional molecules are substituted into polyallylamine have been applied as hydrophilic dyes [19], hydrogen storage materials [21, 24], and electrode-active materials for aqueous batteries [20, 22, 23]. Recently, we developed a novel quaternized polymer by substituting butanediol into polyallylamine. Furthermore, we demonstrated that the high hydrophilicity and electrostatic repulsion of the resulting polymer improved the reactivity of butanediol [24]. In other words, we confirmed that the substitution of organic functional molecules into polyallylamine can not only increase their hydrophilicity but also enhance their reactivity.

In the current work, we focused on hydroquinone. Although hydroquinone has a high theoretical capacity based on its small molecular weight, it is usually challenging to store charge reversibly and thoroughly due to the formation of quinhydrone, which hinders its application as an electrode-active material [25]. We hypothesized that by substituting hydroquinone into polyallylamine (Fig. 1), the resulting organic redox polymer can reversibly and thoroughly store charge with high capacity based on the improved hydrophilicity and electrostatic repulsion. Furthermore, we also investigated the decomposition of polyallylamine substituted with functional organic molecules into raw materials (recyclability, Fig. 1).

Experimental section

Preparation of hydroquinone-substituted polyallylamine (PDA)

2,5-Dihydroxybenzoic acid (2.54 mmol) and 4-(4,6-dimethoxy-1,3,5-triazin-2-yl)-4-methylmorpholinium chloride (DMT-MM) (2.54 mmol) were put in N,N-dimethylformamide (DMF) (10 mL). To this solution, a 15 wt% aqueous solution of polyallylamine (2.54 mmol) was added dropwise over 10 min, and the mixture was stirred for 10 h. The reaction mixture was subsequently poured into acetone, resulting in the formation of a precipitate. This precipitate was collected via filtration and washed with acetonitrile and acetone to obtain PDA as a brown powder. The degree of hydroquinone substitution into polyallylamine was calculated using 1H-NMR spectroscopy. The polymer was confirmed to be PDA as follows (Figs. S1, S2): 1H-NMR (400 MHz, dimethyl sulfoxide, δppm)ː 0.7−2.4 (CH2, CH (polyallylamine)), 3.3–4.2 (CH2, NH2 (polyallylamine)), 6.5–7.5 (Ph (HQ)), 7.5–8.5 (NH (polyallylamine)), 8.8–9.3 (OH). FT-IR (ATR): v = 2700−3500 (br; v(N-H, O-H)), 2917 (s; v(C-H)), 1657 (s; v(C = O)), 1585 (s; δ(NH2)), 1446 (s; v(C = C), 1356 (s; δ(C-H)).

Decomposition of hydroquinone-substituted polyallylamine

PDA (0.54 mmol) was added to a 15 M sulfuric acid or acetic acid aqueous solution (10.8 mmol) and stirred at 80 °C. After the reaction, the reaction mixture was poured into water, resulting in the formation of a precipitate. This precipitate was collected via filtration and washed with acetone to yield brown powder. The decomposition rate was calculated from the ratio of the substitution of hydroquinone into polyallylamine before and after the decomposition reaction.

Results and discussion

Synthesis of hydroquinone-substituted polyallylamine

Facile condensation of 2,5-dihydroxybenzoic acid and polyallylamine produces hydroquinone-substituted polyallylamine (PDA) (Scheme 1). Increasing the temperature is considered to improve the reaction rate and, consequently, the incorporation rate. In other words, the degree of substitution could be easily adjusted in the range of 16–50% by changing the reaction temperature (Table 1). PDA could be purified by facile washing with acetonitrile and acetone, with high yields (e.g., 84% for Run 4). The resulting polymer was purified by simple washing with acetonitrile and acetone, with high yields (e.g., 84% for Run 2). All the PDAs were soluble in DMF, dimethyl sulfoxide, and NMP and were insoluble but swollen in water.

Electrochemical properties of hydroquinone-substituted polyallylamine

Chronoamperometric evaluation of the thin polymer film (610 nm) in 0.5 M H2SO4 aqueous solution (Fig. 2a) revealed that the diffusion coefficient of protons and electrons within the polymer layer was determined to be 1.7 × 10−13 cm2 s−1 (with the rate constant for the electron self-exchange reaction estimated to be 3.5 × 10 M–1 s–1). This is comparable to that of conventional organic redox polymers [26,27,28]. This result indicates that the polymer/carbon composite electrode is likely to perform at a moderate rate capability.

PDA with a 43% degree of substitution, synthesized using the conditions of Table 1 (Run 4), was used in a carbon composite electrode, which exhibited a measurable current within the potential range of 0– + 0.8 V in 0.5 M H2SO4 aqueous solution. The charge‒discharge curves (Fig. 3b) indicated a potential plateau at + 0.4 V vs. Ag/AgCl and showed that the PDA electrode delivered a high capacity close to its theoretical capacity of 197 mAh/g (99% of the theoretical capacity, 199 mAh/g), which was calculated based on the molecular weight of the repeating unit (Columbic efficiency of >99%). This indicated that the improved hydrophilicity and electrostatic repulsion of PDA allowed the polymer/carbon composite electrode to reach almost full capacity. We also confirmed that PDAs with less than 43% substitution could achieve full capacity. Meanwhile, PDA with 50% substitution could not achieve the full capacity (143 mAh/g), presumably because of inadequate hydrophilicity. The polymer/carbon composite electrode demonstrated excellent rate capabilities (e.g., close to its theoretical capacity even at a high rate of 60 C), presumably because of a rapid electron (proton) exchanging reaction in the polymer (Fig. 2b). In addition, the excellent cyclability of the PDA electrode, with 99% of the initial capacity even after 100 cycles (Fig. 3b Inset), indicates the strong robustness of PDA. These results supported our hypothesis that by substituting hydroquinone into polyallylamine, the resulting organic redox polymer can reversibly and thoroughly store charge with high capacity based on the improved hydrophilicity and electrostatic repulsion.

Polymer–air secondary battery

Air batteries that utilize an organic redox polymer as the anode and an acidic aqueous solution as the electrolyte have demonstrated the capability to achieve high cyclability [14]. Therefore, as an example of the application of PDA, a polymer–air secondary battery was fabricated with a PDA electrode as the anode, a conventional Pt/C catalyst as the cathode, and a 0.5 M H2SO4 aqueous solution as the electrolyte. (Fig. 4a, b). The anode was under inert gas, and the cathode was exposed to air. The battery was operated at 0.5 V during discharge and demonstrated a discharge capacity of 197 mAh/g (more than 99% of the theoretical capacity) with a high Coulombic efficiency of 99% (Fig. 5a), a high capacity close to its theoretical capacity even at a high rate of 60 C (Fig. 5b), and high cyclability (more than 99% of the initial capacity even at 100 cycles, Fig. 5a inset). Therefore, functionalizing polyallylamine with hydroquinone enables the use of the polymer in aqueous batteries.

Decomposition of hydroquinone-substituted polyallylamine into raw materials

To prevent plastic pollution, the design of polymer materials must consider their recycling after use [29, 30]. As shown in Scheme 2, we demonstrated that PDA was decomposed to the raw materials by acid hydrolysis (see also Fig. S3). As a representative example, the decomposition rates of PDA (Table 1, Run 4) for each decomposition condition were investigated and are summarized in Table 2. A comparison of Runs 1 and 2 indicates that a reaction time of 48 h is insufficient for decomposition, whereas nearly complete decomposition is achieved in 72 h. A comparison of Runs 2 and 3 indicates that sulfuric acid is better than acetic acid for PDA decomposition. Therefore, acid hydrolysis using 15 M sulfuric acid can almost completely decompose PDA to its raw materials, which is the first time that material recycling has been demonstrated in polymer design using polyallylamine. This work demonstrates a polymer design strategy for integrating typically hydrophobic organic redox molecules into recyclable aqueous batteries.

Conclusion

The substitution of hydroquinone into polyallylamine allowed the redox polymer (PDA with a degree of substitution below 43%) to achieve almost full capacity (99% of the theoretical capacity) due to the improvement in hydrophilicity and electrostatic repulsion. The polymer–air battery discharged at a constant output voltage and displayed high cyclability (more than 100 cycles) and rate capability (up to 60 C). In addition, we also investigated the decomposition (recyclability) of PDA into raw materials. The current work demonstrates a polymer design strategy that enables not only the application of hydrophobic organic redox molecules that typically aggregate in aqueous environments but also their recycling after use.

References

Oka K, Nishide H. Radical polymers for rechargeable batteries. Redox Polym Energy Nanomed. 2020;34:137.

Oyaizu K. Reversible and high-density energy storage with polymers populated with bistable redox sites. Polym J. 2024;56:127–44.

Wylie L, Oyaizu K, Karton A, Yoshizawa-Fujita M, Izgorodina EI. Toward improved performance of all-organic nitroxide radical batteries with ionic liquids: a theoretical perspective. ACS Sustain Chem Eng. 2019;7:5367–75.

Tanaka M, Hatta K, Edura T, Tsutsui K, Wada Y, Nishide H. Conductive characteristics of radical-bearing polythiophenes using a microcomb-shaped electrode. Polym Adv Technol. 2007;18:925–31.

Kato T, Gon M, Tanaka K, Chujo Y. Modulation of stimuli-responsiveness toward acid vapor between real-time and write-erase responses based on conjugated polymers containing azobenzene and schiff base moieties. J Polym Sci. 2021;59:1596–602.

Ito, S, Tanaka, K. Π-conjugated polymers consisting of heavier group 13 elements. Polymer Chem. 2025;16:2046–57.

Lutkenhaus JL, Wu Y, Thangadurai V. Organic battery materials. ACS Appl Energy Mater. 2024;7:7560–1.

Maniam S, Oka K, Nishide H. N-phenyl naphthalene diimide pendant polymer as a charge storage material with high rate capability and cyclability. MRS Commun. 2017;7:967–73.

Yoshimura A, Hemmi K, Moriwaki H, Sakakibara R, Kimura H, Aso Y, et al. Improvement in cycle life of organic lithium-ion batteries by in-cell polymerization of tetrathiafulvalene-based electrode materials. ACS Appl Mater Interfaces. 2022;14:35978–84.

Yao M, Senoh H, Sakai T, Kiyobayashi T. Redox active poly(N-Vinylcarbazole) for use in rechargeable lithium batteries. J Power Sources. 2012;202:364–8.

Yao M, Sano H, Ando H, Kiyobayashi T. Molecular ion battery: a rechargeable system without using any elemental ions as a charge carrier. Sci Rep. 2015;5:10962.

Sano H, Yoshimura A, Zhang L, Ebisawa H, Kiyokawa T, Fujita K, et al. Cation-independent anion battery using organic cathodes utilizing a triphenylamine moiety for in-cell electropolymerization. ACS Appl Polym Mater. 2024;6:7542–50.

Kim J, Kim Y, Yoo J, Kwon G, Ko Y, Kang K. Organic batteries for a greener rechargeable world. Nat Rev Mater. 2023;8:54–70.

Akai, R, Tohnai, N, Oka, K.. Organic-Based Batteries for the Future of Energy Storage. In Batteries, Jenny Stanford Publishing, pp 155-216.

Li Y, Lu J. Metal–air batteries: will they be the future electrochemical energy storage device of choice?. ACS Energy Lett. 2017;2:1370–7.

Dewi EL, Oyaizu K, Nishide H, Tsuchida E. Cationic polysulfonium membrane as separator in zinc–air cell. J Power Sources. 2003;115:149–52.

Guo L, Miyatake K, Wada S, Oka K, Kitajima S, Kasai H, et al. Alkyl-ether group-modified anthraquinone-based negative electrode for enhanced electrochemical performance of all solid-state rechargeable air batteries. ACS Sustain Chem Eng. 2024;12:16518–23.

Yonenaga M, Kaiwa Y, Oka K, Oyaizu K, Miyatake K. All-solid-state rechargeable air batteries using dihydroxybenzoquinone and its polymer as the negative electrode. Angew Chem Int Ed Engl. 2023;62:e202304366.

Kinoshita Y, Maruoka K, Takahashi Y, Teruuchi Y, Takeuchi M, Igarashi K, et al. Hydrophilization of hydrophobic azulene derivative by substitution with polyallylamine without drastically changing its optical properties. MRS Commun. 2025;15:127–31.

Oka K, Murao S, Kataoka M, Nishide H, Oyaizu K. Hydrophilic anthraquinone-substituted polymer: its environmentally friendly preparation and efficient charge/proton-storage capability for polymer–air secondary batteries. Macromolecules. 2021;54:4854–9.

Oka K, Tobita Y, Kataoka M, Murao S, Kobayashi K, Furukawa S, et al. Synthesis of vinyl polymers substituted with 2-propanol and acetone and investigation of their reversible hydrogen storage capabilities. Polym J. 2021;53:799–804.

Strietzel C, Oka K, Strømme M, Emanuelsson R, Sjödin M. An alternative to carbon additives: the fabrication of conductive layers enabled by soluble conducting polymer precursors–a case study for organic batteries. ACS Appl Mater interfaces. 2021;13:5349–56.

Oka K, Murao S, Kobayashi K, Nishide H, Oyaizu K. Charge- and proton-storage capability of naphthoquinone-substituted poly(allylamine) as electrode-active material for polymer–air secondary batteries. ACS Appl Energy Mater. 2020;3:12019–24.

Oka K, Kaiwa Y, Kobayashi K, Tobita Y, Oyaizu K. Accelerating the dehydrogenation reaction of alcohols by introducing them into poly(allylamine). Polym Chem. 2023;14:2588–91.

Barathi P, Vinothbabu P, Sampath S. Use of quinhydrone as a promising cathode material for aqueous zinc-ion battery. J Energy Storage. 2023;74:109154.

Choi W, Harada D, Oyaizu K, Nishide H. Aqueous electrochemistry of poly(vinylanthraquinone) for anode-active materials in high-density and rechargeable polymer/air batteries. J Am Chem Soc. 2011;133:19839–43.

Oka, K, Kato, R, Oyaizu, K, Nishide, H. poly(vinyldibenzothiophenesulfone): its redox capability at very negative potential toward an all-organic rechargeable device with high-energy density. Adv Funct Mater. 2018;28:1805858.

Oka K, Furukawa S, Murao S, Oka T, Nishide H, Oyaizu K. Poly (dihydroxybenzoquinone): its high-density and robust charge storage capability in rechargeable acidic polymer–air batteries. Chem Commun. 2020;56:4055–8.

Oka, K, Kasai, H. Recyclable organic redox molecules for sustainable batteries. ChemSusChem. 2025;18:e202402707.

Nguyen TP, Easley AD, Kang N, Khan S, Lim S-M, Rezenom YH, et al. Polypeptide Organic Radical Batteries. Nature. 2021;593:61–66.

Acknowledgements

This work was partially supported by Grants-in-Aids for Scientific Research (Nos. JP23K17945, JP23H03827, JP24K01552, and JPJSBP120258801) from MEXT, Japan. This work was partially supported by the Environment Research and Technology Development Fund (JPMEERF20241RA4) of the Environmental Restoration and Conservation Agency provided by the Ministry of the Environment of Japan. KO also acknowledges support from the Shorai Foundation for Science and Technology, the TEPCO Memorial Foundation, the Amano Industry Technology Laboratory, Sugiyama Houkoukai, the Yamada Science Foundation, the Kenjiro Takayanagi Foundation, the Kansai Research Foundation for Technology Promotion, the Yashima Environment Technology Foundation, the JACI Prize for Encouraging Young Researcher, the Iketani Science and Technology Foundation, the Foundation for Interaction in Science & Technology, and the Kato Foundation for Promotion of Science (KS-3416).

Author information

Authors and Affiliations

Contributions

All the authors have approved the final version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Oka, K., Kitajima, S., Okubo, K. et al. Hydroquinone-substituted polyallylamine: redox capability for aqueous polymer–air secondary batteries and recyclability. Polym J (2025). https://doi.org/10.1038/s41428-025-01085-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41428-025-01085-x