Abstract

Polymers incorporating hydrogen bonding (H-bonding) units have attracted significant attention for their ability to enhance mechanical properties, including elastic modulus, toughness, and stretchability, owing to the reversible nature of H-bonds. These interactions can act as apparent crosslinks under small strains and facilitate energy dissipation and network restoration under large strains or upon stress release. A critical aspect influencing the macroscopic behavior of such materials is the structural flexibility of the H-bonding motifs. This review categorizes H-bonds into two groups: “rigid” multiple H-bonds, often characterized by π-conjugated units and structural complementarity (e.g., UPy and nucleobases), which impart directionality and strong association, and “flexible” multiple H-bonds (e.g., aliphatic vicinal diols), which exhibit various bonding modes due to conformational freedom and the absence of strong π-conjugation. We discuss how these differences in structural flexibility profoundly affect the mechanoresponsive behavior of the polymers. This review is specifically focused on H-bonds within polymers without solvents, thereby elucidating the intrinsic effects of H-bond architecture on material properties, independent of solvent or small-molecule interactions.

Similar content being viewed by others

Introduction

Polymers bearing hydrogen bonding (H-bonding) units have attracted significant attention over the years [1, 2]. In the small-strain regime, H-bonds in polymers work as apparent crosslinks, leading to an increase in the elastic modulus. Moreover, H-bonds exchange in the large-strain region before covalent bonds start to break, as H-bonds are relatively weak and reversible. H-bonds dissipate energy prior to the failure of a material and thereby contribute to high stretchability and toughness. When the stress is released, the exchange of H-bonds facilitates the restoration of the polymer network and its mechanical strength. Furthermore, external stimuli such as heat can plasticize the material, rendering these polymers promising candidates for recyclable applications. These unique properties have the potential to overcome conventional limitations in crosslinked polymer materials, thereby enabling broader applications across diverse industries.

H-bonds are electrostatic interactions between an electron-deficient hydrogen atom (donor) and an electronegative atom (acceptor), such as oxygen (O), nitrogen (N), sulfur (S), or certain halogens [3]. The strength of H-bonds is determined by multiple factors, such as the electronegativity of the donor and acceptor atoms and various environmental parameters (e.g., pressure, solvent polarity, and acidity). Generally, H-bonds are stronger than dipolar interactions or London dispersion forces, with bond energies typically ranging from 4 to 15 kJ/mol [4]. The distance between the donor H atom and acceptor correlates with the bond strength. H-bonds tend to become increasingly linear as their strength increases because the arrangement of H-bonds reaches an energy minimum when the donor dipole is collinear with the charged point on the acceptor [4]. The uneven spatial distribution of lone-pair electron density around the acceptor also influences the directionality [5]. For example, the oxygen atom in a carbonyl group possesses a lone pair in its sp²-hybridized orbital, which interacts with the donor within the plane of the R2C = O group. Consequently, the H-bonds formed between the carbonyl group and hydrogen are confined to the plane, reinforcing their directionality. Multiple H-bonding motifs, such as those found in DNA nucleic acids (i.e., carbonyl groups and N-H groups constrained within conjugated cyclic structures), also exhibit similar tendencies, enabling strong directionality.

Another intriguing characteristic of H-bonds is π-bond cooperativity. In systems where a functional group with π-conjugated systems forms multiple H-bonds (i.e., more than two bonds between a pair of functional groups), the overall bond energy exceeds the sum of the individual bond energies owing to resonance and depolarization effects. For example, in formic acid, H-bonding is associated with an increase in the C = O bond length and a decrease in the C–OH bond length. This additional stabilization arises from the partial delocalization of π-electrons within a H-bonding motif composed of conjugated single and double bonds, thereby establishing an interplay between π-delocalization and H-bond strengthening [6].

Owing to these characteristics, H-bonds play a central role in molecular recognition and related processes, such as self-assembly, self-organization, and self-replication, contributing to the development of supramolecular chemistry [7]. Lehn first introduced this concept by demonstrating noncovalent interactions between cryptands and guest molecules. His work greatly contributed to its establishment and ultimately earned him the Nobel Prize in Chemistry in 1987 [8]. Multiple H-bonds have proven to be effective subunits in molecular recognition. Since the late 1980s, the emergence of supramolecular polymer chemistry, which combines supramolecular and polymer chemistry, has advanced materials science [9]. Currently, numerous studies have reported the unique characteristics of polymers bearing H-bonds, especially multiple H-bonds. Multiple H-bonds widely reported in recent studies often feature structural complementarity and π-conjugated units, with nucleobases and 2-ureido-4[1H]-pyrimidinone (UPy) serving as representative examples. This configuration effectively facilitates dimer association through π-bond cooperative effects, while the π-conjugated units impart directionality to H-bond formation by confining the bonds to a specific plane. These multiple H-bonds, characterized by their rigidity, are referred to as “rigid” H-bonds in this review (Fig. 1a). Meanwhile, the effects of “flexible” multiple H-bonds in polymers have also been reported. Flexible multiple H-bonds, such as those formed between aliphatic vicinal diol groups, exhibit various stable H-bonding modes because of their flexible configuration in the polymer chain and the absence of strong π-conjugated units or complementary interactions (Fig. 1b) [10, 11]. Although there are far fewer studies on flexible H-bonds than rigid H-bonds, recent studies have revealed that differences in their structural flexibility significantly affect the mechanical properties of polymers. In this review, we summarize the characteristics of polymers bearing either rigid or flexible H-bonds and discuss the effects of the structural flexibility of H-bonds on the mechanoresponsive behavior of polymers. The studies introduced in this review are intentionally limited to those that incorporate H-bonds into solvent-free polymer systems, rather than gels, and specifically exclude the effects of solvents that may interact with H-bonding motifs.

Rigid multiple H-bonds

The dawn of supramolecular polymers based on H-bonds

In the earliest stage of supramolecular polymer chemistry, researchers aimed to extend polymer chains by incorporating rigid double and triple H-bonding motifs at the end of the polymer chain. The effective polymer length increases, which leads to slower relaxation. Lehn et al. first demonstrated this concept in 1989 with a self-assembling liquid‒crystalline polymer based on a triple complementary H-bond array between uracil and 2,6-diaminopyridine [12]. They introduced these motifs at the termini of nonmesogenic molecules consisting of aliphatic chains. The supramolecular polymer displayed a mesomorphic phase in which the triple H-bonded termini were stacked in a hexagonal columnar manner. Another breakthrough was Meijer’s development of 2-ureido-4[1H]-pyrimidinone (UPy) [13]. UPy has H-bond donors (D) and acceptors (A) in a DDAA sequence that leads to dimerization through self-complementary quadruple H-bonds with a high association constant of ~10⁶ M⁻¹ in CHCl₃. Linear poly(dimethylsiloxane) oligomers end-capped with UPy drive end-to-end associations, yielding supramolecular polymers with greatly extended contour lengths [14]. Dynamic mechanical analysis (DMA) revealed a rubbery plateau and substantially prolonged relaxation times. These behaviors confirm that reversible UPy–UPy dimerization connects two independent chains together, making them behave as much longer entities. Since these seminal works, the utility of rigid H-bond motifs in supramolecular polymer networks has been recognized, and their integration into diverse polymer backbones has been extensively studied [15,16,17,18].

UPy

As a UPy–UPy dimer has an extraordinary association constant, it has been used as a strong reversible crosslink to prolong the relaxation of polymers and improve their mechanical properties. For example, Kramer et al. synthesized random polyacrylate copolymers bearing UPy in their side chains [19]. DMA revealed that higher UPy loadings elevated the glass transition temperature (Tg) and storage modulus in the rubbery plateau region and substantially delayed polymer relaxation. Anthamatten et al. synthesized poly(n-butyl acrylate) bearing either weak H-bonding motifs such as acrylic acid or UPy [20]. The Tg of the polymers bearing 5 mol% of either H-bonding group increased to a similar extent (ca. -39 °C), whereas the polymer containing UPy effectively suppressed its relaxation in DMA. Furthermore, Guan et al. introduced a titin-inspired, expandable modular crosslink by covalently joining two UPy units into a cyclic motif and embedding it in poly(n-butyl acrylate) (Fig. 2a) [21]. The Tg of the network polymers, as measured by DMA, was in the range of 0 to 15 °C. With 6 mol% crosslinks, the network exhibited a tensile strength (σmax) of 4.5 MPa and a fracture strain (εbreak) of 0.8, which are approximately seven- and fourfold greater, respectively, than those of a control network with irreversible covalent crosslinks (σmax = 0.63 MPa, εbreak = 0.19). These enhancements are attributed to the cyclic UPy pair repeatedly unfolding and refolding under loading, thereby dissipating energy while preserving network connectivity. These studies collectively demonstrate that the binary association of UPy units can increase the energy barrier for segmental motion, thereby increasing the relaxation time, extensibility, and toughness.

Moreover, several groups have reported mechanical responses that originate from local densification of UPy motifs in hydrophobic polymer chains. Because the H-bonded dimer of UPy is rigid and planar, it easily forms disordered aggregates [22] or, under certain conditions, crystallites in which the dimers stack regularly [23]. The emergence of such nanoscale structures is sensitive to the UPy content [24], arrangement of UPy along the backbone [25,26,27,28,29], polymer morphology and crystallinity [30], and chain length [14, 23]. When the UPy units residing in the aggregated domain begin to organize, they can nucleate in a crystalline order, altering the mechanical response of the polymer. This transition is especially pronounced when urethane or urea moieties, which promote ordered packing, are introduced near UPy. Under such conditions, nanofibrillar crystalline phases have been observed [25, 31,32,33]. Meijer and coworkers synthesized poly(ethylene butylene) oligomers in which both UPy and urea groups were incorporated at the chain ends. They first identified a microphase-separated morphology resulting from the segregation of polar UPy-urea termini from the nonpolar backbone. Upon cooling, UPy dimers stack in an ordered manner [25]. Similar behavior was reported by Ahmadi et al., who systematically varied the UPy content in poly(n-butyl acrylate-ran-hydroxyethyl acrylate) with a relatively high molecular weight (Mn = 142 kg mol−1). They found that 2–3 mol% UPy produced spherical microphase-separated domains, whereas 4 mol% UPy promoted needle-like supramolecular assemblies [34]. According to the observations of these studies, the mechanism of the local densification of UPy motifs involves (i) the formation of disordered UPy-rich domains arising from one-to-one H-bonded pairs, followed by (ii) the transition to an ordered crystalline domain through regular UPy stacking as the local UPy density increases.

Aggregates and crystalline domains formed by UPy units are known to decelerate polymer relaxation [32, 35]. In a simple binary association, the quadruple H-bond has a relatively short lifetime (of course, the lifetimes of single/double/triple multiple H-bonds are even shorter) and rapidly exchanges partners, permitting fast stress relaxation. In aggregated or crystalline domains, however, individual H-bonds persist far longer, and partner exchange proceeds only through the cooperative dissociation and association of multiple dimers, which is a much slower process [36]. Taking advantage of this kinetic trapping, several groups have developed polymers that deliberately incorporate aggregated or densely packed UPy domains [37, 38]. We reported one such design based on the microphase separation of an ABA triblock copolymer [39]. The short A blocks contain a high UPy density and thus form spherical hard domains with ~30 nm periodicity, whereas the long B block carries only 10 mol% UPy, serving as a surrounding matrix in which the UPy units are isolated and confined to binary associations (Fig. 2b). This architecture yields a tough elastomer with a σmax of ~16.3 MPa and an εbreak of ~716%. In a cyclic test in which the elastomer was stretched to 650% strain (stress > 17 MPa, energy dissipation of 27 MJ/m), the elastomer recovered ~83% of its original hysteresis in the 2nd cycle. The data indicate that aggregated UPy domains act as strong physical crosslinks that endow the network with rubber-like elasticity, whereas the dispersed UPy in the soft matrix serves as relatively weak and transient crosslinks that enhance extensibility and impart self-recovery. Furthermore, Meijer and coworkers developed an elastomer by incorporating urea groups in the main chain and UPy units at the chain ends [31]. Poly(ethylene-butylene) chains bearing both urea linkers and UPy termini developed long fibers with estimated widths <7 nm (Fig. 2c). Differential scanning calorimetry (DSC) revealed that the material had a melting point (Tm) of 129 °C, indicating a crystalline phase in the polymer. The polymer displayed a Young’s modulus comparable to that of an otherwise identical urea-only analog, yet its εbreak was approximately four times greater. These observations imply that nanofibrillar crystalline domains formed through UPy stacking and urea (or urethane) H-bonding concurrently curtail segmental motion while improving extensibility.

Collectively, the literature featuring polymers incorporating UPy indicates two trends. First, when UPy units remain dispersed in the polymer matrix, their rigid quadruple H-bonds behave as physical crosslinks that increase the extensibility and toughness. Second, if the UPy motifs further assemble into nanoscale domains, they can add greater strength because of the slower exchange of H-bonds. Moreover, the movement of polymer chains is usually suppressed by strong crosslinks and UPy-rich domains; therefore, dynamic properties such as self-healing ability are rarely observed.

Other rigid H-bonding motifs

Rigid multiple H-bond motifs are not limited to UPy. The DNA base pairs adenine (A)–thymine (T) and guanine (G)–cytosine (C) form complementary double and triple H-bonds known as Watson–Crick pairings, respectively (Fig. 3a, b). Although DNA base pairs form a dimer in several ways, Watson–Crick pairing is the dominant binding mode in which all donors and acceptors lie in the same plane. Although their planar, π-conjugated heteroaromatic rings enhance bond stability, their association constants in CHCl₃ are only ≈ 10² M⁻¹ for A–T and 10⁴–10⁵ M⁻¹ for G–C, which are considerably lower than that of the UPy quadruple H-bond [40]. Various studies on polymers incorporating such base pairs have been reported, but these studies have focused mainly on solutions or gels [40, 41]. Notably, Jiang et al. grafted G–C motifs into poly(dimethylsiloxane) [42]. The Tg of the backbone polymer is low (ca. -125 °C), which enables the movement of the polymer network. The material displayed an εbreak of ~225% and a σmax of ~0.17 MPa.

In addition, even more robust multiple H-bond motifs have been devised, such as the Hamilton receptor-barbiturate complex (Fig. 3c) [43, 44], oligoamide-based linear arrays [45], and bis-ureido naphthyridines [46], all of which can generate sextuple H-bonds [47, 48]. These functional groups exhibit exceptionally high association constants (up to 10⁹ M⁻¹ in CHCl₃ [45]), yet their poor compatibility with common polymer backbones makes it difficult to incorporate them into polymers with high molecular weights. Even when incorporation is achieved, characterization and processing are often troublesome [49]. As a consequence, successful integrations of sextuple H-bonds in solvent-free polymer systems are rare. One notable example is the work of Dalcanale and coworkers [50], who grafted 1-(7-oxo-7,8-dihydro-1,8-naphthyridin-2-yl)urea (ODIN), shown in Fig. 3d, as a pendant group onto crystalline low-density polyethylene (LDPE). ODIN presents a DDADA H-bond pattern in which the terminal acceptor engages two donors to create a sixfold H-bond ensemble. The bulky motif grafted onto the polymer backbone hinders crystallization of the main chain, reducing crystallinity and Tm. LDPE lacking ODIN exhibited a σmax of 12 MPa, whereas the incorporation of 2 mol% ODIN increased the σmax to ~15 MPa. However, further increases in the ODIN content produced little additional gain. Additionally, the highest Young’s modulus ( ~ 16.5 MPa) was observed for neat LDPE, presumably because extensive ODIN incorporation disrupted the crystalline packing of the polyethylene backbone.

H-bond network formation by rigid multiple H-bonds

Thus far, our discussion has focused on rigid, binary multiple H-bonds. In segmented polyureas and polyurethanes, however, an H-bonding motif can interact with two or more adjacent motifs oriented in different directions, giving rise to a continuous H-bonded network. A typical example is urea groups, which contain two H-bond donors and one acceptor, forming double H-bonds. Because the donors and acceptors point in opposite directions while the donors, acceptors, and carbonyl π-systems lie in one plane, the urea units assemble into an extended ladder-like array. When such polar units are incorporated into a nonpolar backbone, local phase separation of the H-bond motifs appears to be driven by the collective effect of the polarity contrast between H-bonding motifs and the polymer backbone, the formation of H-bonds, and the thermodynamic stabilization afforded by the ordered array [51,52,53,54]. The resulting hard domains markedly reinforce the polymer. Increasing the urea content systematically increased the stiffness and σmax while reducing εbreak. However, recent studies have shown that some polymer backbone designs of polyurethane help overcome this trade-off. Bao et al. copolymerized polypropylene glycol (PPG) with 4,4′-methylenebis(phenylurea) (MPU), as shown in Fig. 4a, in which MPU accounted for ≈ 38 wt% of the material [55]. Two-dimensional SAXS/WAXS revealed that the unstretched copolymer was amorphous, whereas stretching induced orientational ordering of H-bonds, which was not driven by backbone crystallization but by stretch-induced crystallization of the aligned H-bond ladder. The material achieved a σmax of 70 MPa and an εbreak of 500%, combining high strength with extraordinary toughness. Upon heating, the chains and H-bonds contract to their initial disordered state. Zhao et al. synthesized polyureas by condensing isophoronediamine (IPDA) with trioxa-1,13-tridecanediamine (TTD) at various ratios and evaluated their mechanical properties [56]. TTD–TTD interactions readily form strong, ordered H-bonds, whereas IPDA-rich sequences generate weaker, disordered H-bonds. The DSC results revealed that with increasing TTD/IPDA ratio, the Tm decreased and then disappeared at some point, indicating that the material transformed from semicrystalline to amorphous. The TTD-only polymer was semicrystalline and brittle, but the copolymer containing both IPDA and TTD in equal proportions displayed phase separation and balanced properties, with σmax ≈ 6.6 MPa and εbreak ≈ 1073%. This polymer also demonstrated self-healing ability. When the dumbbell-shaped sample was cut into two separate pieces followed by reattachment, > 92% of the strength was recovered after 24 h under ambient conditions (30 °C). Taken together with other studies [57,58,59,60], these examples show that ladder-type H-bond networks formed by urea (or urethane) groups promote aggregation and, consequently, enhance mechanical performance.

Rigid H-bond networks can also be built from motifs beyond urea. Sumerlin et al. incorporated a Janus-faced G–C base (GCB, Fig. 4b) into poly(butyl acrylate) [61]. GCB, first reported by Sanjayan et al [62], provides triple H-bond sites on both faces, enabling the formation of a H-bond network rather than simple binary H-bond crosslinks. Sumerlin et al. revealed that as the GCB content increased, the storage modulus increased, as a random copolymer containing 15 mol% GCB exhibited a rubbery plateau from −50 °C to above 200 °C. The data indicate that the rigid, multivalent GCB network effectively suppresses chain mobility and shifts relaxation to much longer timescales.

Challenges and outlook of rigid H-bonds

Multiple H-bonds have been shown to (i) retard polymer relaxation by end-linking the oligomer and increasing the effective polymer length, (ii) enhance the mechanical properties (Young’s modulus, σmax, and εbreak) by adding additional crosslinks, and (iii) improve the dynamic performance (toughness, self-recovery, and self-healing) by reversibly exchanging the bonds. Owing to their high association constants and planar binding geometry, they further strengthen materials by driving the formation of H-bond-rich domains. The dissociation of H-bonds in the domain is highly suppressed; therefore, the existence of the domain restrains chain movement, resulting in remarkable mechanical strength. However, several limitations can be seen as well. First, H-bonds with high association constants often suffer from immiscibility with the hydrophobic polymer backbone [40, 42, 45, 49]. The polar functional groups are likely to aggregate in the polymer throughout synthesis, purification, and characterization, making the polymer difficult to analyze. Even if such motifs are molecularly dispersed in the polymer matrix, increasing the H-bond density or placing additional cooperative H-bonding motifs such as urea or urethane nearby promotes the appearance of nanoscale domains [23, 34]; thus, even binary H-bonds face quantitative limits. A previous study revealed that the emergence of aggregation and crystalline domains is controllable and can be used as an effective way to design strong and tough polymers, while H-bond-rich domains can be vulnerable to thermal changes. Guo et al. correlated microstructural changes in polyurea with long-term high-temperature exposure [63]. This study quantitatively demonstrated that annealing at elevated temperatures disrupts the ordered crystalline phase, leading to the subsequent coarsening of irregular aggregates. These changes ultimately reduce the Young’s modulus to approximately 25% of its initial value. Consequently, even when H-bond-rich domains are successfully incorporated into polymers, maintaining the original material strength during practical use can be challenging. In summary, while rigid multiple H-bonds offer significant benefits, a key limitation remains in achieving both remarkable strength and dynamicity simultaneously.

Flexible multiple H-bonds

Aliphatic diols

To address the challenges mentioned in the previous section, we propose that the concept of flexible multiple H-bonds offers a path forward. This type of H-bonding group often lacks strong π-conjugated units, allowing it to form dimers with high spatial freedom and therefore possess several stable binding modes. These H-bonds remain reasonably dispersed even at high loadings (i.e., they are less prone to aggregation) because their various binding modes prevent them from forming an ordered structure. They also impose minimal constraints on chain mobility, permitting highly dynamic properties alongside strengthening of the polymers. The moderate binding strength that comes from the lack of strong π-conjugated units also allows the polymer to retain good miscibility, making it easier to handle throughout the synthesis. In this section, we review the flexible H-bond systems reported to date and their impact on the mechanical properties of polymers, showing evidence that flexible H-bonds can overcome the key shortcomings of rigid H-bonds.

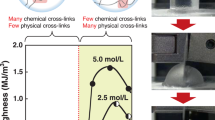

Our group recently demonstrated that random incorporation of two hydroxy groups attached to adjacent carbon atoms (vicinal diol units) into poly(1,4-butadiene) yields a copolymer with exceptional toughness and autonomous self-healing [10]. A sample containing 20 mol% vicinal diol groups per C = C double bond displayed no phase-segregated morphology but achieved σmax ≈ 3.5 MPa and εbreak ≈ 1,400% without chemical crosslinks. After fracture, nearly 100% of the original mechanical properties of the material were recovered by standing at room temperature for ~3 days. To rationalize these unusual dynamics, we performed density functional theory (DFT) calculations on vicinal diol conformations and dimer structures, using 2,3-butanediol as a model. The two hydroxy groups possess low rotational barriers, and the molecule can form several distinct dimers, as shown in Fig. 5a, with binding energies of 45–65 kJ mol⁻¹. Owing to the flexibility of aliphatic vicinal diol groups, we suppose that kinetic effects are derived from the frequent interconversion between various dimer modes. When one or two H-bonds in a dimer of vicinal diol groups are dissociated by a fluctuation of the polymer chain, the vicinal diol group easily switches to another stable dimer mode. This mechanism effectively prevents complete disruption of the dimer and prolongs its lifetime. In addition, even after a dimer is completely dissociated, the isolated vicinal diol group can easily form a new dimer with a different partner because, for them, the relative spatial arrangement is of minor importance. Vicinal diol groups have omnidirectionality, which makes reassociation easier. Another study has shown that, for polymers bearing the same overall hydroxy content, a vicinally arranged hydroxy group restricts backbone motion more effectively and lengthens relaxation times compared with randomly distributed hydroxy groups [64].

Minor geometric differences also matter. We synthesized norbornene derivatives carrying two hydroxymethyl groups (dimethanol groups) in either a vicinal or geminal configuration and randomly copolymerized each monomer with a norbornene matrix via ROMP [11]. DFT calculations predicted only one stable H-bonded dimer for geminal dimethanol, whereas vicinal dimethanol could adopt at least three distinct dimers, indicating greater conformational flexibility (Fig. 5b). The copolymers containing 50% dihydroxymethyl monomer did not aggregate in either case. DSC measurements and rheological tests revealed that the polymer bearing vicinal dimethanol exhibited a lower Tg and a shorter terminal relaxation time, indicating that it is less constrained by chain mobility, and cyclic tensile experiments confirmed its superior self-recovery. In each of these hydroxy-based studies, despite their high density, H-bonding motifs are uniformly dispersed throughout the matrix. Comparing motifs that differ in the number of accessible dimer modes shows that the more flexible vicinal arrangement helps polymers retain their dynamic properties, as evidenced by their superior self-healing ability and self-recoverability.

To demonstrate the general superiority of flexible H-bonds, we compared the mechanical properties of copolymers bearing either vicinal dimethanol groups as flexible H-bonding units or amide groups embedded within a cyclopentane ring as rigid counterparts [65]. Owing to their confinement within the ring structure, the amide groups in this system are fixed in cis-form, enabling them to form double H-bonds with a single partner at a time (Fig. 5c). The H-bonding energy of the interaction between amide groups was nearly identical to that observed between vicinal dimethanol groups. The copolymer containing amide groups exhibited a higher Young’s modulus and εbreak than did the copolymer bearing a similar number density of vicinal dimethanol groups. To achieve comparable mechanical elasticity, 1.2 times more vicinal dimethanol groups had to be incorporated into the polymer backbone. When comparing copolymers with similar Young’s moduli, both materials exhibited comparable toughness values when stretched to 400%. However, the copolymer with vicinal dimethanol groups demonstrated superior recoverability in the cyclic tensile test. These findings suggest that flexible H-bonds likely contribute to improved mechanical strength by increasing their number density while retaining dynamic characteristics, such as self-recoverability.

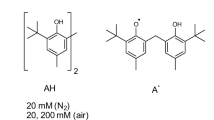

Thiourea

The other flexible H-bond motif that might overcome this trade-off is the thiourea group. Aida and coworkers synthesized self-healing glass made of poly(ether-thiourea) (TUEG3), in which three ethylene-glycol units serve as spacers [66]. Whereas the urea analog with the same spacer (UEG3) is semicrystalline at room temperature because of the ordered H-bond network, TUEG3 is completely amorphous. TUEG3 delivers outstanding mechanical performance, such as σmax ≈ 45 MPa, Young’s modulus ≈ 1.4 GPa, and εbreak ≈ 400%, whereas UEG3 achieves only ≈ 10 MPa, 0.2 GPa, and 13%, respectively. Notably, TUEG3 also self-heals to full strength after ~6 h at 24 °C, which is below the Tg of TUEG3 (27 °C). A high density of urea groups normally promotes a crystalline structure due to their ordered H-bonded network (Fig. 6a), as evidenced by the semicrystalline nature of UEG3. In contrast, thiourea possesses two conformers (trans/trans and cis/trans), as shown in Fig. 6b, which readily interconvert owing to a low rotational barrier [65]. Continuous interconversion of these conformers generates disordered, diverse H-bonding patterns that suppress the formation of crystalline domains, preventing excessive restriction of chain mobility. Thus, the flexible H-bonds between the thiourea groups enhance the dynamic properties, which is consistent with our studies of vicinal diol groups. Similarly, several reports have exploited thiourea to improve the dynamic properties [67,68,69,70]. Fu et al. reported ultrastretchable self-healing poly(dimethylsiloxane) with urea and thiourea groups [68] and a composite consisting of poly(urea-urethane) with partially incorporated thiourea and MXene (two-dimensional transition metal carbide/carbonitride) [69]. Wu et al. reported self-healing glass made of hyperbranched polymers bearing thiocarbamate groups at the chain ends [70]. Overall, the greater conformational freedom of thiourea inhibits ordered stacking, preserves backbone mobility, and promotes dynamic mechanical behavior.

Effects of H-bond flexibility

The studies introduced indicate a clear trend. Because flexible H-bonds can adopt several binding modes, they endow polymers with more dynamic mechanical responses. Similar trends have also been reported in polymer systems crosslinked by reversible metal‒ligand coordination [71]. Bao et al. incorporated either Zn(II) or Ni(II)-2,6-bis((propylimino)methyl)-4-chlorophenol complexes into poly(dimethylsiloxane). Both exhibit similar association constants, but the former demonstrates a rapid ligand exchange process between two coordination modes at the Zn(II) center, whereas the latter shows only single and planar complex modes. The polymer bearing the Zn(II) complex showed a high stretchability of up to 2400%, whereas the Ni(II) counterpart broke at 20%. These findings support the fact that the lability of transient bonds affects the dynamic properties of polymers and align well with observations related to flexible H-bonds. Although the effectiveness of the flexibility of reversible bonds has not yet been fully understood, one plausible origin could be bond-exchange kinetics.

The correlation between the kinetics of reversible bonds (e.g., dissociation rate constant) and the relaxation of polymers has been demonstrated in gel systems with host‒guest interactions, metal‒ligand coordination, DNA strands, and dynamic covalent bonds [72,73,74,75]. Craig and coworkers [76] compared network gels crosslinked via reversible metal‒ligand coordination with Pd(II) and Pt(II), which exhibit similar association constants but have dissociation rate constants that differ by two orders of magnitude. Network gels with slower-exchanging Pt(II) complexes displayed viscosities 80–100 times greater than those with faster-exchanging Pd(II) complexes, along with markedly delayed terminal relaxation. Furthermore, DMA data from the two distinct reversible networks collapsed onto a single master curve when scaled by the respective dissociation rate constants, proving that the dissociation rate constant of the reversible bond governs the relaxation of network gels.

Although these studies employed metal–ligand bonds in gels rather than H-bonds in solvent-free polymers, they provide a compelling kinetic analog. Only a few studies have correlated H-bond kinetics with relaxation behavior in solvent-free polymers, yet the evidence suggests that kinetic parameters can govern mechanical performance. Our group prepared uniform star‒polymer networks in which the arm ends carry amide, hydroxy, urethane, or carboxylic acid groups that associate through H-bonds. DFT calculations revealed that, among them, hydroxy and urethane groups have comparable H-bonding energies [77]. In contrast, the activation energies for backbone relaxation, which are calculated from the terminal relaxation of the polymer, are greater for the urethane system. Both polymers exhibit similar Young’s moduli, but cyclic tensile tests reveal markedly lower hysteresis for the hydroxy-terminated polymer. We attribute this to the lower energy barrier for bond reformation in the hydroxy group, which enables faster recovery of H-bonds during each loading cycle.

Probing H-bond kinetics in solvent-free polymers is intrinsically difficult due to two main reasons: (i) Although indirect methods, such as stress-relaxation measurements, DMA, and broadband dielectric spectroscopy, are available for analyzing the kinetics of polymer chains bearing H-bonding groups, a direct method to observe the kinetics of H-bonding groups alone in solvent-free polymers is still in development. Most spectroscopic techniques capable of capturing fast bond exchange operate in solution, and they rarely monitor solvent-free polymers at sufficiently short time scales. (ii) Determining kinetic parameters requires a well-defined “state jump” (temperature, pH, strain, etc.), yet imposing such perturbations instantaneously and homogeneously throughout solvent-free polymers is challenging. Consequently, past analyses of H-bonded polymer networks have likely focused on thermodynamic aspects, which favor rigid and highly stable H-bonding motifs. A deeper understanding of bond dynamics, however, is essential for further advances in the strength and functionality of polymers. Moreover, the bond dynamics are influenced by the formation of microphase separation and the crystalline phase. As the incorporation of both rigid and flexible H-bonds seems to disrupt an ordered structure formed via rigid H-bonds [68], further discussion on the influence of the structural flexibility of H-bonds on the formation of aggregates and crystalline phases should be addressed. Systematic investigations of flexible H-bonds will clarify how kinetic factors shape macroscopic mechanical properties in contrast to their rigid counterparts and thus represent a highly valuable direction for future research.

Conclusion

This review systematically explores the role of multiple H-bonds in the design of the mechanical and mechanoresponsive properties of polymers. A clear distinction is drawn between rigid H-bonds, characterized by high directionality that often leads to local densification of H-bonds, and flexible H-bonds, distinguished by conformational flexibility and multiple binding modes that enhance dynamic characteristics such as toughness and self-recovery. While rigid H-bonds are invaluable for developing materials with significant strength, they often present challenges concerning processability and the suppression of dynamic responses such as self-healing and self-recovery under ambient conditions. In contrast, flexible H-bonds offer a compelling strategy to address the inherent trade-off between mechanical robustness and dynamic behavior. The ability of these adaptable motifs to maintain network integrity through rapid and versatile bond exchange without the formation of H-bond-rich domains is fundamental to achieving polymers that are simultaneously strong and dynamic. In future research, we will investigate the kinetics of these flexible H-bonds within solvent-free polymer systems. A comprehensive understanding of the interplay among H-bond flexibility, H-bond exchange dynamics, and the resulting macroscopic mechanical properties will be crucial for the rational design of advanced polymeric materials that seamlessly integrate exceptional strength with sophisticated dynamic functionalities, thereby unlocking new applications across a broad spectrum of technological domains.

References

Song P, Wang H. High-performance polymeric materials through hydrogen-bond cross-linking. Adv Mater. 2020;32:1901244. https://doi.org/10.1002/adma.201901244.

Xie Z, Hu B-L, Li R-W, Zhang Q. Hydrogen bonding in self-healing elastomers. ACS Omega. 2021;6:9319–33. https://doi.org/10.1021/acsomega.1c00462.

Kollman PA, Allen LC. Theory of the hydrogen bond. Chem Rev. 1972;72:283–303. https://doi.org/10.1021/cr60277a004.

Gilli G, Gilli P. The nature of the hydrogen bond: outline of a comprehensive hydrogen bond theory. Oxford: Oxford University Press; 2009. https://doi.org/10.1093/acprof:oso/9780199558964.001.0001.

Allen FH, Bird CM, Rowland RS, Raithby PR. Hydrogen-bond acceptor and donor properties of divalent sulfur (Y-S-Z and R-S-H). Acta Cryst B. 1997;53:696–701. https://doi.org/10.1107/S0108768197002644.

Mahmudov KT, Pombeiro AJL. Resonance-assisted hydrogen bonding as a driving force in synthesis and a synthon in the design of materials. Chem Eur J. 2016;22:16356–98. https://doi.org/10.1002/chem.201601766.

Lehn J M. Supramolecular chemistry. Weinheim: VCH; 1995.

Lehn J-M. Supramolecular Chemistry—Scope and Perspectives Molecules, Supermolecules, and Molecular Devices (Nobel Lecture). Angew Chem Int Ed Engl. 1988;27:89–112. https://doi.org/10.1002/anie.198800891.

Lehn J-M. Supramolecular chemistry — molecular information and the design of supramolecular materials. Makromol Chem Macromol Symp. 1993;69:1–17. https://doi.org/10.1002/masy.19930690103.

Kim C, Nakagawa S, Seshimo M, Ejima H, Houjou H, Yoshie N. Tough supramolecular elastomer via entropy-driven hydrogen bonds between vicinal diols. Macromolecules. 2020;53:4121–5. https://doi.org/10.1021/acs.macromol.9b02639.

Ishizaka S, Nakagawa S, Yoshie N. A Minor Difference in the hydrogen-bonding group structure has a major impact on the mechanical properties of polymers. Polym Chem. 2024;15:3967–76. https://doi.org/10.1039/D4PY00580E.

Brienne M-J, Gabard J, Lehn J-M, Stibor I. Macroscopic expression of molecular recognition. supramolecular liquid crystalline phases induced by association of complementary heterocyclic components. J Chem Soc Chem Commun. 1989:1868–70. https://doi.org/10.1039/C39890001868.

Beijer FH, Sijbesma RP, Kooijman H, Spek AL, Meijer EW. Strong dimerization of ureidopyrimidones via quadruple hydrogen bonding. J Am Chem Soc. 1998;120:6761–9. https://doi.org/10.1021/ja974112a.

Hirschberg JHKK, Beijer FH, van Aert HA, Magusin PCMM, Sijbesma RP, Meijer EW. Supramolecular polymers from linear telechelic siloxanes with quadruple-hydrogen-bonded units. Macromolecules. 1999;32:2696–705. https://doi.org/10.1021/ma981950w.

Sijbesma RP, Meijer EW. Quadruple hydrogen bonded systems. Chem Commun. 2003:5-16. https://doi.org/10.1039/B205873C.

Aiswarya S, Awasthi P, Banerjee SS. Self-Healing thermoplastic elastomeric materials: challenges, opportunities and new approaches. Eur Polym J. 2022;181:111658. https://doi.org/10.1016/j.eurpolymj.2022.111658.

Li J, Du X, Zhang A, Wen J, Shuai L, Li S, et al. Hydrogen-bonded polymeric materials with high mechanical properties and high self-healing capacity. Mater Chem Front. 2024;8:3828–58. https://doi.org/10.1039/D4QM00472H.

Verjans J, Hoogenboom R. Supramolecular Polymer Materials Based on Ureidopyrimidinone Quadruple Hydrogen Bonding Units. Prog Polym Sci. 2023;142:101689. https://doi.org/10.1016/j.progpolymsci.2023.101689.

Feldman KE, Kade MJ, Meijer EW, Hawker CJ, Kramer EJ. Model transient networks from strongly hydrogen-bonded polymers. Macromolecules. 2009;42:9072–81. https://doi.org/10.1021/ma901668w.

Lewis CL, Stewart K, Anthamatten M. The influence of hydrogen bonding side-groups on viscoelastic behavior of linear and network polymers. Macromolecules. 2014;47:729–40. https://doi.org/10.1021/ma402368s.

Kushner AM, Gabuchian V, Johnson EG, Guan Z. Biomimetic design of reversibly unfolding cross-linker to enhance mechanical properties of 3D network polymers. J Am Chem Soc. 2007;129:14110–1. https://doi.org/10.1021/ja0742176.

Fang X, Zhang H, Chen Y, Lin Y, Xu Y, Weng W. Biomimetic Modular Polymer with Tough and Stress Sensing Properties. Macromolecules. 2013;46:6566–74. https://doi.org/10.1021/ma4014862.

Li X, Xu W, Yuan W, Liu K, Zhou J, Shan G, et al. Separate Crystallization and Melting of Polymer Blocks and Hydrogen Bonding Units in Double-Crystalline Supramolecular Polymers. Polymer. 2021;222:123670. https://doi.org/10.1016/j.polymer.2021.123670.

Kan L, Zhang P, Jiang H, Zhang S, Liu Z, Zhang X, et al. Microphase Separation of a Quadruple Hydrogen Bonding Supramolecular Polymer: Effect of the Steric Hindrance of the Ureido-Pyrimidone on Their Viscoelasticity. RSC Adv. 2019;9:8905–11. https://doi.org/10.1039/C8RA08861F.

Appel WPJ, Portale G, Wisse E, Dankers PYW, Meijer EW. Aggregation of Ureido-Pyrimidinone Supramolecular Thermoplastic Elastomers into Nanofibers: A Kinetic Analysis. Macromolecules. 2011;44:6776–84. https://doi.org/10.1021/ma201303s.

Sharma AK, Caricato M, Quartarone E, Edizer S, Schieroni AG, Mendichi R, et al. Polystyrene-based self-aggregating polymers based on UPy Units. Polym Bull. 2012;69:911–23. https://doi.org/10.1007/s00289-012-0844-5.

Hohl DK, Ferahian A-C, Montero de Espinosa L, Weder C. Toughening of glassy supramolecular polymer networks. ACS Macro Lett. 2019;8:1484–90. https://doi.org/10.1021/acsmacrolett.9b00710.

Lamers BAG, van der Tol JJB, Vonk KM, de Waal BFM, Palmans ARA, Meijer EW, et al. Consequences of molecular architecture on the supramolecular assembly of discrete block co-oligomers. Macromolecules. 2020;53:10289–98. https://doi.org/10.1021/acs.macromol.0c02237.

Cooper CB, Bao Z. Using periodic dynamic polymers to form supramolecular nanostructures. Acc Mater Res. 2022;3:948–59. https://doi.org/10.1021/accountsmr.2c00101.

Söntjens SHM, Renken RAE, van Gemert GML, Engels TAP, Bosman AW, Janssen HM, et al. Thermoplastic elastomers based on strong and well-defined hydrogen-bonding interactions. Macromolecules. 2008;41:5703–8. https://doi.org/10.1021/ma800744c.

Kautz H, van Beek DJM, Sijbesma RP, Meijer EW. Cooperative end-to-end and lateral hydrogen-bonding motifs in supramolecular thermoplastic elastomers. Macromolecules. 2006;39:4265–7. https://doi.org/10.1021/ma060706z.

van Beek DJM, Spiering AJH, Peters GWM, te Nijenhuis K, Sijbesma RP. Unidirectional dimerization and stacking of ureidopyrimidinone end groups in polycaprolactone supramolecular polymers. Macromolecules. 2007;40:8464–75. https://doi.org/10.1021/ma0712394.

Wietor J-L, van Beek DJM, Peters GW, Mendes E, Sijbesma RP. Effects of branching and crystallization on rheology of polycaprolactone supramolecular polymers with ureidopyrimidinone end groups. Macromolecules. 2011;44:1211–9. https://doi.org/10.1021/ma1026065.

Jangizehi A, Ghaffarian SR, Ahmadi M. Dynamics of entangled supramolecular polymer networks in presence of high-order associations of strong hydrogen bonding groups. Polym Adv Technol. 2018;29:726–35. https://doi.org/10.1002/pat.4178.

Hawke LGD, Ahmadi M, Goldansaz H, van Ruymbeke E. Viscoelastic Properties of Linear Associating Poly(n-Butyl Acrylate) Chains. J Rheol. 2016;60:297–310. https://doi.org/10.1122/1.4942231.

Amin D, Likhtman AE, Wang Z. Dynamics in supramolecular polymer networks formed by associating telechelic chains. Macromolecules. 2016;49:7510–24. https://doi.org/10.1021/acs.macromol.6b00561.

Jangizehi A, Ahmadi M, Seiffert S. Emergence, evidence, and effect of junction clustering in supramolecular polymer materials. Mater Adv. 2021;2:1425–53. https://doi.org/10.1039/D0MA00795A.

Golkaram M, Loos K. A critical approach to polymer dynamics in supramolecular polymers. Macromolecules. 2019;52:9427–44. https://doi.org/10.1021/acs.macromol.9b02085.

Yoshida S, Ejima H, Yoshie N. Tough elastomers with superior self-recoverability induced by bioinspired multiphase design. Adv Funct Mater. 2017;27:1701670. https://doi.org/10.1002/adfm.201701670.

Yang H, Xi W. Nucleobase-containing polymers: structure, synthesis, and applications. Polymers. 2017;9:666 https://doi.org/10.3390/polym9120666.

Liu B, Spiering GA, McDonough RK, Moore RB, Long TE. Guanine and cytosine-containing acrylic supramolecular networks. J Polym Sci. 2024;62:733–42. https://doi.org/10.1002/pol.20230320.

Chen L, Peng H, Wei Y, Wang X, Jin Y, Liu H, et al. Self-Healing Properties of PDMS Elastomers via guanine and cytosine base pairs. Macromol Chem Phys. 2019;220:1900280. https://doi.org/10.1002/macp.201900280.

Chang SK, Hamilton AD. Molecular recognition of biologically interesting substrates: synthesis of an artificial receptor for barbiturates employing six hydrogen bonds. J Am Chem Soc. 1988;110:1318–9. https://doi.org/10.1021/ja00212a065.

Dirksen A, Hahn U, Schwanke F, Nieger M, Reek JNH, Vögtle F, et al. Multiple Recognition of Barbiturate Guests by “Hamilton-Receptor”-Functionalized Dendrimers. Chem Eur J. 2004;10:2036–47. https://doi.org/10.1002/chem.200305461.

Zeng H, Miller RS, Flowers RA, Gong B. A Highly Stable, Six-Hydrogen-bonded molecular duplex. J Am Chem Soc. 2000;122:2635–44. https://doi.org/10.1021/ja9942742.

Corbin PS, Zimmerman SC. Complexation-induced unfolding of heterocyclic ureas: a hydrogen-bonded, sheetlike heterodimer. J Am Chem Soc. 2000;122:3779–80. https://doi.org/10.1021/ja992830m.

Burd C, Weck M. Self-sorting in polymers. Macromolecules. 2005;38:7225–30. https://doi.org/10.1021/ma050755w.

Kolomiets E, Buhler E, Candau SJ, Lehn J-M. Structure and properties of supramolecular polymers generated from heterocomplementary monomers linked through sextuple hydrogen-bonding arrays. Macromolecules. 2006;39:1173–81. https://doi.org/10.1021/ma0523522.

Zou Y, Ji X, Cai J, Yuan T, Stanton DJ, Lin Y-H, et al. Synthesis and solution processing of a hydrogen-bonded ladder polymer. Chem. 2017;2:139–52. https://doi.org/10.1016/j.chempr.2016.12.008.

Tellers J, Canossa S, Pinalli R, Soliman M, Vachon J, Dalcanale E. Dynamic cross-linking of polyethylene via sextuple hydrogen bonding array. Macromolecules. 2018;51:7680–91. https://doi.org/10.1021/acs.macromol.8b01715.

Pérez-Folch J, Subirana JA, Aymami J. Polar Structure of N,N′-Dimethylurea Crystals. J Chem Crystallogr. 1997;27:367–9. https://doi.org/10.1007/BF02576570.

Versteegen RM, Kleppinger R, Sijbesma RP, Meijer EW. Properties and morphology of segmented copoly(Ether Urea)s with Uniform Hard Segments. Macromolecules. 2006;39:772–83. https://doi.org/10.1021/ma051874e.

Grujicic M, Snipes J, Ramaswami S, Galgalikar R, Runt J, Tarter J. Molecular- and domain-level microstructure-dependent material model for nano-segregated polyurea. Multidiscip Model Mater Struct. 2013;9:548–78. https://doi.org/10.1108/MMMS-10-2012-0014.

Tyagi D, Yílgör I, McGrath JE, Wilkes GL. Segmented organosiloxane copolymers: 2 thermal and mechanical properties of siloxane—urea copolymers. Polymer. 1984;25:1807–16. https://doi.org/10.1016/0032-3861(84)90255-6.

Cooper CB, Nikzad S, Yan H, Ochiai Y, Lai J-C, Yu Z, et al. High energy density shape memory polymers using strain-induced supramolecular nanostructures. ACS Cent Sci. 2021;7:1657–67. https://doi.org/10.1021/acscentsci.1c00829.

Wu P, Cheng H, Wang Y, Shi R, Wu Z, Arai M, et al. New Kind of thermoplastic polyurea elastomers synthesized from CO2 and with self-healing properties. ACS Sustain Chem Eng. 2020;8:12677–85. https://doi.org/10.1021/acssuschemeng.0c04732.

Colombani O, Barioz C, Bouteiller L, Chanéac C, Fompérie L, Lortie F, et al. Attempt toward 1D Cross-linked thermoplastic elastomers: structure and mechanical properties of a new system. Macromolecules. 2005;38:1752–9. https://doi.org/10.1021/ma048006m.

Korley LTJ, Pate BD, Thomas EL, Hammond PT. Effect of the degree of soft and hard segment ordering on the morphology and mechanical behavior of semicrystalline segmented polyurethanes. Polymer. 2006;47:3073–82. https://doi.org/10.1016/j.polymer.2006.02.093.

Cooper CB, Kang J, Yin Y, Yu Z, Wu H-C, Nikzad S, et al. Multivalent assembly of flexible polymer chains into supramolecular nanofibers. J Am Chem Soc. 2020;142:16814–24. https://doi.org/10.1021/jacs.0c07651.

Wan D, Jiang Q, Song Y, Pan J, Qi T, Li GL. Biomimetic tough self-healing polymers enhanced by crystallization nanostructures. ACS Appl Polym Mater. 2020;2:879–86. https://doi.org/10.1021/acsapm.9b01094.

Mondal S, Lessard JJ, Meena CL, Sanjayan GJ, Sumerlin BS. Janus cross-links in supramolecular networks. J Am Chem Soc. 2022;144:845–53. https://doi.org/10.1021/jacs.1c10606.

Meena CL, Singh D, Kizhakeetil B, Prasad M, George M, Tothadi S, et al. Triazine-Based Janus G–C Nucleobase as a building block for self-assembly, peptide nucleic acids, and smart polymers. J Org Chem. 2021;86:3186–95. https://doi.org/10.1021/acs.joc.0c02530.

Li T, Zhang C, Xie Z, Xu J, Guo B-H. A multi-scale investigation on effects of hydrogen bonding on micro-structure and macro-properties in a polyurea. Polymer. 2018;145:261–71. https://doi.org/10.1016/j.polymer.2018.05.003.

Nakagawa S, Xia J, Yoshie N. Quantifying the effects of cooperative hydrogen bonds between vicinal diols on polymer dynamics. Soft Matter. 2022;18:1275–86. https://doi.org/10.1039/D1SM01747K.

Custelcean R. Crystal engineering with urea and thiourea hydrogen-bonding groups. Chem Commun. 2008:295–307. https://doi.org/10.1039/B708921J.

Yanagisawa Y, Nan Y, Okuro K, Aida T. Mechanically robust, readily repairable polymers via tailored noncovalent cross-linking. Science. 2018;359:72–6. https://doi.org/10.1126/science.aam7588.

Fujisawa Y, Asano A, Itoh Y, Aida T. Mechanically robust, self-healable polymers usable under high humidity: humidity-tolerant noncovalent cross-linking strategy. J Am Chem Soc. 2021;143:15279–85. https://doi.org/10.1021/jacs.1c06494.

Xu J, Chen P, Wu J, Hu P, Fu Y, Jiang W, et al. Notch-Insensitive, ultrastretchable, efficient self-healing supramolecular polymers constructed from multiphase active hydrogen bonds for electronic applications. Chem Mater. 2019;31:7951–61. https://doi.org/10.1021/acs.chemmater.9b02136.

Xu J, Li Y, Liu T, Wang D, Sun F, Hu P, et al. Room-Temperature self-healing soft composite network with unprecedented crack propagation resistance enabled by a supramolecular assembled lamellar structure. Adv Mater. 2023;35:2300937. https://doi.org/10.1002/adma.202300937.

Li W, Cai M, Yao Y, Huang Y, Wu H, Wu W, et al. Moisture-Resistant and room-temperature self-healing glassy plastic with thiocarbonyl and hyperbranched structure. J Mater Chem A. 2024;12:23638–46. https://doi.org/10.1039/D4TA04006F.

Lai J-C, Jia X-Y, Wang D-P, Deng Y-B, Zheng P, Li C-H, et al. Thermodynamically stable whilst kinetically labile coordination bonds lead to strong and tough self-healing polymers. Nat Commun. 2019;10:1164. https://doi.org/10.1038/s41467-019-09130-z.

Huang Z, Chen X, O’Neill SJK, Wu G, Whitaker DJ, Li J, et al. Highly Compressible glass-like supramolecular polymer networks. Nat Mater. 2022;21:103–9. https://doi.org/10.1038/s41563-021-01124-x.

Chen H, Zhang J, Yu W, Cao Y, Cao Z, Tan Y. Control Viscoelasticity of polymer networks with crosslinks of superposed fast and slow dynamics. Angew Chem Int Ed. 2021;60:22332–8. https://doi.org/10.1002/anie.202105112.

Ohira M, Katashima T, Naito M, Aoki D, Yoshikawa Y, Iwase H, et al. Star-Polymer–DNA Gels showing highly predictable and tunable mechanical responses. Adv Mater. 2022;34:2108818. https://doi.org/10.1002/adma.202108818.

Katashima T, Kudo R, Naito M, Nagatoishi S, Miyata K, Chung U, et al. Experimental comparison of bond lifetime and viscoelastic relaxation in transient networks with well-controlled structures. ACS Macro Lett. 2022;11:753–9. https://doi.org/10.1021/acsmacrolett.2c00152.

Yount WC, Loveless DM, Craig SL. Small-Molecule Dynamics and mechanisms underlying the macroscopic mechanical properties of coordinatively cross-linked polymer networks. J Am Chem Soc. 2005;127:14488–96. https://doi.org/10.1021/ja054298a.

Huang X, Nakagawa S, Houjou H, Yoshie N. Insights into the Role of Hydrogen Bonds on the Mechanical Properties of Polymer Networks. Macromolecules. 2021;54:4070–80. https://doi.org/10.1021/acs.macromol.1c00120.

Tajima R, Nakagawa S, Yoshie N. Correlation between structural flexibility of h-bonding motifs and mechanical properties of dynamic crosslinked polymers. Macromolecules. 2025;58:8923–8933. https://doi.org/10.1021/acs.macromol.5c01025.

Funding

Open Access funding provided by The University of Tokyo.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tajima, R., Nakagawa, S. & Yoshie, N. Multiple hydrogen bonds as tools to enhance the mechanical and mechanoresponsive properties of polymers. Polym J 58, 1–13 (2026). https://doi.org/10.1038/s41428-025-01098-6

Received:

Revised:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41428-025-01098-6