Abstract

Exploring efficient electrocatalysts with fundamental understanding of the reaction mechanism is imperative in CO2 electroreduction. However, the impact of sluggish water dissociation as proton source and the surface species in reaction are still unclear. Herein, we report a strategy of promoting protonation in CO2 electroreduction by implementing oxygen vacancy engineering on Bi2O2CO3 over which high Faradaic efficiency of formate (above 90%) and large partial current density (162 mA cm−2) are achieved. Systematic study reveals that the production rate of formate is mainly hampered by water dissociation, while the introduction of oxygen vacancy accelerates water dissociation kinetics by strengthening hydroxyl adsorption and reduces the energetic span of CO2 electroreduction. Moreover, CO3* involved in formate formation as the key surface species is clearly identified by electron spin resonance measurements and designed in situ Raman spectroscopy study combined with isotopic labelling. Coupled with photovoltaic device, the solar to formate energy conversion efficiency reaches as high as 13.3%.

Similar content being viewed by others

Introduction

Electrochemical CO2 reduction (CO2RR) to valued chemicals coupled with renewable energy power generation is considered as a promising and elegant step in carbon capture, utilization and storage (CCUS) technologies1,2. Among CO2RR products, formate with high energy density is regarded as the most cost-effective and commercially profitable product based on technoeconomic analysis, which has been attracting great attentions3,4,5. In pursuit of the commercial goal, developing efficient catalysts with high selectivity for CO2RR to formate is prerequisite. Though great endeavors have been undertaken, the catalytic performance is still unsatisfactory6,7. Thus, developing robust strategies to design efficient electrocatalysts and understanding the reaction route are imperative tasks.

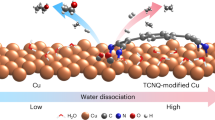

The process of CO2 electroreduction to hydrocarbons involves multistep proton-coupled electron transfer process and a series of adsorbed species. Water as proton source has been clarified while the sluggish water dissociation which will seriously hinder the overall reaction rates of CO2RR is commonly overlooked so far8,9,10,11. Moreover, the local alkaline condition in CO2RR caused by proton depletion and slow H+ diffusion will further elevate the barrier of H2O dissociation12,13. From this perspective, promoting water dissociation through rational material design is attractive and promising to achieve efficient CO2RR, which is preliminarily supported by recent studies14,15,16. Nevertheless, exploring intrinsic active sites of electrocatalysts instead of extra additions for promoting water dissociation and understanding the mechanism of water dissociation in CO2RR further are highly challenging but desirable.

For electrode materials, metal oxide attracts broad attentions due to high selectivity and low overpotentials which are the crucial parameters for commercial scale in CO2RR to formate17,18,19,20,21,22,23. Moreover, recent studies demonstrate that surface metal oxide over metal electrocatalysts largely promotes the catalytic performance in CO2RR, which highlights the critical role of metal oxide in developing efficient catalyst and excites the exploration of mechanism behind24,25. As a universal intrinsic defect, oxygen vacancy (VO) in metal oxide is commonly considered to modify metal active site, while the role of VO itself is neglected generally26,27,28,29,30,31. Yet VO possesses strong oxygen affinity and fast interaction with water, which indicates it can serve as promising active site in tuning the energy barrier of water dissociation32,33. Thus, it is anticipated that constructing VO might enable enhancing CO2 performance by relieving the effect of sluggish H2O dissociation and optimizing active sites, which is of great significance in offering a new avenue in efficient electrocatalyst exploration for CO2RR and deeper understanding the role of water dissociation in the whole reaction. Another main obstacle in the investigation on complex CO2RR reaction route is the identification of initial surface species. Previous studies propose that CO2 tends to adsorb on oxygen site in metal oxide to form CO3 and participates in sequent reduction process as the key surface species, which is considered to be the origin of attractive performance for metal oxide electrocatalysts34,35,36,37,38. However, compelling evidence on the participation of CO3 is still in absence due to the complicated environment in CO2RR and ambiguous identification of species.

Therefore, Bi2O2CO3 (BOC) is selected here based on the following two considerations: (i) there are abundant Bi-O bonds for implementing VO engineering to promote water dissociation in CO2RR; (ii) the natural carbonate species in BOC is favorable to clarify whether CO3 is involved in CO2RR with the help of isotopic labeling. Through introducing VO, the production rate of formate reaches 3.0 mmol h−1 and the high Faradaic efficiency of formate keeps well over a wide potential window. Dynamic study and DFT calculations reveal the crucial role of water dissociation in promoting CO2RR kinetics while the introduction of VO expedites the water dissociation kinetics through improving OH* adsorption which notably reduces the energetic span of formate formation. Theoretical analysis shows CO3* participates in the formation of formate as the key surface species, which is demonstrated clearly through electron spin resonance (EPR) measurements and in situ Raman spectroscopy study combined with isotopic labelling. Finally, full-cell electrocatalysis coupled with solar cell was constructed and achieves the solar to formate energy conversion efficiency of 13.3%.

Results

Material synthesis and the identification of VO

The Bi2O2CO3 samples supported on carbon paper were prepared by electrodeposition method. VO enginneering was achieved by tuning the proportion of water in the mixed electrolyte with ethylene glycol, and a series of samples denoted as BOC-1, BOC-2, BOC-3 and BOC-4 respectively, were obatined39. The tetragonal structure of Bi2O2CO3 is clearly identified from X-ray diffraction (XRD) patterns for the synthesized samples (JCDPS 41-1488, Supplementary Fig. 1). As revealed by scanning electron microscopy (SEM), the BOC samples are grown on carbon paper vertically, exhibiting stacked and curved nanosheet morphology (Fig. 1a and Supplementary Fig. 2). Transmission electron microscope (TEM) images show that the average lateral size of BOC nanosheets ranges from 100 to 200 nm (Fig. 1b and Supplementary Fig. 3). A lattice distance of 0.275 nm corresponding to (110) plane is clearly discerned in high-resolution TEM (HRTEM) images (Fig. 1c), while the selected area electron diffraction (SAED) patterns display that the BOC nanosheets are consisted of individual single crystalline nanosheet (inset in Fig. 1c and Supplementary Fig. 3d). Notably, variation and distortion in lattice fringes are preliminarily observed, indicating the presence of defects which might be VO (Supplementary Fig. 4).

a SEM, (b) TEM and (c) HRTEM images of BOC-2. d, e Atomic-resolution HAADF-STEM images of BOC-2, where the circled areas show the lattice disorders. The scale bar is 2 nm in (d) and 0.5 nm in (e), respectively. f ABF-STEM image of BOC-2, where the pink and blue circles represent oxygen and bismuth atoms, respectively. The scale bar is 0.5 nm. g Intensity profile corresponding to the black dashed line in (f), as directed by the arrow. h EPR spectra of all samples, where the g value of 2.002 is the characteristic signal of VO. i Fourier transform of Bi L3 edge EXAFS data recorded at R space. j Normalized XANES spectra of Bi foil, BOC-1, BOC-2 and BOC-3. Inset: the magnified area marked by red line. k XPS spectra of BOC-C, BOC-1, BOC-2, BOC-3 and BOC-4 on Bi 4 f, where the blue and pink area represent Bi3+ and Bi(3−x)+, respectively.

Aberration-corrected scanning transmission electron microscopy (STEM) was conducted to disclose the fine structure and verify the defects. Local lattice disorders in nanosheets are clearly detected in high-angle annular dark-field (HAADF) images (Fig. 1d, e and Supplementary Fig. 5), owing to the unsaturated coordination of metal atoms40,41. With the help of angular bright-field STEM (ABF-STEM), the nonperiodic intensity of oxygen can be discerned, demonstrating the presence of VO as marked in Fig. 1f, g and Supplementary Fig. 6. The regular variation of the sharp signal intensity with g value of 2.002 in EPR characterization not only further clarifies the presence of VO but also indicates that VO concentration increases in the sequence of BOC-1, BOC-2, BOC-3 and BOC-4 (Fig. 1h)42. Commercial BOC (denoted as BOC-C) was adopted for comparison, and the VO concentration is much lower than that of BOC-1 as suggested by the weak EPR signal. The VO concentration was also quantified from EPR while atomic VO contents are estimated to be 0.031%, 0.044%, 0.060% and 0.076% for BOC-1, BOC-2, BOC-3 and BOC-4, respectively (Supplementary Table 1)43. The location of VO is disclosed from extended X-ray absorption fine structure (EXAFS) spectroscopy, and two peaks at around 1.6 Å and 3.5 Å corresponding to the scattering path of Bi-O and Bi-O-C are found, respectively (Fig. 1i, Supplementary Fig. 7 and Supplementary Table 2). The intensity of Bi-O manifests a decrease for BOC with more VO contents while there is no obvious difference in that of Bi-O-C, which implies that VO mainly exists in Bi-O-Bi structure44. X-ray absorption near edge structure (XANES) region (Fig. 1j) shows that the absorption edge for BOC with VO just slightly shifts to lower energy, which is in agreement with XPS spectra of Bi 4 f and indicates the presence of low chemical state Bi induced by VO (Fig. 1k)45. Based on the characterizations above, it can be concluded that the BOC with different contents of VO is successfully prepared.

The evaluation of CO2RR performance

Electrocatalytic CO2 reduction was first evaluated in the traditional H-type cell using 0.5 M KHCO3 as electrolyte. The linear sweep voltammetry (LSV) curves of all samples in CO2-saturated electrolyte show that BOC-2 exhibits superior CO2RR performance with smaller potentials and larger current density (Fig. 2a). Then, the selectivity and activity as function of potentials were testified via chronoamperometry (Supplementary Fig. 8). For BOC-C, the Faradaic efficiency of formate (FEformate) is 7.6% (Fig. 2b) with the partial current density of formate (jformate) of 0.04 mA cm−2 at −0.68 V vs. RHE (unless mentioned specifically, all potentials referred are versus reversible hydrogen electrode hereafter), which is consistent with early report28. With the introduction of VO, the FEformate increases remarkably to 90.2% at −0.68 V while the jformate raises to 16.5 mA cm−2 with the increase of VO concentration up to 0.044 at.%, which demonstrates that the introduction of VO can enhance the selectivity and activity of CO2RR to formate. At −1.08 V, the maximum jformate of BOC with VO is three times as high as that of BOC-C (Fig. 2c). The further increase of VO concentration makes the FEformate and production rate of formate drop accompanied with notable FEhydrogen (Fig. 2d and Supplementary Fig. 9). Nevertheless, the performance of BOC samples with excessive VO contents can be elevated through filling VO partially, which was achieved through thermal treatment in air at 200°C (these annealed samples are denoted as BOC-A) with the maintenance of phase structures (Supplementary Fig. 10). As compared with original BOC, the decrease of VO concentration in all BOC-A samples is verified by EPR measurement and the signal of BOC-1-A is hardly to be discerned, indicating the VO is almost eliminated in BOC-1-A as shown in Supplementary Fig. 11. For CO2RR evaluated in the same set-up (Supplementary Fig. 12 and Supplementary Fig. 13), both the FEformate and current density are promoted for BOC-3-A and BOC-4-A with reduced VO concentration (Fig. 2e and Supplementary Fig. 14). In particular, the production rate of formate for BOC-4-A is 2.8 times higher than that of initial BOC-4 without annealing (Fig. 2d, black line). These experiments establish an obvious correlation between VO and formate production, which proves that promoting CO2RR to formate over BOC can be achieved through VO engineering.

a LSV curves of BOC-C, BOC-1, BOC-2, BOC-3 and BOC-4 in Ar-saturated (dashed lines) and CO2-saturated (solid lines) 0.5 M KHCO3 solutions. b FEformate and jformate of BOC with differnt VO concentrations at −0.68 V. c jformate on different samples as function of applied potentials. d The production rate of formate for all samples at −0.88 V. The red and black lines represent samples before and after thermal treatment, respectively. e FEformate of all samples before and after thermal treament at −0.88 V. f The FE of all products and current density for BOC-2 at different applied potentials in H-cell. The error bars represent the standard deviation of three independent experiments.

BOC-2 with the superior performance of CO2RR is studied further at different potentials. The FEformate is 70% at −0.58 V initially and increases rapidly to 94% with current density of 34.6 mA cm−2 at −0.88 V while HER is almost negligible, outperforming most of reported Bi-based catalysts (Fig. 2f and Supplementary Table 3). Moreover, the FEformate for BOC-2 is above 80% at a wide potential window (−0.68 V to −1.08 V) despite slight decay at more negative potentials due to the restriction of CO2 solubility and mass transfer. During 11 h operation in H-cell, the FEformate above 90% for BOC-2 could be maintained with formate yield reaching 6.5 mmol (Supplementary Fig. 15). Meanwhile, there is no obvious change in phase structure, morphology and valance state, which demonstrates the stability of BOC-2 (Supplementary Fig. 16). To relieve the limitation on mass transfer and pursue commercial current density, BOC-2 was further integrated into gas diffusion electrode (GDE) and evaluated in flow-cell system46. The jformate of BOC-2 is 1.6 times as high as that of BOC-C at −1.68 V while the turnover frequency can be up to 0.72 s−1 at 200 mA cm−2, which demonstrates the activity enhancement through introducing VO can also be achieved in flow-cell system (Supplementary Fig. 17 and Supplementary Table 4). In addition, a stable FEformate of 80% at large current density of 200 mA cm−2 can be observed during 15 h, which indicates the potential for practical application (Supplementary Fig. 18). Even though Bi3+ could be reduced at negative potentials in thermodynamics, the good stability of BOC can be explained by the spontaneous CO2 adsorption and high local pH where the oxide state of Bi is stable24,28,47,48. Moreover, 13CO2 labeling experiment was carried out. The proton doublet resulting from H-13C coupling and H13COO− is observed in 1H NMR and 13C NMR, respectively (Supplementary Fig. 19), demonstrating that the produced formate derives from CO249. Trace amount of formate produced in Ar-saturated KHCO3 should be attributed to slight CO2 decomposed by HCO3− in electrolyte (Supplementary Fig. 20). These results reveal that, through VO engineering, BOC-2 demonstrates efficient CO2RR to formate with high selectivity, large current density and stability.

Investigation about the effect of VO in CO2RR

To clarify the intrinsic activity of BOC with VO, the jformate of different samples were normalized by specific surface area (Supplementary Figs. 21, 22) and electrochemical surface area, respectively (Supplementary Fig. 23 and Supplementary Table 5). It can be found that the introduction of VO notably increases the intrinsic activity and the degree of this enhancement is closely related with the VO contents (Supplementary Fig. 24). Tafel plots were then obtained at sufficient low overpotential to investigate the role of VO in the kinetics of CO2RR. As can be seen from Fig. 3a, BOC-2 shows smaller Tafel slope among all catalysts, indicating that the introduction of VO favors the kinetics of CO2RR50. It’s noteworthy that the value of Tafel slope is much larger than the reported typical value, which indicates that the chemical step precedes the electron transfer or the chemical step is rate-limiting. The detailed investigation of the reaction mechanism will be discussed later. Next, electrochemical impendence spectroscopy (EIS) was carried out and fitted by equivalent circuit to investigate the electrochemical interface properties51,52. With the introduction of VO, the charge transfer can be accelerated, which is beneficial for conductivity and reducing the overpotential (Supplementary Fig. 25, Supplementary Table 6). Besides, the resistance induced by water and hydroxyl adsorption (Rp) is related with VO concentration, implying that VO might affect the proton transfer by changing water and hydroxyl adsorption. Before conducting the investigation on proton transfer further, the proton source was clarified through isotopic labelling of D2O. The product in KHCO3-D2O is almost DCOO− while the signal of HCOO− in 1H NMR is negligible, which demonstrates that the dominate source of proton is from water instead of HCO3− (Supplementary Fig. 26). Subsequently, kinetic isotopic effect (KIE) experiments were carried out by varying H2O and D2O in electrolyte to study the effect of water dissociation and proton transfer in CO2RR (Fig. 3b and Supplementary Fig. 27). The KIE value is calculated by the ratio of formate production rate in KHCO3-H2O and KHCO3-D2O. In general, KIE value is >1 if water dissociation is involved in rate-limiting process of formate production due to the proton tunneling effect, while the higher KIE value indicates the greater impact of water dissociation in CO2RR (Supplementary Fig. 28 and detailed discussion can be seen in Method section)53. For BOC-C, the KIE value was determined to be 2.34, suggesting the reaction rate of CO2RR is predominately limited by water dissociation (Fig. 3c). With the introduction of VO, the KIE value of BOC-2 drops rapidly to 1.19, which reveals that VO can remarkably promote water dissociation and subsequently enhance CO2RR activity. Nevertheless, the KIE value of BOC-3 and BOC-4 with higher VO concentration increase again, indicating that excessive VO is unbeneficial to water activation. Interestingly, the ability of water dissociation for these two samples could be elevated by partially filling VO (Supplementary Fig. 29), which can be seen from the lower KIE value and enhanced activity in CO2RR (see BOC-3-A and BOC-4-A). These results agree well with the formate production rates dissused above and a strong correlation among VO, water dissociation ability and formate production is identified. Besides, less enhancement in activity induced by cations can be observed on BOC-2 as compared with that on BOC-C, indicating the intrinsic faster water dissociation kinetics of BOC-2 (Supplementary Fig. 30)54. The role of VO in water dissociation was further clarified through varying local pH achieved by using three electrolytes with different buffer capacity (K2HPO4, K2CO3 and K2SO4). It has been demonstrated that the local pH value increased in the order of K2HPO4, K2CO3 and K2SO4, while water dissociation becomes more difficult at high pH value15. The same concentations of cations among those three kinds of electrolyte can exlude the effect of cations in CO2RR55,56. As can be seen from Fig. 3d and Supplementary Fig. 31, the production rate of formate for BOC-2 is much higher than that of other samples at high local pH values, which indicates the beneficial effect of VO. Moreover, it can be found that BOC-2 shows superior activity and selectivity than BOC-C in flow-cell at large current density where water dissociation is more difficult due to the high local pH induced by rapid protons depletion (Supplementary Fig. 17c, d). So, it can be concluded that water dissociation is involved in the rate-determining step for CO2RR to formate, and the presence of VO remarkably boosts the performance of CO2RR by accelerating H2O dissociation.

a Tafel plots of different samples. b The production rates of formate in 0.5 M KHCO3-H2O (blue column) and 0.5 M KHCO3-D2O (purple column). The columns with shadows represent samples after thermal treatment. c The KIE value of H/D for different samples. The red and black lines represent samples before and after annealing, respectively. d The production rates of formate over BOC-1, BOC-2, BOC-3 and BOC-4 in K2HPO4, K2CO3 and K2SO4 electrolytes. The error bars represent the standard deviation of three independent experiments.

The investigation of reaction pathway and the role of water dissociation in CO2RR

Density functional theory (DFT) simulation was carried out to gain an deeper understanding of the reaction route and the promoting effect of VO. Computational hydrogen electrode (CHE) method was used to get the reaction free energy diagram (FED) of CO2RR57,58, while the ″virtual energetic span″ (denoted as δEv) was introduced as the activity determining term59. Subsequent to CO2 adsorption (CO2 + O* → CO3*, step I), the formation of OCHO* is a relatively complex process at least involving electron transfer, C-O cracking and protonation. More importantly, as demonstrated above, water dissociation plays a crucial role in protonation. So, it is reasonable and necessary to divide the process of OCHO* formation into elemental steps involving water dissociation as follows:

H2O (aq)+*→H2O* step II

CO3*+H2O*→OCHO-OH*+O* step III

OH*+e→OH− step IV

Take consideration of the two-dimensional property of BOC, both the edge and terrace sites are first investigated, and the FEDs along the whole process of CO2RR to formate are plotted in Fig. 4a and Supplementary Fig. 32. The δEv of edge sites is much lower than that of terrace sites (0.96 eV vs. 2.35 eV), which indicates that CO2RR proceeds preferentially at edge sites. Meanwhile, it can be noted that the Step III is the main uphill barrier for BOC, which involves H-OH cleavage in water dissociation (H2O* → OH*), C-O cracking and C-H formation (Fig. 4b, c). With the introduction of VO (BOC-VO−1, Fig. 4d), the energy barrrier of step III (EIII) reduces siginificantly compared with that of normal BOC (0.70 eV vs. 1.66 eV). Correspondingly, the BOC with VO possesses much smaller δEv (0.61 eV) relative to normal BOC (0.96 eV), which indicates that the introduction of VO promotes CO2RR by reducing energetic span (Supplementary Fig. 33). In order to figure out the rate-limiting process in step III, the chemical potential difference between H2O* and OH* (denoted as ΔμOH−w), reflecting water dissociation ability, is obtained and plotted with EIII. As can be deduced from Fig. 4e, the energy variation of the step III is mainly from ΔμOH−w, which suggests that the formate production rate is dominantly restricted by the sluggish water dissociation. While the introduction of VO accelerates the kinetics of water dissociation by notably reducing ΔμOH−w, which largely decreases the energy barrier in the formation of OCHO*. These results are in good agreement with KIE experiments discussed above. On the other hand, the accelerated water dissociation kinetics has minor effects on HER due to the poor H* adsorption on BOC (Supplementary Fig. 34).

a The key intermediates during CO2RR to formate. Colours in the models: blue balls are bismuth (Bi); purple balls are oxygen (O); green balls are carbon (C); white balls are hydrogen (H); red balls are added oxygen (Oadd); grey balls are added carbon (Cadd); brown balls are added hydrogen (Hadd). b The free energy plots for BOC with and without VO along the reaction pathway. c, d The basic computed models of normal BOC and BOC with VO on surface (BOC-VO−1), respectively. e The free energy of step III, ΔμOH−w, the adsorption energy of OH* and the adsorption energy of H2O* for BOC with different VO contents. f LSV curves of BOC with different VO concentrations in Ar-saturated 0.1 M KOH.

To clarify the cause of decreased ΔμOH−w, the adsorption energy of OH* and H2O* are plotted at the bottom of Fig. 4e, respectively. The introduction of VO significantly reduces the adsorption energy of OH*, i.e., enhancing OH* adsorption, while the change in the energy of water adsorption is limited. That is, the reduced ΔμOH−w is predominately originated from the strengthened OH* adsorption induced by the introduction of VO, which leads to the decrease of ΔμOH−w and easier CO2 protonation. This might be caused by the speculation that OH* formed in step III can alternatively adsorb on the VO site while the vacancy is not large enough in volume to accommodate H2O*. Based on BOC-VO−1, VO was further introduced into the subsurface to increase the VO contents (Supplementary Fig. 35). Excessive VO makes the barrier in step III rise again with relatively weak OH* adsorption, which should be due to the structure distortion and lower O coordinate numbers of Bi induced by more VO. To verify the correlation of OH* adsorption energy and VO in experiments further, OH* adsorption over BOC with differnet VO contents were investigated through conducting LSV in Ar-saturated 0.1 M KOH solutions60. As can be seen from Fig. 4f, BOC with VO exhibits more positive peak compared with BOC-C, which implies that the introduction of VO strengthens the OH* adsorption indeed. These simulation and experimental results reveal that the introduction of VO remarkably promotes water dissociation by strengthening the adsorption of OH*, which reduces the energetic span of the key intermediate of OCHO* formation and ultimately boosts the efficiency of CO2RR to formate.

For CO2 adsorption and forming surface species, DFT calculations show that intrinsic CO32− in BOC will spontaneously undergo charge rearrangement and be in-situ transformed into CO3* which participates in the sequent formate production with a O* site left (Supplementary Fig. 36). Then, CO2 prefers to adsorb on this oxygen site to form CO3* species again than adsorb on bismuth. The charge distribution of CO3* based on Bader charge analysis indicates the CO3* is in the form of radical with an unpaired electron (Supplementary Fig. 37). To clarify the presence of CO3*, EPR measurements were first performed with the trapping agent of 5,5-dimethyl-1-pyrroline-N-oxide (DMPO). In the absence of CO2, there is just the nonet ascribed to H* radicals (hyperfine splitting constants, AN = 1.65 mT, AH = 2.25 mT) which are originated from water dissociation (Fig. 5a)61. With the feed of CO2, the characteristic sextet of carbon radicals can be found (AN = 1.59 mT, AH = 2.28 mT), which agrees well with theoretical analysis62. These observations imply the presence of CO3* during CO2RR process.

Then, in-situ Raman measurements were implemented to probe the related species directly along the reaction route. For the intrinsic Raman spectrum of BOC, the bands at 155 cm−1 and 367 cm−1 are the characteristic vibrational modes of Bi=O bond lattice in [Bi2O2]2+. The peak centered at 1069 cm−1 is attributed to the typical C-O stretching of carbonate in Bi2O2CO3 (Supplementary Fig. 38)63. At open circuit voltage (OCV), this signal blueshifts to the center of 1067 cm−1, which indicates the transformation of CO3* from intrinsic CO32− at least occurs under OCV in consideration of DFT calculations and EPR results64. Similar results are obtained in the electrolyte of K2HPO4, which excludes the interference of HCO3− and CO32− in electrolyte. Then, the Raman spectra of BOC-2 were collected at different potentials (from −0.58 V to −1.08 V) and all these peaks could be kept well without the appearance of metallic Bi signals, demonstrating the stability of BOC-2 under a series of negative potentials (Fig. 5b). Specially, the signal at 1364 cm−1 assigned to the O-C-O symmetric vibration of OCHO* can be observed at −0.78 V while the intensity of OCHO* increases continuously with more negative potentials applied, indicating that OCHO* is the intermediate in formate formation65,66. The observation of OCHO* intermediate provides a strong support for the reaction mechanism proposed in our DFT calculations.

To verify the cycle of CO3* in CO2RR, three steps with isotopic labelling were designed by using 12CO2 and 13CO2 as the carbon source interchangeably. First, 12CO2 was introduced into the reactor, and there is an obvious peak of 12CO3* accompanied with Bi=O and 12OCHO* vibration at −0.88 V (Fig. 5c and Supplementary Fig. 39). Subsequent to Ar purging to remove the residual dissolved 12CO2 in reactor, 13CO2 was introduced into the system for 15 min to achieve saturation. It can be noted that a new and wide peak at 1012 cm−1 appears which indicates the presence of 13CO3* based on the isotopic effect67. The slight difference of peak position between experiments and theoretical calculations may be derived from solvent effect and applied potential68. Moreover, the intensity of 13CO3* increases accompanied with the intensity decrease of 12CO3* as time goes on, indicating that the initial 12CO3* in the first step is gradually consumed and replaced by 13CO3*. It’s noteworthy that there was no similar exchange at OCV and −0.18 V far away from the onset potential of formate production, which suggests that the observed exchange is indeed resulted from the involvement of CO3* in CO2RR. In the final step, 12CO2 was fed into the system again and the intensity of 12CO3* increases impressively with the gradual disappear of 13CO3*, which manifests clearly that CO3* is involved in CO2RR as the key surface species. To exclude the occasionality of BOC-2, BOC-3 with higher VO concentration and BOC-C were also tested under the same process (Fig. 5d,e). The experimental results are well consistent with the study discussed above, which indicates that the participation of CO3* is universal in CO2RR. The partial exchange in BOC-C after 13CO2RR indicates that there are some CO32− fail to be transformed into the active CO3*, which may be one of the reasons for the poor activity of BOC-C. Besides, the signal of CO3* disappears when CO2 was replaced by Ar, which suggests the involvement of CO3* as well (Supplementary Fig. 40). Based on the characterization and discussion above, it can be concluded that CO3* is involved in formate production as the key surface species.

In brief, CO2 tends to adsorb on oxygen site to form CO3* species which participates in the sequent reduction process where the uphill barrier is mainly originated from the sluggish water dissociation kinetics. The introduction of VO favors OH* adsorption and reduces the energy barrier on H-OH cracking, which results in accelerating water dissociation and enhances the formate production rates ultimately. The schematic diagram in Fig. 6a plots the overall reaction routes and the promoting role of VO in CO2RR to formate.

a The schematic plot of the reaction pathways and the role of VO in CO2RR. b The schematic illustration of PV-CO2RR system. c I–V curves of the solar pannel and the polarization curves of this full-cell electrochemical system. d Stability test of PV-CO2RR system and correponding current density as well as Faradaic efficiency. e The formate production and solar to formate energy conversion efficiency during stability test.

The coupling of photovoltic device and electrochemical CO2RR (PV-EC system)

In our PV-EC system, the electrochemical CO2RR was driven by an commercial GaInP/GaAs/Ge solar cell under the illumination of a 100 mW cm−2 (1 Sun) solar simulator (Fig. 6b). BOC-2 with the area of 1 × 1 cm2 worked as cathode while MoNi0.05Fe0.05O2 was chosen as anode due to the lower overpotentials in oxygen evolution reaction69. According to the node of the current-voltage (I-V) curve and the polarization curve of full CO2-H2O system, the actual working potential (WP) can be estimated to be 2.1 V with the current density of 9.1 mA cm−2 (Fig. 6c). Notably, this working outpower is close to the maximum outpower point (MPP) with the solar photovoltaic conversion efficiency of 23.0% (Supplementary Fig. 41). During 8 h operation, this full-cell system with the only energy input of solar can keep stable with the average current density of 8.8 mA cm−2, while the FEformate can be above 93% on average (Fig. 6d). The solar to formate (STF) conversion efficiency is as high as 13.3% with the average STF up to 12.9%, outperforming the typical efficiency in solar to formate conversion (Fig. 6e; Supplementary Table 7).

In summary, we demonstrate an effective strategy to promote CO2RR to formate by accelerating water dissociation through oxygen vacancy engineering. The BOC-2 exhibits FEformate of 94% with partial current density of 32.5 mA cm−2. Equipped with flow-cell system, the production rate of formate can reach as high as 3.0 mmol h−1 at 200 mA cm−2. KIE experiments and DFT calculations reveal that the production of formate is predominately hindered by sluggish water dissociation serving as proton source. The in-depth theoretical analysis and dynamic experiments as well as electrochemical analysis demonstrate that the introduction of VO remarkably promotes water dissociation via strengthening hydroxyl adsorption which reduces the ΔμOH−w and energetic span of formate formation. Moreover, the participation of CO3* (CO2 adsorbs on oxygen site) in CO2RR as the key surface species is clearly confirmed by EPR tests and in situ Raman spectroscopy study with the help of isotopic labeling. Finally, the full-cell electrocatalysis driven by solar cell was constructed with the STF reaching 13.3%. We hope that this overall study of reaction process and effect of water dissociation would motivate more efficient strategies to boost CO2RR activity in the future.

Methods

Synthesis of BOC samples

The BOC with different VO concentrations were synthesized by electrodeposited method. In the typical synthesis, 0.02 M BiCl3 (dissolved in the mixed solution of ethylene glycol and water) was prepared as electrolyte and cooled in refrigerator at 0 °C for 2 h in advance. Carbon paper was cut into 1 × 2 cm2 and immersed into the electrolyte with the area of 1 × 1 cm2 as working electrode. The cathodic current of 40 mA was applied to the carbon paper for 15 mins by galvanostatic method while CO2 was bubbled into the electrolyte during the whole process. The electrode was removed and cleaned with deionized water subsequently. Promoting the breakage of Bi-O bond through varying solvent is in favor of increasing the VO concentration. Here, by varying the volume ratio of ethylene glycol and water in electrolyte, BOC-1 (pure ethylene glycol), BOC-2 (3:1), BOC-3 (1:1) and BOC-4 (pure water) were obtained, respectively. Before the electrocatalysis of CO2, the prepared electrode was pretreated in CO2-saturated 0.5 M KHCO3 by conducting cyclic voltammetry from 0 to −1.0 V vs. RHE with the scan rates of 50 mV s−1.

Physical characterization

X-ray diffraction (XRD) patterns were recorded on X-ray diffractometer (D8 Advanced, Bruker, Germany) equipped with Cu Kα radiation with a scanning rate of 5° min−1. The morphologies were observed by scanning electron microscopy (SEM, Apreo S LoVac, FEI, America) and transmission electron microscope (TEM) with an acceleration voltage of 200 kV (Tecnai G2 F20, FEI, America). The local structure and oxygen vacancy were discerned through Aberration-corrected scanning transmission electron microscopy (JEM-ARM200F, JEOL, Japan). The electron spin resonance (EPR) spectra were obtained on JES-FA 200 spectrometer (JEOL, Japan). Surface elements were analyzed by X-ray photoelectron spectroscopy (XPS, Escalab 250, Thermo SCIENTIFIC, America). All energies were referenced to C 1 s peaks (284.8 eV) of the surface adventitious carbon. X-ray absorption spectroscopy (XAS) measurements for the Bi L3-edge were performed in fluorescence mode on beamline 20-BM-B with electron energy of 7 GeV and an average current of 100 mA. The radiation was monochromatized by a Si (111) double-crystal monochromator. X-ray absorption near edge structure (XANES) and extended X-ray absorption fine structure (EXAFS) data reduction and analysis were processed by Athena software.

Electrochemical measurements

The electrochemical performance in CO2RR was evaluated in H-type cell and flow cell, respectively while electrochemical workstation (CS150H, Corrtest, China) was used as the electricity power. In H-type electrochemical cell, the proton exchange membrane (Nafion 117) was selected to separate cathode and anode while CO2-saturated 0.5 M KHCO3 (50 ML) was filled into the cell as electrolyte. The reference electrode and counter electrode were Ag/AgCl (saturated KCl). and Pt plate (1 × 1 cm2), respectively. In flow-cell system, the GDE was prepared by electrodepositing BOC onto commercial carbon paper with hydrophobic microporous layer (Sigracet, Fuel cell store). Specifically, the bare GDL of this carbon paper was covered by Kapton tape to avoid the blockage of microporous channel. Then, the BOC-GDE was prepared in the same process as described in synthesis section. The flow cell experiments were carried out in a commercial cell (GaossUnion, Tianjin, China). The synthesized BOC-GDE was used as cathode while Ni foam was selected as anode. The reference electrode was Ag/AgCl (saturated KCl) as well. CO2 was fed through the GDL of cathode with the flow rate of 50 mL min−1. Both the catholyte and anolyte electrolyte (1 M KOH or 1 M KHCO3) were circulated through a peristaltic pump with the flow rate of 10 mL min−1. Linear sweep voltammetry (LSV) measurement was conducted preliminarily to evaluate the activity of catalysts with the scan rates of 5 mV s−1. Then, chronoamperometry measurement was adopted to evaluate the selectivity and activity in CO2RR at one certain potential. In this work, the potentials were converted to RHE scale based on the Nernst equation as follows:

The gas product was analyzed by the on-line gas chromatograph (GC-2014, Shimadzu, Japan) equipped with thermal conductivity detector (TCD) and flame ionization detector (FID). The Faradaic efficiency for gas products (including CO and H2) were calculated by the following equation:

where \({{{{{{\rm{Q}}}}}}}_{{{{{{\rm{product}}}}}}}\) is the number of electric charge for CO and H2, and \({{{{{{\rm{Q}}}}}}}_{{{{{{\rm{total}}}}}}}\) represents the total number of electric charge during the whole CO2RR process. z represents the number of transfer electrons for producing a molecular product, which is 2 and 2 for CO and H2, respectively. v is the flow rate of gas products through GC and c stands for the concentration of gaseous products. F is the Faraday constant (96485 C mol−1) and \({{{{{{\rm{V}}}}}}}_{{{{{{\rm{m}}}}}}}\) is the gas molar volume (24 L mol−1 at the condition of T = 20°C, P = 101.3 kPa). \({{{{{{\rm{j}}}}}}}_{{{{{{\rm{total}}}}}}}\) is the recorded total current.

As for liquid product (formate), 1H nuclear magnetic resonance (NMR) spectra (Avance III 400 MHz, Bruker, Germany) was used to quantify the production of formate. The Faradaic efficiency of formate was calculated by the following equation:

where \({{{{{{\rm{Q}}}}}}}_{{{{{{\rm{product}}}}}}}\) is the number of electric charge for formate and \({{{{{{\rm{Q}}}}}}}_{{{{{{\rm{total}}}}}}}\) is the total number of electric charge in CO2RR. zformate is the number of transfer electrons for producing a molecular formate, which is 2. \({{{{{{\rm{N}}}}}}}_{{{{{{\rm{formate}}}}}}}\) represents the moles of formate based on the stand curve line of 1H NMR. \({{{{{{\rm{j}}}}}}}_{{{{{{\rm{total}}}}}}}\) is the total current on average during a fixed time (t) recorded by electrochemical working station and F is the Faraday constant (96485 C mol−1).

The turnover frequency (TOF) was calculated according to the equation as follows

where \({{{{{\rm{j}}}}}}\) is the total current density; \({{{{{{\rm{FE}}}}}}}_{{{{{{\rm{formate}}}}}}}\) is the corresponding Faradaic efficiency; z is the number of transfer electrons, which is 2; F is the Faraday constant (96485 C mol−1); n is the mole of active sites and all Bi atoms in electrode were assumed to be active sites in our work.

To investigate the effect of water dissociation, D2O was used to relpace the solvent of H2O in 0.5 M KHCO3 while the test of CO2RR was the same with the details above. The liquid products were analyzed by 1H NMR and 2H NMR to detect the signal of H and D, respectively. Due to the difference in tunneling probability between H and D, the water dissociation barrier can be different, which affects the reaction rate if water dissociation is involved in the rate-limiting step. To be specific, the reaction of water dissociation will proceed along the potential energy surface in general (Supplementary Fig. 28a, route 1). With the consideration of tunneling probability, the particle will move as marked in red arrow (route 2) due to the probability of matter wave (assuming the wavelength λ). The tunnelling probability is positive correlation with λ while λH with small nuclear mass is larger than λD according to de Broglie formula. As a result, the dissociation of H2O requires smaller energy than that of D2O. If water is involved in RLS, the KIE (the reaction rate ratio between H2O and D2O) will be >1 and the higher KIE value indicates that water dissociation plays a more important role in rate-limiting step. Apart from the H vs. D tunneling probability, the water dissociation is also influenced by water adsorption and OH adsorption. Herein, the water dissociation can be accelerated by improving OH* adsorption and reducing the energetic barrier of water dissociation due to the introduction of VO. Thus, the difference between the reaction rate in H2O and D2O is smaller exhibited as the decreased KIE value.

To investigate the effect of the difference of viscosity between H2O and D2O, we have executed a finite element based simulation about the diffusions of CO2 (aq) in H2O and D2O on planar electrode surfaces. For H2O, the diffusion coefficient is set to be 1.9 × 10−9 m2 s−1, and the velocity field in convection is set to be −5 × 10−4 m s−1. As for the case of D2O, we import the Wilke Chang equation to discuss the deviation in diffusion coefficient with the value of 1.65 × 10−9 m2 s−1 in terms of the viscosity coefficient70. The results of the concentration distribution are shown in Supplementary Fig. 28b, which indicates that the diffusion thickness of BOC in H2O is slightly larger than that in D2O (5.00 μm of H2O vs. 4.74 μm of D2O). As a result, the current difference is estimated to be 5–10% when switching the electrolyte from H2O to D2O. Besides, the bulk concentration of CO2 in D2O is a little higher than that in H2O due to the higher solubility, which will conversely shrink this diffusion current gap between H2O and D2O. While, the smallest KIE value in our work is of 1.19 which is larger than the diffusion current difference induced by mass transfer. In addition, the KIE experiments were carried out with stirred electrolyte in order to mitigate the limit of mass transport. Overall, the reaction rate ratio (kH2O/kD2O) is predominately affected by water dissociation probability due to tunneling effect and the KIE value can be used to reflect the water dissociation probability.

In situ Raman spectroscopy

The Raman spectra were recorded on Raman spectrometer (XploRa, HORIBA Scientific, Japan) equipped with a green laser of 532 nm. In situ Raman spectra were obtained through the commercial reactor and CO2 was continuously bubbled into the solution of 0.5 M KHCO3 which was pumped into the reactor slowly. The signal was collected at open circuit voltage (OCV) first and different potentials were applied to monitor the stability of BOC. Meanwhile, the laser hit one certain point of electrode in the whole process. It’s worth mentioning that the signal of carbonate and CO3* was observed accompanied by Bi = O at 155 cm−1 whereas it was difficult to detect these signals at carbon paper without samples and pure electrolyte, which excluded the disturbing effects of minor carbonate in electrolyte. The vibrational frequency of materials with rich 13C tends to shift towards lower wavenumber according to equation as follows:

ω is the frequency of one certain Raman mode in the 13C-riched materials; ω0 is the corresponding frequency in the 12C materials; c is the concentration of 13C with the value of 0.99 while c0 is the natural abundance of 13C with the value of 0.0107. For 13CO3, ω can be deduced with the value of 1026 cm−1.

DFT calculations

The DFT calculations are implemented via the Quantum Espresso. Spin-polarized DFT calculations were performed with periodic super-cells under the generalized gradient approximation (GGA) using the Perdew-Burke-Ernzerhof (PBE) functional for exchange-correlation and the ultrasoft pseudopotentials for nuclei and core electrons57. The kinetic energy and charge-density cutoff by pseudo producers are 30 Ry and 300 Ry, respectively. the convergence criteria are set as 10−4 Ry/Bohr of Cartesian force components acting on each atom and 10−4 Ry of total energy. The 001 and 100 planes are cleaved to model the terrace and edge of Bi2O2CO3, respectively. The terrace models are consisted with two atoms layers, while edge model contains thickness of 7 Å. During the structure optimization, half of atoms are kept fixed. The chemical potentials of adsorbates X* is calculated by the following expression:

The EX* and E* are the DFT based total energies of active sites with and without the adsorbates X*. The ZPE and TS are the contributions from zero points and entropies of adsorbates, whose values are listed on Supplementary Table 8.

PV-EC system

Nickel and iron co-doped molybdenum oxide (Mo0.9Ni0.05Fe0.05O2) nanospheres reported before was chosen as the anode for oxygen evolution reaction while BOC-2, the best sample in this work, served as cathode to catalyze CO2RR to formate. A commercial three junction GaInP/GaInAs/Ge solar cell (0.846 cm2) was driven by an AM 1.5 solar simulator (XES-50S1-RY, San-Ei Electric, Japan) to provide electricity. The solar to formate conversion efficiency (η) was calculated as below,

\({{{{{{\rm{J}}}}}}}_{{{{{{\rm{solar}}}}}}}\) means the current density in the working system, \({{{{{{\rm{S}}}}}}}_{{{{{{\rm{electrode}}}}}}}\) is the geometric area of working electrode, \({{{{{{\rm{E}}}}}}}_{{{{{{\rm{formate}}}}}}}^{0}\) is thermodynamic cell potential for formate with the value of 1.25 V, \({{{{{{\rm{P}}}}}}}_{{{{{{\rm{solar}}}}}}}\) is the power of input solar (100 mW cm−2) and \({{{{{{\rm{S}}}}}}}_{{{{{{\rm{illuminated\; area}}}}}}}\) is the irradiation area of PV.

Data availability

All relevant data are available from the corresponding author on reasonable request.

References

Wakerley, D. et al. Gas diffusion electrodes, reactor designs and key metrics of low-temperature CO2 electrolysers. Nat. Energy 7, 130–143 (2022).

Wang, G. et al. Electrocatalysis for CO2 conversion: from fundamentals to value-added products. Chem. Soc. Rev. 50, 4993–5061 (2021).

Shin, H., Hansen, K. U. & Jiao, F. Techno-economic assessment of low-temperature carbon dioxide electrolysis. Nat. Sustain. 4, 911–919 (2021).

Weber, R. S. The challenges of electrolytic valorization of carbon dioxide. Nat. Sustain. 4, 839–840 (2021).

Grigioni, I. et al. CO2 electroreduction to formate at a partial current density of 930 mA cm–2 with InP colloidal quantum dot derived catalysts. ACS Energy Lett. 6, 79–84 (2020).

Liu, H. et al. Assembling metal organic layer composites for high-performance electrocatalytic CO2 reduction to formate. Angew. Chem. Int. Ed. 61, e202117058 (2022).

Chen, X. et al. Boron dopant induced electron-rich bismuth for electrochemical CO2 reduction with high solar energy conversion efficiency. Small 17, e2101128 (2021).

Pang, R. et al. Tracking structural evolution: operando regenerative CeOx/Bi interface structure for high-performance CO2 electroreduction. Natl Sci. Rev. 8, nwaa187 (2021).

Zhang, J. et al. Electro‐reconstruction‐induced strain regulation and synergism of Ag‐In‐S toward highly efficient CO2 electrolysis to formate. Adv. Funct. Mater. 32, 2113075 (2022).

Wang, X. et al. Dynamic activation of adsorbed intermediates via axial traction for the promoted electrochemical CO2 reduction. Angew. Chem. Int. Ed. 60, 4192–4198 (2021).

Koshy, D. M. et al. Chemical modifications of Ag catalyst surfaces with imidazolium ionomers modulate H2 evolution rates during electrochemical CO2 reduction. J. Am. Chem. Soc. 143, 14712–14725 (2021).

Yang, K., Kas, R. & Smith, W. A. In situ infrared spectroscopy reveals persistent alkalinity near electrode surfaces during CO2 electroreduction. J. Am. Chem. Soc. 141, 15891–15900 (2019).

Zhang, M. et al. Engineering a conductive network of atomically thin bismuthene with rich defects enables CO2 reduction to formate with industry-compatible current densities and stability. Energy Environ. Sci. 14, 4998–5008 (2021).

Ma, W. et al. Promoting electrocatalytic CO2 reduction to formate via sulfur-boosting water activation on indium surfaces. Nat. Commun. 10, 892 (2019).

Ma, W. et al. Electrocatalytic reduction of CO2 to ethylene and ethanol through hydrogen-assisted C–C coupling over fluorine-modified copper. Nat. Catal. 3, 478–487 (2020).

Wang, X. et al. Proton capture strategy for enhancing electrochemical CO2 reduction on atomically dispersed metal-nitrogen active sites. Angew. Chem. Int. Ed. 60, 11959–11965 (2021).

Duan, J. et al. Active and conductive layer stacked superlattices for highly selective CO2 electroreduction. Nat. Commun. 13, 2039 (2022).

Masel, R. I. et al. An industrial perspective on catalysts for low-temperature CO2 electrolysis. Nat. Nanotechnol. 16, 118–128 (2021).

Li, L. et al. Tuning oxygen vacancies of oxides to promote electrocatalytic reduction of carbon dioxide. ACS Energy Lett. 5, 552–558 (2020).

Zhang, Y. et al. Controllable synthesis of few-layer bismuth subcarbonate by electrochemical exfoliation for enhanced CO2 reduction performance. Angew. Chem. Int. Ed. 57, 13283–13287 (2018).

Liu, P., Zu, M., Zheng, L. & Yang, H. Bismuth oxyiodide microflower-derived catalysts for efficient CO2 electroreduction in a wide negative potential region. Chem. Commun. 55, 12392 (2019).

An, X. et al. The in situ morphology transformation of bismuth-based catalysts for the effective electroreduction of carbon dioxide. Sustain. Energy Fuels. 4, 2831–2840 (2020).

Yuan, W. et al. In situ transformation of bismuth metal–organic frameworks for efficient selective electroreduction of CO2 to formate. J. Mater. Chem. A 8, 24486 (2020).

Li, L. et al. Stable, active CO2 reduction to formate via redox-modulated stabilization of active sites. Nat. Commun. 12, 5223 (2021).

Gao, S. et al. Partially oxidized atomic cobalt layers for carbon dioxide electroreduction to liquid fuel. Nature 529, 68–71 (2016).

Zhang, B. et al. Regulating *OCHO intermediate as rate-determining step of defective oxynitride nanosheets enabling robust CO2 electroreduction. Adv. Energy Mater. 12, 2200321 (2022).

Gao, S. et al. Atomic layer confined vacancies for atomic-level insights into carbon dioxide electroreduction. Nat. Commun. 8, 14503 (2017).

Fan, T. et al. Achieving high current density for electrocatalytic reduction of CO2 to formate on bismuth-based catalysts. Cell Rep. Phys. Sci. 2, 100353 (2021).

Zhang, J., Yin, R., Shao, Q., Zhu, T. & Huang, X. Oxygen vacancies in amorphous InOx nanoribbons enhance CO2 adsorption and activation for CO2 electroreduction. Angew. Chem. Int. Ed. 58, 5609–5613 (2019).

Han, H. et al. Plasma-induced oxygen vacancies in amorphous MnOx boost catalytic performance for electrochemical CO2 reduction. Nano Energy 79, 105492 (2021).

Liu, G. et al. Black reduced porous SnO2 nanosheets for CO2 electroreduction with high formate selectivity and low overpotential. Appl. Catal. B: Environ. 260, 118134 (2020).

Feng, Z. A., El Gabaly, F., Ye, X., Shen, Z. X. & Chueh, W. C. Fast vacancy-mediated oxygen ion incorporation across the ceria-gas electrochemical interface. Nat. Commun. 5, 4374 (2014).

Shen, R. et al. Engineering bimodal oxygen vacancies and Pt to boost the activity toward water dissociation. Small 18, e2105588 (2022).

Lv, W. et al. Bi2O2CO3 nanosheets as electrocatalysts for selective reduction of CO2 to formate at low overpotential. ACS Omega 2, 2561–2567 (2017).

Birdja, Y. Y. et al. Advances and challenges in understanding the electrocatalytic conversion of carbon dioxide to fuels. Nat. Energy 4, 732–745 (2019).

Ren, B. et al. Nano-crumples induced Sn-Bi bimetallic interface pattern with moderate electron bank for highly efficient CO2 electroreduction. Nat. Commun. 13, 2486 (2022).

Baruch, M. F., Pander, J. E., White, J. L. & Bocarsly, A. B. Mechanistic insights into the reduction of CO2 on tin electrodes using in situ ATR-IR spectroscopy. ACS Catal. 5, 3148–3156 (2015).

Dutta, A. et al. A tandem (Bi2O3 → Bimet) catalyst for highly efficient ec-CO2 conversion into formate: operando Raman spectroscopic evidence for a reaction pathway change. ACS Catal. 11, 4988–5003 (2021).

Xu, X. et al. Oxygen vacancy boosted photocatalytic decomposition of ciprofloxacin over Bi2MoO6: oxygen vacancy engineering, biotoxicity evaluation and mechanism study. J. Hazard. Mater. 364, 691–699 (2019).

Chen, S. et al. Oxygen vacancy associated single-electron transfer for photofixation of CO2 to long-chain chemicals. Nat. Commun. 10, 788 (2019).

Dou, Y. et al. Approaching the activity limit of CoSe2 for oxygen evolution via Fe doping and Co vacancy. Nat. Commun. 11, 1664 (2020).

Foo, C. et al. Characterisation of oxygen defects and nitrogen impurities in TiO2 photocatalysts using variable-temperature X-ray powder diffraction. Nat. Commun. 12, 661 (2021).

Wei, S. et al. Oxygen vacancy enhanced visible light photocatalytic selective oxidation of benzylamine over ultrathin Pd/BiOCl nanosheets. Appl. Catal. B: Environ. 305, 121032 (2022).

Wang, Y. et al. Sub-2 nm ultra-thin Bi2O2CO3 nanosheets with abundant Bi-O structures toward formic acid electrosynthesis over a wide potential window. Nano Res 15, 2919–2927 (2021).

Hou, D., Fan, H., Zhang, A., Jia, Y. & Wang, W. Role of BO6 octahedral distortion on high temperature piezoelectric properties in Bi3-x (Li0.5Sm0.5)xTiNbO9. Ceram. Int. 48, 22163–22171 (2022).

Burdyny, T. & Smith, W. A. CO2 reduction on gas-diffusion electrodes and why catalytic performance must be assessed at commercially-relevant conditions. Energy Environ. Sci. 12, 1442–1453 (2019).

Chen, H. et al. The effect and mechanism of bismuth doped lead oxide on the performance of lead-acid batteries. J. Power Sources 95, 108–118 (2001).

Cho, W. et al. Porously reduced 2-dimensional Bi2O2CO3 petals for strain-mediated electrochemical CO2 reduction to HCOOH. Energy Environ. Mater. e12490 https://doi.org/10.1002/eem2.12490 (2022).

Shi, Y. et al. Unveiling hydrocerussite as an electrochemically stable active phase for efficient carbon dioxide electroreduction to formate. Nat. Commun. 11, 3415 (2020).

Pandiarajan, A. & Ravichandran, S. Investigation of electrochemical CO2 Reduction on cost effective copper zinc oxide electrocatalyst. J. Electrochem. Soc. 169, 106505 (2022).

Xie, C. et al. In-situ phase transition of WO3 boosting electron and hydrogen transfer for enhancing hydrogen evolution on Pt. Nano Energy 71, 104653 (2020).

Wen, Q. et al. Engineering a local free water enriched microenvironment for surpassing platinum hydrogen evolution activity. Angew. Chem. Int. Ed. 61, e202206077 (2022).

Deng, W., Zhang, P., Seger, B. & Gong, J. Unraveling the rate-limiting step of two-electron transfer electrochemical reduction of carbon dioxide. Nat. Commun. 13, 803 (2022).

Monteiro, M., Dattila, F., López, N. & Koper, M. T. The role of cation acidity on the competition between hydrogen evolution and CO2 reduction on gold electrodes. J. Am. Chem. Soc. 144, 1589–1602 (2021).

Monteiro, M. et al. Absence of CO2 electroreduction on copper, gold and silver electrodes without metal cations in solution. Nat. Catal. 4, 654–662 (2021).

Gu, J. et al. Modulating electric field distribution by alkali cations for CO2 electroreduction in strongly acidic medium. Nat. Catal. 5, 268–276 (2022).

Nørskov, J. K. et al. Origin of the overpotential for oxygen reduction at a fuel-cell cathode. J. Phys. Chem. B 108, 17886–17892 (2004).

Peterson, A. A., Abild-Pedersen, F., Studt, F., Rossmeisl, J. & Nørskov, J. K. How copper catalyzes the electroreduction of carbon dioxide into hydrocarbon fuels. Energy Environ. Sci. 3, 1311–1315 (2010).

Chen, J., Chen, Y., Li, P., Wen, Z. & Chen, S. Energetic span as a rate-determining term for electrocatalytic volcanos. ACS Catal. 8, 10590–10598 (2018).

Strmcnik, D. et al. Improving the hydrogen oxidation reaction rate by promotion of hydroxyl adsorption. Nat. Chem. 5, 300–306 (2013).

Mu, S. et al. Hydroxyl radicals dominate reoxidation of oxide-derived Cu in electrochemical CO2 reduction. Nat. Commun. 13, 3694 (2022).

Chong, X., Liu, C., Wang, C., Yang, R. & Zhang, B. Integrating hydrogen production and transfer hydrogenation with selenite promoted electrooxidation of α-nitrotoluenes to E-nitroethenes. Angew. Chem. Int. Ed. 60, 22010–22016 (2021).

Taylor, P., Sunder, S. & Lopata, V. J. Structure, spectra, and stability of solid bismuth carbonates. Can. J. Chem. 52, 2863–2873 (1984).

Tavender, S., Johnson, S., Balsom, D., Parker, A. & Bisby, R. The carbonate, CO3−·, in solution studied by resonance Raman spectroscopy. Laser Chem. 19, 311–316 (1999).

Vasileff, A. et al. Selectivity control for electrochemical CO2 reduction by charge redistribution on the surface of copper alloys. ACS Catal. 9, 9411–9417 (2019).

Shen, H. et al. In-situ constructuring of copper-doped bismuth catalyst for highly efficient CO2 electrolysis to formate in ampere-level. Adv. Energy Mater. 13, 2202818 (2022).

Kalbac, M. et al. Raman spectroscopy and in situ Raman spectroelectrochemistry of bilayer 12C/13C graphene. Nano Lett. 11, 1957–1963 (2011).

Shan, W. et al. In situ surface-enhanced Raman spectroscopic evidence on the origin of selectivity in CO2 electrocatalytic reduction. ACS Nano 14, 11363–11372 (2020).

He, H. et al. Dual sites modulating MoO2 nanospheres for synergistically enhanced electrocatalysis of water oxidation. Chem. Eng. J. 443, 136339 (2022).

Cho, C. H., Urquidi, J., Singh, S. & Robinson, G. Thermal offset viscosities of liquid H2O, D2O, and T2O. J. Phys. Chem. B 103, 1991–1994 (1999).

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (22072106, L.L.), National Key R&D Program of China (2021YFA1500800, L.L.), Science Foundation of State Key Laboratory of Structural Chemistry (20210025, J.C.), Science Foundation of Fujian Province (2021J01526, J.C.) and Beiyang Reserved Academic Program of Tianjin University (L.L.).

Author information

Authors and Affiliations

Contributions

X.C. carried out the experiments and related data processing of this work. J.C. conducted theoretical calculations. H.C. and Q.Z. gave help in PV-EC system. J.L. performed EPR measurements. J.W.C. and Y.S. performed XRD tests. X.C. and L.L wrote and revised the manuscript. D.W. and J.Y. provided experimental supports. L.L. supervised the project.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Siddhartha Subramanian, Wan Jae Dong and the other anonymous reviewer(s) for their contribution to the peer review of this work. Peer review reports are available.

Additional information

This study is dedicated to Professor Jinhua Ye on the occasion of her 60th birthday.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chen, X., Chen, J., Chen, H. et al. Promoting water dissociation for efficient solar driven CO2 electroreduction via improving hydroxyl adsorption. Nat Commun 14, 751 (2023). https://doi.org/10.1038/s41467-023-36263-z

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-023-36263-z

This article is cited by

-

Highly efficient heterogeneous thermal catalysis for noble-metal-free hydrogen production from formic acid

Nature Communications (2025)

-

Industrial-level CO2 to formate conversion on Turing-structured electrocatalysts

Nature Synthesis (2025)

-

Copper-stabilized bismuth subcarbonate electrocatalysts for durable large-scale formate production at kilowatt power

Nature Communications (2025)

-

Sulfur-modified promoting the electrochemical CO2 reduction into formate performance of BiOI

Ionics (2025)

-

Advances in ferroelectric and piezoelectric photocatalysts with oxygen vacancy

Carbon Letters (2025)