Abstract

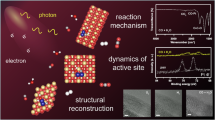

Dual-interfacial structure within catalysts is capable of mitigating the detrimentally completive adsorption during the catalysis process, but its construction strategy and mechanism understanding remain vastly lacking. Here, a highly active dual-interfaces of CeO2-x/CoO1-x/Co is constructed using the pronounced interfacial interaction from surrounding small CeO2-x islets, which shows high activity in catalyzing the water-gas shift reaction. Kinetic evidence and in-situ characterization results revealed that CeO2-x modulates the oxidized state of Co species and consequently generates the dual active CeO2-x/CoO1-x/Co interface during the WGS reaction. A synergistic redox mechanism comprised of independent contribution from dual functional interfaces, including CeO2-x/CoO1-x and CoO1-x/Co, is authenticated by experimental and theoretical results, where the CeO2-x/CoO1-x interface alleviates the CO poison effect, and the CoO1-x/Co interface promotes the H2 formation. The results may provide guidance for fabricating dual-interfacial structures within catalysts and shed light on the mechanism over multi-component catalyst systems.

Similar content being viewed by others

Introduction

Previous findings have validated that the surface reaction normally proceeded at the metal-support interface upon the numerous hybrid catalysts1,2,3,4. The most well-known strategy is anchoring metal atoms onto the surface of oxide support to establish mono-interfacial structure5,6,7, while the ubiquitously competitive adsorption between reactant and product molecules would inevitably interfere with catalytic efficiency8,9. From this perspective, a strategy based on the synergistic participation of dual interfaces is validated as an efficient path for catalyst design targeted for industrial catalysis processes3,10. However, the efficiently targeted fabrication of the dual interface is impeded by the intricacy of the multifarious sorption ability desired for the catalysis process11,12,13,14.

As a reducible transition metal, cobalt is promising for dual-interface design based on the prerequisite that dual kinds of Co species could integrate the advantages of each component14,15,16. The metallic Co0 atom is commonly regarded as an active site for activating CO molecules in kinds of catalysis processes owing to its intense CO adsorption energy and electron-donor character17. The importance of Co2+ to the optimum adsorption/coverage of reactants or intermediates has been gradually recognized in recent studies14,15,18. The co-presence of Co and CoOx on the surface of Al2O3 or ZrO2 was favorable for CO/CO2 activation and C-H bond scission19,20. The structural engineering of Co-based catalysts aiming to establish highly active and stable dual-interface targeting to specific catalysis processes is thus desirable. However, fabricating a stable abundance Co/CoOx interface within an analogous Co/CoOx/MOx structure is severely impeded by the unstable feature of Co2+(CoO) species, especially under a reductive atmosphere11,12,21. Meanwhile, the respective role of each interface and the corresponding synergistic mechanism have been insufficiently substantiated so far12,13,14,15,22. A possible approach to overcoming the above obstacles is modulating the oxidized state of metal atoms via modifying the metal-support interaction23,24.

CeO2 is encouraging for enhancing the stability of CoOx species and establishing efficient dual interfacial Co-based catalysts because the defective structures (Ov(CeO2)) derived from spontaneous Ce3+/Ce4+ change, which are prone to provide activated O species and thus more readily modulate the oxidized state of atoms at the interface25. In this work, we reported the crucial role of CeO2-x in maintaining the CoO phase under reductive conditions, resulting in the fabrication of a stable CeO2-x/CoO1-x/Co dual-interfaces structure. The as-formed CeO2-x/CoO1-x/Co structure efficiently catalyzes the water gas shift (WGS) reaction (CO + H2O ⇌ CO2 + H2), a vital process for both model catalysis and hydrogen upgrading applications13,14,26,27,28. The in situ characterization and DFT calculation disclosed that CeO2-x/CoO1-x and Co/CoO1-x interfaces are synergistically involved in reaction cycles. The findings in this work provide a strategy to optimize the sorption process upon the catalyst surface via dual-interfacial engineering.

Result and discussion

Catalytic performance of CeCoOx catalysts

The CeCoOx catalysts were prepared through an ultrasonic spray approach (Supplementary Fig. 1) with tunable atomic ratios of Ce/Co for the raw materials (Ce/Co = 1/9, 9/1 and 0/10), labeled by 1Ce9CoOx, 9Ce1CoOx and Co3O4 respectively29,30. The overall structure illustrated in transmission/scanning electron microscopy (TEM/SEM) images (Fig. 1a and Supplementary Fig. 2) revealed that the Co and Ce species were assembled into a spherical framework. As shown in Supplementary Fig. 3, apart from the weak diffracted peaks for the Co3O4 phase, non-detectable crystalized CeO2 can be identified in the XRD patterns of the fresh 1Ce9CoOx catalyst, suggesting the small crystalized size of CeO2. The elemental mapping results (Supplementary Fig. 4) further illustrated the Co and Ce species homogenously distributed over the 1Ce9CoOx sample. In contrast with pristine Co3O4 catalyst, the averaged Co3O4 crystal size in the 1Ce9CoOx determined by the Scheler equation is much smaller (ca. 15.4 vs. 6.1 nm), indicating the influential role of the minor CeO2 species in stabilizing and dispersing predominantly present Co species.

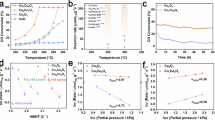

a SEM image of fresh 1Ce9CoOx catalyst. b CO conversions of WGS reaction over the 1Ce9CoOx, Co3O4 and 9Ce1CoOx catalysts at various temperatures. Reaction condition: 2%CO/10%H2O/N2, GHSV = 42,000 mL/gcat/h. c Comparison of the reaction rate with reference catalysts at 250 °C16,21,31,32. The detailed reaction conditions and CO conversions for these catalysts are summarized in Supplementary Table 1. d Stability test results of the 1Ce9CoOx and Co3O4 catalysts evaluated at 300 °C. Other reaction condition: 5%CO/15%H2O/5%H2/5%CO2/N2, GHSV = 400,000 mL gcat−1 h−1. e, HAADF-STEM image and X-ray EDS elemental mappings (Co, Ce, and O) for the spent 1Ce9CoOx catalyst.

The as-prepared samples were evaluated as catalysts for the WGS reaction after pretreating by 5%H2/Ar at 400 °C for 1 h. The CO conversions were valued with the WGS reaction temperatures elevated from 180 to 320 °C. In detail, the CO conversion of 1Ce9CoOx reached 28% at ca. 240 °C with a high gas hourly space velocity (GHSV) of 168,000 mL g−1 h−1 (Supplementary Fig. 5), which was tremendously better than that of the Co3O4 catalyst (3%). This gap in CO conversion between the 9Ce1CoOx and bare Co3O4 catalysts was further widened with a relatively low GHSV of 42,000 mL g−1 h−1 at ca. 240 °C (95% vs. 14% as illustrated in Fig. 1b). Otherwise, the pristine CeO2 was almost inactive in catalyzing the WGS reaction as the reaction temperature below 300 °C, suggesting that the momentous synergetic effect present between CeO2 and Co-related species. This hypothesis is further evidenced by the kinetic experiments. The apparent activation energy (Ea) value was distinctly decreased (Supplementary Fig. 6) for the 1Ce9CoOx catalyst (100.7 kJ/mol) as compared with that of the Co3O4 catalyst (188.4 kJ/mol), implying that the reactant molecules might react through an advantageous reaction pathway upon the 1Ce9CoOx catalyst.

The 1Ce9CoOx catalyst demonstrated a remarkable mass-normalized reaction rate of 169.3 mmolCO/gcat/h at 250 °C (Fig. 1c, Supplementary Table 1), 3-folds of the value of 50.1 mmolCO/gcat/h for the 1Al9CoOx catalyst with irreducible Al2O3 species, indicative of the exclusive role of reducible CeO2 in activating Co species. The boosted activity of 1Ce9CoOx catalyst was also higher than commercial CuZnAl catalyst and noble Au-Cluster/CeO2 catalyst (64.8 and 27.8 mmolCO/gcat/h, Supplementary Table 1) under the same reaction condition31,32. The 1Ce9CoOx catalyst revealed good stability during the long-term test at 250 °C for 1800 min with a mild reaction atmosphere of (2%CO/10%H2O/N2), which outperformed the performance of the Co3O4 catalyst (Supplementary Fig. 7). To be noted, the gap in stability between 1Ce9CoOx and Co3O4 catalyst was more significant under a relatively harsh reaction condition (T = 300 °C, 5%CO/15%H2O/5%H2/5%CO2/N2, GHSV = 400,000 mL gcat−1 h−1), where the 1Ce9CoOx was relatively stable over 3000 min on stream and the bare Co3O4 catalyst rapidly deactivated from 20% to 2% in the initial 40 min (Fig. 1d). The spent 1Ce9CoOx catalysts were primarily explored by the aberration-corrected high-angle annular dark-field scanning transmission electron microscopy (ac-HAADF STEM). Supplementary Fig. 8 depicted that the nanoparticles within the spent 1Ce9CoOx catalyst maintained assembled sphere morphology. Elemental mapping results proved that the Co and Ce species distributed homogeneously after either transient (Fig. 1e and Supplementary Fig. 9) or a long-term WGS reaction test (Supplementary Fig. 10). The average diameter of CeO2 and CoO species derived from statistical results based on the HRTEM images were about 4.0 and 4.3 nm, where the lattice distance of all nanoparticles was verified prior to counting (Supplementary Figs. 11, 12). The aforementioned results evidenced the essential role of introduced CeO2 species in enhancing the catalytic efficiency and stability during catalyzing WGS reaction for the CeCoOx catalyst.

Identification of the CeO2-x/CoO1-x/Co dual-interface structure

The as-formed CeO2-x nanoparticles with a ca. 2−4 nm diameter were located neighboring Co species (Fig. 2a–c, Supplementary Fig. 13), which were in line with the mean size as derived from HRTEM images or the XRD results based on the Scherrer Formula (CeO2: ~4.3 nm and CoO: ~4.2 nm). In sharp comparison, the nanoparticles within the Co3O4 sample seriously aggregated after the long-term WGS reaction, as shown in Supplementary Fig. 14, suggesting that the presence of CeO2 species effectively inhibits the excessive crystallization of Co species under the WGS reaction condition. In most cases, the optimal metal-oxides interface was commonly achieved by anchoring highly dispersed metal sites onto the surface of oxide support. In contrast, the inevitable growth of metal species, especially under reductive conditions, results in the irreversible loss of specific sites at the interface8,9. The amount of the CeO2-Co interfacial sites within the 1Ce9CoOx catalyst was defined by the perimeter outline of small CeO2-x particles with favored thermostability, which consequently resist the loss of interfacial Co-CeO2 sites under reaction conditions.

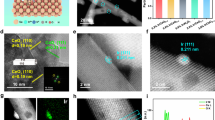

a HAADF-STEM images; (b) magnified STEM image; (c) elemental mappings (Co, Ce, and O) for the selected area of 1Ce9CoOx catalyst after light-off WGS reaction test. d–f XPS spectra of fresh and used 1Ce9CoOx: (d) Co 2p, (e) Ce 3d and (f) O 1s spectra. The XPS spectra for the spent catalyst were collected after light-off WGS reaction (2%CO/10%H2O/Ar, 180–320 °C). g in situ Raman spectra collected under WGS reaction condition at 250 °C. h HRTEM image of spent 1Ce9CoOx catalyst, where the interfacial region is illustrated by dotted line. i the corresponding FFT image of selected region A in Fig. 2h. j Schematic illustration of the phase transformation within the 1Ce9CoOx catalyst during the WGS reaction.

The coexistence of metallic Co and CoO was also demonstrated by the XRD and XAFS results as shown in Supplementary Fig. 15 and Fig. 16. Lattice distances of 0.20, 0.24, and 0.27 nm respectively ascribed to Co(111), CoO(111) and CeO2(200) were identified as shown in Fig. 2a, where the dominant CoO phase was identified in the region between metallic Co and CeO2 (Fig. 2a, b) or directly anchored with CeO2 nanoparticles (Supplementary Fig. 13). Similarly, as proven by the elemental mapping results, the differentiated distribution of Ce and Co implied that the CeO2 islets interspersed among the Co species (Fig. 2c). The XPS spectra collected before and after light-off WGS reaction was collected and deconvoluted. As shown in Fig. 2d, the fresh 1Ce9CoOx catalyst was characterized by the Co 2p3/2 binding energy at 779.9 eV and a shake-up satellite signal at 790.4 eV with low intensity, which is the typical feature for the Co2+/Co3+ ions in the Co3O4 spinel structure. The primary presence of the Co3O4 phase for the fresh 1Ce9CoOx catalyst was also confirmed by the Raman results, as shown in Supplementary Fig. 3b. After the light-off WGS reaction (2%CO/10%H2O/Ar), the binding energy of Co species was observed at 780.1 eV coupling with a strong satellite peak at 6.1 eV higher, which was typically ascribed to CoO phase33. Only Co2+ ions in octahedral sites of rock-salt CoO may result in these typical photoemission features, where the Co2+ ions in Co3O4 do not locate on octahedral sites14. The spin-orbit coupling peak at ca. 16.0 eV higher was also a characteristic feature for CoO33, which could be clearly identified for the spent 1Ce9CoOx catalyst. In addition, a small shoulder peak at 778.0 eV ascribed to metallic Co was detected after the WGS reaction. Based on the above comparison, an unambiguous change from Co3O4 to Co/CoO upon the surface of the 1Ce9CoOx catalyst was induced by the pretreatment and the WGS reaction. The Ce 3d spectrum was deconvoluted and labeled according to Burroughs formalism (Fig. 2e), where the fitted u′ and u0 resulted from Ce3+. Interestingly, compared with fresh catalyst, the Ce3+ fraction was significantly boosted from 0.15 to 0.28, indicating that the amount of Ov-Ce increased after the WGS reaction. A similar conclusion could be derived from the O 1s results (Fig. 2f), in which the vacancy-related O species (O2 and O3) were increased from 0.40 to 0.68 after the WGS reaction34. In addition, it should be noted that the relative amount of Ce3+ species upon the surface layer as determined by XPS results was lower than 0.03 (Ce3+/(CeOx + CoOx)), suggesting that the O species related with Ov-Ce3+ structure should be a minor component. Videlicet, this discrepancy indicated the plausible presence of CoO1-x species upon the surface of the 1Ce9CoOx catalyst.

To exclude the plausible interference from oxidation, quasi in situ XPS experiments were conducted over the 1Ce9CoOx catalyst (2%CO/3%H2O/Ar, 250 °C) to further estimate the reconstruction process of Co species during the WGS reaction. Supplementary Fig. 17a shows the Co 2p photoemission feature of 1Ce9CoOx catalyst where the robust satellite peaks at ca. 786.2 eV indicate that the dominant presence of CoO on the surface layer of 1Ce9CoOx was generated during the WGS reaction instead of being oxidized by the air. The Ce3+ content (μ0 + μ′) as a percentage of total cerium content was calculated to be 0.24 over 1Ce9CoOx catalyst after in situ WGS reaction (Supplementary Fig. 17b), proving the abundant generation of Ov(CeO2) under reaction condition35. The corresponding CO conversions for various catalysts were determined with the comparable conditions (260 °C, 2%CO/3%H2O/Ar), where the 1Ce9CoOx catalyst demonstrated much better catalytic performance than the reference catalysts (Supplementary Fig. 18).

The presence of defective sites over the 1Ce9CoOx and bare Co3O4 catalysts was further explored by the Raman experiments. The peaks at 191, 484, and 690 cm−1 were detectable for fresh 1Ce9CoOx catalyst (Supplementary Fig. 3), which were attributed to F2g, Eg and A1g symmetry modes of the crystalline Co3O4 respectively36. After in situ feeding 2%CO/3%H2O/Ar upon the surface of 1Ce9CoOx catalyst at 250 °C, three peaks at regions of ca. 450, 530–550, and 580 cm−1 were observed as shown in Fig. 2g, whereas they were absent for pristine Co3O4 catalyst (Supplementary Fig. 19). According to previous reports, the signals at ca. 450 and 580 cm−1 could be ascribed to the F2g mode and defect-induced mode (D1) of the ceria fluorite phase37,38,39,40. There are two plausible affiliations for the signal at the region of 530–550 cm−1: it might be derived from the oxygen vacancies within the surface or sub-surface layer of CeO2 nanoparticles (surface Ov(CeO2))37; or the possible presence of oxygen vacancy in CoO phase (Ov(CoO)) contribute to this Raman signal36. On the basis of the predominant presence of Co2+ in CoO identified by XPS results (Fig. 2d), we tend to attribute the Raman peak at the region of 530–550 cm−1 to the combinative signals of Ov(CeO2) and Ov(CoO) within the CeO2-x/CoO1-x interface region. As shown in Supplementary Fig. 20, the presence of the Ov(CoO) was also supported by the EELS results for the spent 1Ce9CoOx catalyst. The calculated L3/L2 ratio for Co L-edge collected in the Co-rich region was ca. 3.2. In contrast, the corresponding values calculated for regions overlapped with CeO2 increased to ca. 4.8. The intensity ratio of L3/L2 is determined by the occupation state of 3d-states, which the increased L3/L2 value might thus indicate the lower valence state of Co species induced by the creation of oxygen vacancies within the interface region34. The facile formation of oxygen vacancies on CoO1−x could result from a larger Co−O bond length and relatively weak bond strength in rock-salt CoO, in contrast to those of Co3O414.

In addition, the presence of CeO2-x/CoO1-x and Co/CoO1-x interface within the spent 1Ce9CoOx catalysts was carefully substantiated by microscopy evidence. As shown in Fig. 2h, the crystal lattice spacing ascribed to CeO2(100), CoO(111), and Co(100) could be identified, where the boundary as marked by the dotted line was correspondingly contributed to CoO1-x/Co or CeO2-x/CoO1-x interfaces. Specifically, the metallic Co species are generally found in the central zone, which is further proven by the corresponding FFT image as shown in Fig. 2i. More importantly, the coexistence of CoO and CeO2 could always be identified in the same regions, such as the regions C as illustrated in Supplementary Figs. 21, 22, where it is adjacent to the metallic Co species in the central area. Similar results could be frequently observed in other HRTEM images, as shown in Supplementary Fig. 23, indicative of the abundant presence of dual interfaces over the 1Ce9CoOx catalysts after the WGS reaction. Therefore, on the basis of the above microscopic and spectral evidence, we believed that the initial CeO2-Co3O4 structure re-constructed to the CeO2-x/CoO1-x/Co dual-interfaces during the WGS reaction (Fig. 2j).

Functions of CeO2-x/CoO1-x and Co/CoO1-x dual-interfaces within the 1Ce9CoOx catalyst

As an indicator of the heterogenous interaction, the oxygen reducibility of catalysts was determined by the H2 temperature-programmed reduction (H2-TPR) tests41. As shown in Fig. 3a, three peaks were respectively identified for pristine Co3O4 at ca. 300, 350, and 410 °C, correspondingly denoted as the α, β and δ peak. In detail, the α reduction peak is indicative of the phase transformation from Co3O4 to CoO; the β and δ peaks imply the reduction process of surface or inner CoO to metallic Co, respectively15,42. The ratio of peak area for α/(β+δ) is 1/3.4, which is close to the stoichiometric ratio of 1/3. In comparison with the pristine Co3O4 catalyst, the 1Ce9CoOx demonstrates a similar α reduction peak at around 290 °C, suggesting the comparable reduction behavior from Co3O4 to CoO for both catalysts. In addition, the relative intensity of β reduction peak was apparently decreased over 1Ce9CoOx; meanwhile, one additional γ peak emerged at an elevated temperature of ca. 500 °C. To note, the α/(β+δ+γ) value of 1/3.2 is close to the stoichiometric ratio of 1/3, implying that the γ peak might be derived from the reduction process of the CoO species strongly interacted with additive CeO2. Videlicet, the surrounded CeO2-x islets can play a vital role in maintaining the O-containing structure of Co species even at relatively high temperatures (>400 °C) under a reductive atmosphere. The ability of small CeO2 nanoparticles to provide O atoms for oxidizing adjacent Co atoms was also validated by the auto-regenerated α peak as shown in the second-round TPR profile (Supplementary Fig. 24). These results demonstrated the pivotal role of CeO2-x islets in fabricating the CeO2-x/CoO1-x/Co dual interface.

a H2-TPR profile of 1Ce9CoOx, Co3O4, and pristine CeO2 samples. b, c The in situ XRD patterns were collected under 5%H2/Ar atmosphere with different temperatures for the (b) Co3O4 and (c) 1Ce9CoOx catalysts. d The CO conversions of WGS reaction at 250 °C for the 1Ce9CoOx catalysts pretreated by 5%H2/Ar under various temperatures. e Apparent reaction order of H2O and CO for the 1Ce9CoOx and Co3O4 catalysts. f The amount of adsorbed CO (NCO) and the site coverage of CO (θCO) determined by the SSITKA results for the 1Ce9CoOx and Co3O4 catalysts.

The in situ XRD patterns collected under the H2 atmosphere were further used to substantiate the phase evolution over the 1Ce9CoOx and Co3O4 catalysts. We observed a distinct phase transformation from Co3O4 to metallic Co over the pristine Co3O4 catalysts at 300 °C (Fig. 3b), coupling with negligible signal centered at 42.3° for the CoO phase. In sharp contrast, a remarkable diffracted peak at 42.3° for CoO emerged at 300 °C over the 1Ce9CoOx sample, while the signal for metallic Co is relatively weak at around 44.4°. This evidence is well consistent with the H2-TPR results that the small CeO2-x nanoparticles can maintain the oxidized state of Co species with a broader temperature range under reductive conditions, which is in line with its stabilization effect found in the previous report43.

To validate the superiority of CeO2-x/CoO1-x/Co dual-interfaces, pretreatments with 5%/H2/Ar under various temperatures were conducted on the 1Ce9CoOx to differentiate the initial phase state of catalysts (Fig. 3c and Supplementary Table 2), where the samples labeled by 1Ce9CoOx-x respectively (x is pretreated temperatures). After pre-reducing at 200 °C (1Ce9CoOx-200), the Co3O4 phase was predominant according to the in situ XRD results, and the 1Ce9CoOx-200 was almost inactive for catalyzing the WGS reaction. As the temperature elevated to 250 °C, the initial CO conversion was boosted to ~20%, indicating that the CoO site is superior to Co3O4. Interestingly, compared with the 1Ce9CoOx-350 sample, the slightly lower reduction temperature of 320 °C led to a significant decrease in CO conversion from ~60% to ~20% for the 1Ce9CoOx-320. This inflected temperature of 320 °C coincides nicely with the starting temperature of the β reduction process (Co2+ → Co0) as depicted in the H2-TPR profile (Fig. 3a), indicating that metallic Co0 species is an essential component for the efficient catalysis process. Remarkably, physically mixed metallic Co catalysts and CeO2 nanoparticles displayed an inferior CO conversion of 5.2% at 250 °C (Supplementary Table 1), proving that CoO sites induced by coordinated CeO2-x/CoO1-x interaction were also indispensable for highly active performance. Furthermore, the copresence of CoO and metallic Co coupling with best catalytic performance (Fig. 3d) was observed after in situ reduction under 5%H2/Ar at 400 °C for the 1Ce9CoOx, reconfirming the co-existing of dual active Co sites (Co0 and Co2+) was crucial for efficiently catalyzing WGS reaction.

The apparent reaction orders of H2O and CO were determined at ca. 230 °C over the 1Ce9CoOx and Co3O4 catalysts. The H2O order on 1Ce9CoOx is relatively lower than the Co3O4 catalyst (0.66 vs. 0.84, Fig. 3e), implying that the CeO2-x/CoO1-x/Co dual-interfaces have more substantial adsorption and coverage of O/OH/H2O species than bare metallic Co surface. The CO order is 0.14 on the 1Ce9CoOx catalyst, whereas the CO order for the Co3O4 catalyst is −0.95. The inverse-first order of CO upon bare Co0 sites within Co3O4 proved the excessively strong CO adsorption at relatively low temperatures17,23, which might correspondingly block the active sites for the H2O activation. The moderate CO adsorption ability for the 1Ce9CoOx suggested that the CoO1-x/Co interface behaved differently from its metallic counterpart23. We further substantiate this speculation by conducting steady-state isotopic transient kinetic analysis (SSITKA) experiments over the 1Ce9CoOx and Co3O4 catalysts. By in situ switching 12CO/He to 13CO/Ar with or without feeding 3%H2O inside, the total number of active sites (Ntot) and adsorbed amount of reversibly adsorbed CO (NCO) molecules under steady state were determined as shown in Supplementary Fig. 2544. Subsequently, dividing the NCO with Ntot gave the surface coverage of CO (θCO) with the presence of H2O molecules. As shown in Fig. 3f, the metallic Co0 sites within the Co3O4 catalyst demonstrated a higher θCO of 0.89 in comparison with 0.64 for the CoO1-x/Co interface within 1Ce9CoOx catalyst at 250 °C, further proving that the excessively stable CO molecules exactly impaired H2O activation upon the pristine surface of metallic Co0. Therefore, the re-constructed CoO1-x/Co interface effectively weakened the CO poisoning effect at the relatively low reaction temperature, which provides more active sites for the following surface reaction.

Synergistic reaction pathway proceeded upon CeO2-x/CoO1-x and CoO1-x/Co dual-interfaces

In situ Raman spectra were sequentially collected under different modes over the 1Ce9CoOx catalyst to offer a deeper insight into the detailed reaction pathway. Figure 4a depicted that numerous V(CoO) and V(CeO2) with defect modes at ca. 540 and 580 cm−1 were generated in the interface region over 1Ce9CoOx catalyst when pretreating the 1Ce9CoOx catalyst with 5%H2/Ar at 400 °C. Based on previous reports, the value of the D/F2g ratio can qualitatively represent the concentration of Ov(CeO2)37. Notably, the D(CeO2)/F2g ratio of ~2.3 over 1Ce9CoOx catalyst is much higher than that of the pristine CeO2 nanoparticles with an averaged diameter of ca. 5−8 nm (D/F2g = ~0.1, Supplementary Fig. 26), indicative of the vastly boosted concentration of oxygen vacancy by forming CeO2-x/CoO1-x interface. When co-feeding CO and H2O inside, the relative intensity of D mode signal at 540 cm−1 apparently decreased at 150 °C and further weakened at 350 °C (Fig. 4a), suggesting that these vacancy structures participated in dissociating H2O molecules and can be refilled by the dissociated O(H) species at elevated temperatures.

a In situ Raman spectra collected under 5%H2/Ar or 2%CO/3%H2O/Ar atmospheres at 400 °C. b–e In situ Raman spectra continuously collected as the feeding gas switched between 3%H2O/Ar and 5%CO/Ar at 250 °C for (b) 1Ce9CoOx, (c) Co3O4, (d) CoO-CeO2 and (e) CeO2 catalysts. The right part demonstrates the transformations of Co and CeO2 species during experiments. f CO-TPSR profile for the CoO-CeO2 catalyst and 1Ce9CoOx catalyst. The catalysts were pre-hydroxylated (3%H2O/Ar, 250 °C) before experiments. g Schematic illustration of plausible WGS reaction pathway upon the CeO2-x/CoO1-x/Co dual interface.

Next, the CO-H2O switch test was used to visualize the stepwise process between the CeO2-x/CoO1-x and CoO1-x/Co interfaces for the 1Ce9CoOx catalyst (Fig. 4b). After feeding 3%H2O/Ar onto the surface of 1Ce9CoOx catalyst at 250 °C, typical Eg mode at 480 cm−1 and A1g mode at 680 cm−1 for crystallized Co3O4 were observed, while the Raman signals at 540 and 580 cm−1 for V(CoO) and V(CeO2) vanished. This experimental fact evidenced that the dissociated O(H) species from H2O molecules can refill the vacant structures and oxidize the CeO2-x/CoO1-x interface at a relatively low temperature. Subsequently, the D mode signals at 540 and 580 cm−1 for the V(CoO) and V(CeO2) recurred when feeding 5%CO/Ar inside, implying the reversible regeneration of vacancies and consumption of active O(H) species at the CeO2-x/CoO1-x interface. In sharp contrast, no detectable structure transformations were observed upon the pristine surface of metallic Co species during the continuous CO-H2O switching tests for the Co3O4 catalyst (Fig. 4c), implying that the presence of CeO2 is essential for boosting the H2O activation ability.

The CoO-CeO2 catalyst and bare CeO2 nanoparticles were prepared (Supplementary Figs. 27–29) and investigated further to dig out the role of the CoO/CeO2 interface. Typical Raman active signals for CeO2 centered at 463 cm−1 (F2g mode) and ca. 580 cm−1 (D mode) could be identified during the CO-H2O sequential switching tests (Fig. 4d). In the presence of CO molecules at 250 °C, the signal of D mode could be enhanced over the CoO-CeO2 catalyst, implying that the O species occupied vacancies could be easily removed in this step. More importantly, this consumption of O species upon the vacancies could be regenerated as H2O molecules purge inside. However, the bare CeO2 demonstrated negligible variation for the D mode at 580 cm-1 as CO or H2O feeding inside (Fig. 4e), proving the low O species activity in the absence of the CoO/CeO2 interface. This recyclability of O vacancies for the CoO-CeO2 catalyst induced by gas switching between reactant molecules was indicative that the structural changes of CoO/CeO2-CoO1-x/CeO2-x might participate in the CO oxidation step and H2O dissociation step.

Additionally, it should be noted that the reversible structural changes over the CoO-CeO2 catalyst were different from those of the 1Ce9CoOx catalyst. As shown in Fig. 4b, typical phonon vibration signals at 480 cm−1 (Eg mode) and 680 cm−1 (A1g mode) for Co3O4 were observed as the H2O molecules fed inside, while it was absent for the CoO-CeO2 catalyst (Fig. 4c). This implied that the oxidation behavior of the Co species should be strongly correlated with the presence of the Co/CoO interface over the 1Ce9CoOx catalyst. Videlicet, the H2O molecules could dissociate on the CoO/CeO2 interface, while the dissociated O-related species were unable further to oxidize cobalt species without the Co/CoO interface. In addition, we collected the H2-TPR profile for the 1Ce9CoOx catalysts after the in situ WGS reaction (250C, 2%CO/3%H2O/Ar). Interestingly, as shown in supplementary Fig. 30, another sharp peak centered at 172 °C was observed when the 1Ce9CoOx was exposed to the feed gas, which might belong to the reduction of active O species generated by redox reaction cycles on the surface. As expected, this deduction was also supported by the CO-TPSR results. In the typical carboxyl pathway, the adsorbed CO molecules would react with the dissociated OH* group by forming the HOCO intermediate upon the surface of catalysts31,45. Based on the prerequisite that adsorbed molecules reacted on the surface of the catalyst as CO + OH → CO2 + 1/2H226, the CO temperature-programmed surface reaction (CO-TPSR) test normally can validate such an association process from the stoichiometric ratio (1/2) for produced H2 and CO2. As shown in Fig. 4f, the generated products for the CoO-CeO2 catalyst follow a CO2/H2 ratio of ~2/1, implying that the O-related species involved in the surface reaction should be hydroxy groups rather than active O atoms. However, when the Co/CoO interface was generated by pretreatment at 400 °C (Fig. 3c), the 1Ce9CoOx catalyst with dual-interface structure demonstrated a distinctly different CO2/H2 evolution during the CO-TPSR test. Negligible H2 (CO2/H2 » 2) was identified in the CO-TPSR profile over the hydroxylated 1Ce9CoOx catalyst, indicating that the CO molecules on Co1-x/Co interface might be oxidized by activated O atoms rather than OH groups upon the dual-interfaces. Moreover, the evolution slope of produced CO2 in CO-TPSR (m/z = 44, Fig. 4f) was well in step with the evolution of CO conversions as shown in Fig. 1b, in which the reaction activity increased sharply at about 230 °C. Such a correlation rationalized that the surface reaction between activated O atoms and CO molecules contributes primarily to the WGS reaction activity over the 1Ce9CoOx catalyst. Based on these results, it is reasonable to conclude that the Co/CoO interface within the 1Ce9CoOx catalyst was indispensable for dissociating H2O molecules to active O atoms.

The H/D kinetic isotopic effect (KIE) has been widely used to explore the WGS reaction mechanism46, owing to differentiated zero-point energies of the D- and H- labeled molecular species induced by the significant mass distinction between the D and H atoms. The relatively larger H/D KIE value of 5.6 indicated the O-D bond cleavage involved in the primary kinetic mode on the bare Co0 surface (Supplementary Fig. 31), implying that the breaking O-H in H2O molecules should be the rate-determining step (RDS) of WGS reaction process over the surface of the pristine Co. In contrast, the 1Ce9CoOx catalyst demonstrated a lower KIE value of 1.9, implying a normal isotopic effect on the CeO2-x/CoO1-x dual interface structure. Considering its H2 reaction order of −0.9 (Supplementary Fig. 32), we speculated that a slow H transfer/spillover step might be involved in the reaction pathway 1Ce9CoOx catalyst according to previous research findings46.

Based on these observations mentioned above, as schematically illustrated in Fig. 4g, we propose that two sequentially redox steps were synergistically involved over the CeO2-x/CoO1-x/Co dual-interfaces while catalyzing the WGS reaction:

To verify the rationality of the proposed mechanism, we conducted DFT calculations to investigate the reaction path on the dual-interface structures. Since the above experimental data provided a strong indication that CoO sites modified the CO adsorption and CeO2-x islets contribute to efficient H2O activation, the reaction energy of elementary steps over Co0 sites or CeO2-x/CoO interfacial sites was investigated. On the basis of the experimental characterization findings, we conducted three catalyst models as illustrated in Supplementary Fig. 33 (Co(0001), CeO2-x/CoO(100) and Co10/CoO(100)). The CO adsorption energy was determined to be −1.69 eV on the pristine Co(0001), which would thermodynamically compete for the H2O dissociation process on the same Co0 sites (Supplementary Fig. 34). The intense CO adsorption on Co(0001) surface led to the poisoning of active sites and induced sequential high activation energy of 1.15 eV and 1.08 eV for forming *COOH intermediate and subsequently generating *CO2 and *H2 on Co(0001) surface, implying the detrimental effect of strong CO adsorption on independent Co0 sites. In contrast, the CeO2-x/CoO interface showed moderate energy of −0.28 eV via the CO adsorption process upon Co2+ sites, and coupling with a reasonably low reaction barrier of 0.89 eV (TS1) to subsequently react with lattice O atom of CeO2-x (Fig. 5a, b), resulting in the generation of an Ov(CeO2-x) vacancy. As-formed Ov(CeO2-x) within the CeO2-x/CoO interface enables H2O molecules to dissociate into two *OH with a favorable exothermic step of 1.28 eV, which is consistent with the superior activation ability of 1Ce9CoOx catalyst as experimentally evidenced above.

a Energy profile for the CO oxidation with lattice O, H2O dissociation and H2 formation steps on the CeO2-x/CoO(100) and Co10/CoO(100) interfaces, respectively. The x-axis shows the reaction intermediates and transition states (TS); the y-axis demonstrates the relative energy. b Structures of the CO molecules react with interfacial O from CeO2-x. c Structures of the *H2 derived through an H-H direct combination way on the CeO2-x/CoO interface. d Illustrations of H diffusion on CoO(100) surface. e Illustrations of H2 formation at the Co10/CoO(100) interface. Co, Ce, O, and H atoms are shown in purple, yellow, red and white, respectively.

To note, the metallic Co0 atoms are also prerequisite sites for high WGS activity according to experimental results shown in Fig. 3, whereas its exact function is still ambiguous in previous reports15,18,47. In addition, our DFT calculation results demonstrated that the downstream step of H2 direct formation from two independent *OH groups at CeO2-x/CoO interface underwent the transition state of TS2 (Fig. 5c), which had an extremely high barrier of 2.3 eV (red line). A similar process was also found in calculation results for the Ir1Ox/FeOx catalyst that direct formation of *H2 molecules from two independent H atoms revealed a disadvantageous energy barrier of 3.25 eV5. The enormous energy barrier implied that the single CeO2-x/CoO interface is insufficient for a thermodynamically favored WGS reaction cycle. Comprehensively, in consideration of the indispensable role of metallic Co0 sites for an efficient catalysis process, we calculated the H2 formation step at the Co10/CoO(100) interface. As expected, the H atom diffuses on CoO(100) with a mild migration barrier of 0.78 eV (Fig. 5d). In addition, it is interesting that breaking the H atom from OH onto CoO(100) with the aid of the metal Co0 site is relatively facile with a rational energy barrier of 1.03 eV (Fig. 5e). The transition structure (TS4) comprises Hδ+ and Hδ− atoms that are coordinated with the O atom and Co0 atom, respectively (Supplementary Fig. 35). After two H atoms approach each other, the H2 molecule is formed and only has physical adsorption at the Co0/CoO(100) interface, which could easily be removed. We underlined the synergistic participation of dual interfaces, CeO2-x/CoO and Co0/CoO, in the proposed redox mechanism, which well rationalized our experimental finding as discussed above.

In summary, a highly active dual-interfacial catalyst was fabricated through a spray pyrolysis approach, demonstrating boosted WGS reaction activity than other Co-based catalysts and even comparable with some noble catalysts. We have conducted a combined experimental and theoretical study to explore the anthemically active structure and reaction pathway over the dual-interfacial structure. The CeO2-x/CoO1-x/Co dual-interfaces are structurally active for efficiently catalyzing WGS reaction, where the surrounded presence of small CeO2-x islets is the induction for dominantly existing CoO1-x in the intermediate region. The as-formed CoO1-x can optimize the CO activation step by avoiding CO poisoning due to the excessively strong CO-Co0 binding. A redox mechanism comprising dual interfaces (CeO2-x/CoO1-x and Co/CoO1-x) synergistically participating in a reaction cycle has been identified. The CeO2-x/CoO1-x interface offers an activated O atom to react with adsorbed CO molecule and also takes part in initially dissociating H2O into two adsorbed OH groups. Directly breaking two dissociated OH groups to form an H2 molecule is energetically unfavorable at the CeO2-x/CoO1-x interface, while the H atoms are much easier to migrate and desorb at the Co/CoO1-x interface.

Methods

Catalyst preparations

The CeCoOx mesoporous hollow spheres were synthesized by a spray pyrolysis method48. 8 mmol of mixed cobalt nitrate and cerium nitrate (molar ratio of Ce/Co is 1/9, 9/1, and 0/10) were added to the 60 mL ethanol. After 10 min stirring, the stock solution was transferred to the household ultrasonic humidifier to produce microspheres via the aerosol-spraying process. The atomized spray was sequentially carried by pure N2 flow through a 90 cm -length glass tube placed in a tube furnace at 400 °C. Then, the hybrid powders were collected and further dried in an oven at 70 °C overnight. The reference catalyst of 1Al9CoOx was prepared with the same procedures described above, in which the molar ratio of Al/Co is 1/9.

Hydrogen temperature programmed reduction (H2-TPR)

The H2-TPR tests were conducted in a Builder PCSA-1000 instrument (Beijing, China) equipped with a thermal conductivity detector (TCD) to detect H2 consumption. The fresh catalysts (ca. 30 mg, 20–40 mesh) were pretreated at 300 °C in the air (0.5 h). Following cooling to room temperature, the sample was flushed using pure N2 at room temperature for about 30 min, then switched to 10% H2/Ar and heated from room temperature to 900 °C with a ramping rate of 5 °C·min−1. The second-round H2-TPR profile for the catalyst was continuously collected after conducting the first-round test without exposure to air.

X-ray diffraction (XRD)

The ex-situ XRD patterns were obtained by a PANalytical X’pert3 powder diffractometer (40 kV, 40 mA, λCu-Kα = 0.15418 nm) with an acquisition time of 8.5 min in the range of 10−90°. The in situ XRD patterns were obtained from the same machine with an Anton Paar XRK-900 reaction chamber. Samples were loaded in a ceramic sample holder (diameter of 10 mm; depth of 1 mm) and then treated with various conditions. The in situ reaction camber was heated from room temperature to 600 °C (interval: 100 °C) with a ramping rate of 30 °C/min under 5%H2/Ar (30 mL/min). Two rounds of measurements lasting for 20 min were carried out for each selected temperature. The second measurement round was collected and used to determine the structure of the catalysts.

Raman test

The ex-situ and in situ Raman spectra were recorded on a LabRAM HR800 spectrometer (HORLBA Jobin Yvon) using 473 nm laser excitation. The spectral resolution was 2 cm−1 with a scanning range of 200 to 800 cm−1. The micro-Raman in situ reactor (Xiamen TOPS) with a thermo-module was used for in situ experiments. Before each measurement, ca. 25 mg of the catalysts were pretreated in 5%H2/Ar (99.997%, 30 mL/min) at 400 °C for 60 min. Then, the in situ Raman spectra were collected in the following two condition modes: (1) ~3%H2O/Ar or 5%CO/Ar with a flow rate of 30 mL/min alternatively flowed inside the reaction chamber at 250 °C; (2) the WGS reaction gas (5%CO/∼3%H2O/Ar, 30 mL/min) was continuously injected to the reaction cell at various temperatures. The six-way valve was used to avoid the plausible oxidation of the catalysts.

X-ray photoelectron spectroscopy (XPS)

X-ray photoelectron spectroscopy (XPS) analysis was carried out on an Axis Ultra X-ray photoelectron spectrometer using Al Kαradiations with the C 1s line at 284.8 eV calibrating the binding energies. Quasi in situ XPS experiments were conducted on a Thermo ScientificESCALAB Xi+ XPS instrument.

Catalytic tests

A fixed-bed flow reactor was used for the WGS reaction tests on the catalysts. The reaction gas was 2%CO/10%H2O/N2 (99.997% purity), and the total GHSV was 42,000 or 168,000 mL gcat−1 h−1. The catalyst was pretreated in synthetic air at 300 °C for 30 min before the measurement. The reactivity results of catalysts were measured from 150 to 300 °C per step under reaction gas. A non-dispersive IR spectroscopy was used to quantify the outlet gases online. The residual water was gathered in an ice trap before the IR gas analyzer.

Data availability

The main data supporting the findings of this study are available within the paper and its Supplementary Information. Additional data are available from the corresponding authors upon reasonable request. Source data are provided with this paper.

References

Rodriguez, J. A. et al. Activity of CeOx and TiOx nanoparticles grown on Au(111) in the water-gas shift reaction. Science 318, 1757–1760 (2007).

Xu, K. et al. Catalytically efficient Ni-NiOx-Y2O3 interface for medium temperature water-gas shift reaction. Nat. Commun. 13, 2443 (2022).

Xie, C., Niu, Z., Kim, D., Li, M. & Yang, P. Surface and interface control in nanoparticle catalysis. Chem. Rev. 120, 1184–1249 (2020).

Saavedra, J., Doan, H. A., Pursell, C. J., Grabow, L. C. & Chandler, B. D. The critical role of water at the gold-titania interface in catalytic CO oxidation. Science 345, 1599–1602 (2014).

Liang, J. X. et al. Dual metal active sites in an Ir1 /FeOx single-atom catalyst: a redox mechanism for the water-gas shift reaction. Angew. Chem. Int. Ed. 59, 12868–12875 (2020).

Guo, Y. et al. Low-temperature CO2 methanation over CeO2-supported Ru single atoms, nanoclusters, and nanoparticles competitively tuned by strong metal–support interactions and H-spillover effect. ACS Catal. 8, 6203–6215 (2018).

Yao, S. et al. Atomic-layered Au clusters on a-MoC as catalysts for the low-temperature water-gas shift reaction. Science 357, 389–393 (2017).

Campbell, C. T., Parker, S. C. & Starr, D. E. The effect of size-dependent nanoparticle energetics on catalyst sintering. Science 298, 811–814 (2002).

Simonsen, S. B. et al. Direct observations of oxygen-induced platinum nanoparticle ripening studied by in situ TEM. J. Am. Chem. Soc. 132, 7968–7975 (2010).

Bruix, A. et al. A New type of strong metal–support interaction and the production of H2 through the transformation of water on Pt/CeO2(111) and Pt/CeOx/TiO2(110) Catalysts. J. Am. Chem. Soc. 134, 8968–8974 (2012).

Lee, Y.-L. et al. Optimization of cobalt loading in Co–CeO2 catalyst for the high temperature water–gas shift reaction. Top. Catal. 60, 721–726 (2017).

Vovchok, D. et al. In situ characterization of mesoporous Co/CeO2 Catalysts for the high-temperature water-gas shift. J. Phys. Chem. C 122, 8998–9008 (2018).

Nagai, M. & Matsuda, K. Low-temperature water–gas shift reaction over cobalt–molybdenum carbide catalyst. J. Catal. 238, 489–496 (2006).

Zhang, S. et al. WGS catalysis and in situ studies of CoO(1-x), PtCo(n)/Co3O4, and Pt(m)Co(m’)/CoO(1-x) nanorod catalysts. J. Am. Chem. Soc. 135, 8283–8293 (2013).

Cao, Y. et al. Structural evolution of active entities on Co3O4/CeO2 catalyst during water gas shift reaction. Ind. Eng. Chem. Res. 58, 17692–17698 (2019).

Sun, X.-C. et al. Weakening the metal–support interactions of M/CeO2 (M = Co, Fe, Ni) using a NH3-treated CeO2 Support for an enhanced water–gas shift reaction. ACS Catal. 12, 11942–11954 (2022).

Li, M.-R. & Wang, G.-C. The mechanism of ethanol steam reforming on the Co0 and Co2+ sites: A DFT study. J. Catal. 365, 391–404 (2018).

Zhan, Y. et al. Molecular-level understanding of reaction path optimization as a function of shape concerning the metal–support interaction effect of Co/CeO2 on water-gas shift catalysis. Catal. Sci. Tech. 9, 4928–4937 (2019).

Li, X. et al. Insights into the role of dual-interfacial sites in Cu/ZrO2 catalysts in 5-HMF hydrogenolysis with isopropanol. Acs. Appl. Mater. Interfaces 13, 22292–22303 (2021).

Wang, L. et al. Selective hydrogenation of CO2 to ethanol over cobalt catalysts. Angew. Chem. Int. Ed. 57, 6104–6108 (2018).

Gnanamani, M. K. et al. Low temperature water–gas shift reaction over alkali metal promoted cobalt carbide catalysts. Top. Catal. 57, 612–618 (2013).

Ge, Y. et al. Maximizing the synergistic effect of coni catalyst on alpha-MoC for robust hydrogen production. J. Am. Chem. Soc. 143, 628–633 (2021).

Have, I. C. T. et al. Uncovering the reaction mechanism behind CoO as active phase for CO2 hydrogenation. Nat. Commun. 13, 324 (2022).

Wang, H. et al. Strong metal–support interactions on gold nanoparticle catalysts achieved through Le Chatelier’s principle. Nat. Catal. 4, 418–424 (2021).

Montini, T., Melchionna, M., Monai, M. & Fornasiero, P. Fundamentals and catalytic applications of CeO2-based materials. Chem. Rev. 116, 5987–6041 (2016).

Zhai, Y. et al. Alkali-stabilized Pt-OHx species catalyze low-temperature water-gas shift reactions. Science 329, 1633–1636 (2010).

Yao, S. et al. Atomic-layered Au clusters on α-MoC as catalysts for the low-temperature water-gas shift reaction. Science 357, 389–393 (2017).

Lee, Y.-L., Kim, K.-J., Hong, G.-R. & Roh, H.-S. Target-oriented water–gas shift reactions with customized reaction conditions and catalysts. Chem. Eng. J. 458, https://doi.org/10.1016/j.cej.2023.141422 (2023).

Li, L. et al. Multifunctional mesostructured silica microspheres from an ultrasonic aerosol spray. Adv. Funct. Mater. 18, 2956–2962 (2008).

Zhu, Y. J. et al. Recent progress on spray pyrolysis for high performance electrode materials in lithium and sodium rechargeable batteries. Adv. Ener. Mater. 7, 1601578 (2017).

Fu, X.-P. et al. Direct identification of active surface species for the water–gas shift reaction on a gold–ceria catalyst. J. Am. Chem. Soc. 141, 4613–4623 (2019).

Yan, H. et al. Construction of stabilized bulk-nano interfaces for highly promoted inverse CeO2/Cu catalyst. Nat. Commun. 10, 3470 (2019).

Biesinger, M. C. et al. Resolving surface chemical states in XPS analysis of first row transition metals, oxides and hydroxides: Cr, Mn, Fe, Co and Ni. Appl. Surf. Sci. 257, 2717–2730 (2011).

Tian, Y. et al. Engineering crystallinity and oxygen vacancies of Co(II) Oxide nanosheets for high performance and robust rechargeable Zn–Air batteries. Adv. Funct. Mater. 31, 2101239 (2021).

Meng, Q., Liu, H., Xu, K., Wang, W. & Jia, C. CeO2‒x modified Ru/γ-Al2O3 catalysts for ammonia decomposition reaction. Journal of Rare Earths, https://doi.org/10.1016/j.jre.2023.01.017 (2023).

Rivas-Murias, B. & Salgueiriño, V. Thermodynamic CoO-Co3O4 crossover using Raman spectroscopy in magnetic octahedron-shaped nanocrystals. J. Raman Spectrosc. 48, 837–841 (2017).

Wu, Z., Li, M., Howe, J., Meyer, H. M. 3rd & Overbury, S. H. Probing defect sites on CeO2 nanocrystals with well-defined surface planes by Raman spectroscopy and O2 adsorption. Langmuir 26, 16595–16606 (2010).

Ziemba, M. & Hess, C. Influence of gold on the reactivity behaviour of ceria nanorods in CO oxidation: combining operando spectroscopies and DFT calculations. Catal. Sci. Tech. 10, 3720–3730 (2020).

Du, L. et al. Copper-ceria sheets catalysts: Effect of copper species on catalytic activity in CO oxidation reaction. J. Rare Earths 35, 1186–1196 (2017).

Zhou, L., Wei, S., Wang, W., Jin, Z. & Jia, C. Au/La-CeOx catalyst for CO oxidation: effect of different atmospheres pretreatment on gold state―Commemorating the 100th anniversary of the birth of Academician Guangxian Xu. J. Rare Earths 39, 364–373 (2021).

Ahn, S.-Y. et al. Unravelling the active sites and structure-activity relationship on Cu–ZnO–Al2O3 based catalysts for water-gas shift reaction. Appl. Catal. B: Environ. 325, 122320 (2023).

Lee, Y.-L. et al. Effect of alkali and alkaline earth metal on Co/CeO2 catalyst for the water-gas shift reaction of waste derived synthesis gas. Appl. Catal. A: Gen. 551, 63–70 (2018).

Parastaev, A. et al. Boosting CO2 hydrogenation via size-dependent metal–support interactions in cobalt/ceria-based catalysts. Nat. Catal. 3, 526–533 (2020).

Chen, W. et al. Molecular-Level Insights into the notorious CO poisoning of platinum catalyst. Angew. Chem. Int. Ed., https://doi.org/10.1002/anie.202200190 (2022).

Rodriguez, J. A. et al. Water-gas shift reaction on a highly active inverse CeOx/Cu111 catalyst: unique role of ceria nanoparticles. Angew. Chem. Int. Ed. 48, 8047–8050 (2009).

Jacobs, G. & Davis, B. H. Low temperature water–gas shift: applications of a modified SSITKA–DRIFTS method under conditions of H2 co-feeding over metal/ceria and related oxides. Appl. Catal. A: Gen. 333, 192–201 (2007).

Jha, A., Jeong, D.-W., Lee, Y.-L., Nah, I. W. & Roh, H.-S. Enhancing the catalytic performance of cobalt oxide by doping on ceria in the high temperature water–gas shift reaction. RSC Adv. 5, 103023–103029 (2015).

Fu, X. P. et al. Facile fabrication of CeO2-Al2O3 hollow sphere with atomically dispersed fe via spray pyrolysis. Inorg. Chem. 60, 5183–5189 (2021).

Acknowledgements

This work is funded by the National Key Research and Development Program of China (2021YFA1501103), the National Science Fund for Distinguished Young Scholars of China (22225110), the National Science Foundation of China (22075166, 22271177), the Young Scholars Program of Shandong University. We thank the Center of Structural Characterizations and Property Measurements at Shandong University for the help on sample characterizations.

Author information

Authors and Affiliations

Contributions

C.-J.J. supervised the work; X.-P.F., C.-P.W. and C.-J.J. had the idea and designed the experiments. X.-P.F. and C.-J.J. analyzed the results and wrote the manuscript; X.-P.F. and C.-P.W. performed the catalytic tests, H2-TPR and TPSR tests. X.-P.F. and W.-W.W. performed the in situ in situ XRD, in situ Raman and quasi in situ XPS; X.-P.F., Z.J., and C.-P.W. designed and prepared the catalysts; J.-C.L. performed the DFT calculation; C.M. performed the aberration-corrected HAADF-STEM measurements and analyzed the results. All authors have given approval to the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interest.

Peer review

Peer review information

Nature Communications thanks Hyun-Seog Roh, and the other, anonymous, reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Fu, XP., Wu, CP., Wang, WW. et al. Boosting reactivity of water-gas shift reaction by synergistic function over CeO2-x/CoO1-x/Co dual interfacial structures. Nat Commun 14, 6851 (2023). https://doi.org/10.1038/s41467-023-42577-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-023-42577-9

This article is cited by

-

Tunning valence state of cobalt centers in Cu/Co-CoO1-x for significantly boosting water-gas shift reaction

Nature Communications (2025)

-

A review on the low temperature water-gas-shift reaction: reaction mechanism, catalyst design, and novel process development

Frontiers of Chemical Science and Engineering (2025)

-

Inhibitory Effect of Water on Propane Dehydrogenation over Metal Oxides via Dissociative Adsorption

Transactions of Tianjin University (2025)