Abstract

Micro-/nano-robots (MNRs) have impressive potential in minimally invasive targeted therapeutics through blood vessels, which has disruptive impact to improving human health. However, the clinical use of MNRs has yet to happen due to intrinsic limitations, such as overcoming blood flow. These bottlenecks have not been empirically solved. To tackle them, a full understanding of MNR behaviors is necessary as the first step. The common movement principle of MNRs is corkscrew motion with a helical structure. The existing dynamic model is only applicable to standard helical MNRs. In this paper, we propose a dynamic model for general MNRs without structure limitations. Comprehensive simulations and experiments were conducted, which shows the validity and accuracy of our model. Such a model can serve as a reliable basis for the design, optimization, and control of MNRs and as a powerful tool for gaining fluid dynamic insights, thus accelerating the development of the field.

Similar content being viewed by others

Introduction

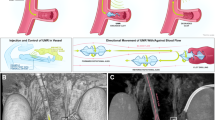

Micro-/nano-robots (MNRs) are shown to have high potential in medical applications in recent years, particularly in minimally invasive targeted therapeutics through blood vessels, which may have disruptive impact to improving human health, due to their small size and externally navigable. Typically, they are navigated through the human circulatory system to access remote body parts1,2. MNRs can be viewed as virtual surgeons without blind spots, performing cellular-level procedures, and can also be used as a sensors to understand the biological environment3,4,5,6,7,8. The precise and efficient navigation of the movement of MNRs in a confined three-dimensional space is a key requirement, especially for delivering medical substances such as drugs to the target9,10,11,12,13.

The movement of MNRs is a fluidic environment of a low Reynolds number (\({Re}\)), and this movement is associated with several factors, including the method of actuation, the structure and state of the MNRs, and the surrounding fluid environment—according to the so-called “FCBPSS” architecture, where F=function, C=context, B=behavior, P=principle, and SS = state & structure14,15,16. It is worth mentioning that the FCBPSS architecture helps us to understand MNRs comprehensively via building the linkage from the structure to the behavior, governed by the principle, and to the function/performance in a particular context. Popular actuation methods include light17,18,19, ultrasound20,21,22, chemical fuels23,24, electrical25,26, and magnetic fields13,27,28,29,30. Regardless of the actuation method, the principle of the movement of MNRs has two kinds: push-pull and corkscrew. The push-pull movement principle refers to linear movement, driven by an external force. The corkscrew movement principle involves the rotational movement, driven by an external torque and converting into a reactive force within the fluid that propels the MNRs to move forward. The corkscrew movement principle is more complex than the push-pull one but is of particular interest because it requires a relatively lower external actuation field to achieve the same propulsion velocity1. MNRs in the present paper take the corkscrew movement principle. Currently, MNRs have a special helical structure with the feature that (i) the cross-section of the helix is circular and (ii) the helix radius maintains identical. Hereafter in this paper, this special MNR is called the standard MNR.

Two important bottlenecks for making it clinically viable target therapeutics in blood vessels with NNRs are (i) correct design of MNRs and (ii) subsequent navigation of them to targets, which further depend on availability of an accurate dynamic model of MNRs in blood vessels or confined fluidic environments. Unfortunately, the existing dynamic model is only valid to the standard MNR, which is further based on the so-called resistance force theory (RFT). The RFT has two further assumptions: (i) there is no dynamic interaction between a moving MNR and a moving fluid medium and (ii) the cross-section area of the wire is infinitely small31,32,33,34. The RFT model is far from validity to the behavior of clinically operative MNRs, which is equipped with medical tools (e.g., drug storage cavities or object-capturing claws) as well as loaded with drugs, notwithstanding poor accuracy in predicting their behavior4,32,33,34.

Indeed, in the current literature, the empirical design of MNRs prevails with the help of the RFT model, specifically following the steps of (i) starting with the standard MNRs, (ii) determining its geometry based on a designer’s experience with the requirements such as the diameter of and the medium in the vessel, (iii) modifying its geometry if a need arises for improving the propelling efficiency (which may deviate from the standard MNR), and (iv) analyzing as well as predicting the movement behavior of the MNR by use of the RFT model9,12,35. As such, MNRs designed based on the foregoing process are difficult for navigating them in vessels because the predicted behavior of MNRs is far from the actual behavior of MNRs in operation12,13,30,36,37. In fact, an inherent conflict presents; namely on one hand, the navigator is informed by the designed behaviour but on the other hand, the navigator acts on the actual behaviour of MNRs. The further implication of this difficulty in the navigation of MNRs includes (i) a high cost for setting up animal-based testbeds for training the navigator, (ii) a long time for training the navigator, and (iii) a high risk of failure in the clinical delivery of target therapeutics. In fact, the phenomenon on MNRs for target therapeutics in vessels is a special case of the more general case governed by the so-called design for control theory38. The design for control theory says that a design of a dynamic system can be tailored to facilitate the control of the system, and a poor design may make it impossible to control the system. Therefore, there is a high need to develop a new theory along with its mathematical model for the general helical MNR to obtain a correct design of the MNR for significantly improving the clinical use of targeted therapeutics in blood vessels.

In this paper, we propose a highly accurate dynamic model for general or non-standard helical MNRs, applicable to special or standard MNRs as well, by considering the clinically operative situation with MNRs in vessels, namely by considering as many factors as possible. The theory behind our model is that the movement state as well as behavior of MNRs and the flow state and behavior of the blood mediums affect mutually. For the convenience of later discussions, this theory is coined as the theory of Fluid-Solid Interaction (FSI). Naturally, the FSI theory along with the model of MNRs removes the two assumptions with the RFT model, as mentioned above.

To validate the proposed FSI model, we first compared the simulation result of the proposed FSI model with that of the RFT model for a standard MNR. We then conducted two experiments. The first experiment is to compare the propulsion velocities of one standard and four general helical MNRs, calculated with the FSI model, with the experimental results as well as with those calculated with the RFT model. The result of this experiment along with the simulation led to the conclusion that the FSI model has a promise for a much better design of general helical MNRs, which is expected eventually to facilitate the navigation of MNRs in blood vessels. The second experiment along with the simulation is to examine the navigation of general helical MNRs with an external magnetic system in an open fluidic medium. The result of this experiment led to the conclusion that the FSI model has a high potential to assist in the physician to navigate MNRs in a fluid medium. We also conducted the parametric study by using the FSI model to examine the transient behavior of the fluid as well as the change of the surface stress of MNRs, the information of which is useful to plan the navigation of MNRs by tailoring individual patients in a clinical setting and as well, useful to understand the behavior of bloods while interacting with MNRs, e.g., blood clog in vessels, etc., thus preventing complications caused in targeted therapeutics with MNRs.

The scientific contribution of the present paper is the provision of the FSI theory for MNRs in a confined fluid channel along with the FSI model for general helical MNRs. The FSI model is an indispensable tool for us to further explore the state and behaviour of the blood while interacting with MNRs in blood vessels. This tool has a high potential to significantly improve the quality of targeted therapeutics with MNRs in vessels, and eventually make such therapeutics clinically viable.

The study followed the flow of activities, including modeling, design, fabrication, and experiment setup, as shown in Fig. 1. Specifically, establish the FSI model with the following steps: (i) determining the geometric schematic model of MNRs as well as the principle of movement of MNRs in a low Re fluid environment, the corkscrew principle in this case (Fig. 1a and Supplementary Note 1); (ii) formulating the governing equations, i.e., the mathematical description of the principle of movement of MNRs in a fluid (Fig. 1b and Supplementary Note 2); (iii) specifying the initial and boundary conditions (Fig. 1c); (iv) meshing the geometric schematic model (Fig. 1d); and (vi) solving the governing equations to obtain the behavior of both MNRs and fluid (Fig. 1e, Supplementary Movie 1). The experiment setup has three steps: (i) fabrication of MNRs with different geometries using the IP-S material via two-photon polymerization (TPP) (Fig. 1f), where IP-S is a negative-tone photoresist widely used in biomedical applications; (ii) removal of excess materials with a post-cleaning treatment (Fig. 1g); (iii) coating of the MNRs using Nickel (Ni) via magnetron sputtering, to make it magnetic the MNRs (Fig. 1h); (iv) transporting of the MNRs into the fluid commonly used by others in the literature, e.g., water, with a micro-operating platform (Fig. 1i); (vi) putting both the MNRs and fluid in an alternate rotational magnetic field, generated by Helmholtz coils (Fig. 1j).

a Problem identification of micro-/nano-robots (MNRs) in a fluid environment. b Mathematical description. c Determination of initial and boundary conditions. d Meshing of the computational model. e Results (Supplementary Movie 1). f Fabricated process for MNRs structures. g Procedures of cleaning the post-fabrication. h Coating of the printed MNRs with Ni. i The MNRs were transported to the fluid using a micro-operating platform. j Propulsion testing of MNRs using an electromagnetic system.

Results

The validation of FSI model

To validate the FSI model, we took one standard MNR to examine its propulsion velocity, for which the RFT model can accurately predict, and we compared the propulsion velocity predicted by the FSI model and that predicted by the RFT model. The structure of this standard MNR is as this: the pitch \((\lambda )\) of 40 \({\rm{\mu }}{\rm{m}}\), and the number of turns (n) of 3 (Supplementary Fig. 1). The property of the fluid is as this: the viscosity \(\left(\eta \right)\) \({\rm{of}}\ 1.\)01 × 10–3 \({\rm{mPa}}\cdot {\rm{s}}\), and the density \(\left(\rho \right) \, {\rm{of}}\ 970\,{\rm{kg}}\,{{\rm{m}}}^{-3}\). The torque created on the MNR from the external magnetic field is 1 × 10–15 \({\rm{N}}\cdot {\rm{m}}\). In the RFT model, an important mechanics is related to the influence of the fluid to the MNR in two forms, namely normal and tangential directions, and these influences are expressed by the so-called coefficient. At this point, there are three proposals for these coefficients, proposed by Gray39,40, Cox41, and Lighthill42, are defined as \({C}_{t}\) \(=\frac{2{\rm{\pi }}\eta }{\mathrm{ln}\frac{2\lambda }{r}-\frac{1}{2}}\), \(\frac{2{\rm{\pi }}\eta }{\mathrm{ln}\frac{2\lambda }{r}-\frac{3}{2}+\mathrm{ln}2}\), and\(\frac{2{\rm{\pi }}\eta }{\mathrm{ln}\frac{0.36{\rm{\pi }}R}{r\sin \theta }}\), respectively; and \({C}_{n}={2C}_{t}\), \(\frac{4{\rm{\pi }}\eta }{\mathrm{ln}\frac{2\lambda }{r}-\frac{1}{2}+\mathrm{ln}2}\), and \(\frac{4{\rm{\pi }}\eta }{\mathrm{ln}\frac{0.36{\rm{\pi }}R}{r\sin \theta }+\frac{1}{2}}\), respectively, further details can be found in Supplementary Note 3. Figure 2a, b show the results of the comparison. Overall, the two are very close, particularly with the coefficient of Gary (39, 40), a discrepancy less than 1.3% (Fig. 2a, b). Further, the trends of the two while changing the parameters of the standard MNR, namely the radius of the cross-section area (\(r\)) and the radius of the amplitude of the helical wave (\(R\)), agree very well (Fig. 2a, b); specifically, the predicted propulsion velocity of the standard MNR increases with the decrease of \(r\) and \(R\). As such, the FSI model is considered to be valid for MNRs.

a Change of the propulsion velocity with the change of cross-section radius \(r\) of the standard MNR at \(R\) = 20 µm. b Change of the propulsion velocity with the change of helical radius \(R\) of the standard MNR at \(r\) = 5 μm. Experiment propulsion velocities of the MNR-1 (c), MNR-2 (e), MNR-3 (g), MNR-4 (i), and MNR-5 (k) at an external magnetic field strength of 8 mT. Comparison in the propulsion velocities of MNR-1 (d), MNR-2 (f), MNR-3 (h), MNR-4 (j), and MNR-5 (l) between the experiment, RFT (Supplementary Tab. 1) and FSI. Experiment data are presented as means \(\pm\) standard deviations. Error bars stand for the standard error (n = 3).

The verification of the FSI model in term of propulsion velocity

The FSI model was further verified by comparing the propulsion velocities predicted with the FSI model and experimental measured for the prototypes of one standard MNR (MNR-1) and four general MNRs (MNRs-2–5) (Supplementary Fig. 2). They were all fabricated using TPP and coated with a 100 nm thick layer of Ni (Supplementary Fig. 3), which permits to actuate the MNRs in an external magnetic fields. Specifically, the movement behaviors of these helical MNRs were investigated in a fluid environment (\(\eta\) = 1.2 × 10–3 mPa⋅s and \(\rho\) = 1202 kg m–3), driven by an external alternating rotational magnetic field of 8 mT and with varying rotational frequencies of the magnetic field (Supplementary Fig. 4). The results are displayed in Fig. 2c, e, g, i, k. From these figures, it can be found that the propulsion velocity of the standard MNR-1 increased with the frequency of the magnetic field during the period of corkscrew motion, and reached a means value of 396 μm s–1 at the step-out frequency of 6 Hz (Fig. 2c and Supplementary Movie 2). The magnetic torque was insufficient to synchronize the rotation frequency of the MNR with the magnetic field, called the step-out frequency, the MNR could not be controlled at higher frequencies, resulting in a dramatic decrease in its velocity. The propulsion velocities of MNR-1 obtained by RFT model and FSI model are 420.75 μm s–1 and 396.66 μm s–1, respectively. Similar experimental results were obtained for the other four general helical MNRs (Fig. 2e, g, i, k and Supplementary Movie 3–6). The experimental propulsion velocities and step-out frequencies of the general helical MNRs-2–5 was 614.83 μm s–1 at 8 Hz, 521.93 μm s–1 at 10 Hz, 240.2 μm s–1 at 4 Hz, and 218.34 μm s–1 at 6 Hz, respectively. The propulsion velocities of the four general helical MNRs obtained by RFT model and FSI model are 480.63 μm s–1 and 612.54 μm s–1, 954.87 μm s–1 and 546.77 μm s–1, 291.61 μm s–1 and 240.66 μm s–1, 519.62 μm s–1 and 257.64 μm s–1, respectively. Comparison of the experimental result, the result from the RFT model, and the result from the FSI model in the propulsion velocities of all the tested MNRs is shown in Fig. 2d, f, h, j, l. It can be found from these figures that (1) the result produced with the FSI model is in good agreement with that of the experiment for all the tested MNRs, (2) the result produced with the RFT model is in good agreement with that of the experiment for the standard MNR-1 only but in significant discrepancies from the result of the experiment for the tested general helical MNRs, particularly for MNR-3 and MNR-5. Some factors are speculated responsible for the discrepancies in propulsion velocity between the FSI model and the experiment are: (i) lateral motion, (ii) defects in the geometry of the MNR, further due to manufacturing error, (iii) nonuniformity of Ni coating. From the foregoing discussion, it may be clear that the proposed FSI model is more accurate and robust in predicting the propulsion velocities of helical MNRs in a fluidic environment.

The role of micro-/nano-robotic size

The propulsion velocities of MNR-1 of various sizes in a fluid environment (\(\eta\) = 1.2 × 10–3 mPa⋅s, \(\rho\) = 1202 kg m–3) were analyzed by FSI model and experiments. By applying a rotating magnetic field with a strength of 8 mT, the experimental results (Fig. 3a) indicated that the velocity of standard MNR-1 increased with its size increased, while the step-out frequency of standard MNR-1 decreased as its size increased. Furthermore, the propulsion velocities of standard MNR-1 with sizes of 360 (MNR-1-360, Supplementary Movie 7), 480 (MNR-1-480, Supplementary Movie 8), 600 (MNR-1-600, Supplementary Movie 2), 720 (MNR-1-720, Supplementary Movie 9) and 840 μm (MNR-1-840, Supplementary Movie 10) were 158.7, 211.6, 266.4, 317.3, and 370.2 μm s–1, at a rotation frequency of 4 Hz of the external magnetic field, respectively (Fig. 3b). The result indicates that the FSI results closely match the experimental results—the size of helical MNRs with the same structure is directly proportional to the propulsion velocity generated by the rotational magnetic field, as long as the MNRs do not reach the step-out state. The purpose of comparing different sizes of helical MNRs is to determine the relationship between their size and propulsion velocity. This comparison aids decision-making in the design process to meet specific application requirements.

a The relationship between experiment propulsion velocity of MNRs with varying sizes and the different rotation frequencies under the 8 mT external magnetic field. b The propulsion velocity comparison of MNR-1 with sizes of 360, 480, 600, 720, and 840 μm, from FSI model and experiment, at a rotation frequency of 4 Hz. c Screenshots from Supplementary Movie 11 showing the movement of two different sizes of MNR-1. The arrows indicate the displacements of the MNRs in 33.1 s under a rotating magnetic field with a frequency of 4 Hz. d Screenshots from Supplementary Movie 12 illustrating the movements of MNR-2 and MNR-4. The arrows indicate the displacements of the MNRs in 9.8 s when exposed to a rotating magnetic field with a frequency of 8 Hz. e Screenshots from Supplementary Movie 13 showing the movements of MNR-2, MNR-3, and MNR-4. The arrows indicate the displacements of the MNRs in 16.7 s under a rotating magnetic field with a frequency of 4 Hz. f Trajectories of MNR-2 moving along a track forming the letters “MNR” (Supplementary Movie 14). Scale bars, 600 μm. Error bars stand for the standard error (n = 3).

Precise open-control of micro-/nano-robotic navigation

The FSI model can accurately predict the motion behavior of helical MNRs, enabling precise navigated. Verification experimental were conducted to assess the precise control of one standard (MNR-1) with different sizes and three general helical MNRs (MNR-2–4) in a fluid (\(\eta\) = 1.2 × 10–3 mPa⋅s and \(\rho\) = 1202 kg m–3) by applying an external rotating magnetic field with a strength of 8 mT. Accurate propulsion velocity predictions for one standard and three general helical MNRs were obtained from the FSI model (Figs. 2c–j and 3a), effectively guiding they to various destinations. The predicted propulsion velocities of MNR-1-360, MNR-1-480, MNR-2, MNR-3, and MNR-4 were 153.64, 211.55, 299.13, 218.41, and 240.66 μm s–1, at a rotation frequency of 4 Hz, respectively. The predicted propulsion velocity of MNR-2 was 612.54 μm under a rotation frequency of 8 Hz. Within the expected 33.1 s duration, the propulsion distances of MNR-1-360 and MNR-1-480 were anticipated to be 5,083.81 and 7,000.00 μm, respectively. However, the actual propulsion distances of MNR-1-360 and MNR-1-480 were measured at 4,273.54 and 7,184.52 μm, resulting in errors of 15.94% and 2.63%, respectively (Fig. 3c, Supplementary Movie 11, and Table 1). Similarly, MNR-2, selected from MNR-2 and MNR-4, was expected to be propelled 6,000.00 μm in 9.8 s under a rotation frequency of 8 Hz. However, the propulsion distance of MNR-2 was 6,302.24 μm with an error of 5.03% (Fig. 3d, Supplementary Movie S12, and Table 1). The propulsion velocity of MNR-4 was considerably slower at 60.68 μm because it can not follow the rotation of the external electromagnetic coils. It was expected that MNR-2, MNR-3, and MNR-4 would be propelled to distances of 5,000.00, 3,650.75, and 4,022.67 μm in 16.7 s, respectively. However, they were actually propelled to distance of 5,002.60, 3,693.51, and 4,149.35 μm, respectively, with errors of 0.05%, 1.17%, and 3.15% (Fig. 3e, Supplementary Movie 13, and Table 1). Notably, MNR-2 exhibited the highest propulsion velocity among all MNRs. Consequently, it was chosen to move along a track shape to trace the letters “MNR”, precisely driven by an external rotating magnetic field with 8 mT at a frequency of 10 Hz (Fig. 3f and Supplementary Movie 14). This demonstration illustrates the capability of the FSI model to accurately predict MNR propulsion velocity. It enables the efficient guiding of MNRs with varying sizes and geometrical shapes to different destinations, with potential applications for controlling groups or swarms of MNRs.

Transient dynamic analysis of micro-/nano-robots

The RFT model is recognized for its efficacy in determining the stable propulsion and angular velocities of standard MNRs under an external torque. However, it is limited in its ability to investigate the transient dynamic responses of MNRs as they transit to a stable state. Understanding this transient behavior is crucial for evaluating the safety and reliability of MNRs, particularly in biomedical applications which need precision and harm avoidance. Transient analysis is instrumental in quantifying the magnitude of forces exerted by MNRs momentarily after activation in vivo, to ensure that these forces do not pose any risk to human tissues. A notable application of this analysis is in the potential of MNRs to disintegrate blood clots and similar internal obstructions. In such instances, understanding the transient forces becomes critical, as they define the necessary threshold for effectively dismantling these blockages without harming adjacent tissues, highlighting the delicate balance MNRs must maintain between efficacy and safety in life-saving procedures.

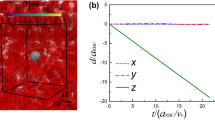

In this study, the transient dynamic behaviors of one standard and four general helical MNRs with lengths of 120 μm in a fluid environment (\(\eta\) = 1.01 × 10–3 mPa⋅s, \(\rho\) = 970 kg m–3) under an external torque of 1 × 10–15 N ⋅ m were studied by FSI model. The results illustrated that both the propulsion and angular velocities of the one standard and four general helical MNRs rapidly reached a stable value of 5.164 μm s–1 and 2.611 rad s–1, 7.267 μm s–1 and 2.999 rad s–1, 4.075 μm s–1 and 2.381 rad s–1, 5.11 μm s–1 and 2.07 rad s–1, 2.521 μm s–1 and 1.889 rad s–1, respectively, in a short period (i.e., 4.27 × 10–4, 5.93 × 10–4, 5.02 × 10–4, 5.03 × 10–4, and 2.35 × 10–4 s, respectively), as shown in Fig. 4a, b. The resistance torque and resistance force (see their definition in Supplementary Note 3) are obtained by integrating stresses on the surface of MNRs. The resistant torques exerted on the one standard and four general helical MNRs increased sharply until they reached the stable value of the external torque of 1 × 10–15 N ⋅ m (Fig. 4c). The resistant forces on the one standard and four general helical MNRs presented as a pulse pattern, peaked initially (1.65 × 10–11, 2.26 × 10–11, 2.29 × 10–11, 1.68 × 10–11, and 1.16 × 10–11 N, respectively) before diminishing to zero (Fig. 4d). Once the motion state became stable, the resistant torque equaled the external torque applied to the MNRs and the resistant force dropped to zero, which is consistent with what the RFT model calculates for standard MNRs (Supplementary Note 3). Therefore, our FSI model demonstrates its efficacy in predicting the transient dynamic behaviors of helical MNRs leading up to their stabilization.

Stress distribution on micro-/nano-robots

The stresses acting on MNR-1 with length of 120 μm in the fluid environment (\(\eta\) = 1.01 × 10–3 mPa⋅s, \(\rho\) = 970 kg m–3) under an external torque of 1 × 10–15 N ⋅ m, including its x-, y-, z-components as well as xyz-total, were color mapped onto the surface of MNRs and vectorized by the black arrows three states: the initial state, when it reached the maximum propulsion force, and at the stable state (Fig. 5a–d). The x-axis component of the stress was informative regarding which parts of MNR-1 contributed positively to its propulsion and which resisted the propulsive motion. It can be noted that the abdomen region of the helical structure contributed the most to the propulsion force (Fig. 5a). The propulsive force was shown to grow from the initial state till the maximum state, and dropped to zero in the stable state. When the motion of MNR-1 reached its stable state, the stresses acting on its top and bottom were equal in magnitude but opposite in direction (Fig. 5b). Similarly, the stresses acting on its left and right sides were also equal in magnitude but opposite in direction (Fig. 5c). In other words, the total stress on MNR-1 was anti-circumferential (Fig. 5d). The x-, y-, and z-components of the stresses on the general four helical MNRs were very similar to those of standard MNR-1. The total stress acting on the one standard and four general helical MNRs, showing an initial increase that then trends toward a stable motion state (Fig. 5d–h). Importantly, as shown by the different colors on the surfaces of the helical MNRs, the stresses on their outer sides are greater than those on their inner ones, suggesting that helical MNRs are subject to annular squeezing. The total stress that the MNR experiences from the fluid reaction is centrosymmetric, meaning that the stress distribution is symmetrical around the center. This symmetrical distribution can be observed in Fig. 5d, e, f, g, h, where the total stress distribution along the circumference is uniform. The black arrows on the surfaces of the helical MNRs reflect the magnitudes and directions of stress forces. The distributions, magnitudes, and directions of stress forces on helical MNRs may serve as good indicators for structural design with different application requirements. It can be seen that the boundary region of the helical structure is the main source of the stress (Fig. 5b–c), as well as the extremities in MNR-1 (Fig. 5d), MNR-2 (Fig. 5e), and MNR-4 (Fig. 5g). The boundary region of MNR-2 was smaller than that of MNR-1, so its stress was also smaller, thus explaining its higher propulsion velocity compared to MNR-1 (Fig. 5d and Fig. 5e). The extremity of MNR-3 aligned with its direction of rotation (Fig. 5f), and the extremity of MNR-5, which was parallel to the direction of rotation (Fig. 5h), experienced significantly less torque resistance compared to the extremities of MNR-1, MNR-2, and MNR-4—which were all perpendicular to the direction of rotation. Therefore, some design strategies can be obtained to optimize the structure of the helical reluctance by increasing the abdomen region, reducing the boundary region, and ensuring that the extremities of the structure are as parallel as possible to the direction of rotation to increase its propulsion velocity.

The stress components acting on the surface of standard MNR-1 from the fluid in the x-component (a), y-component (b), z-component (c). d–h The xyz-total stress acting on the surfaces of one standard and four general helical MNRs and the fluid vortex line surrounding them at the initial, propulsion Forcemax, and stable states.

Fluid vorticity variation around micro-/nano-robots

The results obtained from the FSI model for one standard and four general helical MNRs revealed the dynamic evolution of the fluid vortex lines surrounding them (Fig. 5d–h). These visualizations illustrate the transition from an initial chaotic state to a more ordered flow pattern as the motions of the MNRs reach stable states. At the initial and force maximum states, the vortex line encircles the periphery region and represents a fluid flow passing along the x-axis. At the stable state, the vortex line encircles the cross-section and indicates that the fluid flows along the helical boundary. This transition from chaos to order coincides with the stabilization of motion in helical MNRs, indicates that fluid dynamics plays a crucial role in this mechanism of propulsion. The ordered streamlines observed in the later stages suggest that the motions of helical MNRs can influence the surrounding fluid, inducing a more organized flow pattern. Even in the ordered state observed through the FSI model, the fluid streamline around each segment of a helical MNR interacts dynamically with its neighboring regions39. This interaction aligns with analyses conducted via the RFT model, which similarly anticipated that the front sections of helical MNRs exert a backward propulsion force on their rear sections (Supplementary Note 3). This interaction also affects the step-out-frequency phenomenon, offering deeper insights into the propulsion mechanisms of MNRs.

The role of fluid dynamic viscosity

Dynamic viscosity is a fundamental physical property of fluids that reflects the influence of internal viscous resistance on the movements of helical MNRs. The propulsion velocities of helical MNRs in fluids (\(\rho\) = 970 kg m–3) of different dynamic viscosities (i.e., \(\eta\) = 1.01 × 10–3, 5.0 × 10–3, 7.0 × 10–3, and 0.01 mPa⋅s) under an external torque of 1.0 × 10–15 N ⋅ m were analyzed by FSI model (Supplementary Fig. 5). The propulsion velocities of standard MNR-1 in those four different viscosity fluids were 5.164, 1.043, 0.745, and 0.522 μm s–1, respectively. These results clearly indicated an inverse proportion relationship between the propulsion velocity of standard MNR-1 and the dynamic viscosity of the fluid environment they navigate through.

A similar trend was observed in the velocities of the other four general helical MNRs as the dynamic viscosity of the fluid changed. The helical MNRs has less resistance in fluids of lower dynamic viscosities, allowing helical MNRs to achieve a higher propulsion velocity and greater propulsion force during in helical motion, thus achieving to longer propulsion distances. Conversely, in fluids of higher dynamic viscosities, the motions of helical MNRs encounter greater resistance, leading to decreases in velocity. To complete an expected helical trajectory in such fluids, more energy is required in order to generate a sufficiently strong propulsive force. The FSI model provides valuable insights into the motion behaviors of helical MNRs in fluids of varying dynamic viscosities. Hence, with the assistance of the FSI model, the design and control strategies of MNRs can be improved to enhance their motion in different fluid environments, which allow for more efficient and effective deployment of helical MNRs for a variety of applications.

Discussion

Although MNRs hold significant promise for minimally invasive targeted therapies in various biological applications, their clinical utilization remains unrealized. This is primarily attributed to a limited understanding of their behaviors, resulting in poor design of MNRs and challenges in vessel navigation. Thus, design and precise navigation of MNR motion within three-dimensional spaces is crucial to facilitate further innovation in this field.

In summary, we proposed a comprehensive FSI dynamic model for general helical MNRs. This model accounts for the clinical operative scenario involving MNRs within vessels, considering numerous factors to ensure accuracy. The FSI model was first validated by propulsion velocities of the proposed FSI model matches well with that of the RFT model for a standard MNR. Then two experiments verify the correctness and accuracy of the model in propulsion velocity prediction and navigation of general helical MNRs. Furthermore, we conducted a parametric study using the FSI model to analyze the transient behavior of fluid and the surface stress evolution of MNRs. This information is valuable for customizing MNR navigation plans for individual patients in clinical settings and understanding blood behavior when interacting with MNRs, such as blood clotting in vessels, thereby mitigating complications in targeted therapeutics involving MNRs.

The FSI model not only reveals exceptional potential in propulsion velocity prediction and precise navigation, but also opens new pathways for the structural design and performance optimization of MNRs. The flexibility of model facilitates the construction of general MNRs dynamic relationship between magnetic input and kinetic output through pattern recognition technologies, paving the way for the realization of accurate close-loop control systems. Additionally, the FSI model can be closely integrated with external environmental factors, such as magnetic, acoustic, and thermal fields, thereby broadening the application scope and enhancing the effectiveness of MNRs. In the future, we believe that this FSI model of MNRs is a significant general tool for in a wide variety of medical, science, and engineering fields.

Methods

Numerical mathematical description

Fluid dynamics in ALE coordinate system

To clearly describe the mathematical mapping relationship among the space coordinate system (Eulerian description), material coordinate system (Lagrange description), and mesh coordinate system (Arbitrary Lagrangian-Eulerian (ALE) description). Define \({\bf{x}}\) as the space coordinate system, \({{\bf{R}}}_{{\bf{x}}}\) as the spatial domain, \({\bf{X}}\) as the material coordinate system, \({{\bf{R}}}_{{\bf{X}}}\) as the material domain, \({\boldsymbol{\chi }}\) as the mesh coordinate system, \({{\bf{R}}}_{{\boldsymbol{\chi }}}\) as the referential domain (Supplementary Fig. 2).

The motion of material points in the space coordinate system is defined as follows:

The displacement and velocity of material are,

where \({\bf{u}}\left({\bf{X}},\, t\right)\) is the displacement of material, \({\bf{X}}\) is the initial position, \({\boldsymbol{\varphi }}\left({\bf{X}},\, t\right)\) is the current position, \({\bf{v}}\left({\bf{X}},\, t\right)\) is the velocity of material, \(\big|\begin{array}{c}\,\\ {\bf{X}}\end{array}\) meaning the space coordinate system \({\bf{X}}\) is fixed.

Similarly, the motion of grid points in a space coordinate system is defined as follows,

The displacement and velocity of mesh are,

Similarly, the motion of the material as seen from the mesh coordinate system is defined as follows,

The velocity of material is,

The scalar physical quantity is described by \(f\left({\bf{X}},t\right)\), \(f\left({\bf{x}},t\right)\) and \(f\left({\boldsymbol{\chi }},t\right)\) in material, space, and referential domains, respectively. Their transformation relations can be shown,

When using the COMSOL to simulate the coupling flow around the MNR, the fluid-solid coupling module can be used. The momentum conservation law and the continuity equation for incompressible flow formulated in the ALE method are given as,

where \(\rho\) is the fluid density (SI unit: kg/m3), \({{\bf{F}}}_{{\bf{f}}}\) denotes the volume force vector (SI unit: kg/m3) and \({{\boldsymbol{\sigma }}}_{{\bf{f}}}\) represents the Cauchy stress tensor (SI unit: Pa). The velocity difference \({\bf{v}}{\boldsymbol{-}}\hat{{\bf{v}}}\) is denoted as the convective velocity.

The stress tensor \({{\boldsymbol{\sigma }}}_{{\bf{f}}}\) can be decomposed into its isotropic and deviatoric parts,

where \(p\) represents the static pressure generated by the fluid, \(\eta\) denotes the kinematic viscosity of the fluid, and \({\bf{I}}\) is the third-order unit diagonal matrix. This load represents a sum of pressure and viscous forces.

Due to MNRs swimming in the low \({Re}\) fluid environment, the gravitational and buoyancy terms can be ignored. Substituting Equation (15) into Equation (14), the N-S momentum equation in three-dimensional non-compressible viscous fluids is,

Solid mechanics

The equation governing solid dynamics is,

where \(\rho\) is the density of MNR, \({\boldsymbol{d}}\) is the displacements of MNR, \({{\boldsymbol{\sigma }}}_{{\bf{s}}}\) is the Cauchy stress tensor on the MNR, and \({{\bf{F}}}_{{\bf{s}}}\) is the volumetric force on the MNR.

In this study, the MNRs have propulsion and rotational motion at the same time, and their discretized governing equations are expressed as,

where \({\bf{u}}\) and \({\boldsymbol{\omega }}\) denote the propulsion and rotational velocity of MNRs, respectively, \(m\) and \({\bf{I}}\) depict the mass and moment of inertia. \({{\bf{T}}}_{{\bf{0}}}\) is the external torque, \({\bf{F}}\) and \({\bf{T}}\) represent the force and torque on MNRs generated by fluid, \({{\bf{r}}}_{{\bf{s}}}\) and \({{\bf{r}}}_{{\bf{c}}}\) are the position vectors of the surface and the center of the MNRs.

Fluid-Solid interaction

At the interface between the fluid and solid domain, there is a fluid-solid interaction boundary, \({\Omega }_{f-s}\), in which a viscous fluid flow is interacting with a solid. Consistency and continuity conditions must be satisfied at \({\Omega }_{f-s}\), where the velocity and stress of the fluid and solid should be equal in value and opposite in direction,

where \({{\boldsymbol{\sigma }}}_{{\bf{s}}}\) is the stress on the solid, \({{\boldsymbol{\sigma }}}_{{\bf{f}}}\) is the stress on the fluid, \(\dot{{\bf{d}}}\) is the velocity of the solid boundary node, \({\bf{v}}\) is the velocity of the node at the fluid boundary, and \(\hat{{\bf{v}}}\) is the velocity of the mesh node, \({\bf{n}}\) is the outward normal vector on the \({\Omega }_{f-s}\).

Also, on \({\Omega }_{f-s}\), the propulsion force exerted on the solid boundary by the fluid is the negative of the reaction force on the fluid, similarly, the rotational torque applied over all solid surfaces by the fluid is the negative of the reaction torque on the fluid, which are termed as hydrodynamic force and torque, respectively, are described as,

In this way, a closed-loop interaction of fluid and MNRs is established. Specifically, the hydrodynamic forces and torques generated by the fluid induce changes in the motion state change of MNRs. Simultaneously, the altered state of the MNRs induces changes in the movement of fluid, which, in turn, determines the hydrodynamic force and torque acting on the MNRs. Consequently, it becomes apparent that within this closed-loop interaction, both the hydrodynamic force and the motion state of the MNRs cannot be independently determined in advance. Their solutions can only be obtained after systematically solving the entire coupling system.

Maintaining this characteristic of closed-loop coupling is essential for accurately modeling the motion of MNRs in a fluid environment. Neglecting the coupling aspect would result in the loss of vital information about the dynamic interaction between the MNR and the surrounding fluid, leading to less accurate predictions of its motion and behavior in practical scenarios. Therefore, preserving the closed-loop nature of the fluid-solid interaction is crucial for a comprehensive and precise understanding of MNR motion in a fluid environment.

Numerical implementation of FSI

Geometry construction and materials

The key geometrical parameters of the standard MNR consist of the helical radius \(R\), the radius of the circular cross-section \(r\), the pitch \(\lambda\), the number of turns \(n\), and the helix angle \(\theta\) (Supplementary Fig. 2d). The simulation geometry consists of three parts: the MNR, a peripheral cylinder, and a rectangular flow channel. The central axis of MNR was placed parallel to the x-axis. The peripheral cylinder was set to enhance computational accuracy. Within the simulation space, only the MNR is considered as a solid, while the remainder of the space is defined as a fluid material.

Module selection

As previously mentioned, achieving corkscrewed motion requires the coupling of creeping flow and solid mechanics. However, the limitations of COMSOL only allow for either propulsion motion or rotational motion when adopting the solid mechanic module alone. To simultaneously realize the propulsion and rotational motion of the MNRs in a fluid environment, an ordinary differential equations (ODE) module was used to describe the solid mechanics. In this approach, the Laminar flow module, ODE module, and Moving mesh module were coupled together to accurately describe corkscrewed motion in a fluid environment. The rationale behind this approach is as follows: the Laminar flow module calculates the total traction exerted by the fluid on the surface of the MNR, which is then used in the ODE module to determine the motion state of MNRs based on second law of Newton. The displacement of the MNR, as determined by the ODE module, is subsequently input into the Moving mesh module to facilitate the implementation of the ALE method.

Boundary and initial condition

A no-slip wall condition was imposed on all boundaries except for the boundaries of the MNRs, where flow continuity was applied at all identity boundary pairs. The moving mesh was applied to describe the deformation of the mesh for constructing the ALE method. Specifically, prescribed deformations were applied to the center cylinder. Because the propulsion direction (x-axis) is of primary interest, propulsion, and rotational movements in the y- and z-axis were neglected to substantially reduce the computational cost. Such that, the prescribed deformation in three-dimension is as follows

Mesh generation and convergence test

To achieve accurate results in FSI model simulation calculation, a high level of mesh refinement is required for the motion area of MNR. To improve calculation stability and reduce unnecessary computations, the mesh of the model is divided into 5 parts: (i) the MNR has meshed with tetrahedral elements, (ii) the prescribed deformation domain has meshed with tetrahedral elements, (iii) the deforming domains have meshed with sweep elements, (iv) The boundaries of the two sides of cylinders have meshed with free triangular elements, (vi) the rest of the model is meshed with tetrahedral elements. Here correlation analysis and convergence analysis are conducted to determine the optimal meshing strategy for the FSI model (Supplementary Note 3). During the simulation process, a segregated solver is employed to perform the necessary calculations, ensuring efficient and accurate solution of the governing equations (Supplementary Note 4).

Experimental set up

Fabrication of MNRs

The MNRs were fabricated using TPP direct laser lithography (Nanoscribe GmbH). First, the MNR structures were designed with Solidworks and loaded in the Nanoscribe software. Then, photoresist IP-S (negative-tone photoresist) was spin-coated on an ITO glass substrate. Third, the MNRs were written with a 25x lens under laser power was 40 mW, and the scan speed was 40 mm s–1. Finally, the MNRs were developed in IPA for 15 min, and dried with a nitrogen gun. Then MNRs sample was coated with Ni (100 nm) layer, the growth rates of Ni layer layers were calibrated to be about 3 Å s–1 successfully for 333 s by magnetron sputtering (Kurt J. Lesker, LAB 18). A homogeneous coating on the MNRs surface was achieved at a rotating speed of 20 rpm m–1 at the sample stage.

Characterization of motion performance of MNRs

The swimming behavior of MNRs was investigated using an electromagnetic control system consisting of a triaxial Helmholtz coils system to generate rotating magnetic fields in arbitrary directions. To sweep the MNRs down from the substrate, a microprobe (T-4-22, GGB Industries, Inc., USA) was used to pick up, transport, and release the MNRs into the fluid and make it suspended for subsequent micromanipulation and observation. To capture videos and pictures, a charge-coupled device (CCD) camera with an optical lens and a light-emitting diode (LED) light source was connected to the computer.

Data availability

Source data are provided with this paper.

References

Hu, N. et al. Development of 3D-Printed Magnetic Micro-Nanorobots for Targeted Therapeutics: the State of Art. Adv. NanoBiomed Res. n/a, 2300018, https://doi.org/10.1002/anbr.202300018 (2023).

Wu, J. et al. Helical Klinotactic Locomotion of Two‐Link Nanoswimmers with Dual‐Function Drug‐Loaded Soft Polysaccharide Hinges. Adv. Sci. 8, 2004458 (2021).

Hu, X., Chen, A., Luo, Y., Zhang, C. & Zhang, E. Steerable catheters for minimally invasive surgery: a review and future directions. Comput Assist Surg. 23, 21–41 (2018).

Lee, S. et al. A Capsule-Type Microrobot with Pick-and-Drop Motion for Targeted Drug and Cell Delivery. Adv. Healthc. Mater. 7, 1700985 (2018).

Tirgarbahnamiri, P. & Bagheri-Khoulenjani, S. Biodegradable microrobots for targeting cell delivery. Med. Hypotheses 102, 56–60 (2017).

Servant, A., Qiu, F., Mazza, M., Kostarelos, K. & Nelson, B. J. Controlled In Vivo Swimming of a Swarm of Bacteria‐Like Microrobotic Flagella. Adv. Mater. 27, 2981–2988 (2015).

Jurado-Sánchez, B., Escarpa, A. & Wang, J. Lighting up micromotors with quantum dots for smart chemical sensing. Chem. Commun. 51, 14088–14091 (2015).

Deng, G. et al. Natural-Killer-Cell-Inspired Nanorobots with Aggregation-Induced Emission Characteristics for Near-Infrared-II Fluorescence-Guided Glioma Theranostics. ACS Nano 14, 11452–11462 (2020).

Park, J., Kim, J. Y., Pané, S., Nelson, B. J. & Choi, H. Acoustically Mediated Controlled Drug Release and Targeted Therapy with Degradable 3D Porous Magnetic Microrobots. Adv. Healthc. Mater. 10, 2001096 (2021).

Sun, M. et al. Magnetic biohybrid micromotors with high maneuverability for efficient drug loading and targeted drug delivery. Nanoscale 11, 18382–18392 (2019).

Chen, X.-Z. et al. Magnetically driven piezoelectric soft microswimmers for neuron-like cell delivery and neuronal differentiation. Mater. Horiz. 6, 1512–1516 (2019).

Jeon, S. et al. Magnetically actuated microrobots as a platform for stem cell transplantation. Sci. Robot. 4, eaav4317 (2019).

Dong, M. et al. 3D‐Printed Soft Magnetoelectric Microswimmers for Delivery and Differentiation of Neuron‐Like Cells. Adv. Funct. Mater. 30, 1910323 (2020).

Lin, Y. & Zhang, W. J. Towards a novel interface design framework: function–behavior–state paradigm. Int. J. Hum.-Computer Stud. 61, 259–297 (2004).

Zhang, W. J., Lin, Y. & Sinha, N. ON THE FUNCTION-BEHAVIOR-STRUCTURE MODEL FOR DESIGN. Proc. of the Canadian Engineering Education Association (CEEA) 0, https://doi.org/10.24908/pceea.v0i0.3884 (2011).

Wang, J. W. et al. On domain modelling of the service system with its application to enterprise information systems. Enterp. Inf. Syst. 10, 1–16 (2016).

Wang, D. et al. One-Step Fabrication of Dual Optically/Magnetically Modulated Walnut-like Micromotor. Langmuir 35, 2801–2807 (2019).

Sun, Y. et al. Calligraphy/Painting Based on a Bioinspired Light-Driven Micromotor with Concentration-Dependent Motion Direction Reversal and Dynamic Swarming Behavior. ACS Appl. Mater. Interf.11, 40533–40542 (2019).

Villangca, M. J., Palima, D., Bañas, A. R. & Glückstad, J. Light-driven micro-tool equipped with a syringe function. Light.: Sci. Appl. 5, e16148–e16148 (2016).

Kaynak, M. et al. Acoustic actuation of bioinspired microswimmers. Lab a Chip 17, 395–400 (2017).

Feng, J., Yuan, J. & Cho, S. K. 2-D steering and propelling of acoustic bubble-powered microswimmers. Lab a Chip 16, 2317–2325 (2016).

Wang, Q. et al. Ultrasound Doppler-guided real-time navigation of a magnetic microswarm for active endovascular delivery. Sci. Adv. 7, eabe5914 (2021).

Li, J. et al. Dynamics of catalytic tubular microjet engines: Dependence on geometry and chemical environment. Nanoscale 3, 5083 (2011).

Paxton, W. F. et al. Catalytic Nanomotors: Autonomous Movement of Striped Nanorods. J. Am. Chem. Soc. 126, 13424–13431 (2004).

Zhang, L., Xiao, Z., Chen, X., Chen, J. & Wang, W. Confined 1D Propulsion of Metallodielectric Janus Micromotors on Microelectrodes under Alternating Current Electric Fields. ACS Nano 13, 8842–8853 (2019).

Fan, D. et al. Subcellular-resolution delivery of a cytokine through precisely manipulated nanowires. Nature Nanotechnology 5, 545–551 (2010).

Wang, Z., Guo, S., Guo, J., Fu, Q., Zheng, L., & Tamiya, T. Selective Motion Control of a Novel Magnetic-Driven Minirobot With Targeted Drug Sustained-Release Function. IEEE/ASME Trans. Mechatron. 27, 336–347 (2022).

Wei, T. et al. Development of Magnet‐Driven and Image‐Guided Degradable Microrobots for the Precise Delivery of Engineered Stem Cells for Cancer Therapy. Small 16, 1906908 (2020).

Shuai, C. et al. A magnetic micro-environment in scaffolds for stimulating bone regeneration. Mater. Des. 185, 108275 (2020).

Xin, C. et al. Conical Hollow Microhelices with Superior Swimming Capabilities for Targeted Cargo Delivery. Adv. Mater. 31, 1808226 (2019).

Danhier, F., Feron, O. & Préat, V. To exploit the tumor microenvironment: Passive and active tumor targeting of nanocarriers for anti-cancer drug delivery. J. Controlled Release 148, 135–146 (2010).

Wang, X., Hu, C., Pane, S. & Nelson, B. J. Dynamic Modeling of Magnetic Helical Microrobots. IEEE Robot. Autom. Lett. 7, 1682–1688 (2022).

Xu, T. et al. Dynamic Morphology and Swimming Properties of Rotating Miniature Swimmers With Soft Tails. IEEE/ASME Trans. Mechatron. 24, 924–934 (2019).

Xu, T., Hwang, G., Andreff, N. & Régnier, S. Influence of geometry on swimming performance of helical swimmers using DoE. J. Micro-Bio Robot. 11, 57–66 (2016).

Xin, C. et al. Light-triggered multi-joint microactuator fabricated by two-in-one femtosecond laser writing. Nat. Commun. 14, 4273 (2023).

Chen, Y. et al. Carbon Helical Nanorobots Capable of Cell Membrane Penetration for Single Cell Targeted SERS Bio‐Sensing and Photothermal Cancer Therapy. Adv. Funct. Mater. 32, 2200600 (2022).

Wang, X. et al. MOFBOTS: Metal–Organic‐Framework‐Based Biomedical Microrobots. Adv. Mater. 31, 1901592 (2019).

Zhang, W. J., Li, Q. & Guo, L. S. Integrated design of mechanical structure and control algorithm for a programmable four-bar linkage. IEEE/ASME Trans. Mechatron. 4, 354–362 (1999).

Hancock, G. J. The self-propulsion of microscopic organisms through liquids. Proc. R. Soc. Lond. Ser. A. Math. Phys. Sci. 217, 96–121 (1953).

Gray, J. & Hancock, G. J. The Propulsion of Sea-Urchin Spermatozoa. J. Exp. Biol. 32, 802–814 (1955).

Cox, R. G. The motion of long slender bodies in a viscous fluid Part 1. General theory. J. Fluid Mech. 44, 791–810 (1970).

Lighthill, J. Flagellar Hydrodynamics. SIAM Rev. 18, 161–230 (1976).

Acknowledgements

This work was supported by the High-level Talent Recruitment Research Start-up Fund, Shanghai University No. 13-G210-18-230 (C.Z.), China Scholarship Council No. 202106890059 (N.-N.H) and National Natural Science Foundation of China No. 81801795 (B.Z.). The authors acknowledge the Mingche Biotechnology (Suzhou) Co., Ltd for the experimental support of the samples.

Author information

Authors and Affiliations

Contributions

N.-N.H. conceived the idea and designed the project. N.-N.H., and L.-J.D. completed the simulation and all the experiments. N.-N.H., A.-H.W. and C.Z. completed data analysis and figure depicture. A.-H.W., W.-J.Z., C.Z., and B.Z. discussed the results and made recommendations. All authors wrote and revised the paper. R.-X.Y. supervised the project.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

41467_2024_51518_MOESM10_ESM.mp4

Supplementary Movie 7: The motion of MNR-1-360 (360 μm length) under external magnetic fields with various rotating frequencies.

41467_2024_51518_MOESM11_ESM.mp4

Supplementary Movie 8: The motion of MNR-1-480 (480 μm length) under external magnetic fields with various rotating frequencies.

41467_2024_51518_MOESM12_ESM.mp4

Supplementary Movie 9: The motion of MNR-1-720 (720 μm length) under external magnetic fields with various rotating frequencies.

41467_2024_51518_MOESM13_ESM.mp4

Supplementary Movie 10: The motion of MNR-1-840 (840 μm length) under external magnetic fields with various rotating frequencies.

41467_2024_51518_MOESM17_ESM.mp4

Supplementary Movie 14: MNR-2 moved along a track resembling the letter “MNR” with precise control under an external rotating magnetic field.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hu, N., Ding, L., Wang, A. et al. Comprehensive modeling of corkscrew motion in micro-/nano-robots with general helical structures. Nat Commun 15, 7399 (2024). https://doi.org/10.1038/s41467-024-51518-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-51518-z