Abstract

The direct synthesis of light aromatics, especially para-xylene (p-X), from syngas/CO2 is drawing strong interest, but improving the space-time yield (STY) of p-X is a significant challenge. Here, a dynamic “dual-engine-driven” (DED) catalytic system is designed by combining two partners of ZnCr and FeMn (named “dual-engine”) with Z5@SiO2 capsule zeolite. The DED catalyst of 1.0%FeMn&[ZnCr&Z5@SiO2] shows an extremely higher p-X STY of 36.1 gp-x·kgcat-1·h-1, about eight times higher than that of [ZnCr&Z5]. DED manipulates ZnCr engine for methanol formation and drives FeMn engine for light olefins generation together, and then the formed methanol and light olefins are coordinately converted in situ into p-X-rich aromatics over Z5@SiO2. The DED model boosts the driving force for syngas/CO2 conversion, simultaneously concerting the cooperation of “dual-engine” for p-X generation, resulting in extremely high STY of p-X. This study achieves non-petroleum p-X production at industrial-relevant level and advances knowledge in designing innovative heterogeneous catalysts.

Similar content being viewed by others

Introduction

Aromatic compounds play critical roles in industry and biochemistry, which are widely employed to produce a range of important chemicals and polymers, such as styrene, phenol, aniline, polyester, and nylon1,2,3,4,5,6,7,8,9,10. Among the major aromatics, para-xylene (p-X) is an essential feedstock in the chemical industry, being used on a large scale for polymers synthesis. In particular, p-X-derived terephthalic acid can be polymerized into polyesters like polyethylene terephthalate (PET)11,12,13. Currently, most of p-X is produced by the catalytic reforming of petroleum naphtha and the energy-consuming chemical separation process for BTX (benzene, toluene, and the xylene isomers). A non-petroleum p-X synthesis approach is urgently required to alleviate the enormous pressure imposed by the decline of crude oil resources.

Over the past decades, several new p-X synthesis pathways with non-petroleum molecules as feedstocks have been proposed, such as CO or CO2 hydrogenation3,10,14,15,16,17,18,19,20,21,22,23,24, methanol to aromatics (MTA)25,26,27,28,29,30,31, toluene methylation11,12,13,32, methane aromatization33, hydrodeoxygenation (HDO) and aromatization of raw bio-oil34, and glycerol catalytic pyrolysis35. The highly efficient conversion of syngas into p-X is a promising strategy to bridge the utilization of biomass, natural gas, etc., with value-added chemicals synthesis. Syngas can be converted into light aromatics, especially p-X, in a single-pass through some tandem catalytic processes, such as the methanol-mediated pathway (syngas→methanol→aromatics, SMA)14,15,16,17,36 and the route with olefins as the core intermediates (syngas→olefins→aromatics, SOA)37,38,39,40,41,42,43. For the SMA route, methanol is first produced from syngas over high-temperature methanol synthesis catalysts, such as ZnCr2O415,36, Cr2O344, MnCrOx16, and Ce0.2Zr0.8O245, and then converted into aromatics via the MTA process catalyzed by acidic HZSM-5 zeolite. For the SOA route, the olefins produced during the Fischer-Tropsch (FT) synthesis over the Fe-based catalysts such as Fe3O4@MnO42, FeNiOx(5:1)-0.41Na38, and Na-Zn-Fe5C243 can be continuously converted into aromatics over HZSM-5 with high efficiency. In comparison to the SOA pathway, the SMA pathway achieves high p-X-rich aromatic selectivity due to the existence of methanol and the extraordinary shape selectivity of HZSM-5 zeolite during the methanol conversion process13,28,32,44.

Very recently, Tsubaki’s group presented a promising ZnCr&Zn/Z5@S1 hybrid catalyst to achieve a p-X selectivity of 27.6% in the total products and 77.3% in xylene14. Wang et al. further explored a tailor-made capsule zeolite with Ga doping and SiO2 coating on HZSM-5 and combined it with the Cr2O3 methanol synthesis catalyst to enhance the synthesis of p-X-rich aromatics3. However, the p-X yield obtained from the SMA route is severely suppressed by the dominant byproduct of CO2 that stems from the higher temperature-facilitated water-gas-shit (WGS) reaction on the reducible metal oxide. The SOA process with alkene as intermediates exhibits high syngas conversion but low selectivity to p-X. Therefore, it is urgent to fabricate an innovative catalytic system with tailor-made catalytic active components to simultaneously enable high p-X selectivity and excellent syngas conversion efficiency. At the same time, undesirable CO2 formation should be suppressed to meet the demand of high p-X yield for large scale industrialization of this syngas to p-X reaction.

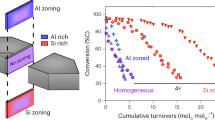

Herein, we proposed a “dual-engine-driven” (DED) catalytic system by fabricating a new DED catalyst composed of FeMn (olefin-engine), ZnCr (methanol-engine), and capsule zeolite of HZSM-5@SiO2 (Z5@SiO2). We have broken the limitation of the traditional “single-engine-driven” of SMA or SOA route (Fig. 1). The single FeMn engine has been frequently used as a high-efficient catalyst for light olefins synthesis from syngas via FT process (FTO), while ZnCr engine has been widely used in methanol synthesis from syngas with high methanol selectivity but low CO conversion46,47. In this DED catalytic system, syngas is rapidly and efficiently converted into olefins over the olefin-engine, followed by their further conversion to form benzene over zeolite. Another methanol-engine offers enough methanol, but the further methanol-to-olefins process will be severely depressed at the same time due to the existence of the pre-formed olefins from olefin-engine. According to our design, most of the formed methanol intermediates can facilely participate in benzene methylation reactions to produce more p-X, instead of MTO (methanol to olefins) and MTA paths. The catalytic system fabricated by the DED catalyst overcomes the problems faced by the traditional single reaction routes. The rationally designed capsule zeolite Z5@SiO2 also plays a vital role in determining the high p-X selectivity. By organizing the “dual-engine” of FeMn and ZnCr partners with the capsule zeolite Z5@SiO2, extremely higher p-X STY was obtained. The p-X STY of the 1.0%FeMn&[ZnCr&Z5@SiO2] DED catalyst is as high as 36.1 gp-X·kgcat-1·h-1 under optimal reaction conditions (Fig. 1), which is much higher than that of the traditional “single-engine-driven” [ZnCr&Z5] catalyst (4.5 gp-X·kgcat-1·h-1) or [FeMn&Z5] catalyst (8.7 gp-X·kgcat-1·h-1).

a A highly active “dual-engine-driven” catalyst was designed by combining methanol synthesis partner of ZnCr and olefins synthesis partner of FeMn, named “dual-engine”, with capsule zeolite Z5@SiO2. b A comparison of the STY of p-X between general single-engine-driven and new dual-engine-driven catalysts.

Results

Catalyst performance of DED catalyst for p-X synthesis from CO2-containing syngas

Figure 2a, b illustrates the catalytic performance of CO2-containing syngas conversion over pure metal oxides, conventional, and DED catalysts under 375 °C and 5 MPa. By investigating the effect of Zn/Cr molar ratio on the catalytic performance of aromatics synthesis from syngas, it was confirmed that the molar ratio of Zn/Cr = 1/2, when combined with Z5@SiO2, is optimal for generating p-X-rich aromatics via CO hydrogenation (Table S1). The pure ZnCr partner exhibited high methanol and dimethyl ether (MeOH&DME) selectivity (72.29%, Table S2) but low CO conversion (2.7%), which is in good agreement with the previous research47,48. When it was integrated with the commercial HZSM-5 (Z5), the catalyst [ZnCr&Z5] showed good aromatic selectivity (57.59%, Table S2) and better CO conversion (5.1%) due to the thermodynamic driving force of tandem reaction. But there were mostly C9+ aromatics and few light aromatics among them, with meta-xylene (m-X) dominating the light aromatics. The p-X STY was only 4.5 gp-x·kgcat-1·h-1 over the [ZnCr&Z5] catalyst (Fig. 2a). By contrast, another [FeMn&Z5] catalyst with FeMn as partner instead of ZnCr exhibited high CO conversion (38.1%) but a low aromatics selectivity (17.25%, Table S2). The p-X STY was only 8.7 gp-x·kgcat-1·h-1 over the [FeMn&Z5] catalyst (Fig. 2a and Table S2).

a, b The content effect of FeMn on the catalytic performance of [FeMn&ZnCr&Z5@SiO2] DED catalysts. a The CO conversion and STY of p-X. b The selectivity of p-X, o-X, m-X, E, T, B, and Ar(C9+) in all of the hydrocarbons, in which p-X = Para-Xylene, o-X = Ortho-Xylene, m-X = Meta-Xylene, E = Ethylbenzene, T = Toluene, B = Benzene, and Ar(C9+) = Aromatics containing more than 9 carbon atoms. c, d The effect of the integration manner of three partners on the catalytic performance with the FeMn content was 1.0%. (I): powder mixing, [FeMn&ZnCr&Z5@SiO2]; (II): granule mixing, FeMn&[ZnCr&Z5@SiO2], ZnCr and Z5@SiO2 powder were mixed, shaped and crushed to 20-40 mesh ([ZnCr&Z5@SiO2]) before being mixed with FeMn granules; (III): dual bed, FeMn||[ZnCr&Z5@SiO2]; (IV): granule mixing, FeMn&ZnCr&Z5@SiO2, FeMn, ZnCr and Z5@SiO2 granules (20–40 mesh) were mixed. c The CO conversion and STY of p-X. d The aromatic selectivity in total hydrocarbons. Reaction conditions: 375 °C, 5 MPa, H2:CO = 1, WHSV = 7400 mL·gcat-1·h-1, mZnCr: \({{{\rm{m}}}_{{{\rm{Z}}}5{{{\rm{@Si}}{{\rm{O}}_{2}}}}}}\) = 2:1.

To achieve high-yield synthesis of p-X-rich aromatics, we first passivated the external acid sites of Z5 with SiO2 as a modifier to improve p-X selectivity, which had been proved to be successful in a number of studies3,14,25,26,28,32. Furthermore, a new DED catalyst being composed of FeMn, ZnCr, and Z5@SiO2 partners was scheduled, designed, and fabricated. Firstly, the effect of FeMn content on the catalytic performance of this DED catalyst, especially on the STY of p-X, was studied (Figs. 2a-2b). FeMn, ZnCr, and Z5@SiO2 powder were combined together, and the weight of ZnCr and Z5@SiO2 remained constant. When 0.1% FeMn partner was employed with ZnCr and Z5@SiO2 partners, CO conversion was boosted while the aromatic selectivity decreased in comparison with [ZnCr&Z5] catalyst (Table S2). However, compared with the sole SOA route over [FeMn&Z5], here the aromatic selectivity of [0.1%FeMn&ZnCr&Z5@SiO2] catalyst was considerably improved, especially for p-X product. The [FeMn&ZnCr&Z5@SiO2] catalyst also showed lower CO2 selectivity than [ZnCr&Z5] catalyst (Table S2), which is favorable for improving the STY of p-X (Fig. 2a and Table S2). The STY of p-X from the DED catalysts increased dramatically when the FeMn content was increased from 0.1% to 1.0% (Fig. 2a).The DED catalyst of [1.0%FeMn&ZnCr&Z5@SiO2] showed a high p-X STY (23.8 gp-X·kgcat-1·h-1, Fig. 2a and Table S2), which was considerably higher than [ZnCr&Z5] (4.5 gp-X·kgcat-1·h-1, Fig. 2a and Table S2) and [FeMn&Z5] (8.7 gp-X·kgcat-1·h-1, Fig. 2a and Table S2) catalysts. When the FeMn content reached 1.5%, the aromatics selectivity of the DED catalyst declined dramatically, and undesirable methane and C2-C4 paraffin dominated the product composition. Despite the highest CO conversion, the aromatic selectivity of [1.5%FeMn&ZnCr&Z5@SiO2] was lower than that of [FeMn&Z5], and the STY of p-X started to drop (Fig. 2a and Table S2). Drawing from these results, it is justifiable to deduce that the DED catalyst put forward in this study exhibits superior performance in terms of p-X-rich aromatics synthesis efficiency when compared to the currently popular single SMA ([ZnCr&Z5]) or SOA ([FeMn&Z5]) catalysts.

In the DED catalytic system, syngas is converted to methanol by the ZnCr engine, to olefins mainly by the FeMn engine, and methanol or olefins are further converted to aromatics by Z5@SiO2, each requiring different reaction temperatures. As shown in Fig. S1, the methanol synthesis from CO hydrogenation is thermodynamically restricted at temperatures higher than 150 °C. By contrast, the FT synthesis is a thermodynamically favorable approach to convert syngas into lower olefins, achieving high CO conversion over a wide temperatures range. Therefore, we investigated the effect of reaction temperature (325 ~ 425 °C) on the catalytic performance of DED catalysis system (Table S3). As demonstrated in Table S3, there was a significant increase in CO conversion with increasing reaction temperature from 325 °C to 375 °C, and then the CO conversion remained relatively constant within the range of 375 °C to 425 °C. With an elevation in reaction temperature, it is worth noting that the side reactions involving methane and paraffin formation were considerably enhanced, leading to a decrease in the selectivity towards aromatics. The STY of p-X reached its maximum at 375 °C, suggesting the most suitable reaction temperature for p-X synthesis from syngas over the DED catalyst.

The effect of integration manner and contact time on the catalytic performance of DED catalyst

To achieve optimal catalytic performance, the effect of the integration manner of these three active partners was further explored. For the different integration manners, the distance between FeMn, ZnCr, and Z5@SiO2 was quantitatively estimated by an iterative method proposed by Wang et al. 49 (Table S4). The SMA tandem reaction is notably sensitive to the distance and requires bifunctional catalysts with close proximity and contact (1-2 μm, nanoscale) between ZnZrOx and HZSM-549. Conversely, for the SOA route, a substantial distance between the FTO catalyst and HZSM-5 proves more conducive to the synthesis of aromatic compounds and CO conversion50. Figure 2c, d demonstrates the catalytic performance of the three partners in the DED catalyst under distinct integration modes, as the manner in which a tandem catalyst is integrated is anticipated to be crucial for its catalytic behavior. We observed that increasing the distance between FeMn and ZnCr, or FeMn and Z5@SiO2 with a microscale (manner II and IV, ~640 μm) or millimeter-scale (manner III, ~2 mm) distance, boosted CO conversion (modes II-IV in Fig. 2c and Table S5). The aromatics selectivity and the p-X STY appeared to have grown, reaching its greatest value with the dual-bed manner (manner III, 32.9 gp-X·kgcat-1·h-1, Fig. 2c and Table S5). In pursuit of a deeper understanding of the proximity effect, we extended the separation between ZnCr and Z5@SiO2 through the stacking of granules containing all three catalyst components (integration manner IV). The CO conversion in integration mode IV was comparable to modes II and III, but its p-X selectivity was lower, leading to a reduced STY of p-X (15.8 gp-X·kgcat-1·h-1, Figs. 2c, d and Table S5). This might be because the large distance (~640 μm, microscale) between ZnCr and Z5@SiO2 is not conducive to the H species removal from Z5@SiO2 to ZnCr partner49. Therefore, the sluggish H species removal phenomenon could slow down the essential dehydrogenation step for aromatics synthesis17. In addition, methanol formed on ZnCr partner is also difficult to diffuse into the channel of Z5@SiO2 to produce p-X.

The formation of aromatics from methanol or olefins involves a complicated reaction mechanism, and the last dehydrogenation step is often considered as one of the rate-determining steps. To facilitate the formation of aromatics on HZSM-5, the formed hydrogen species in zeolite must be removed effectively17,49. The transfer of methanol or olefins intermediates occurs via a gas diffusion mechanism from metal oxides to zeolite, while the hydrogen species formed during the dehydrogenative aromatization of olefins on zeolite typically follows a surface migration mechanism known as H-spillover49,51. To facilitate the H species removal from zeolite to other metal sites and accelerate the dehydrogenation step, a close proximity between methanol-engine of ZnCr and Z5@SiO2 zeolite is essential. In the presence of this close contact, the hydrogen species can be effectively eliminated through the generation of gaseous hydrogen (H2) on ZnCr, and then reacted with the CO molecules chemisorbed on ZnCr partner, forming MeOH&DME, which participates in the following reactions for the formation of aromatics17. However, in the SOA route, if there is a close contact between the FT partner and zeolite, the hydrogen species diffused onto FeMn partner will hydrogenate olefin intermediates, thereby impeding aromatics synthesis49. The hydrogen activation ability of FeMn, ZnCr, and Z5@SiO2 was also explored by H2-D2 exchange experiments to support this hypothesis (Fig. 3a). H2 and D2 could be catalyzed to form HD (m/z = 3) with high intensity of HD signal by both ZnCr engine and Z5@SiO2, while the formation rate and intensity of HD over FeMn engine were very lower (Fig. 3a). The results of this H2-D2 exchange experiments further indicated that when FeMn engine and Z5@SiO2 were integrated in proximity, the hydrogen species that migrated from zeolite would be removed by hydrogenating olefin intermediates on FeMn engine (Fig. 3b), therefore inhibiting the formation of more aromatics derived from olefins coupling. To comprehensively understand the removal process of H species from Z5@SiO2 zeolite to ZnCr or FeMn partner, we also employed molecular dynamics (MD) simulations to meticulously analyze the diffusion behavior as a function of distance, ranging from 5 to 15 Å, as depicted in Fig. S2. It revealed that the diffusion coefficient of H species is notably higher when the diffusion direction from Z5 to FeMn partner compared to that from Z5 to ZnCr partner. Utilizing DFT calculations, we further compared the hydrogenation energy barriers of ethylene to ethane on FeMn and ZnCr partners. As evidenced by Fig. S3, the hydrogenation energy barrier of ethylene adsorbed on the FeMn partner is lower. To prevent the over-hydrogenation of olefin intermediates by H species from zeolite-catalyzed, a certain distance (~640 μm–2 mm) must be maintained between FeMn partner and the Z5@SiO2 zeolite. This observation further underscores the above finding that the intimate contact (1-2 μm, nanoscale) between FeMn and Z5@SiO2 facilitates the undesirable hydrogenation of alkenes to alkanes, thereby inhibiting the production of aromatics.

a The results of H2-D2 exchange experiments over FeMn, ZnCr, and Z5@SiO2. b The suitable distance required respectively for FeMn, ZnCr, and Z5@SiO2 in DED catalyst to obtain high catalytic performances. c The proportion of χ-Fe5C2 phase in the spent FeMn partner of DED catalyst with varied integration manner of three partners. The Mössbauer spectrum of the spent FeMn partner in the DED catalysts: d 1.0%FeMn&[ZnCr&Z5@SiO2] catalyst; e [1.0%FeMn&ZnCr&Z5@SiO2] catalyst.

Moreover, it suggested that χ-Fe5C2 is the dominate active phase of iron-based partner for CO hydrogenation to olefins52. The X-ray diffractometer (XRD) patterns of the fresh FeMn partner showed diffraction peaks of α-Fe2O3 (PDF No. 33-0664)46, and the diffraction peaks of Mn species were not detected, indicating that manganese oxide was not formed (Fig. S4a). The carburization process of FeMn partner was tracked by in-situ XRD at 375 °C and 0.1 MPa under syngas (CO/H2 = 1) ambient. From the in-situ XRD patterns in Fig. S4b, Fe5C2 phase can be immediately observed under syngas ambient, suggesting that α-Fe2O3 phase of FeMn partner transforms into Fe5C2 phase rapidly during the reaction. However, a certain distance between FeMn and ZnCr&Z5@SiO2 should be maintained to keep the Fe5C2 active site stable for continuous olefins supply and avoid the undesirable hydrogenation of olefins. Mössbauer spectroscopic results indicated that χ-Fe5C2 phase occupied the dominating type of Fe species of spent FeMn partner in 1.0%FeMn&[ZnCr&Z5@SiO2] catalyst (73.5%) (Fig. 3c, d, and Table S6)53. Whereas, the spent FeMn partner in [1.0%FeMn&ZnCr&Z5@SiO2] catalyst kept a much lower concentration of χ-Fe5C2 phase (16.8%) (Figs. 3c, e, and Table S6)53. This was most likely due to the spatial separation, which facilitated the reduction of α-Fe2O3 in the FeMn partner into the FexC phase during the reaction. The formation of χ-Fe5C2 phase in DED catalyst promotes higher CO conversion and the formation of olefin intermediates, thus realizing a high STY of p-X. Therefore, from the viewpoint of migrating H species from zeolite to metal sites and the continuous supply of olefin intermediates from the FeMn partner, it is crucial to maintain a close proximity between the methanol-engine of ZnCr and Z5@SiO2 zeolite on a nanoscale level (1-2 μm) while maintaining a large distance (~640 μm–2 mm) between the olefin-engine of FeMn and Z5@SiO2 zeolite, by which to optimize the overall efficiency of p-X-rich aromatics synthesis over the DED catalyst.

To better understand the reaction routes and the functions of the three partners in this DED catalyst, the effect of contact time on the catalytic performance of 1.0%FeMn&[ZnCr&Z5@SiO2] catalyst was further investigated (Figs. 4a, b and S5). The products distribution and CO conversion are both influenced by the contact time. The alteration in reaction path in the DED catalysis system may be understood well by investigating the effect of contact time on catalytic performance. The optimum space velocity can help to realize a more effective synthesis of p-X. As shown in Fig. 4b and S5, CO conversion decreased with increasing space velocity, whereas CO2 selectivity increased (Fig. S5), implying that a long contact time is beneficial to reduce CO2 selectivity by suppressing the WGS reaction. The main products of MeOH&DME generated over the ZnCr partner were scarcely detected as space velocity increased, which indicated that they were completely consumed on the Z5@SiO2 partner in the case of short contact time. The growing selectivity of aromatics and the decreasing selectivity of C2-C4 olefins with the decreased space velocity indicated that olefins were efficiently converted into aromatics. The distribution of aromatics changed slightly as altering space velocity, and a higher p-X STY of 36.1 gp-X·kgcat-1·h-1 was achieved under the WHSV of 14400 mL·gcat-1·h-1 (Figs. 4a, b, Table S7), which is the highest value among the reported literature (Table S8). These findings further supported that the aromatics were synthesized from the intermediates of MeOH&DME and C2-C4 olefins over the DED catalyst.

By varying the weight ratio of ZnCr to Z5@SiO2, it was also confirmed that methanol intermediates benefited p-X synthesis over the DED catalyst (Fig. S6a, b). As the mass ratio of ZnCr to Z5@SiO2 was adjusted from 1:2 to 2:1, the selectivity of p-X in aromatics products was enhanced from 15.10% to 19.42% (Table S9), whereas the selectivity of toluene (T) decreased from 23.83% to 15.39% (Figs. S6a, b and Table S9). This result revealed that methanol-toluene alkylation reactions for p-X production occurred over the DED catalyst, and more methanol intermediates produced on ZnCr were favorable for p-X synthesis. The catalytic performance discussed above indicated that the DED catalyst comprising of both olefins synthesis engine and methanol synthesis engine together with Z5@SiO2 is feasible to boost the efficient conversion of syngas into p-X by breaking the limitation of the old reaction network in the traditional sole SOA or SMA process. Despite encountering the general challenge of coke formation on the Z5@SiO2 zeolite, there is promising evidence that the catalyst’s activity can be facilely regenerated (Fig. S7a, b).

Structural characterization on the partners of DED catalyst

The structural information and morphologies of the FeMn, ZnCr, Z5, and Z5@SiO2 partners were further investigated. The diffraction peaks of ZnCr spinel were clearly identified in the ZnCr partner (30.30°, 35.73° and 63.11°, ZnCr2O4, PDF No. 22-1107)36, confirming the synthesis of a spinel-structured ZnCr catalyst (Figs. S4a and S8). Furthermore, in-situ XRD measurements reveal that the ZnCr structure remains stable throughout the reaction process, indicating its robustness and suitability for catalytic applications (Fig. S8). To further validate the structural characteristics of the ZnCr and FeMn components, we employed high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) in conjunction with energy dispersive spectroscopy (EDS) elemental mapping images (Fig. 5a–d). Analysis of local fast Fourier transformation (FFT) derived from the HAADF-STEM images and lattice spacing indicated that the ZnCr nanoparticles possess a spinel structure, while the FeMn component comprises α-Fe2O3 phase, consistent with XRD findings (Fig. S4a). Additionally, EDS elemental mapping yielded molar ratios of Cr/Zn = 1.98 and Fe/Mn = 11.54, closely resembling the theoretical values (Fig. 5b, d and Table S10). Notably, the EDS elemental mapping images of the FeMn component in Fig. 5d demonstrated the highly dispersed nature of Mn within the FeMn engine.

To gain insights into the cation distribution within the spinel phase, we collected the X-ray adsorption fine structure (XAFS) spectra of Cr K-edge and Zn K-edge54,55. Analysis of the Cr K-edge XAFS spectra revealed two pre-edge peaks at 5992 eV and 5995 eV, corresponding to octahedrally coordinated Cr(III) and Cr(VI), and/or Cr(III) species in tetrahedral coordination, respectively (Fig. 5e)54. Additionally, the normalized Zn K-edge XAFS spectra displayed a minor peak at 9669 eV, attributed to Zn atoms occupying octahedral sites within the ZnCr2O4 spinel structure (Fig. 5f)55. These observations provide evidence that some Zn cations have interchanged with Cr cations, supporting the assertion that the prepared ZnCr sample comprises a mixed spinel phase, possibly incorporating an inverse spinel structure. With only a slight decline in crystallite intensity, the XRD patterns of Z5@SiO2 matched well with the unmodified Z5 (Fig. S9a). This means that the structural integrity of Z5 was maintained well after the surface silylation with TEOS using the chemical liquid deposition (CLD) technique, and there was no new phase being generated during modification. The SEM images of Z5@SiO2 displayed a conventional elliptic column morphology with particle sizes of around 4 μm (Fig. 5g). The EDS elemental mapping of Si and Al showed the highly uniform distribution of all elements over the corresponding entire particle area (Fig. 5h). The textural properties of the partners obtained from N2 physisorption are compared in Table S11. Due to the penetration of SiO2 into the channel’s ends of Z5, the BET surface area of Z5@SiO2 was lower than that of its parent Z5, accompanied by a reduction in pore size and volume. Additionally, in STA reaction, the migration of metal species to Z5 zeolite driven by the harsh reaction conditions is also a great concern56. To visualize the Zn migration during reaction, X-ray photoelectron spectroscopy (XPS) and HAADF-STEM imaging and the corresponding EDS mapping analysis were conducted over the fresh and 50 h run time DED 1.0%FeMn[ZnCr&Z5@SiO2] catalysts (Figs. S10, S11). The HAADF-STEM images of the fresh 1.0%FeMn[ZnCr&Z5@SiO2] reveal that both ZnCr particles and H-ZSM-5 crystals were intact without observable metal migration (Fig. S10a–e). After reaction, the surface of Z5@SiO2 was covered by carbon deposition, together with the existence of large ZnCr particles (Fig. S10f–j), but no visible Zn migration between oxides and Z5@SiO2 after CO hydrogenation. XPS was further used to investigate whether any elemental Zn migrated into the Z5@SiO2 (Fig. S11a–c)57. Figure S11b illustrates that, after reaction of 50 h, the ratio of Zn-Al bond of the 1.0%FeMn[ZnCr&Z5@SiO2] catalyst increased, indicating that trace amount of Zn migrated from ZnCr partner and bonded with the Al of Z5@SiO2. These demonstrated that during the 50 h reaction process, significant carbon deposition occurred on the Z5@SiO2 zeolite, whereas the ZnCr structure exhibited relative stability. A minimal amount of Zn migrated to Z5@SiO2 zeolite, indicating that the ZnCr partner maintained its structural integrity throughout the reaction. To better understand the stability of the Z5@SiO2, the amount and type of coke precursor on the catalysts collected after 50 h reaction were analyzed by GC-MS (Fig. S12). With the prolongation of reaction time, the deposition of polycyclic aromatic hydrocarbons (PAHs) on or in Z5@SiO2 has emerged as a significant factor contributing to its deactivation. The accumulation of PAHs gradually blocked active sites of Z5@SiO2, reducing the availability of reactive interfaces and ultimately leading to deactivation slowly.

The distribution of the acid sites with different strengths of the partners was characterized by NH3-TPD. And the quantitative results were listed in Table S12. In the NH3-TPD profiles shown in Fig. S13, two distinct acid sites were observed, with one exhibiting weak acidity at a low temperature of 160 °C, while the other demonstrated strong acidity at a high temperature of 413 °C. The peaks area and intensity of the Z5@SiO2 zeolite declined in comparison with the naked Z5, indicating that the external surface acid sites of Z5 were successfully passivated after surface silylation. To distinguish the Brønsted and Lewis acid sites of partners, we employed n-propylamine-TPD-MS (NPA-TPD-MS). NPA can coordinate to Lewis acid sites and desorb intact, but become protonated by Brønsted acid sites and decompose via Hoffman-type elimination reactions to form ammonia and the corresponding propene56. In the profiles shown in Fig. 6a, the desorption peak of unreacted NPA that adsorbed at Lewis acid sites was indicated by the detection of mass fragments with m/z = 30 (NPA) at 155 °C. The detection of mass fragments with m/z = 41 (propene) at 409 °C allowed for the identification of the desorption peak of chemisorbed NPA at Brønsted acid sites. As the peak area of desorbed NPA was obviously larger than that of formed propene, there were more Lewis acid sites on the Z5 zeolite. Subsequent to silylation, the encapsulated Z5@SiO2 catalyst exhibited a marked reduction in the peak area associated with desorbed NPA in contrast to the Z5 catalyst. This observation suggests that the SiO2 modification predominantly impacted the Lewis acid sites of the Z5 catalyst. The acid and basic property of metal oxides were characterized and the analysis results are illustrated in Fig. S14a–c and Tables S12, 13.

a The NPA-TPD-MS profiles of the naked Z5 and Z5@SiO2 zeolites. b The CO-TPD-MS profiles of the partners. c The CO-TPR profiles of the partners. The results obtained from TPSR at 375 °C, 0.1 MPa and CO/H2 = 1: d mass signal of CO (m/z = 28); e mass signal of butene (m/z = 56); f mass signal of xylenes (m/z = 91).

Mechanistic insights into the enhanced performance of DED catalyst for p-X synthesis

CO-TPD-MS was employed to analyze the active sites governing CO adsorption and activation on both individual partners and the DED catalyst. In the CO desorption profiles of both individual partners and the DED catalyst, as presented in Fig. 6b, the desorption peaks corresponding to CO and CO2 were identified by detecting mass signals with m/z = 28 and m/z = 44, respectively. Notably, the CO2 desorption peak was prominent, while the CO desorption peak was barely discernible across all the samples. This observation indicates that adsorbed CO underwent conversion to CO2 through interaction with oxygen on the surfaces of both the ZnCr and FeMn engines. The CO2 desorption peak for the FeMn catalyst occurred at approximately 213 °C, signifying the presence of a singular type of CO adsorption site on the FeMn engine with relatively weak adsorption strength (Fig. 6b). In contrast, CO-TPD-MS results for the ZnCr catalyst displayed three distinct CO2 desorption peaks around 177, 253, and 300 °C, associated with strongly adsorbed CO at oxygen vacancies (Fig. 6b)5. The CO and CO2 desorption peaks were undetectable for the pure Z5@SiO2 catalyst, whereas the [ZnCr&Z5@SiO2] catalyst exhibited CO2 desorption peaks at higher temperatures (approximately 326 °C and 433 °C). This indicates enhanced CO adsorption strength due to the synergistic effect between ZnCr and encapsulated Z5@SiO2 zeolite. The [1.0%FeMn&ZnCr&Z5@SiO2] catalyst displayed a broad CO2 desorption peak at approximately 234 °C, resembling the behavior of the individual FeMn engine. This observation suggests that CO predominantly adsorbed on the FeMn engine within the DED catalyst during syngas conversion. The findings from CO-TPD-MS strongly imply a preference for CO adsorption on the FeMn partner of the DED catalyst during the tandem reaction. The ability of a single partner and DED catalysts on activating CO was further investigated using the CO-TPR. The CO-TPR profiles demonstrated that single FeMn displayed a peak of CO consumption at 348 °C, while the other three partners did not exhibit any CO consumption signals (Fig. 6c), suggesting a stronger ability of the FeMn engine to activate CO. The CO consumption peak of the single FeMn was partly derived from the reduction process of α-Fe2O3 to Fe3O4 and Fe carbide phases52,53,57,58.

To gain a deeper understanding of the key factors influencing the p-X STY over the DED catalyst, we further conducted a comprehensive series of mechanistic investigations. The olefin cycle mechanism in the single SMA route supports that methanol is first converted into olefins on zeolite. The generated olefins are then converted into aromatics through a single methanol-mediated pathway, which includes polymerization, cyclization, dehydrogenation, hydrogen transfer, and alkylation59. This suggested that olefins are the more direct intermediates during the conversion of syngas to final aromatics. By assembling SMA and SOA routes, olefins and methanol intermediates coexist during reaction, and the yield of olefins generated on FeMn engine is higher than that of methanol formed on ZnCr engine (Fig. S15). Therefore, the methanol-to-olefins reaction on Z5@SiO2 zeolite could be severely depressed with the adsorption of olefins on the zeolite, and the conversion of SOA-derived olefins to aromatics would be the main reaction pathway in the DED catalytic system. To confirm this deduction, temperature-programmed surface reaction (TPSR) was performed to identify the main reaction pathway in the DED catalytic system (Figs. 6d–f and S16). The FeMn, [FeMn&Z5@SiO2] and [FeMn&ZnCr&Z5@SiO2] catalysts showed clear CO and H2 conversion between 384 °C and 411 °C (Figs. 6d and S16a). Furthermore, the reaction temperature of the [FeMn&ZnCr&Z5@SiO2] DED catalyst is slightly lower than that of [FeMn&Z5@SiO2], suggesting that a synergistic effect of FeMn, ZnCr, and Z5@SiO2 makes it easier to activate CO (Figs. 6d and S16a). The results in Fig. 6e showed that FeMn engine could convert syngas to olefins at around 375 °C and 0.1 MPa, but ZnCr engine could not convert syngas to methanol under the same conditions, which is consistent with the results calculated by HSC 10.0 (Fig. S17). As a consequence, in contrast to the [ZnCr&Z5@SiO2] catalyst, which did not exhibit any signals corresponding to aromatics (benzene, toluene or xylenes), both [FeMn&Z5@SiO2] and [FeMn&ZnCr&Z5@SiO2] catalysts clearly demonstrated mass signals corresponding to aromatics (Figs. 6f and S16b,c). Moreover, the peak intensity of the [FeMn&ZnCr&Z5@SiO2] DED catalyst was the highest among three catalysts. These observations strongly suggest that the conversion of SOA-derived olefins to aromatics is the dominant reaction pathway in the syngas conversion process over the DED catalyst, and the synergistic combination of FeMn and ZnCr engines with Z5@SiO2 significantly enhances the efficiency of aromatic synthesis.

A cofeeding experiment involving methanol and ethylene was conducted within a Z5@SiO2 catalyzed reaction system to elucidate the reaction pathway. The influence of the partial pressures of methanol and ethylene on the catalytic performance was investigated by changing the carbon molar ratio of methanol to ethylene (M/E) from 4 to 0.25 (Fig. S18, Table S14). Notably, when the M/E ratio was 1:1, the aromatic products accounted for 95.29% of the hydrocarbons (Table S14). Figure S18 illustrated the distribution of aromatic products. At an M/E ratio of 4, toluene was the predominant aromatic compound. When the M/E ratio was adjusted to 1, ethylbenzene emerged as the main product. And at an M/E ratio of 0.25, both ethylbenzene and p-X were the primary aromatics produced. As the M/E ratio decreased from 4 to 0.25, the proportion of p-X rose from 4.65% to 19.48%. The selectivity of xylenes among the aromatics showed a marked surge, increasing from 6.95% at an M/E ratio of 4 to 43.21% at an M/E ratio of 0.25 (Fig. S18, Table S14). It is worth noting that an M/E feed ratio of 0.25, which is close to the molar ratio of olefins produced on FeMn partner to methanol produced on ZnCr partner in the DED catalytic system (Fig. S15, Table S2), exhibited optimal selectivity for p-X. The results revealed that the partial pressures of olefins and methanol in the co-reaction significantly affected the p-X synthesis performance. Specifically, when methanol was present in a higher proportion than olefins, it was preferential to convert methanol to olefins and then to benzene. When the number of olefins, represented by ethylene, is greater than that of methanol, the conversion of olefins to aromatics is the preferred reaction route. And methanol predominantly engages in alkylation reactions with benzene or toluene, which are formed from olefins, to yield p-X.

To further elucidate the reaction pathways, a co-reaction of 13C-methanol and 12C-ethylene was conducted with varying molar percentages of 13C-methanol (1%, 4%, and 6%). The isotopic distribution of p-X in the liquid products was analyzed to assess the incorporation information of 13C atoms from methanol. Based on the co-reaction results, the majority of the 13C-labelled p-X was centrally presented as the mono-13C and bis-13C labelling modes, with the proportion of these two labelling types accounting for over 90% under 1% 13C-methanol feeding. 13C-labelled p-X containing 6-8 13C substitutions only accounts for 10.6% under 6% 13C-methanol feeding. This indicates that 12C-ethylene aromatization is the preferential reaction pathway for aromatics synthesis, whereas 13C-methanol preferentially participates in the alkylation of benzene or toluene (Fig. 7a). The co-reaction of 13C-methanol and 12C-ethylene revealed that the reaction pathway for p-X in the DED system is distinct from that observed in the single-engine catalyzed process. We further employed in-situ diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS, Fig. S19) alongside density functional theory (DFT) calculations to gain insights into the synergistic effects of FeMn, ZnCr, and Z5@SiO2. Based on the comprehensive analysis of TPSR, 13C-methanol labeling experiments, and in-situ DRIFTS characterization results, it can be conclusively stated that in the DED catalytic system, characterized by the presence of abundant olefins and appropriate methanol intermediates, the conversion from olefins to aromatics emerged as the predominant reaction pathway for the generation of aromatics. At the same time, methanol intermediates formed on the surface of the ZnCr engine participated in the alkylation reaction. This is because the reaction rate of olefins on the zeolite is faster than that of methanol, especially when the concentration of olefin is greater than that of methanol.

Isotopic labeling and methanol−ethylene co-reactions for reaction mechanism. a 13C isotopic distribution of p-X resulting from 13C-methanol and 12C-ethylene co-reactions. b The Gibbs free energy diagrams comparing the conversion of methanol to ethylene in the absence and presence of ethylene, including activation barriers for the three stages of H2 generation. Additionally, a diagram depicting the alkylation of methanol with toluene to produce p-X is also presented. Arrhenius plots of neat methanol and the co-reaction of methanol with ethylene towards the formation of c C3=-C4= and (d) p-X on Z5@SiO2. e The “dual-engine-driven” reaction protocol realized by the FeMn&[ZnCr&Z5@SiO2] DED catalyst for the direct conversion of syngas to p-X with higher yield.

The competitive adsorption of various intermediates on the catalyst surface plays crucial roles in catalytic reactions60,61. Therefore, using MD simulations and DFT calculations, we examined the differences between the adsorption energies of ethylene and methanol on Z5 zeolite. Figure S20 showed the results derived through MD simulation, showing the adsorption densities of methanol and ethylene with varied molar ratios. Apparently, under various partial pressures of methanol and ethylene, more bright blue spots were detected in Fig. S20d–f, suggesting that the adsorption density of ethylene was consistently higher than that of methanol. In addition, the adsorption energy of ethylene was greater than that of methanol (Table S15). These findings suggest that ethylene has a higher adsorption priority than methanol on Z5 zeolite. The reaction path energy barrier of methanol to olefins, methanol alkylation reaction, and ethylene aromatization, as well as the influence of the adsorption strength of CH3O* on the reaction energy barrier of the toluene alkylation reaction with methanol (Fig. 7b). Herein, the adsorption energy results of methanol, CH3O*, and olefins on Z5, evaluated by DFT calculation, were shown in Fig. S21. The stable adsorption configuration structures of methanol, CH3O*, and olefins on Z5 employed in DFT calculations are illustrated in Figs. S22–S24. CH3O* had a much higher adsorption energy than methanol on Z5, indicating that methanol would exist as CH3O* after adsorption on Z5 (Fig. S21a). The adsorption energy of olefins on Z5 steadily increases as the carbon number increases, and the adsorption energy of butene on Z5 gradually exceeds methanol (Fig. S21b). These results indicated that when methanol and various types of olefins co-existed in the DED catalytic system, the olefins with a higher concentration than methanol would preferentially adsorb onto the active sites of Z5. In other words, when olefin and methanol intermediates were available together in the DED catalytic system, olefin intermediates could stably adsorb onto the zeolite, preventing methanol from being converted into olefins59. Consequently, more methanol intermediates could actively participate in the subsequent alkylation reaction with heightened intent62.

This hypothesis was supported by the reaction energy barrier evolution of methanol to olefins with and without the presence of ethylene on Z5 zeolite (path I and path II in Fig. 7b and Figs. S25, S26). The considered reaction pathways start from methanol (oxidation state b in path I and path II, Fig. S25a, b) reacting with an acid site to form a surface methoxy species and ultimately culminate in the production of ethylene (Fig. S25a). In this concerted reaction, the releasing of CO stands as a key step (TS2 → TS3, Figs. 7b and S25a), as it functions as a crucial intermediate in initiating the first C−C bond formation. The calculations reveal that the CO release step requires the highest activation free energy, calculating 3.70 eV in the presence of ethylene, which is higher than that of in the absence of ethylene (3.65 eV). A comparative analysis of the reaction energy barriers of overall reaction profiles and the activation free energy of transition states in the conversion of methanol to ethylene on Z5 zeolite, both in the absence of ethylene and methanol combined with ethylene, clearly indicates that the presence of ethylene increased the reaction energy barrier for the conversion of methanol to ethylene (path I and path II in Fig. 7b). Additionally, comparing the overall reaction energy barriers of methanol to ethylene conversion and methanol alkylation with benzene to produce p-X, it is observed that the latter has a lower reaction energy barrier (path I and path III in Fig. 7b). Therefore, in the DED catalytic system, the presence of olefins increases the reaction energy barrier for methanol to olefins reaction on Z5 zeolite. As the reaction energy barrier for methanol alkylation with benzene is lower, more methanol will participate in the alkylation reaction with benzene or toluene (Fig. 7b). This pattern aligns with the changes observed in p-X STY as we varied the ZnCr content of the DED catalyst (Fig. S27 and Table S16). As the increase in the concentration of methanol available for alkylation reaction leads to a decrease in the alkylation reaction energy barrier, thus accelerating the rate of methanol alkylation with toluene/benzene to produce p-X (Figs. 7b, S28d). These findings lead to the conclusion that a judicious reduction in the adsorption strength of CH3O* on Z5 would lower the energy barrier for the alkylation reaction between toluene and methanol. However, if the adsorption strength of CH3O* becomes excessively low, the energy barrier for the toluene alkylation reaction would rise (Fig. S28d). Consequently, within the DED reaction system, the generation of p-X is not only driven by a strong driving force, but is also enhanced by the synergistic effect of all three catalyst components.

Having established the overall reaction profiles of methanol to ethylene and the alkylation of benzene with methanol to p-X, we determined the reaction rate of p-X formation from neat methanol and the co-reaction of methanol and ethylene (M/E = 0.25) based on apparent kinetic model (Figs. 7c, 7d, S29 and Tables S17–S19). In order to reduce the number of reaction species, we employed a lumping strategy. This lumping approach involves grouping the same type of products together and selecting one product with higher selectivity as the representative, thereby simplifying the complexity of the reaction system and allowing us to understand the reaction process more clearly. Considering the complexity of reaction system, we employed the lumping strategy to establish the apparent kinetic model of neat methanol and the co-reaction of methanol and ethylene on Z5@SiO2. In this way, C3=-C4= and p-X represent the reaction species involved in the MTA reaction and co-reaction of methanol and ethylene. Figure 7c, d and Table S19 show the kinetic modelling results, with the experimental data on propene, butene, and p-X formations plotted as function of contact time in Fig. S29. The calculated apparent formation rate constant of C3=-C4= increased from 1.96 ×10-5mol·atm-1·gcat-1·s-1 of neat methanol to 5.98 ×10-5 mol·atm-1·gcat-1·s-1 of co-reaction of methanol and ethylene at 375 °C. Similarly, the rate constant for p-X formation also experienced a noteworthy rise, surpassing from 0.39 ×10-5 mol·atm-1·gcat-1·s-1 of neat methanol to 0.80 ×10-5 mol·atm-1·gcat-1·s-1 during the co-reaction at 375 °C (Figs. 7c, d, S29, and Table S19). The apparent activation energy of C3=-C4= formation decreased from 115.11 kJ/mol of neat methanol to 60.23 kJ/mol of co-reaction, and the apparent activation energy of p-X formation lowered from 79.05 kJ/mol of neat methanol to 68.02 kJ/mol of co-reaction of methanol and ethylene (Figs. 7c, d). The kinetic model elucidated that the co-reaction of methanol and ethylene exhibited an accelerated trend towards the generation of C3=-C4=, in comparison to the neat methanol conversion process. Subsequently, this could facilitate the reaction rate of C3=-C4= → diene → diene cyclization → aromatics in co-reaction process. Therefore, the formation rate of p-X was enhanced in the co-reaction process of methanol and ethylene. Given that the kinetic experiment was conducted with the elimination of both internal and external diffusion, we attributed these varied formation rates to the decreased reaction energy barrier encountered in the co-reaction of methanol and olefins. The adsorption of reactants on the catalyst surface and the reaction energy barriers encountered throughout the entire reaction process can significantly influence their dominances in the reaction network and reaction rate.

Figure 7e shows the novel reaction network for one-pass syngas conversion to p-X with high yield, achieved by the FeMn&[ZnCr&Z5@SiO2] DED catalyst. More specifically, light olefins and MeOH&DME are generated through CO hydrogenation by the FeMn partner and ZnCr partner, respectively. The rapid conversion of syngas to olefins over FeMn partner inhibits the deeper conversion of methanol intermediate to olefins over Z5@SiO2 capsule zeolite. The generated olefins are further converted into aromatic compounds such as benzene and toluene via aromatization processes on the Z5@SiO2 capsule zeolite. Moreover, the alkylation of benzene, as well as toluene with the rich methanol produced in situ from ZnCr partner guarantees the enhanced p-X production yield, which has also been clearly verified by Yuan et al. 62 with the assistance of controlled experiments and detailed characterization. Therefore, the conversion of syngas to p-X-rich aromatics over the DED catalysts within a DED mode is superior to the traditional single SMA or SOA pathway, resulting in extremely higher p-X yield during the tandem reaction system.

Discussion

In summary, we presented a DED catalytic system to realize the direct synthesis of p-X with an extremely higher yield from CO2-containing syngas. The designed DED catalysts were composed of FeMn (olefin-engine), ZnCr (methanol-engine), and capsule zeolite Z5@SiO2. The syngas/CO2 were rapidly and efficiently converted into olefins over the olefin-engine of FeMn, followed by the further conversion of olefins to form benzene over Z5@SiO2. Another methanol-engine of ZnCr offered necessary methanol to push benzene’s alkylation reactions to produce p-X. Side-reaction like methanol-to-olefins could be severely depressed at the same time since the existence of the quickly pre-formed olefins by olefin-engine. This tailor-made catalytic system fabricated by these DED catalysts solved the problems faced by the traditional single engine routes for p-X synthesis. The p-X STY obtained over these DED catalysts reached up as high as 36.1 gp-x·kgcat-1·h-1, considerably higher than that of any “single-engine-driven” catalysts such as [FeMn&Z5] (8.7 gp-X·kgcat-1·h-1) or [ZnCr&Z5] (4.5 gp-X·kgcat-1·h-1). The catalytic performance of the DED catalyst was significantly influenced by the combination modes and proximity of active partners. A large distance between FeMn and Z5@SiO2 but a short distance between ZnCr and Z5@SiO2 is favourable for highly efficient synthesis of p-X-rich aromatics. The characterization results and DFT calculations demonstrated that, in the tandem catalytic conversion reaction of syngas/CO2, the DED model offered greater driving force and synergistic effect to realize extremely higher STY of p-X. The olefinic intermediates, with significantly higher concentration than methanol, dominated the reaction pathway for the synthesis of aromatics and lowered the adsorption energy of CH3O* intermediates on Z5@SiO2, which is favourable for the alkylation reaction of toluene with methanol, resulting in the effective synthesis of p-X from syngas. These findings in this paper can also be extended into other tandem catalyst and reaction routes design, by which to realize superior efficient synthesis of target product.

Methods

Catalysts preparation

FeMn

The FeMn catalyst (Fe/Mn molar ratio = 10/1) was prepared by a co-precipitation method. Typically, Fe(NO3)3·9H2O (Wako, Japan) of 26.26 g and Mn(NO3)2·6H2O (Wako, Japan) of 1.87 g were dissolved in deionized water (71.5 mL), denoted as solution A. Na2CO3 (Wako, Japan) of 23.00 g was dissolved in deionized water (208 mL), denoted as solution B. Solutions A and B were dropped, at the same time, into a beaker that contained deionized water of 200 mL under vigorous stirring to form a suspension liquid and the pH value was kept at 8.0 by controlling the injection speed of solution B. The co-precipitation procedure was carried out at 60 °C in a water bath, and then the precipitate was aged for another 2 h under stirring at the same temperature. After filtration and washing several times by deionized water, the precipitate was dried at 120 °C for 12 h and calcined at 400 °C for 4 h (2 °C/min).

ZnCr

The ZnCr catalyst was prepared by a co-precipitation method as well. Typically, Cr(NO3)3·9H2O (Wako, Japan) of 42.00 g and Zn(NO3)2·6H2O (Wako, Japan) of 15.80 g were dissolved in deionized water (400 mL), denoted as solution A. (NH4)2CO3 (Wako, Japan) of 46.50 g was dissolved in deionized water (300 mL), denoted as solution B. Solution A and solution B were dropped, at the same time, into a beaker that contained deionized water of 100 mL under vigorous stirring to form a suspension liquid and the pH value was kept at 7.0 by controlling the injection speed of solution B. The co-precipitation procedure was carried out at 75 °C in a water bath, and then the precipitate was aged for 4 h under stirring at the same temperature. The product was collected by filtration and washed for several times by deionized water after static aging at room temperature for another 12 h. The precipitate was then dried at 60 °C for 12 h and calcined at 400 °C for 4 h (2 °C/min).

Z5@SiO2

HZSM-5 (denoted as Z5) zeolite (SiO2/Al2O3 = 105) was purchased from Mizusawa Industrial Chemicals Co. (Japan). The capsule Z5@SiO2 catalyst was obtained by a chemical liquid deposition (CLD) method using tetraethyl orthosilicate (C8H20O4Si, TEOS, OSAKA, Japan) as silica source and n-hexane (Wako, Japan) as solvent. Bare zeolite (Z5) of 1.00 g was dispersed into n-hexane (10.00 g) with TEOS of 2.40 g by slowly dropping into it. After magnetic stirring for 4 h, the sample was dried at 60 °C and calcined at 550 °C for 5 h (5 °C/min). The above deposition procedure was repeated once more, and the resulting sample was denoted as Z5@SiO2.

The DED catalysts were fabricated by physically mixing FeMn, ZnCr, and Z5@SiO2 in specific modes, as described in counterparts. x% (x = 0.1, 0.5, 1.0, 1.5) in x%FeMn&ZnCr&Z5@SiO2 represents the weight ratio of FeMn to FeMn+ZnCr, and the weight of ZnCr and Z5@SiO2 remained constant with the mass ratio of ZnCr to zeolite being 2:1.

Catalysts characterization

A Rigaku RINT 2400 X-ray diffractometer with Cu Kα radiation was used to record of the XRD patterns of the catalysts. A scanning electron microscopy (SEM, JSM-IT700HR/LA, JEOL) equipped with energy dispersive spectrometer (EDS) was used to examine the morphologies of catalysts. A Micromeritics 3Flex 2MP instrument was engaged to measure the specific surface area and pore size distribution of the samples.

High-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) experiments were carried out on a JEM-ARM200F electron microscope with a HAADF detector at 200 kV. X-ray absorption fine structure (XAFS) was performed on Table XAFS-500 (Specreation Instruments Co., Ltd.).

Thermogravimetric (TG) analysis of the spent catalysts without calcination was performed on a Shimadzu DTG-60 thermal analyzer. In a typical TG measurement, the temperature was heated from room temperature to 600 °C with a ramping rate of 10 °C/min under air atmosphere.

NH3/CO2 temperature-programmed desorption (NH3/CO2-TPD) and CO temperature-programmed reduction (CO-TPR) were performed on a MicrotracBEL BELCATII-T-SP instrument equipped with a thermal conductivity detector (TCD) and mass detector (MS). For NH3-TPD, catalyst of 0.05 g was pretreated at 300 °C for 1 h under a helium (He) atmosphere, then cooled to 100 °C before being saturated with NH3 for 1 h at 100 °C. The sample was then swept with He flows for 1 h to remove the physically adsorbed NH3 and stabilize the baseline. Subsequently, the NH3-TPD profiles were recorded under He flow with a heating rate of 10 °C/min. The procedure for CO2-TPD was performed in the same way to that of NH3-TPD, only with the exception that the NH3 was replaced with CO2. For CO-TPR, catalyst of 0.05 g was pretreated under He atmosphere for 1 h at 300 °C, then cooled down to 100 °C before being swept with He for 1 h to stabilize the baseline. Subsequently, the CO-TPR profiles were recorded under CO flow with a heating rate of 10 °C/min.

The H2-D2 exchange experiments were carried out on a MicrotracBEL BELCATII-T-SP instrument connected to a Bell mass spectrometer at 200 °C. First, 0.05 g sample was pretreated in argon (Ar) atmospheres at 300 °C for 1 h and then cooled down to 200 °C. The mixture of D2 and H2 (10 mL/min) was then passed through the sample, and the reaction products H2 (m/z = 2), D2 (m/z = 4), and HD (m/z = 3) were analyzed by the equipped mass spectrometry. TPD measurements of n-propylamine (NPA-TPD-MS) were performed simultaneously using MicrotracBEL BELCATII-T-SP instrument connected to a Bell mass spectrometer. Before the adsorption, approximately the catalyst of 0.05 g was pretreated at 300 °C for 1 h to remove any impurity under Ar atmosphere. Then the pretreated catalysts were cooled to 50 °C, exposed to n-propylamine vapor for 1 h, and then swept for 1 h under Ar atmosphere. Finally, the sample temperature was ramped to 600 °C with a linear heating rate of 10 °C/min under Ar atmosphere. To monitor the desorbed products leaving the sample, the effluent was analyzed for the presence of n-propylamine (m/z = 30), ammonia (m/z = 17), and propene (m/z = 41).

CO-TPD-MS was performed in the same way to that of NPA-TPD-MS, only with the exception that the n-propylamine was replaced with CO. The initial temperature of adsorption was 100 °C. The effluent was analyzed for the presence of CO (m/z = 28) and CO2 (m/z = 44).

Temperature-programmed surface reactions (TPSR) were performed on MicrotracBEL BELCATII-T-SP instrument connected to a Bell mass spectrometer. Before the adsorption, the samples were pretreated at 300 °C for 1 h to remove any impurity under Ar atmosphere. Then the pretreated samples were cooled to 100 °C and swept with Ar for 1 h to stabilize the baseline. Subsequently, the mass signal profiles were recorded under syngas (CO/H2 = 1) flow with a heating rate of 10 °C/min.

The Mössbauer measurement was carried out using a typical spectrometer (Germany, Wissel MS-500) in transmission geometry and constant acceleration mode at room temperature. A 57Co(Rh) source with an activity of 25 mCi was used. α-Fe absorber that operated at room temperature was used for the velocity calibration. The software Recoil used Lorentzian Multiplet Analysis to fit the spectra.

In-situ diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS) experiments at atmospheric pressure were conducted on a NICOLET 6700 Fourier transform IR spectrometer with PIKE Diffuse IR device (64 scans, 4 cm-1 resolution). 0.02 g fresh catalyst powder was packed in an infrared sample cell with ZnSe windows and firstly pretreated on-line under pure H2 flow (15 mL/min) for 30 min at 400 °C. Then H2 was switched to He, and He was purged for 1 h (15 mL/min). The background spectrum was recorded after He purging. Subsequently, syngas (H2/CO = 1) flow was introduced into the infrared cell and swept for 30 min with the spectra recorded simultaneously.

The coke-deposited sample was obtained after the CO hydrogenation reaction at 375 °C and 5 MPa for time on stream (TOS) of 50 h. To reveal the nature of coke retained on spent catalyst, the extract of reacted catalyst was (tested for 50 h) determined by gas chromatographs-mass spectrometer (GC-MS, Shimadzu, GCMS-TQ8050). In this technique, 50 mg sample of spent zeolite was treated with 2 mL of HF acid (40%) in order to dissolve the zeolite and liberate the coke. 14 mL of dichloromethane (CH2Cl2) were added in order to recover the soluble coke compounds. Finally, the coke molecules soluble in CH2Cl2 was analyzed by GC-MS (Shimadzu GCMS-QP2010 SE). Compounds were identified by comparing mass spectra with NIST 11 library data.

In-situ XRD measurement was conducted on a SmartLab-TD diffraction system using a Cu Kα source with an XRK 900 heater. The pretreatment was carried out under the conditions of pure hydrogen, following the reaction process performed under syngas gas (H2/CO = 1) ambient at 375 °C.

A commercially built X-ray photoelectron spectroscopy (XPS) system (Thermo ESCALAB 250XI) was used to conduct a surface elemental analysis of fresh and spent catalysts to investigate the Zn migration. The spectrum of C1s was calibrated to 284.6 eV.

13C-methanol and ethlyene hydrogenation was carried out by the fixed bed reactor, similar to the kinetic experiments at 375 °C and 0.5 MPa. The effluent products were absorbed by octane in ice bath, followed by analysis with GC-MS (Shimadzu GCMS-QP2010 SE).

Catalytic performance evaluation

The CO hydrogenation reactions were carried out in a fixed-bed stainless steel reactor (inner diameter = 6 mm). Prior to the reaction, the catalyst of 0.25 g (ZnCr:Z5@SiO2 = 2:1, powder mixing) was reduced in situ for 6 h at 400 °C under pure H2 flow. The CO hydrogenation reaction was carried out under 5 MPa and 375 °C with syngas (45 vol% CO, 45 vol% H2, 5 vol% CO2, Ar balance, H2/CO = 1) as the feed gas. The hydrocarbons and oxygenate compounds were analyzed using two on-line Shimadzu GC (GC 2014 and GC-14 B, both being connected to a flame ionization detector) equipped with HP-PLOT/Q and HP-INNOWax capillary column, respectively. The on-line Shimadzu GC 8 A equipped with a PLOT-Q packed column and a thermal conductivity detector (TCD) was used to analyze Ar, CO, CH4 and CO2. Ar was used as an internal standard.

CO conversion (\({{{\rm{Conv}}}}_{{{\rm{CO}}}}\)) and product selectivity were calculated on a carbon-atom basis as follows, where \({{{\rm{CO}}}}_{{{\rm{inlet}}}}\) and \({{{\rm{CO}}}}_{{{\rm{outlet}}}}\) represent the moles of CO at the inlet and outlet, respectively.

The selectivity of individual hydrocarbon \({{{\rm{C}}}}_{n}{{{\rm{H}}}}_{m}\) (\({{{\rm{Sel}}}}_{{{{\rm{C}}}}_{n}{{{\rm{H}}}}_{m}}\)) among hydrocarbons was obtained as the following equation.

The STY of p-X was calculated according to the following equation, where \({{{\rm{mol}}}}_{{{\rm{CO}}}}\) and 106.18 represented the moles of CO at the inlet and molecular weight of p-X, respectively.

Kinetic experiments

The kinetic experiments were carried out to simplify the co-existence of methanol and ethylene speeding up the p-X formation, the carbon molar ratio of methanol to ethylene was 1:4 in the coupling reaction so as to be consistent with the carbon molar ratio of methanol to olefin in the DED catalytic system. The inner diameter of the reaction tube (Dt) is 0.06 m, and the catalyst particle size is 0.0004 m (40–60 mesh). The catalyst bed height after diluting with quartz sand is 0.015 m. Therefore, Dt/Dp = 15 > 10, H / Dp = 37.5 > 30, which meets the dynamic experiments requirements. In both the neat methanol conversion and the coupling aromatization, the reaction conditions were controlled to be the same with respect to methanol, i.e. the reactant partial pressure (0.1 KPa) and weight space velocity were all calculated based on methanol. All the experimental data were collected within a reaction time of 2 h to avoid the effect of catalyst deactivation. The reaction rates and apparent activation energies were determined by using the Bassett kinetic formula of first-order reaction63,64 (Eq. 4) and Arrhenius equation (Eq. 5).

where x is the yield of a specific product.

where \(k\), A, \({E}_{a}\), R, and T represents the reaction rate constant, pre-factor, reaction barrier, the molar gas constant, and temperature, respectively.

Computational methods and modeling

The periodic DFT calculations were used to investigate the adsorption of methanol (MeOH), methoxy group (CH3O*), ethylene (C2=), propylene (C3=), butenes (C4=), n-pentene (C5=) and n-hexene (C6=) on Z5 zeolite. All the calculations were carried out using the Vienna Ab Initio simulation package (VASP)65,66. The electron-ion interaction was described by the projector augmented wave (PAW) method67. The Perdew-Burke-Ernzerhof (PBE) function was employed during all the calculation processes68. The kinetic energy cutoff of plane wave basis set was 400 eV. The sampling of Brillouin zone was only gamma point. The threshold of force and energy convergence for all structure optimization were 0.03 eV/Å and 1.0 × 10-4 eV, respectively. The DFT-D3 scheme was used to compensate the long-range van der Waals dispersion interaction between the adsorbates and Z569.

The Z5 molecular was modeled using a periodic orthorhombic cell that consisted of 96 T unit cells, with the chemical composition of H4Al4Si92O192. In the MFI molecular sieve skeleton composed of all-silica-oxygen, the substitution of an Al atom for a Si atom at the T-position creates a negative charge in the framework. After ion exchange, the negative charge is balanced by the presence of a proton H (Si-O(H)-Al), leading to the formation of Brönsted acid sites70. The lattice constants were optimized as a = 19.09 Å, b = 19.62 Å, c = 12.86 Å. All atoms in the cell were allowed to relax with the lattice constants being fixed. The adsorption energies of adsorbates were calculated according to the following formula:

where Emol/Z5 was the electronic energy of the system after the adsorbate adsorption on Z5, Emol was the electronic energy of the adsorbate, and EZ5 was the electronic energy of the Z5.

All transition states were searched by combining the climbing image nudged elastic band (CI-NEB) method with the dimer method71,72. The transition state structure was optimized until the forces on atom became converged to 0.05 eV/Å.

The reaction energy (∆E) and barrier (Eact) are calculated via the following formula:

where EIS, ETS, and EFS are the total energy of the corresponding initial state (IS), transitional state (TS), and final state (FS), respectively.

Adsorption density

To assess the underlying mechanism p-X synthesis from the co-reaction of methanol and olefins on Z5 zeolite, Materials Studio (MS) was employed to perform systematically investigating the effect of partial pressure of methanol and ethylene on their adsorption on Z5 zeolite by computational simulations. For Z5 zeolite, we adopted the P1 space group with lattice constants: a = 19.09 Å, b = 19.62 Å, c = 12.85 Å, and angles α = γ = 90.00°, β = 89.95°, and employed a 2x2x2 supercell. We first optimized the geometric structure of our model using Forcite module. Van der Waals interactions between atoms were described using a universal force field, with a specified cutoff distance of 12.5 Å. Atomic charges were computed through the QEq method, and the electrostatic potential was calculated using the Ewald summation method. We employed a stringent convergence criterion of 0.001 kcal/mol/Å for the geometry optimization. To simulate the adsorption of methanol and ethylene, a Sorption module was used. We determined the partial charges of both the adsorbates and adsorbents using the QEq method, and elucidated electrostatic interactions through the Ewald summation method. Van der Waals interactions between adsorbates and adsorbents were considered using the universal force field, with a cutoff distance set at 12.5 Å. To ensure the accuracy of our simulations, we conducted 1.0 × 105 equilibration steps at a temperature of 375 °C, followed by 1.0 × 106 production steps to generate a diverse ensemble of adsorbate and adsorbent configurations.

Diffusion of hydrogen

Molecular dynamics simulation was conducted to investigate the diffusion of hydrogen from Z5 zeolite and to Fe5C2 and ZnCr2O4. For Fe5C2, the P1 space group was employed with lattice constants: a = 23.20 Å, b = 22.53 Å, c = 14.97 Å, and angles α = γ = 90.00°, β = 97.57°. For ZnCr2O4, the P1 space group was used with lattice constants: a = b = 22.53 Å, c = 16.69 Å, and angles α = γ = β = 90.00°. The Forcite module of MS was employed for the molecular dynamics simulation calculations in this study. The NPT ensemble was used at the temperature of 375 °C and pressure of 5 MPa. To ensure the reliability and consistency of our calculations, the tolerance was set at 2.0 × 10-5 kcal/mol for energy, 0.001 kcal/mol/Å for force, and 1.0 × 10-5 Å for displacement. The Universal Force Field (UFF) was utilized for modeling van der Waals interactions with a cutoff distance of 12.5 Å, while electrostatic interactions were handled using the Ewald summation method.

Data availability

Source data are provided in this paper. The source data generated in this study are provided in the Source Data file. Source data are provided in this paper.

References

Wei, J. et al. Precisely regulating Brønsted acid sites to promote the synthesis of light aromatics via CO2 hydrogenation. Appl. Catal. B: Environ. 283, 119648 (2021).

Wang, T. et al. ZnZrOx integrated with chain-like nanocrystal HZSM-5 as efficient catalysts for aromatics synthesis from CO2 hydrogenation. Appl. Catal. B: Environ. 286, 119929 (2021).

Wang, Y. et al. Boosting the synthesis of value-added aromatics directly from syngas via a Cr2O3 and Ga doped zeolite capsule catalyst. Chem. Sci. 12, 7786–7792 (2021).

Ni, Y., Zhu, W. & Liu, Z. Formaldehyde intermediate participating in the conversion of methanol to aromatics over zinc modified H-ZSM-5. J. Energy Chem. 54, 174–178 (2021).

Fu, Y. et al. Insights into the size effect of ZnCr2O4 spinel oxide in composite catalysts for conversion of syngas to aromatics. Green. Energy Environ. 2, 530–537 (2023).

Fu, Y., Ni, Y., Chen, Z., Zhu, W. & Liu, Z. Achieving high conversion of syngas to aromatics. J. Energy Chem. 66, 597–602 (2022).

Fu, T., Shao, J. & Li, Z. Catalytic synergy between the low Si/Al ratio Zn/ZSM-5 and high Si/Al ratio HZSM-5 for high-performance methanol conversion to aromatics. Appl. Catal. B: Environ. 291, 120098 (2021).

Kasipandi, S. & Bae, J. W. Recent advances in direct synthesis of value-added aromatic chemicals from syngas by cascade reactions over bifunctional catalysts. Adv. Mater. 31, 1803390 (2019).

Ali, M., Koo, H.-M., Kasipandi, S., Han, G. Y. & Bae, J. W. Direct synthesis of liquid fuels and aromatics from syngas over mesoporous FeZrOx catalyst mixed with Mo/ferrierite. Fuel 264, 116851 (2020).

Wang, H. et al. Bifunctional catalysts with versatile zeolites enable unprecedented para-xylene productivity for syngas conversion under mild conditions. Chem. Catal. 2, 779–796 (2022).

Han, M. et al. Effect of Lewis/Brønsted acid sites in HZSM−5 zeolite on the selectivity of para-xylene during methylation of toluene with methanol. Mol. Catal. 509, 111622 (2021).

Zhao, Y., Ma, X., Ren, D. & Xia, Y. A strategy to improve the para-selectivity in toluene methylation on P2O5-ZSM-5 modified by the para-xylene placeholder method. React. Kinet., Mech. Catal. 132, 967–981 (2021).

Wang, C. et al. Maximizing sinusoidal channels of HZSM-5 for high shape-selectivity to p-xylene. Nat. Commun. 10, 4348 (2019).

Zhang, P., Tan, L., Yang, G. & Tsubaki, N. One-pass selective conversion of syngas to para-xylene. Chem. Sci. 8, 7941–7946 (2017).

Tian, G. et al. Accelerating syngas-to-aromatic conversion via spontaneously monodispersed Fe in ZnCr2O4 spinel. Nat. Commun. 13, 5567 (2022).

Miao, D. et al. Selective synthesis of benzene, toluene, and xylenes from syngas. ACS Catal. 10, 7389–7397 (2020).

Cheng, K. et al. Bifunctional catalysts for one-step conversion of syngas into aromatics with excellent selectivity and stability. Chem 3, 334–347 (2017).

Gao, W. et al. Capsule-like zeolite catalyst fabricated by solvent-free strategy for para-Xylene formation from CO2 hydrogenation. Appl. Catal. B: Environ. 303, 120906 (2022).

Gao, W. et al. Selective conversion of CO2 into para-xylene over a ZnCr2O4-ZSM-5 catalyst. ChemSusChem 13, 6541–6545 (2020).

Wang, Y. et al. Direct and oriented conversion of CO2 into value-added aromatics. Chemistry. A Eur. J. 25, 5149–5153 (2019).

Wang, Y. et al. Rationally designing bifunctional catalysts as an efficient strategy to boost CO2 hydrogenation producing value-added aromatics. ACS Catal. 9, 895–901 (2019).

Tu, C. et al. CO2-assisted ethane aromatization over zinc and phosphorous modified ZSM-5 catalysts. Appl. Catal. B: Environ. 304, 120956 (2022).

Sibi, M. G., Khan, M. K., Verma, D., Yoon, W. & Kim, J. High-yield synthesis of BTEX over Na-FeAlOx/Zn-HZSM-5@SiO2 by direct CO2 conversion and identification of surface intermediates. Appl. Catal. B: Environ. 301, 120813 (2022).

Zhou, C. et al. Highly active ZnO-ZrO2 aerogels integrated with H-ZSM-5 for aromatics synthesis from carbon dioxide. ACS Catal. 10, 302–310 (2020).

Huang, X. et al. Catalyst design strategies towards highly shape-selective HZSM-5 for para-xylene through toluene alkylation. Green. Energy Environ. 5, 385–393 (2020).

Hu, Q. et al. High yield production of C2-C3 olefins and para-xylene from methanol using a SiO2-coated FeOx/ZSM-5 catalyst. RSC Adv. 7, 28940–28944 (2017).

Ma, Y. et al. The influence of straight pore blockage on the selectivity of methanol to aromatics in nanosized Zn/ZSM-5: An atomic Cs-corrected STEM analysis study. RSC Adv. 6, 74797–74801 (2016).

Zhang, J., Qian, W., Kong, C. & Wei, F. Increasing para-xylene selectivity in making aromatics from methanol with a surface-modified Zn/P/ZSM-5 catalyst. ACS Catal. 5, 2982–2988 (2015).

Kim, S. et al. Gd/HZSM-5 catalyst for conversion of methanol to hydrocarbons: effects of amounts of the Gd loading and catalyst preparation method. Appl. Catal. B: Environ. 220, 191–201 (2018).

Wang, N. et al. Modulation of b-axis thickness within MFI zeolite: Correlation with variation of product diffusion and coke distribution in the methanol-to-hydrocarbons conversion. Appl. Catal. B: Environ. 243, 721–733 (2019).

Zhang, J. et al. Solvent-free synthesis of core-shell Zn/ZSM-5@silicalite−1 catalyst for selective conversion of methanol to BTX aromatics. Ind. Eng. Chem. Res. 58, 15453–15458 (2019).

Tan, W. et al. Para-selective methylation of toluene with methanol over nano-sized ZSM-5 catalysts: Synergistic effects of surface modifications with SiO2, P2O5 and MgO. Microporous Mesoporous Mater. 196, 18–30 (2014).

Xu, G. & Zhu, X. A core-shell structured Zn/SiO2@ZSM-5 catalyst: Preparation and enhanced catalytic properties in methane co-aromatization with propane. Appl. Catal. B: Environ. 293, 120241 (2021).

Hita, I. et al. Enhanced production of phenolics and aromatics from raw bio-oil using HZSM-5 zeolite additives for PtPd/C and NiW/C catalysts. Appl. Catal. B: Environ. 259, 118112 (2019).

He, S. et al. Catalytic conversion of pure glycerol over an un-modified H-ZSM-5 zeolite to bio-based aromatics. Appl. Catal. B: Environ. 281, 119467 (2021).

Arslan, M. T. et al. Selective conversion of syngas into tetramethylbenzene via an aldol-aromatic mechanism. ACS Catal. 10, 2477–2488 (2020).

Xu, Y. et al. Yolk@ shell FeMn@ hollow HZSM-5 nanoreactor for directly converting syngas to aromatics. ACS Catal. 11, 4476–4485 (2021).

Wang, T. et al. Sodium-mediated bimetallic Fe-Ni catalyst boosts stable and selective production of light aromatics over HZSM-5 zeolite. ACS Catal. 11, 3553–3574 (2021).

Nawaz, M. A. et al. Harnessing the synergistic interplay of Fischer-Tropsch synthesis (Fe-Co) bimetallic oxides in Na-FeMnCo/HZSM-5 composite catalyst for syngas conversion to aromatic hydrocarbons. ChemCatChem 13, 1966–1980 (2021).

Yang, X. et al. Exploring the reaction paths in the consecutive Fe-based FT catalyst-zeolite process for syngas conversion. ACS Catal. 10, 3797–3806 (2020).

Sun, T. et al. Syngas conversion to aromatics over the Co2C-based catalyst and HZSM-5 via a tandem system. Ind. Eng. Chem. Res. 59, 4419–4427 (2020).

Xu, Y. et al. Selective conversion of syngas to aromatics over Fe3O4@ MnO2 and hollow HZSM-5 bifunctional catalysts. ACS Catal. 9, 5147–5156 (2019).

Zhao, B. et al. Direct transformation of syngas to aromatics over Na-Zn-Fe5C2 and hierarchical HZSM-5 tandem catalysts. Chem 3, 323–333 (2017).

Liu, C. et al. Insights into the key factor of zeolite morphology on the selective conversion of syngas to light aromatics over a Cr2O3/ZSM-5 catalyst. ACS Catal. 10, 15227–15237 (2020).

Huang, Z. et al. Ceria-zirconia/zeolite bifunctional catalyst for highly selective conversion of syngas into aromatics. ChemCatChem 10, 4519–4524 (2018).

Yang, Z. et al. Tuning direct CO hydrogenation reaction over Fe-Mn bimetallic catalysts toward light olefins: Effects of Mn promotion. Appl. Catal. B: Environ. 285, 119815 (2021).

Song, H. et al. Spinel-structured ZnCr2O4 with excess Zn is the active ZnO/Cr2O3 catalyst for high-temperature methanol synthesis. ACS Catal. 7, 7610–7622 (2017).

Errani, E., Trifiro, F., Vaccari, A., Richter, M. & Del Piero, G. Structure and reactivity of Zn-Cr mixed oxides. Role of non-stoichiometry in the catalytic synthesis of methanol. Catal. Lett. 3, 65–72 (1989).

Li, Y. et al. Distance for communication between metal and acid sites for syngas conversion. ACS Catal. 12, 8793–8801 (2022).

Song, G., Li, M., Yan, P., Nawaz, M. A. & Liu, D. High conversion to aromatics via CO2-FT over a CO-reduced Cu-Fe2O3 catalyst integrated with HZSM-5. ACS Catal. 10, 11268–11279 (2020).

Karim, W. et al. Catalyst support effects on hydrogen spillover. Nature 541, 68–71 (2017).

Peña, D. et al. Identification of carbon species on iron-based catalysts during Fischer-Tropsch synthesis. Appl. Catal. A: Gen. 554, 10–23 (2018).

Liu, X. W. et al. Mössbauer spectroscopy of iron carbides: From prediction to experimental confirmation. Sci. Rep. 6, 26184 (2016).

Santos, V. P. et al. Direct conversion of syngas to light olefins (C2-C3) over a tandem catalyst CrZn-SAPO-34: Tailoring activity and stability by varying the Cr/Zn ratio and calcination temperature. J. Catal. 381, 108–120 (2020).

Chen, S. et al. Cation distribution in ZnCr2O4 nanocrystals investigated by X-ray absorption fine structure spectroscopy. J. Phys. Chem. C. 117, 25019–25025 (2013).

Wang, Y. et al. Visualizing element migration over bifunctional metal-zeolite catalysts and its impact on catalysis. Angew. Chem. 133, 17876–17884 (2021).

Arslan, M. T. et al. Single-step conversion of H2-deficient syngas into high yield of tetramethylbenzene. ACS Catal. 9, 2203–2212 (2019).

Harris, J. W. et al. Titration and quantification of open and closed Lewis acid sites in Sn-Beta zeolites that catalyze glucose isomerization. J. Catal. 335, 141–154 (2016).

Ma, Z. et al. Co-precipitated Fe-Zr catalysts for the Fischer-Tropsch synthesis of lower olefins (C2O∼C4O): Synergistic effects of Fe and Zr. J. Catal. 378, 209–219 (2019).

Jin, Y. & Datye, A. K. Phase transformations in iron Fischer-Tropsch catalysts during temperature-programmed reduction. J. Catal. 196, 8–17 (2000).

Dai, W. et al. Effect of n-butanol cofeeding on the methanol to aromatics conversion over Ga-modified nano H-ZSM-5 and its mechanistic interpretation. ACS Catal. 8, 1352–1362 (2018).

Zuo, J. et al. Selective methylation of toluene using CO2 and H2 to para-xylene. Sci. Adv. 6, eaba5433 (2020).