Abstract

Increasing the molecular weight while maintaining mono-dispersity has been proved crucial in innovating high-performance photovoltaic materials in giant oligomeric acceptors. However, developing efficient giant oligomeric donors to replace the batch-varied polymers remains challenging due to a lack of design principles. Here, by designing two unique isomeric rhodanine-based linkers, we successfully regulate the assembly behaviors of giant dimeric donors (G-Dimer-Ds) and fabricate the first all-giant-oligomer OSCs pairing with giant dimeric acceptor DY. Multiple characterizations demonstrate the small homo-molecular interaction with strong thermal-driven assembly capability in G-Dimer-D2 simultaneously facilitates reducing energetic disorder, improving charge transport and obtaining stable morphology, resulting in a satisfactory efficiency of 15.70% and long-term photostability with an extrapolated T80 of ca.10,000 hours, and further enhancing thermal-driven assembly promotes efficiency of 16.05%. Our results provide construction approaches on efficient giant donors, and propose a promising type of OSC with completely definite structures, high efficiency and superior stability.

Similar content being viewed by others

Introduction

Material innovation is a main driving force in promoting the development of organic solar cells (OSCs). Both the small molecule (SM) and the polymer are successful photovoltaic materials with double-edge swords. In all-small-molecule organic solar cells (ASM-OSCs), the SM possesses a definite structure and good assembly, but the strong assembly brings mutual restriction of parameters and lowers the probability of long-term stability1,2,3,4. In comparison, the polymer obtains potential excellent thermal stability due to its low diffuse speed originating from large molecular weight (MW), but exhibits significant batch-to-batch differences and serious chains-entanglements simultaneously5,6,7,8. To increase the MW while maintaining mono-dispersity, we integrate the advantages of SM and polymer and successively explored “N-π-N” type giant dimeric acceptor9 (G-Dimer-A) and “star-shaped” giant trimeric acceptor10 (G-Trimer-A), by combining highly-efficient non-fullerene acceptors through an aromatic linker. Both G-Dimer-A and G-Trimer-A exhibit definite structures, cutting-edge power conversion efficiencies (PCEs), and excellent stabilities, which have been proved by various groups, validating the successful design11,12,13. However, all these giant oligomers-based devices still apply batch-varied polymers such as PM6 as the donor, limiting their reproducibility for commercial applications.

If efficient giant oligomeric donors could further replace polymers, we would construct a type of all-giant-oligomer OSCs (AGO-OSCs) with completely definite structures and probably excellent stability14,15. However, constructing an efficient oligomeric donor remains a great challenge. Although the dimerized donors have been reported with targeted purposes, such as dimeric porphyrins16,17 and BODIPY18, they behave poorly in binary devices. Learning from the success of G-Dimer-A, we propose to combine two highly efficient SMs to synthesize G-Dimer-Ds. However, as in G-Dimer-A, linking groups and positions play critical roles in device performances, such as rigid aromatic groups and flexible alkyl chains with reaction sites in the core or the end-capped acceptor units15,19,20,21. Currently, the material design principle in efficient G-Dimer-Ds is almost blank, and we think the key challenge is to design the linkers and their linked positions.

Herein, based on our successful experience in designing highly-efficient SM donors22,23 and G-Dimer-As9,24, we successfully synthesized two isomerically dimeric rhodanine-based linkers with connection sites in the para- and meta-position, and constructed two isomeric G-Dimer-D1 and G-Dimer-D2 through “building block design”. The two isomeric linkers in G-Dimer-Ds adjust the dihedral angle between the two monomers, and significantly impact their molecular interaction and thermal-driven assembly capability. Interestedly, G-Dimer-D2 performs a smaller homo-molecular interactions but stronger thermal-driven assembly capability, leading to more ordered stacking with thermodynamically stable morphology after thermal annealing (TA). Thus, G-Dimer-D2 based AGO-OSC exhibited a superior PCE of 15.70% with a fill factor (FF) of 75.00%, and further shortening the end-capped alkyl chains promotes a PCE of 16.05% with an FF of 76.64%. Moreover, it shows the smallest burn-in and excellent photostability with an extrapolated T80 of ca.10000 hours. Compared to corresponding ASM-OSCs, both optimized AGO-OSCs exhibit suppressed non-radiative voltage loss during TA and much superior stability. Limited by the exiguous study on all-oligmer system, there is still large room for improvement in PCE. However, the advantages of clear chemical structure for both the donor and acceptor as well as improved photostability will significantly promote the development of AGO-OSCs. This study proposed a conceptual type of OSCs based on giant donors and acceptors, and provided the design principles of giant donors.

Results and discussion

Design and synthesize giant dimeric donors

Before designing G-Dimer-Ds, we took our experience of designing highly-efficient SM donors in ASM-OSCs as reference, and the two key design points are as follows: 1) strong hetero-molecular interaction between donor and acceptor to ensure proper phase separation22; 2) proper thermal-driven assembly capability to purify the phase domains23. Consequently, the design for G-Dimer-Ds in AGO-OSCs is probably quite different from G-Dimer-As in polymer OSCs15,19,20,21, and both strong homo-molecular interaction originated in a conjugated rigid linker and poor molecular assembly influenced by flexible linker may not facilitate forming an ideal microstructure. Hence, we gap a flexible methylene unit between the linked benzene and conjugated backbone to construct G-Dimer-Ds, choosing the reported efficient SM donor MPhS-C6 as monomer22. To further tune the molecular assembly, the dihedral angle of the two monomers is adjusted by the para- and meta-position of the benzyl linker (compounds 1 and 2, Fig. 1). Considering no coupling reaction site in the rhodanine units, to largely retain the property of the monomer, we creatively synthesized dimerized end-capped units to construct the G-Dimer-Ds by modular design. Both the unilateral product of the Knoevenagel reaction and the following condensation with linkers exhibit a high yield of 50 − 70% (Fig. 1 and Supplementary Information), indicating our approach provides an effective method for oligomer synthesis.

Expectedly, the isomerism of the linker largely tuned the relative position of building blocks and electron density of frontier energy levels. The former is paralleled in G-Dimer-D1 but perpendicular in G-Dimer-D2, and the latter extends over the whole molecular backbone in G-Dimer-D1 but is only restricted to one building block in G-Dimer-D2 (Supplementary Fig. 1). Compared with MPhS-C6, both G-Dimer-Ds exhibit a slightly red-shifted absorption in solution and blue-shifted absorption in film, together with downshifts of the highest occupied molecular orbital energy levels (Supplementary Fig. 2), illustrating the double MW well decreases the molecular packing ability. Furthermore, the absorbance ratios of the three films between 0 − 0 and 0 − 1 are largely different, further indicating their vastly different assembly behaviors.

Homo-molecular interaction, thermal-driven assembly, and molecular packing

Differential scanning calorimetry (DSC) results demonstrate that compared to G-Dimer-D1, the G-Dimer-D2 exhibits ca. 90 oC lower melting point (Tm, from 264.8 to 176.3 oC) and an almost half reduced melting enthalpy (△Hm, from 34.8 to 19.3 J/g), indicating its much inferior homo-molecular interaction (Fig. 2a and Supplementary Table 1). The intermediate Tm and △Hm for MPhS-C6 suggest the large tailoring space of homo-molecular interactions in G-Dimer-Ds. And for G-Dimer-D1, a weak exothermic peak at 221.8 oC before melting point can be attributed to a crystal modification25.

a DSC curves of three donors; b Tg of donors and the slope of deviation metric over temperature above Tg; c 2-D GIWAXS images of pristine donor films before and after TA treatment; d calculated CCL of pristine donor films with/without TA and their ratio. Source data are provided as a Source Data file.

Besides the molecular interaction, the thermal-driven assembly capability also significantly impacts crystalline23, which is related to whether the high crystallinity with ordered stacking morphology can be effectively formed after the TA treatment. Similar to Tm, G-Dimer-D2 exhibited a much lower TC of 124.0 °C than G-Dimer-D1 (197.3 °C), with MPhS-C6 (132.5 °C) in between. During the temperature range of device processing, G-Dimer-D2 with MPhS-C6 undergoes a glass transition, while G-Dimer-D1 possibly undergoes a low-temperature crystallization transition26 below the glass state temperature, with a glass transition temperature (Tg) of 171.3 °C (Supplementary Fig. 3). To further quantitatively characterize their thermal-driven assembly, the low-temperature crystallization temperature (TLTC) for G-Dimer-D1 and Tgs for G-Dimer-D2 and MPhS-C6 as well as the slope above corresponding temperature (KDMT) were obtained by fitting temperature-dependent deviation metric27 (Fig. 2b and Supplementary Fig. 4). G-Dimer-D1 exhibits the highest TLTC of 96.2 °C, followed by MPhS-C6 (83.5 °C) and G-Dimer-D2 (75.1 °C). The lowest Tg of G-Dimer-D2, together with its maximum KDMT (0.053), indicates its easier molecular rearrangement under a small thermal drive. Conversely, the maximum TLTC of G-Dimer-D1 with a minimum KDMT (0.0038) indicates its least thermal-driven assembly capability during device optimization.

Grazing Incident Wide-Angle X-ray Scattering (GIWAXS) measurements for the pure film with/without TA were carried out to confirm the above results. Different from the MPhS-C6 and G-Dimer-D1, G-Dimer-D2 exhibits a dominated face-on packing mode with a prominent (010) peak in the out-of-plane (OOP) direction and a preferential (100) peak in the in-plane (IP) direction, which is more evident after TA (Fig. 2c). Taking the (010) peak representing π–π stacking as an example, the coherence crystalline length (CCL) for the untreated films is gradually increased from G-Dimer-D2 (16.4 Å) to G-Dimer-D1 (25.1 Å) to MPhS-C6 (31.9 Å), further supported by their gradually more apparent alternately dark and light Transmission Electron Microscopy (TEM) images (Supplementary Fig. 5). Their differed CCLs are a combined effect of molecular interaction (△Hm) and diffusion speed resulted from MW. However, after TA, both the G-Dimer-D2 and MPhS-C6 exhibit effective packing enhancement, with 1.79 times and 1.59 times CCL increment, respectively (Fig. 2d, Supplementary Fig. 6 and Supplementary Table 2), while TA makes negligible effects on the CCL increment for G-Dimer-D1, which is consistent with their thermal-driven assembly capability. Noteworthy, compared to G-Dimer-D2, TA induced a complex stacking mode in MPhS-C6, as deduced by its changes in absorption shapes (Supplementary Fig. 7) and multi-orientation diffraction points in GIWAXS after TA.

Conclusively, compared to SMs, G-Dimer-Ds exhibit poorer packing after spin-coating, and the molecular interaction and thermal-driven assembly capability are well regulated through the isomeric.

linkers. G-Dimer-D2 performs the poorest intrinsic molecular interaction with the highest thermal-driven assembly capability after spin-coating, leading to an ordered π–π stacking with improved crystallinity after TA post-treatment, promoting the annealed film to approach a thermodynamic steady state.

Influence of molecular interactions and thermal-driven assembly on the morphology of blends

The influence of molecular interactions and thermal-driven assembly on morphology based on AGO (G-Dimer-D/G-Dimer-A) and ASM blend (MPhS-C6/Y6) was investigated by in-situ UV−visible-NIR absorption during the spin-coating and TA processes, and the corresponding molecular structures are shown in Fig. 3a. The 0 − 0 absorbance for donors and the red-shifts of maximum absorption peaks for acceptors are selected to characterize their aggregations, respectively. There is an apparent sequential aggregation with G-Dimer-D1 segregating first in the G-Dimer-D1/DY, whereas simultaneous aggregation of donor and acceptor is shown in the G-Dimer-D2/DY and MPhS-C6/Y6 (Fig. 3b–d, Supplementary Fig. 8). Based on the similar hetero-molecular interaction for G-Dimer-D1/DY and G-Dimer-D2/DY (Supplementary Fig. 9 and Supplementary Table 3), this disparity should result from the stronger homo-molecular interaction, together with the reduced solubility of G-Dimer-D1. Furthermore, the assembly time of G-Dimer-D2/DY (ca. 180 ms) is double of MPhS-C6/Y6 (ca. 80 ms), ascribed to the decreased diffusion and thus assemble rates influenced by its double MW. The simultaneous aggregation and slow assembly in G-Dimer-D2/DY endow it with the loosest packing (dπ−π = 3.67 Å), shortest CCL of (010) peak (23.1 Å) but the smallest energetic disorder (Eu = 21.8 meV, Fig. 4f and Supplementary Fig. 10). The longest assemble time and G-Dimer-D1 segregated first result in the most condensed packing (dπ−π = 3.61 Å), while the MPhS-C6 with fast diffusion exhibits the longest CCL of 36.5 Å (Supplementary Fig. 11 and Supplementary Table 4).

a chemical structure of DY, MPhS-C6 and Y6; 2-D in-situ UV-visible-NIR absorption during film formation and corresponding curves of 0 − 0 absorbance for donors and redshift peaks for acceptors over time for b G-Dimer-D1/DY, c G-Dimer-D2/DY and d MPhS-C6/Y6, respectively. Source data are provided as a Source Data file.

TEM images for optimized a G-Dimer-D1/DY, b G-Dimer-D2/DY and c MPhS-C6/Y6 blend films before and after TA treatment; calculated CCL of d (010) in OOP direction and e (010) in IP direction for optimized blend films with/without TA treatment; f calculated Eu for optimized blend films with/without TA treatment.

The TA effect on the in-situ UV-visible-NIR absorption is not as obvious as spin-coating (Supplementary Fig. 12), but its effect on the morphology could be visually observed from the TEM images (Fig. 4a–c), where the G-Dimer-D2/DY and MPhS-C6/Y6 blends show an enlarged phase separation, while the G-Dimer-D1/DY remains almost unchanged. Their different packing changes were further confirmed and elaborated by GIWAXS (Fig. 4d–e, Supplementary Fig. 13, and Supplementary Table 4). Taking (010) peak as an example, TA treatment makes the CCL of G-Dimer-D2/DY blend increase sharply from 23.1 Å to 35.6 Å in OOP direction with an improved condense packing (dπ-π from 3.67 Å to 3.59 Å), while the (010) increment for MPhS-C6/Y6 and G-Dimer-D1/DY blends mainly happens in the IP direction with a smaller CCL increment, especially for G-Dimer-D1/DY. To further investigate the effect of thermal-dependent aggregation of donors on the blended morphology, the optimized morphologies of G-Dimer-D2/Y6 and MPhS-C6/DY before and after TA were characterized with TEM, Atomic Force Microscope (AFM) and GIWAXS (Supplementary Figs. 14−15 and Supplementary Table 5). Both blends performed an enhanced phase separation after TA, while the CCL of (010) peak in OOP direction increased only significantly in G-Dimer-D2/Y6 (from 25.0 to 38.4 Å), which is similar to that of G-Dimer-D2/DY blend. As for MPhS-C6/DY, a notable CCL increment of (010) was in the IP direction, which is also similar to that of the MPhS-C6/Y6 blend. This phenomenon suggests that the thermal driving packing mode is more prone to donors than acceptors and quite consistent with their KDMTs. Consequently, G-Dimer-D2 based blends obtain the longest CCL increment while G-Dimer-D1/DY exhibits the opposite. The consistent packing mode for donor and acceptor induces a more ordered homogeneous packing in G-Dimer-D2/DY, and thus its Eu increase during TA (△Eu = 0.5 meV) is as small as G-Dimer-D1/DY, which is half smaller than that of MPhS-C6/Y6 (△Eu = 1.4 meV, Fig. 4f and Supplementary Fig. 10). G-Dimer-D2/Y6 shows the similar Eu increase during TA as G-Dimer-D2/DY, while MPhS-C6/DY performs a double △Eu of 1.1 meV, similar to that of MPhS-C6/Y6 (Supplementary Fig. 20). Consequently, the morphology and Eu of blend is more dependent on donors rather than acceptors, which is probably because of their much lower Tg (Supplementary Fig. 16).

Summarily, the slower film-forming and easier thermal assembly of the G-Dimer-D2/DY blend make it obtains appropriate CCL with the smallest Eu and dπ−π, facilitating reduced energy loss and improved photon utilization simultaneously.

Device performance, photophysical process, and non-radiative voltage loss

The AGO-OSCs, ASM-OSCs and SM/G-Dimer-based OSCs were fabricated with a structure of indium tin oxide (ITO)/poly(3,4-ethylenedioxythiophene): polystyrene sulfonate (PEDOT: PSS)/active layer/poly[(9,9-bis(3’-((N,N-dimethyl)-N-ethylammonium)-propyl)−2,7-fluorene)-alt-2,7-fluorene)-alt-2,7-(9,9-dioctylfluorene)]dibromide (PFN-Br)/Ag. By adjusting the donor-to-acceptor ratios, additive ratios, and TA temperatures (Table 1 and Supplementary Tables 6−8), devices based on G-Dimer-D2/DY performed an ideal PCE of 15.70%, with an excellent open circuit voltage (VOC) of 0.858 V, a short circuit current (JSC) of 24.40 mA cm−2 and an FF of 75.00%. Shortening the end-capped alky chains from n-hexyl to n-butyl (G-Dimer-D3, Supplementary Fig. 39) allows better thermal-driven assembly capability inferred from its KDMT and GIWAXS (Supplementary Figs. 17−19 and Supplementary Table 9), further increasing the PCE to 16.05% with an improved FF of 76.64%. The G-Dimer-D1/DY-based device obtained a PCE of 14.12%, with a similar VOC of 0.858 V, inferior JSC of 23.47 mA cm−2 and FF of 70.06%. The MPhS-C6/Y6-based device performed an in-between PCE of 15.31%, with a reduced VOC of 0.830 V, a JSC of 24.34 mA cm−2 and an FF of 75.74%. As for SM/G- Dimer references, both G-Dimer-D2/Y6 and MPhS-C6/DY-based devices performed high FF over 75%, and the optimized device of G-Dimer-D2/Y6 obtained a relatively higher PCE of 15.28% with enhanced JSC. And compared with G-Dimer-D2/DY, G-Dimer-D2/Y6-based devices mainly manifested a decreased VOC. The best J–V curves, corresponding external quantum efficiency (EQE) curves (Supplementary Fig. 20), and efficiency distribution for the optimized devices are shown in Fig. 5a–c.

a optimized J-V curves; b corresponding EQE curves; c statistical distribution of optimized PCE; d hole and electron mobility; e VOC variation with light intensity; f Veff-Jph curves for optimized devices; g TPC curves of the optimized devices; h EQEEL for optimized devices; i non-radiative energy loss changes with TA temperature. Source data are provided as a Source Data file.

Benefiting from the optimized microstructure resulting from favorable film-formation kinetics and thermal-driven assembly capability, both the hole and electron mobility for G-Dimer-D2/DY is double of G-Dimer-D1/DY and comparable to that of ASM-OSCs (Fig. 5d). Thereinto, the hole mobility is 0.6×10−3, 1.17×10−3 and 1.70×10−3 cm2V−1s−1 for G-Dimer-D1/DY, G-Dimer-D2/DY and MPhS-C6/Y6, respectively, and their corresponding electron mobility is 0.19×10−3, 0.50×10−3 and 0.77×10−3 cm2V−1s−1, respectively. Compared to G-Dimer-D2, the G-Dimer-D3 exhibited higher thermal-driven assembly capability and so did the G-Dimer-D3/DY blends, leading to slightly longer CCL (Supplementary Table 9) and elevated mobilities, and ultimately imporved device performances. Although the bimolecular recombination for the three systems is almost similar (Supplementary Fig. 21), the smallest energetic disorder in G-Dimer-D2/DY largely suppressed the trap-assisted recombination with n value of 1.06, which is much closer to 1 than that of G-Dimer-D1/DY (n = 1.39) and MPhS-C6/Y6 (n = 1.31) blends (Fig. 5e). Hence, the G-Dimer-D2-based device obtained the highest Pdiss (97.75%) and Pcoll (84.62%), which is slightly larger than that of MPhS-C6 (Pdiss = 96.67% and Pcoll = 83.61%) and significantly superior to that of G-Dimer-D1 (Pdiss = 96.02% and Pcoll = 79.81%, Fig. 5f). The efficient charge extraction in G-Dimer-D2/DY was further confirmed by its fastest transient photocurrent lifetime (24.2 ns), which is half faster than MPhS-C6 (34.6 ns) and almost double faster than that of G-Dimer-D1/DY (40.6 ns) (Fig. 5g). Benefiting from the better thermal-driven assembly capability of G-Dimer-D2, the G-Dimer-D2/Y6-based device also obtained efficient exciton dissociation and charge collection (Pdiss = 96.76% and Pcoll = 84.78%) with suppressed bimolecular and trap-assisted recombination, and reflected in its faster charge extraction (24.7 ns) and superior JSC than MPhS-C6/DY-based device (Supplementary Fig. 20). For MPhS-C6/DY, significantly reduced JSC may be due to the most roughest optimized blend with the largest Rq of 2.36 nm (Supplementary Fig. 14), thus adverse to charge collection reflected in its worest Pcoll of 83.46%. Noteworthy, all the above-mentioned calculations were provided in Methods. The appropriate charge transport ability, most suppressed trap-assisted recombination, and fastest charge extraction enable the superior JSC and FF in G-Dimer-D2/DY-based devices.

Thermal-driven assembly also impact the radiative quantum efficiency of the solar cell (EQEEL) and thus non-radiative voltage loss (∆Vnr, e∆Vnr = –kBTln (EQEEL)28,29). Although the optimized TA temperature for AGO-OSCs is higher (125 oC) than that of ASM-OSCs (115 oC), the EQEEL for optimized AGO-OSCs are 2–3 times higher than that of optimized ASM-OSCs (Fig. 5h). Similarly, the EQEEL for optimized G-Dimer-D2/Y6-based device also remarkably higher than both MPhS-C6-based devices with a higher TA temperature at 125 oC (Supplementary Fig. 22). The corresponding ∆Vnr is 0.227, 0.214 and 0.209 V for G-Dimer-D1/DY, G-Dimer-D2/DY and G-Dimer-D2/Y6, respectively, which is 20–30 mV smaller than that of MPhS-C6/Y6 (0.241 eV) and MPhS-C6/DY (0.242 eV). Figure 5i (Supplementary Figs. 22−23) illustrates following two facts: one is that the initial ∆Vnr (annealed at 65 oC) for the three devices are similar with a small value below 0.2 V, demonstrating the decreased ∆Vnr in G-Dimer-Ds-based devices should result from their largely suppressed ∆Vnr during TA process; the other is that slopes of ∆Vnr functioned as the temperature for G-Dimer-Ds are almost identical despite their varied thermal-driven assembly capability (Supplementary Table 10), which should be ascribed to their similar and small increment of energetic disorder during heating as discussed above (Fig. 4f, Supplementary Fig. 10 and Supplementary Fig. 22). G-Dimer-D2-based devices performed much suppressed ∆Vnr in despite their thermal-driven assembly capability over ASM-OSC, which is their significant advantage, indicating their superior potential in pursuing higher ultimate efficiency. Summarily, compared to G-Dimer-D1/DY, G-Dimer-D2/DY obtains suppressed trap-assisted recombination, superior mobility and charge extraction speed; compared to MPhS-C6/Y6, G-Dimer-D2/DY obtains smaller ∆Vnr. Consequently, G-Dimer-D2/DY obtained simultaneous superior JSC, FF, and VOC, leading to the highest device performance.

Devices photostability

Obtaining excellent device stability is also our original intention in developing AGO-OSCs, and their photostability was tested under simulated one sun radiation in the N2 atmosphere (Fig. 6a and Supplementary Fig. 24). Compared to ASM-OSC reference, AGO-OSCs suffer from alleviated burn-in, especially for G-Dimer-D2, which retains ca. 86% of the initial efficiency. Benefiting from the high blended Tg over 100 °C of all-oligomer films (Supplementary Fig. 25), both G-Dimer-D1/DY and G-Dimer-D2/DY-based devices show a much slower decay trend than ASM-OSC, indicating their better performance in the long-term irradiation; especially, the extrapolated T80 (retains ca. 80% of the initial efficiency) of G-Dimer-D2-based device was calculated to 9656 hours (Supplementary Fig. 26), among the best in all types of OSCs (Supplentary Table 11). The SM/G-Dimer references perform centered photostability between AGO and ASM-OSCs, in which G-Dimer-D2/Y6 shows a relatively smaller burn-in and better photostability than the MPhS-C6/DY-based device (Supplementary Fig. 27). Obviously, AGO-OSCs exhibited much superior stability over the ASM-OSCs due to the double MW limiting molecular migration, which enabled them to obtain a reduced decay rate after the burn-in process.

Elucidating the fundamental reason behind burn-in30,31 of FF and VOC is significant for further improving the photostability of AGO-OSCs. Hence, the ∆Vnr and energetic disorder after one sun light-soaking for 10 hours were measured. Light soaking leads to ∆Vnr increments of 113 and 9 meV for G-Dimer-D1/DY and G-Dimer-D2/DY, respectively (Supplementary Table 12), which is quite consistent with the corresponding ∆Eu increment of 4.0 and 0.6 meV (Fig. 6b). The Eu represented the energetic disorder of the charge transfer states, forming at D/A mixed region32. The light-soaking effect on the ordered region was detected by GIWAXS, and all the CCLs and d-spacings of the blend films exhibit negligible change (Supplementary Fig. 28 and Supplementary Table 13). Consequently, the D/A amorphous region rather than the ordered region probably leads to non-radiative recombination traps where the amphous molecules struggle to aggregate, and thus the burn-in of VOC and FF. This phenomenon is similar to that of the alloy model in improving morphology stability33. Further, the optimized morphology is usually obtained at metastable state, leading to a material-dependable burn-in34,35,36. Benefiting from better thermal-driven assembly capability and half lower crystalline driving force (∆Gls = (Tm–Tc)/Tm×∆Hm) of –3.57 J/g) than that of the G-Dimer-D1/DY (∆Gls = –8.02 J/g), G-Dimer-D2/DY blends obtained an optimized morphology closer to thermodynamic steady state, and the much larger absolute ∆Gls with shorter CCL will contribute to the unstable morphology of G-Dimer-D1/DY37. (Fig. 6c and Supplementary Table 14). Considering the molecular packing we discussed before, the mismatched larger ∆Gls with shorter CCL of G-Dimer-D1/DY should be the reason for its unstable amorphous region and tendency to change their relative molecular coupling, thus the broadened charge transfer states, and ultimately the increased burn-in38. Conversely, G-Dimer-D2/DY featuring decreased ∆Gls and longer CCL alleviates the burn-in39,40,41, which could be further confirmed by their much less changed AFM images after continuous heating at 140 oC for 3 hours (Supplementary Fig. 29). In addition, relatively stable morphology in G-Dimer-D2/DY is also beneficial for the thermal stability, inferring from similar decay tendency of the three optimized devices during thermal aging at 80 oC under N2 atmosphere (Supplementary Fig. 30).

In summary, as shown in Fig. 7, the overall assembly during spin-coating, thermal-driven assembly capability and ∆Gls were largely tuned by the MW and positional isomerism of the linker. Thereinto, G-Dimer-D2 features with a smallest homo-molecular interaction and strong thermal-driven assembly capability, not only promote smaller ∆Vnr with efficient charge management, but also facilitate a small crystalline driving force with more ordered molecular packing, leading to superior device performance and a more thermodynamically stable optimized morphology with excellent long-term photostability.

The ordered packing is evaluated from the CCLs from GIWAXS for the spin-coating, TA process and optimized film; the ordered packing in thermodynamically stable morphology is evaluated from their ∆Gls of the blends, which is used to describe the disparity in ordered packing between optimized and thermodynamically stable blends for the three systems.

Using a highly efficient SM donor as the building block, by creative synthesis of two unique isomeric linkers, we successfully constructed isomeric G-Dimer-Ds with monomers para- and meta-substituted to the linker. Pairing with G-Dimer-A of DY, AGO-OSCs were successfully constructed for the first time. Comparisons of the two isomeric G-Dimer-Ds highlight the linker design in molecular assembly. Significantly, the unique structure of G-Dimer-D2 endows it with an extra-rare assemble property (small homo-molecular interactions with strong thermal-driven assembly capability), simultaneously facilitating efficient charge management under reduced ∆Vnr and lower burn-in, promoting concurrently improved PCE and stability. Furthermore, compared to corresponding ASM-OSC, AGO-OSC exhibits much better long-term photostability and smaller ∆Vnr, making it a more favorable candidate for commercial OSCs. Our results report a universal method for designing giant donors and propose a potential type of OSCs with high efficiency, high stability, and definite structure.

Methods

Structure characterization

1H NMR (400 MHz) spectra were obtained from a Bruker DMX-400 NMR Spectrometer, and TMS was used as an internal standard. All samples were dissolved in CDCl3 and tested at room temperature. MALDI-TOF-MS spectra were obtained from a Micromass GCT-MS spectrometer.

DFT calculation

The optimized molecular structure and the electron density of the frontier energy levels were calculated by the density functional theory (DFT) method at the B3LYP/6-31 G(d,p) level with Gaussian 09 program, and alkyl groups were replaced by methyl to simplify the calculations. The atomic coordinates of the optimized computational models were provided in Supplementary Data 1.

CV test

The cyclic voltammetry (CV) measurement was carried out by an electrochemical workstation (VMP3 Biologic, France) with Pt electrode coated with target films, Pt plate and Ag/Ag+ electrode acting as the working, counter, and reference electrodes, respectively, in a 0.1 mol L−1 tetrabutylammonium phosphorus hexafluoride (Bu4NPF6) acetonitrile solution. Redox potentials were calibrated using the ferrocene/ferrocenium (Fc/Fc+) redox couple (−4.8 eV).

UV−vis absorption spectra and the measurement of T g

The absorption spectra were tested on Perkin Elmer Lambda950 spectrophotometer. For film testing, the samples to be tested were prepared by spin coating on the quartz sheets. The samples were dissolved in CF with a concentration of ca. 12 mg mL−1, and then spin-coated at a speed of 1500 rpm for 30 seconds. The measured thickness of films is approximately 65 nm. The glass transition temperature (Tg) was characterized by a change in the slope of the deviation metric (the sum of the squared deviation in absorbance between as-cast and annealed films) versus temperature, corresponding to the onset of the formation of photophysical aggregates due to molecular-scale rearrangement. And it was obtained by measuring the absorption spectra of the films during continuous annealing. All the test films were annealed at the corresponding temperature for ten minutes, and their absorption spectra were tested and collected at intervals of ten degrees Celsius. Then linear fitting was performed on the deviation metrics before and after glass transition, and the intersection of the two lines was the Tg value.

Device fabrication and characterization

The photovoltaic devices were fabricated with a conventional structure of ITO/PEDOT:PSS/Active layer /PFN-Br/Ag. The ITO-coated glass substrates with a sheet resistance of ≈15 Ω were sonicated in detergent, deionized water, alcohol, and isopropanol for 30 min each sequentially. After drying, the substrates were treated with UV-ozone for 15 min. The PEDOT:PSS layer was prepared through spin coating at 3500 rpm for 30 s. Then, the PEDOT:PSS substrates were subsequently baked in air at 150 °C for 15 min. The donor and acceptor (D/A 1.9:1) were dissolved in CF with a total concentration of 15 mg mL−1 (MPhS-C6/Y6 16 mg mL−1). And then, the CF blend solution was stirred at 50 °C for 1.5 hours. An additive, 1,8-diiodoctane (DIO) (volume content: 0.2%) was added into the solution 30 min before the spin-coating process. The active layer was spin-coated at a speed of 1400 rpm for 30 seconds from the CF blend solution. Then PFN-Br methanol solution (0.5 mg mL−1) was spin-coated at 3000 rpm for 30 s on the active layer. Finally, a layer of ca. 160 nm Ag layer was evaporated onto the active layer under high vacuum (<1 × 10−4 Pa).

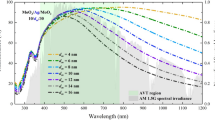

Device J-V characterization

was conducted under AM 1.5 G (100 mW cm−2) using a Newport Thermal Oriel 91159 A solar simulator in a glovebox of nitrogen atmosphere. Light intensity is calibrated with a Newport Oriel PN 91150 V Si-based solar cell. J–V characteristics were recorded using a Keithley 2400 source-measure unit. Typical cells have device areas of 4 mm2, and we also confirmed the device performance with a mask of 2.56 mm2.

EQE spectrum

was measured through the Solar Cell Spectral Response Measurement System FETOS-QE-3011 (Enli Technology Co., Ltd., Taiwan).

Transient photocurrent (TPC)

were measured by applying a 488 nm solid state laser (Coherent OBIS CORE 488LS) with a pulse width of ca. 30 ns. The current traces were recorded using a mixed domain oscilloscope (Tektronix MDO3032) by measuring the voltage drop across a 2 Ω resistor load connected in series with the solar cell.

Photocurrent density (J ph) and effective voltage (V eff) test

was used to characterize the utilization efficiency of photons. Veff equals the the applied bias minus the voltage where photocurrent is zero, and Jph represents the current density differences between illumination and dark. At a sufficiently high Veff, it is assumed that all excitons are dissociated into free charges, and the photogenerated current reaches the maximum saturation (Jsat). The exciton dissociation efficiency (Pdiss) and charge collection efficiency (Pcoll) of the device can be calculated from the Jph/Jsat values under short-circuit and maximum power output conditions, respectively.

Power index α in supplementary Fig. 14 fitted from the function of J ∝ (Plight)α, in which Plight represents the light intensity; ideal factor n in Fig. 5e fitted from the function of VOC ∝ nkTlog(Plight), where k is the Boltzmann constant, T is the temperature in Kelvin.

Charge carrier mobility characterization

The mobility of hole and electron was tested by fitting the current-bias characteristics in the dark utilizing a field-independent space charge limited current (SCLC) model following the Mott-Gurney law:

The structures of hole-only and electron-only devices are ITO/PEDOT:PSS/Active layer/MoO3/Ag and ITO/ZnO/Active layer/PNDIT-F3N/Ag, respectively. The active layers for these two devices were spin-coated under the same conditions as those of solar cells. J–V curves in the range of 0 to 5 V were gained by Keithley 2400 source-measure unit in the dark condition.

Contact angle measurement

Contact angles were measured with a contact angle meter (GBX DIGIDROP). The solution of each organic material was spin-coated on cleaned ITO substrates. Droplets of water, diiodomethane, and glycerol were dripped onto the different films. According to Owens-Wendt method, surface energy could be divided into dispersive and polar components.

Furthermore, the dispersive and polar surface energy can be calculated through the formula below based on the contact angles obtained by two solvents.

where θ is the contact angle of a specific solvent, is the surface energy of the solvent, and refers to the dispersive and polar surface energy of the solid, respectively, and and refers to the dispersive and polar surface energy of the solvent, respectively. Thus, the unknown value and can be solved though combining two equations obtained by contact angle measurement of two different solvents. Solubility parameter (δ) can be calculated from the surface energy,

where γ is the surface energy, K is the proportionality constant (K = 116 × 103 m−1/2). And Flory–Huggins interaction parameter (χij) can be written as a function of two solubility parameter,

where χij is the Flory–Huggins interaction parameter between the material i and j, V0 is the geometric mean of the polymer segment molar volume, R is the gas constant, T is the absolute temperature, and and are the solubility parameter of material i and j, respectively. To simplify, we define the parameter κ = K2V0/RT, then the Flory–Huggins interaction parameter can be written as the formula below,

where and are the surface energy of material i and j, respectively.

Spin-coating in-situ UV–visible-NIR spectroscopy

A specially designed spin coater, which allows the detective beam to pass through the center of the fabricating devices, was applied to measure the in-situ UV–vis spectrum. An F-20 spectrometer from filmetrics was used to record the spectrum, and the time resolution of the spectrum is 5 ms. All data presented and analyzed was processed using savgol-filter from a scipy kit to remove the periodic change in the spectrum brought by the spinning of ITO stripe during fabrication42.

Urbach energy

The Urbach energy (Eu) was obtained by exponential fitting to the FTPS-EQE spectra to evaluate the degree of energetic disorder through the formula43,44: α(E) = α0\({{{\rm{e}}}}^{E-E{{\rm{g}}}/{E}_{{{\rm{u}}}}}\), where E is the photonenergy, α is the light absorbing coefficient and α0 is the absorption coefficient of the bandedge.

Energy loss measurement

Fourier-transform Photocurrent spectroscopy external quantum efficiency (FTPS-EQE) and Electroluminescence quantum efficiency (EQEEL) measurements. FTPS-EQE was conducted by an integrated system with Fourier transform Photocurrent meter (PECT-600, Enlitech). EQEEL measurement was performed by applying external voltage/current sources through the devices (REPS, Enlitech).

Morphology and crystallization characterization

Transmission electron microscopy (TEM) characterization was performed by Tecnai G2 F20 U-TWIN TEM instrument. AFM measurements were performed on Multimode 8 with ScanAsyst mode. Grazing incidence wide angle X-ray scattering (GIWAXS) measurement was conducted at XEUSS WAXS equipment.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

The data that support the findings of this study are presented in Supplementary Information and Source Data file. The source data for Figs and Supplementary Figs generated in this study are provided in the Source Data file. Source data are provided with this paper.

References

Ge, J. et al. 13.34 % Efficiency non‐fullerene all‐small‐molecule organic solar cells enabled by modulating the crystallinity of donors via a fluorination strategy. Angew. Chem. Int. Ed. 59, 2808–2815 (2020).

Wu, S. et al. 15.51 % efficiency all-small-molecule organic solar cells achieved by symmetric thiazolyl substitution. Nano Energy 103, 107801 (2022).

Qin, J. et al. 17% efficiency all-small-molecule organic solar cells enabled by nanoscale phase separation with a hierarchical branched structure. Energy Environ. Sci. 14, 5903–5910 (2021).

Hu, D. et al. A volatile solid additive enables oligothiophene all‐small‐molecule organic solar cells with excellent commercial viability. Adv. Func. Mater. 33, 2211873 (2022).

Zhu, Q. et al. Efficient and mechanically-robust organic solar cells based on vertical stratification modulation through sequential blade-coating. Nano Energy 97, 107194 (2022).

Wang, J. et al. A new polymer donor enables binary all-polymer organic photovoltaic cells with 18% efficiency and excellent mechanical robustness. Adv. Mater. 34, 2205009 (2022).

Hu, K. et al. Solid additive tuning of polymer blend morphology enables non-halogenated-solvent all-polymer solar cells with an efficiency of over 17%. Energy Environ. Sci. 15, 4157–4166 (2022).

Yin, P., Ma, Y. & Zheng, Q. Improving the efficiency and stability of binary small-molecule organic solar cells by incorporating a small amount of polymer acceptor. J. Mater. Chem. A 10, 10400–10407 (2022).

Zhang, L. et al. N‐π‐N” type oligomeric acceptor achieves an OPV efficiency of 18.19% with low energy loss and excellent stability. Adv. Sci. 9, 2202513 (2022).

Wang, C. et al. Unique assembly of giant star-shaped trimer enables non-halogen solvent-fabricated, thermal stable, and efficient organic solar cells. Joule 7, 2386–2401 (2023).

Liang, Y. et al. Organic solar cells using oligomer acceptors for improved stability and efficiency. Nat. Energy 7, 1180–1190 (2022).

Wang, H. et al. Oligomeric acceptor: A “two‐in‐one” strategy to bridge small molecules and polymers for stable solar devices. Angew. Chem. Int. Ed. 61, e202201844 (2022).

Zhuo, H. et al. Giant molecule acceptor enables highly efficient organic solar cells processed using non-halogenated solvent. Angew. Chem. Int. Ed. 62, e202303551 (2023).

Sun, C. et al. Dimerized small-molecule acceptors enable efficient and stable organic solar cells. Joule 7, 416–430 (2023).

Lee, J.-W. et al. Linker engineering of dimerized small molecule acceptors for highly efficient and stable organic solar cells. ACS Energy Lett. 8, 1344–1353 (2023).

Hsu, F.-C. et al. Porphyrin dimers as donors for solution-processed bulk heterojunction organic solar cells. RSC Adv. 6, 60626–60632 (2016).

Lai, T. et al. Dimeric porphyrin small molecules for efficient organic solar cells with high photoelectron response in the near-infrared region. ACS Appl. Mater. Inter. 10, 668–675 (2017).

Li, P. et al. A new BODIPY dimer containing carbazole group as a small molecule donor for ternary organic solar cells with the PCE up to 14.97. Dyes Pigments 215, 111297 (2023).

Li, S. et al. Tethered small‐molecule acceptors simultaneously enhance the efficiency and stability of polymer solar cells. Adv. Mater. 35, 2206563 (2022).

Liu, W. et al. A-π-A structured non-fullerene acceptors for stable organic solar cells with efficiency over 17%. Sci. Chi. Chem. 65, 1374–1382 (2022).

Gu, X. et al. High-efficiency and low-energy-loss organic solar cells enabled by tuning conformations of dimeric electron acceptors. CCS Chem. 5, 2576–2588 (2023).

Zhang, L. et al. High miscibility compatible with ordered molecular packing enables an excellent efficiency of 16.2% in all‐small‐molecule organic solar cells. Adv. Mater. 34, 2106316 (2021).

Zhang, L. et al. Donor end‐capped alkyl chain length dependent non‐radiative energy loss in all‐small‐molecule organic solar cells. Adv. Mater. 34, 2207020 (2022).

Lv, M. et al. Strengthening the hetero-molecular interactions in giant dimeric acceptors enables efficient organic solar cells. Adv. Mater. https://doi.org/10.1002/adma.202310046 (2023).

Yasuniwa, M. et al. X-ray studies of multiple melting behavior of poly(butylene-2,6-naphthalate). Polymer 46, 8306–8312 (2005).

Di Lorenzo, M. L., Androsch, R. & Righetti, M. C. Low-temperature crystallization of poly(butylene succinate). Eur. Polym. J. 94, 384–391 (2017).

Ghasemi, M. et al. A molecular interaction-diffusion framework for predicting organic solar cell stability. Nat. Mater. 20, 525 (2021).

Chen, X.-K. et al. A unified description of non-radiative voltage losses in organic solar cells. Nat. Energy 6, 799–806 (2021).

Cui, Y. et al. Over 16% efficiency organic photovoltaic cells enabled by a chlorinated acceptor with increased open-circuit voltages. Nat. Commun. 10, 2515 (2019).

Oh, H. et al. Reducing burn‐in loss of organic photovoltaics by a robust electron‐transporting layer. Adv. Mater. Interfaces 6, 1900213 (2019).

Cha, H. et al. An efficient, “burn in” free organic solar cell employing a nonfullerene electron acceptor. Adv. Mater. 29, 1701156 (2017).

Heumueller, T. et al. Disorder‐induced open‐circuit voltage losses in organic solar cells during photoinduced burn‐in. Adv. Energy Mater. 5, 1500111 (2015).

An, K. et al. Mastering morphology of non-fullerene acceptors towards long-term stable organic solar cells. Nat. Commun. 14, 2688 (2023).

Xin, J. et al. The importance of nonequilibrium to equilibrium transition pathways for the efficiency and stability of organic solar cells. Small 18, 2200608 (2022).

Xin, J. et al. Cold crystallization temperature correlated phase separation, performance, and stability of polymer solar cells. Matter 1, 1316–1330 (2019).

Voroshazi, E. et al. Light‐induced degradation of polymer:fullerene photovoltaic devices: an intrinsic or material‐dependent failure mechanism? Adv. Energy Mater. 4, 1400848 (2014).

Desré, P. J. & Yavari, A. R. Suppression of crystal nucleation in amorphous layers with sharp concentration gradients. Phys. l Rev. Lett. 64, 1533–1536 (1990).

Liao, X. et al. Inhibiting excessive molecular aggregation to achieve highly efficient and stabilized organic solar cells by introducing a star-shaped nitrogen heterocyclic-ring acceptor. Energy Environ. Sci. 15, 384–394 (2022).

de Zerio, A. D. & Müller, C. Glass forming acceptor alloys for highly efficient and thermally stable ternary organic solar cells. Adv. Energy Mater. 8, 1702741 (2018).

Paleti, S. H. K. et al. Hexanary blends: a strategy towards thermally stable organic photovoltaics. Nat. Commun. 14, 4608 (2023).

Zhao, Q. et al. Elevated stability and efficiency of solar cells via ordered alloy co-acceptors. ACS Energy Lett. 4, 1106–1114 (2019).

Virtanen, P. et al. SciPy 1.0: fundamental algorithms for scientific computing in Python. Nat. Methods 17, 261–272 (2020).

Hinrichsen, T. F. et al. Long-lived and disorder-free charge transfer states enable endothermic charge separation in efficient non-fullerene organic solar cells. Nat. Commun. 11, 5617 (2020).

Liu, S. et al. High-efficiency organic solar cells with low non-radiative recombination loss and low energetic disorder. Nat. Photonics 14, 300–305 (2020).

Acknowledgements

C.X. Wang and X.M.Ma contributed equally to the work. The authors are grateful for the financial support provided by the National Natural Science Foundation of China (22135001 [Z.X.W.], 52422308 [D.D.]), the Strategic Priority Research Program of the Chinese Academy of Sciences (No. XDB36000000 [Z.X.W.], No. XDB0770202 [D.D.]), and the Chinese Academy of Sciences Project for Young Scientists in Basic Research (No. YSBR-110 [D.D.]).

Author information

Authors and Affiliations

Contributions

D.D. and Z.X.W. conceived the idea for the manuscript and designed the experiments. C.X.W. synthesized the materials, and characterized their basic properties, including TEM. X.M.M. performed small-area device fabrication, optimization, characterization, temperature-dependent absorption, and Tg. Z.-G.Z. provided the DY material. J.Q.Z. conducted the GIWAXS measurements, H.Z. helped perform the in-situ UV-visible absorption spectrum. L.L.Z. helped with the synthesis of materials, R.S. and J.M. helped with the photostability tests, M.Y.W. helped with the device fabrication. All of the authors were involved in discussions of data analysis and commented on the manuscript. C.X.W., X.M.M., D.D., Z.-G.Z., and Z.X.W. wrote and revised the manuscript. D.D. and Z.X.W. led the project.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, C., Ma, X., Deng, D. et al. Giant dimeric donors for all-giant-oligomer organic solar cells with efficiency over 16% and superior photostability. Nat Commun 15, 8494 (2024). https://doi.org/10.1038/s41467-024-52821-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-024-52821-5

This article is cited by

-

19.5% Efficiency in binary organic solar cells with enhanced stability using a flexible chain-tethered dimeric acceptor with unprecedentedly high yield

Science China Chemistry (2026)

-

A small molecule donor dimer interconnected by a benzo[1,2-b:4,5-b′]dithiophene central unit side chain enables highly efficient and thermally stable all-giant-molecule solar cells

Science China Chemistry (2026)