Abstract

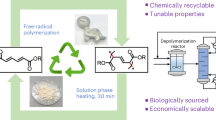

Polymers capable of depolymerizing back to their own monomers offer a promising solution to address the challenges in polymer sustainability. Despite significant progress has been achieved in plastics circularity, chemical recycling of thermoplastic elastomers is relatively less concerned, largely because of their intrinsic complex multicomponents. This work creates a homopolymer-based platform towards chemically recyclable but tough thermoplastic elastomers. It is enabled by a semicrystalline polymer with high molecular weight but low crystallinity, which is prepared through ring-opening metathesis polymerization of a fully biobased cyclic olefin. By shifting the ring−chain equilibrium, quantitative conversions were achieved for both forward polymerization and reverse depolymerization. This simple circular, high-performance thermoplastic elastomer platform based on biomass highlights the importance of monomer design in addressing three challenges in sustainable polymers: the feedstock renewability, depolymerization selectivity, and performance trade-offs.

Similar content being viewed by others

Introduction

The significant increase in plastic production is closely tied to the use of fossil feedstocks and a linear plastic economy based on a take-make-waste model, which has led to a persistent environmental crisis1. While thermoplastic polymeric waste, which comprises plastics and elastomers, can be mechanically recycled, this process often results in the deterioration of material properties2,3. In response to this challenge, the concept of chemical recycling, specifically through depolymerization to monomer, has emerged as a promising solution for managing polymer waste at the end of its lifecycle4. This approach allows for the creation of a circular thermoplastics economy toward sustainability by facilitating the infinite recyclability of materials without any loss of quality5.

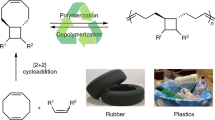

Thermoplastics, typically derived from homopolymers, have been the subject of extensive research on depolymerization strategies6,7,8,9,10. In contrast, chemical recycling strategies in thermoplastic elastomers (TPEs) are much less, largely due to the chemical and structural heterogeneity of TPEs11,12. Representative chemically recyclable TPEs encompass various types, including thermoplastic polyurethanes13, triblock copolymers14,15,16,17, multiblock copolymers18, and random copolymers11,19, as depicted in Fig. 1. Despite their recyclability, these circular alternatives often face challenges in the recycling process, such as incomplete recyclability with the loss of some components of the original monomers, the necessity for selective component recycling and/or multistep monomer separation, and the risk of nonselective chain fracture during storage and/or in service, which ultimately diminish the polycondensation efficiency of telechelic macromomomer building blocks. In addition to existing limitations on TPE recycling efficiency and simplicity, the introduction of biorenewable circularity into TPEs is crucial to ensuring their sustainability and enhancing material performance through bioadvantages20. Overall, new TPEs from renewable feedstocks, with inherent depolymerizability, repolymerizability, and thermomechanical performances competitive to present conventional TPEs, along with simple and efficient recycling processes, represent the design goal for next-generation elastomers5,21.

To address these needs, we developed a fully biomass-based heterocyclic monomer from starch- and castor-oil-derived building blocks. The monomer is judiciously designed to generate an unsaturated polyolefin structure with low crystallinity, consisting of “hard segments” (solid crystallites) and “soft segments” (noncrystalline domain) in a homopolymer system. The concise and efficient depolymerizability of this polyolefin results from the rearrangement of carbon-carbon double bonds along its backbone, achieved through the ring-closing depolymerization metathesis, shifting the ring−chain equilibrium. Mechanistic investigations indicate the interplay between crystallinity and degree of entanglement in determining the exceptional mechanical properties of the biobased TPEs. This work establishes a renewable circularity in TPEs that concomitantly delivers a useful bioadvantage by integrating biomass-based structurally rigid and flexible units alternatively within the linear homopolymer framework.

Results

Synthesis and characterization

A bio-based α,ω-difunctional diene 1 was synthesized by combining structurally rigid isomannide and flexible undecenoic acid (Fig. 2a). 1 can undergo acyclic diene metathesis (ADMET) polymerization to produce a polyester. Despite considerable efforts on this reaction, the stepwise polymerization mechanism posed challenges in achieving the desired molecular weight as a result of limited conversion. This limitation resulted in the achievement of only a modest molecular weight, as evidenced in Supplementary Table S1. We selected the sample with the highest molecular weight (P1, Mn = 23.3 kDa, Table 1) for testing. The presence of linear alkyl chains derived from undecenoic acid can lead to the formation of crystalline polymers. As expected, P1 shows the ability to crystallize with a low melting enthalpy (5.0 J/g, Supplementary Fig. S4), indicating a low crystallinity. The mechanical property test demonstrated a characteristic behavior of elastic materials (with a low Young’s modulus of 0.22 ± 0.05 MPa) but exhibited poor mechanical strength (0.03 ± 0.01 MPa, Supplementary Fig. S6) due to its low molecular weight that lack significant entanglement22. This polymer could undergo ring-closing metathesis depolymerization to yield a cyclic olefin 2 (trans-isomer dominated, in accordance with their ring strain, Supplementary Fig. S7), the same product as obtained from the diene under ring-closing metathesis conditions (Supplementary Fig. S8). This cyclic olefin 2, as a product for upgrading the recycling of P1, could be used in ring-opening metathesis polymerization (ROMP) via the chain growth polymerization mechanism23,24,25,26,27. Due to the low ring strain of this monomer (~4 kcal mol−1, Supplementary Table S4), the polymerization is favored by high monomer concentration, which progressed smoothly with quantitative conversion (>95%) under mild conditions (at 25 °C within 1 h under 1.0 M condition). The molecular weight can be adjusted with the reaction time or the monomer-to-catalyst feeding ratio (Supplementary Table S2), providing greater control and enabling the production of TPEs with high molecular weights (Table 1, P2 − P9, 40 kDa−800 kDa) with enhanced chain entanglement. The improved molecular mass could allow finding outstanding and unique mechanical properties.

a Reaction scheme. b Chemical structure of HDPE, P4 and P10 and transparency of the molded films. c Differential scanning calorimetry (DSC) heating scan of HDPE, P4, and P10. d X-ray diffraction (XRD) spectra of HDPE, P4, and P10. e Polarized optical microscopy (POM) image of P4. f Schematic illustration of the molecular structure of TPEs with a semicrystalline entangled network. g TGA curves of HDPE, P4, and P10.

Thermal properties

To validate the role of isomannide in elastomer formation, a control polymer P10 was prepared by replacing isomannide with a pentanediol motif having a similar contour length but better segmental flexibility (Fig. 2b). A melting peak at 41 °C and a Tg at −21 °C are observed for P4, indicating noticeably reduced crystallinity compared to P10 (Fig. 2c), as evident from the low melting enthalpy (24.5 J/g) and the XRD diffraction pattern of P4 (Fig. 2d and Supplementary Fig. S10, χc = 17%). Unlike high-density polyethylene (HDPE), where the diffraction peaks at 21.4o and 23.7o in Fig. 2d are primarily attributed to polyethylene (110 and 200 lattice planes)28, a prominent peak at 19.5o in P10 indicates the presence of pentanediol ester moieties within the crystalline lamellae. In contrast, P4, which contains bulky isomannide groups along the backbone, displays dominant diffraction peaks at lower angles, suggesting extensive participation of isomannide moieties in crystallite formation. In the chain ordering process of P4, the formation of the amorphous domain leads to defects that significantly impede the thickening of the crystalline lamellae, resulting in a decrease in crystallinity29. When examined under a polarized optical microscope (POM, Fig. 2e), P4 demonstrates pronounced birefringence, indicating the presence of crystals. The crystal size in P4 falls within the micrometer range, providing it with notable transparency, as depicted in Fig. 2b. Furthermore, P4 exhibits excellent thermal stability, with a degradation temperature at 5% weight loss (Td,5%) that reaches 415 °C (Fig. 2g). The thermal stability of all elastomers is comparable to that of HDPE (Supplementary Fig. S23).

Mechanical properties

To investigate the mechanical properties of these polymers, uniaxial tensile testing was performed. P2 − P9, which feature isomannide along the backbone, exhibit elastomeric behavior with a low Young’s modulus (~2 MPa) as depicted in Fig. 3a. Replacement of isomannide with its stereoisomer isosorbide can also produce a TPE (P11, Table 1, Supplementary Fig. S24). However, P10, with pentanediol along the backbone, shows a significantly higher Young’s modulus (43.1 MPa) and undergoes plastic deformation through necking during stretching. This highlights the crucial role of the bulky group in the creation of tough elastomers within these materials. Remarkably, the mechanical strength and elongation at break of these elastomers peak at 32 MPa and 1500%, respectively, surpassing those of many known recyclable TPEs as shown in Fig. 3b11,13,14,15,16,17,18,19,30. The mechanical properties of this material are similar to those of conventional TPEs such as SBS (styrene-butadiene-styrene) and SEBS (styrene-ethylene/1-butene-styrene) block copolymers31, making them competitive alternatives with the added benefit of chemical recyclability. This exceptional performance for isomannide-based polymers is primarily attributed to their unique slightly crystalline structure. In this structure, an amorphous rubbery matrix with significant interchain entanglement envelopes the crystalline domains (Fig. 2f). The amorphous domains provide the initial softness and high extensibility of the material, whereas the crystallites act as strong physical cross-links, reinforcing the overall network. Furthermore, the highly entangled amorphous chains act as tie-chains connecting the small crystalline domains32.

Structure-property relationship

The mechanical strength of elastomers is influenced by several factors, including a high molecular weight and a high content of hard segments33, which correspond to crystallinity in this work. P1–P9 exhibit a high trans carbon–carbon double bond content along the polymer backbone (Supplementary Tables S1 and S2). The slight difference in stereoselectivity (80% ± 7%) between them is not expected to have a significant impact on their inherent crystallinity. It is worth noting that, while higher molecular weights and an increase in hard blocks are generally associated with enhanced material strength, an increase in molecular weight may paradoxically lead to a reduction in polymer crystallinity34. According to the data shown in Fig. 3c, for the P1 − P9 polymers, a nonmonotonic stress at break trend is observed, showing a peak (σb of 32 MPa) at a molecular weight of 158 kDa. Following this peak, the tensile strength decreases as the molecular weights increase, a pattern that aligns closely with the corresponding crystallinity values shown in Fig. 3d. The mechanical strength of the elastomer is primarily influenced by the molecular weight within the range of 100 kDa to 158 kDa. Once the critical molecular weight threshold is exceeded, the significance in determining the mechanical strength shifts from entanglement density to crystallinity. Therefore, the interplay between the density of amorphous entanglements and the stability of crystal blocks ultimately determines the mechanical strength of the homopolymer-based elastomers35.

The elastic performance of the toughest elastomer, P4, was further assessed by cyclical tensile tests, where the sample was stretched to 100% strain and relaxed at a rate of 100 mm/min. For clarity, the curves of each cycle are shifted on the strain axis (Fig. 3e). The P4 sample sustained excellent elastic recovery (>98%) during ten-cycle tensile deformations (Supplementary Fig. S25). The resilience of P4 was also improved during the cyclic tensile deformation processing (Supplementary Fig. S26), leading to a perfection of the network structure36. Step-cycle tensile tests were also performed on P4 (Fig. 3f). The continuous drop in modulus with strain indicates a typical strain-evolving structure of P437, in which the crystals undergo yielding to break into smaller domains38. The isolated crystals generated make the stiffness of the material being dominated by the entanglement amorphous phase, thus leading to an elastomeric-like structure with good elastic recovery (~90%, Supplementary Fig. S27). Stretching of chain segments and strain-induced crystallization (Supplementary Figs. S29 and S30) are responsible for strain hardening after large deformation, resulting in ultrahigh mechanical strength.

Recycling studies

When performing temperature-dependent polymerization thermodynamic studies, the prepared elastomers exhibited a relatively high Tc (1731 oC at 0.15 M, details in Supplementary Figs. S1–S3). At a concentration of 0.15 M, the Gibbs free energy value (ΔG) for 2 polymerization was observed to be −3.14 kcal mol−1 at 25 °C, indicating a more favorable outcome compared to many reported depolymerizable polyolefins prepared through ROMP39,40. When diluted in a solvent, the Tc can be lowered to allow depolymerization under mild conditions41. Consequently, high conversions were anticipated for both forward polymerization and reverse depolymerization processes. To demonstrate a closed chemical recycling loop, 10.0 g of P4 underwent polymer-to-monomer recycling under mild conditions (concentration of repeat units = 20 mM, 50 °C, 1 h) in the presence of 1 mol% Grubbs second generation catalyst (G2). The ring-closing metathesis depolymerization process proceeded smoothly with >99% conversion, resulting in a viscous liquid mixture of diverse ring-sized macrocycles. This outcome indicated an equilibrium between the various cycles42,43, as supported by GPC elution curves (Fig. 4b) and high-resolution mass spectrometry (HRMS) results (Fig. 4d). NMR and mass spectrometry analyzes confirmed that the major depolymerization products were monomers (56% yield, Supplementary Figs. S31–S33). The depolymerization kinetic analysis revealed complete degradation of the pristine polymer within 15 min, followed by further transformation of the oligomeric macrocycles into monomer species until equilibrium was reached at 1 h (Fig. 4c). Component fractions were determined by integrating GPC refractive index (RI) traces, closely aligned with the 1H NMR integration (Supplementary Fig. S35). After removing the residual catalyst, the depolymerized mixture of macrocyclic oligomers could be directly repolymerized via ROMP to recover virgin polymer with high molecular weights (Supplementary Fig. S38 and Table S5). The conversion was found to be quantitative according to the 1H NMR and GPC analyzes (Supplementary Figs. S36 and S37). In particular, 9.2 g of recycled polymer (rP4, Table 1) were obtained, resulting in a quantitative polymer-to-polymer chemical recycling ratio of 92% (Fig. 4b). The structural integrity of rP4 closely resembled that of pristine P4 (Fig. 4a, b), leading to similar thermomechanical properties (Fig. 4e and Supplementary Fig. S23).

To further understand the depolymerization thermodynamics and optimize the depolymerization conditions (including temperature, catalyst type, catalyst loading ratio, and concentration), the monomer recovery ratio was utilized. An increase in monomer recovery efficiency with higher depolymerization temperatures aligns with the entropy-driven nature of depolymerization at this low concenration (concentration of repeat units = 20 mM, Supplementary Fig. S40). Among different Grubbs catalysts (G1, G2, G3, and HG2), G3 demonstrated a superior efficiency over G2, achieving the highest monomer recovery ratio of 62% (Supplementary Fig. S42). A catalyst loading ratio > 0.5 mol% was considered sufficient (Supplementary Fig. S44). The dilute concentrations significantly changed the equilibrium towards monomer formation, particularly at a concentration of 1 mM concentration, where the monomer yield exceeded 90% (Supplementary Fig. S46). In particular, the monomer recovery ratio did not exhibit dependence on molecular weight (Supplementary Fig. S48), suggesting the feasibility of scaling up depolymerization through a one-pot strategy for a mixture of elastomers with varying molecular weights (a mixture of P1 − P9), which was previously unattainable when recovering multicomponent elastomers. The depolymerization of the elastomer specimen mixtures in the presence of G2 demonstrated successful recovery of monomers. Treatment of crude reaction products with DMSO, followed by filtration through a short silica plug, effectively eliminated colored ruthenium by-products and oligomer fractions, leading to recovery of high-purity monomers (HPLC > 99%, Supplementary Figs. S49 and S50).

The ester group within the polymer chain can also serve as a breaking point, allowing degradation through hydrolysis in a conventional manner. Gentle heating of these elastomers in an alkaline aqueous solution for several hours leads to a quantitative recovery of isomannide and unsaturated telechelic diacid (93% yield, Supplementary Figs. S51−S53), which can then be used to produce industrially valuable α,ω-dicarboxylic acids. The resulting hydrolyzed products can undergo polycondensation to regenerate the virgin polymer (Supplementary Fig. S54), although with limited molecular weight44. In summary, three synthesis loops are established based on the linkages that react from the original isomannide and undecenoic acid feedstock (Fig. 5): one involves hydrolysis, esterification, and ADMET polymerization (Cycle 1); another encompasses hydrolysis and polycondensation (Cycle 2); and the third involves cyclodepolymerization and ROMP (Cycle 3).

Discussion

Despite the current synthetic strategies available for producing depolymerizable TPEs, recycling efficiency remains a significant challenge, often requiring labor-intensive multicomponent recovery processes. By synthesizing homopolymer TPEs from entirely renewable feedstocks, a straightforward and robust framework is established for the production of performance-privileged TPEs with closed-loop chemical recyclability. The modular nature of this method, along with targeted sustainability enhancements, opens avenues for the development of other chemically recyclable polyolefin TPEs by leveraging the integrated homopolymer architecture. While this approach offers a promising solution to the current hurdles in TPE recycling, we anticipate that future efforts will address the drawbacks related to solvent cost and the handling of a high dilution during depolymerization.

Methods

Materials

A list of all chemicals and materials can be found in the Supplementary Information Section 1.1.

Characterization methods

Nuclear magnetic resonance (NMR) analysis

NMR experiments (1H and 13C) were recorded on a Bruker Avance NEO 400 instrument by using deuterated chloroform as a solvent. Chemical shifts were calibrated to the proton resonance of solvent (7.26 and 77.0 ppm for 1H NMR and 13C NMR spectroscopies, respectively).

High-resolution mass spectra (HRMS)

The molar masses of small molecules and depolymerized polymer products were measured using a Waters G2-XS QTof mass spectrometer equipped with an ESI ionization source.

Gel permeation chromatography (GPC)

The molecular weight and molecular weight distribution of the polymers were measured with Malvern Viscotek 270 by using THF as the mobile phase at 40 °C. The flow rate was 1 mL/min, and the injection volume was 25 μL. A refractive index (RI) detector was used to determine the number average molecular weight (Mn) and molecular weight distribution (Đ) by calibrating it with narrow-distributed polystyrene as an internal standard.

High-Performance Liquid Chromatography (HPLC)

HPLC curves were measured with Thermo Scientific U3000 using a solvent mixture (methanol: acetonitrile = 50: 50) as the eluent at 1 mL/min. The column used in the study is the gold C18 (150 mm × 4.6 mm, 5 μm), with the temperature set at 25 oC.The detection wavelength was set at 190 nm.

X-ray diffraction (XRD)

Samples for the XRD test were prepared by solution casting with film thickness of ~0.2 μm. The films were then cut into small 2 cm × 2 cm pieces for the XRD test. The tests were carried out using an X-ray diffractometer with 3 kW sealed X-ray tube, D/teX Ultra silicon strip detector and independent θ-θ geometry (XRD Ultima IV, Rigaku Americas Corporation, Japan). The X-ray source was Cu Kα. The 2θ testing range is from 10o to 50o, and the test speed is 5o/min.

Differential scanning calorimeter (DSC)

Calorimetric behavior of polymer samples was characterized with a Netzsch DSC or Mettler-Toledo DSC1 calibrated with an indium standard. The heating and cooling rates were fixed at 10 °C/min from −60 °C to 160 °C. The melting enthalpy was determined from the first heating scan unless otherwise stated.

Thermo-gravimetric analysis (TGA)

The thermal degradation properties of the samples were probed by thermogravimetry by using a Netzsch TG 209 F1 system (Netzsch Instruments). The samples were heated from 30 °C to 800 °C at a rate of 20 °C/min under nitrogen protection.

Uniaxial tensile elongation testing

Rectangular polymer specimens were prepared with solution-casting polymer solutions (in toluene) onto mica substrates. After the specimens were vacuum dried at 110 °C overnight to reach a constant weight, the film could be easily peeled off from substrates and cut into several dogbone specimens. Tensile tests were performed on MTS CMT8502 at a strain speed of 10 mm/min (unless otherwise stated) at ambient temperature (~25 oC).

Cyclic tensile testing

The cyclic deformation with fixed tensile strain was performed to a tensile strain of 100% with the tensile strain rate of 100 mm/min and the relaxation strain rate of 100 mm/min, which was repeated ten times. Cyclic deformation with increased tensile strain was first carried out to the 100% tensile strain and then relaxed to the strain without residual stress; the specimen was then carried out to the 200% tensile strain and then relaxed to the strain without residual stress. In a similar fashion, the tensile strain was raised to 300%, 400%…1300%. The tensile deformation rate and the relaxation deformation rate were fixed to 100 mm/min.

Polarizing optical microscope (POM)

POM was recorded on a Nikon eclipse LV100N polarizing microscope.

Data availability

All data needed to support the findings of this study are included in the main text or in the Supplementary Information. All data are available from the corresponding author upon request.

References

Rosenboom, J.-G., Langer, R. & Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 7, 117–137 (2022).

Zhang, S. et al. Depolymerization of polyesters by a binuclear catalyst for plastic recycling. Nat. Sustain. 6, 965 (2023).

Jehanno, C. et al. Critical advances and future opportunities in upcycling commodity polymers. Nature 603, 803–814 (2022).

Hong, M. & Chen, E. Y. X. Completely recyclable biopolymers with linear and cyclic topologies via ring-opening polymerization of γ-butyrolactone. Nat. Chem. 8, 42–49 (2016).

Coates, G. W. & Getzler, Y. D. Y. L. Chemical recycling to monomer for an ideal, circular polymer economy. Nat. Rev. Mater. 5, 501–516 (2020).

Plummer, C. M., Li, L. & Chen, Y. Ring-opening polymerization for the goal of chemically recyclable polymers. Macromolecules 56, 731–750 (2023).

Young, J. B. et al. Bulk depolymerization of poly(methyl methacrylate) via chain-end initiation for catalyst-free reversion to monomer. Chem 9, 2669–2682 (2023).

Wang, Y., Zhu, Y., Lv, W., Wang, X. & Tao, Y. Tough while recyclable plastics enabled by monothiodilactone monomers. J. Am. Chem. Soc. 145, 1877–1885 (2023).

Li, X.-L., Clarke, R. W., Jiang, J.-Y., Xu, T.-Q. & Chen, E. Y. X. A circular polyester platform based on simple gem-disubstituted valerolactones. Nat. Chem. 15, 278 (2023).

Su, Y.-L. et al. Chemically recyclable polymer system based on nucleophilic aromatic ring-opening polymerization. J. Am. Chem. Soc. 145, 13950–13956 (2023).

Han, X.-W. et al. Circular olefin copolymers made de novo from ethylene and alpha-olefins. Nat. Commun. 15, 1462–1462 (2024).

Zanchin, G. & Leone, G. Polyolefin thermoplastic elastomers from polymerization catalysis: advantages, pitfalls and future challenges. Prog. Polym. Sci. 113, 101342 (2021).

Yan, Q., Li, C., Yan, T., Shen, Y. & Li, Z. Chemically recyclable thermoplastic polyurethane elastomers via a cascade ring-opening and step-growth polymerization strategy from bio-renewable δ-caprolactone. Macromolecules 55, 3860–3868 (2022).

Cederholm, L., Olsén, P., Hakkarainen, M. & Odelius, K. Design for recycling: polyester- and polycarbonate-based A–B–A block copolymers and their recyclability back to monomers. Macromolecules 56, 3641–3649 (2023).

Liu, J. et al. Using redox-switchable polymerization catalysis to synthesize a chemically recyclable thermoplastic elastomer. Angew. Chem. Int. Ed. 63, e202317699 (2024).

Carrodeguas, L. P., Chen, T. T. D., Gregory, G. L., Sulley, G. S. & Williams, C. K. High elasticity, chemically recyclable, thermoplastics from bio-based monomers: carbon dioxide, limonene oxide and ε-decalactone. Green. Chem. 22, 8298–8307 (2020).

Li, C. et al. Rapid and controlled polymerization of bio-sourced delta-caprolactone toward fully recyclable polyesters and thermoplastic elastomers. Angew. Chem. Int. Ed. 61, e202201407 (2022).

Zhao, Y. et al. Chemically recyclable polyolefin-like multiblock polymers. Science 382, 310–314 (2023).

Zhao, J.-Z., Yue, T.-J., Ren, B.-H., Lu, X.-B. & Ren, W.-M. Closed-loop recycling of sulfur-rich polymers with tunable properties spanning thermoplastics, elastomers, and vitrimers. Nat. Commun. 15, 3002 (2024).

Demarteau, J. et al. Biorenewable and circular polydiketoenamine plastics. Nat. Sustain. 6, 1426–1435 (2023).

Hong, M. & Chen, E. Y. X. Future directions for sustainable polymers. Trends Chem. 1, 148–151 (2019).

Shearouse, W. C., Lillie, L. M., Reineke, T. M. & Tolman, W. B. Sustainable polyesters derived from glucose and castor oil: building block structure impacts properties. ACS Macro Lett. 4, 284–288 (2015).

Sathe, D. et al. Olefin metathesis-based chemically recyclable polymers enabled by fused-ring monomers. Nat. Chem. 13, 743 (2021).

Si, G. & Chen, C. Cyclic–acyclic monomers metathesis polymerization for the synthesis of degradable thermosets, thermoplastics and elastomers. Nat. Syn. 1, 956–966 (2022).

Feist, J. D. & Xia, Y. Enol ethers are effective monomers for ring-opening metathesis polymerization: synthesis of degradable and depolymerizable poly(2,3-dihydrofuran). J. Am. Chem. Soc. 142, 1186–1189 (2020).

Shieh, P. et al. Cleavable comonomers enable degradable, recyclable thermoset plastics. Nature 583, 542 (2020).

Johnson, A. M., Husted, K. E. L., Kilgallon, L. J. & Johnson, J. A. Orthogonally deconstructable and depolymerizable polysilylethers via entropy-driven ring-opening metathesis polymerization. Chem. Commun. 58, 8496–8499 (2022).

Haeussler, M., Eck, M., Rothauer, D. & Mecking, S. Closed-loop recycling of polyethylene-like materials. Nature 590, 423–427 (2021).

Hu, W. The physics of polymer chain-folding. Phys. Rep. 747, 1–50 (2018).

Tu, Y.-M., Gong, F.-L., Wu, Y.-C., Cai, Z. & Zhu, J.-B. Insights into substitution strategy towards thermodynamic and property regulation of chemically recyclable polymers. Nat. Commun. 14, 3198–3198 (2023).

Jeon, J. H., Jung, J. H. & Choi, C. Toward a greener future: exploring sustainable thermoplastic elastomers. J. Polym. Sci. 62, 662–678 (2023).

De Rosa, C. & Auriemma, F. Structure and physical properties of syndiotactic polypropylene: a highly crystalline thermoplastic elastomer. Prog. Polym. Sci. 31, 145–237 (2006).

Wang, W. et al. Recent advances in thermoplastic elastomers from living polymerizations: Macromolecular architectures and supramolecular chemistry. Prog. Polym. Sci. 95, 1–31 (2019).

Mandelkern, L. The structure of crystalline polymers. Acc. Chem. Res. 23, 380–386 (1990).

Men, Y. F., Rieger, J. & Strobl, G. Role of the entangled amorphous network in tensile deformation of semicrystalline polymers. Phys. Rev. Lett. 91, 095502 (2003).

Wang, Z., Yuan, L. & Tang, C. Sustainable elastomers from renewable biomass. Acc. Chem. Res. 50, 1762–1773 (2017).

Sbrescia, S., Ju, J., Engels, T., Van Ruymbeke, E. & Seitz, M. Morphological origins of temperature and rate dependent mechanical properties of model soft thermoplastic elastomers. J. Polym. Sci. 59, 477–493 (2021).

Nebouy, M., Louhichi, A. & Baeza, G. P. Volume fraction and width of ribbon-like crystallites control the rubbery modulus of segmented block copolymers. J. Polym. Eng. 40, 715–726 (2020).

Sun, H., Liang, Y., Thompson, M. P. & Gianneschi, N. C. Degradable polymers via olefin metathesis polymerization. Prog. Polym. Sci. 120, 101427 (2021).

Sathe, D., Yoon, S., Wang, Z., Chen, H. & Wang, J. Deconstruction of polymers through olefin metathesis. Chem. Rev. 124, 7007–7044 (2024).

Wang, H. S., Parkatzidis, K., Junkers, T., Truong, N. P. & Anastasaki, A. Controlled radical depolymerization: structural differentiation and molecular weight control. Chem 10, 416–416 (2024).

Hodge, P. Entropically driven ring-opening polymerization of strainless organic macrocycles. Chem. Rev. 114, 2278–2312 (2014).

Kariyawasam, L. S., Rolsma, J. & Yang, Y. Chemically recyclable dithioacetal polymers via reversible entropy-driven ring-opening polymerization. Angew. Chem. Int. Ed. 26, e202303039 (2023).

Weinland, D. H. et al. Overcoming the low reactivity of biobased, secondary diols in polyester synthesis. Nat. Commun. 13, 7370 (2022).

Acknowledgements

We thank the National Natural Science Foundation of China (22375099, 22103038, Y.S.; 32471815, P.J.; 22303042, Y.H.) and the Natural Science Foundation of Jiangsu Province of China (BK20241745, P.J.). We thank Prof. Liang Ding in Guangxi Normal University for help discussion on ADMET polymerization.

Author information

Authors and Affiliations

Contributions

Y.S. and X.C. contributed equally to this work. Y.S. and P.J. contributed to the conceptualization of the project. X.C. contributed the methodology for polymer design and chemical recycling. W.S. contributed the methodology for monomer and polymer characterization. J.Z. and Y.H. contributed to analysing the data. Y.S. and X.C. wrote the original draft. All authors contributed to writing the final draft and editing. E.X. conducted the DFT calculations. Y.S. and P.J. supervised the research. Z.L. and Y.Z. provided project administration. All authors commented on the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Hao Sun and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sha, Y., Chen, X., Sun, W. et al. Biorenewable and circular polyolefin thermoplastic elastomers. Nat Commun 15, 8480 (2024). https://doi.org/10.1038/s41467-024-52850-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-024-52850-0

This article is cited by

-

Diverse polymers with chemical recyclability via regioirregular polymerization of a single monomer

Nature Materials (2026)

-

Tailored synthesis of circular polyolefins

Nature Sustainability (2025)

-

Degradable and functionalizable polyacetals synthesized via ring-opening metathesis copolymerization

Polymer Journal (2025)

-

Delayed crystallization response-inspired waterborne polyurethane with high performance

Nature Communications (2025)

-

Robust, Reprocessable and Scalable Ethylene Acrylic Acid Copolymer (EAA) Derived Vitrimer Based on Dual Cross-linked Networks

Journal of Polymers and the Environment (2025)